Sepson SEPMATIC User manual

Original User Manual

SEPDURANCE - SEPMATIC - FORCEMATIC - SEPGAIN

WORLD CLASS WINCHES

RELIABLE - DEPENDABLE - UNCOMPLICATED

Vehicle Recovery Winch - hydraulically driven

WORLD CLASS WINCHES

RELIABLE - DEPENDABLE - UNCOMPLICATED

1

Table of Contents

1 Introduction.......................................................................................................3

1.1 General .......................................................................................................3

1.2 About this manual...................................................................................4

1.3 Warranty.....................................................................................................4

2 Safety....................................................................................................................5

2.1 Introduction ...............................................................................................5

2.2 Safety symbols ........................................................................................6

2.3 Winch markings.......................................................................................8

2.4 Machine plate...........................................................................................9

2.5 General information.............................................................................11

2.6 Personal Protective Equipment ..................................................... 12

2.7 Precautions ............................................................................................ 13

3 Installation ...................................................................................................... 17

3.1 General .................................................................................................... 17

3.2 Mounting on vehicle............................................................................ 17

3.3 Lifting the winch ................................................................................... 18

3.4 Hydraulic installation .......................................................................... 19

3.5 Pneumatic or hydraulic free spooling control installation ... 20

3.6 Rope installation .................................................................................. 22

3.7 Calibration of automatic rope spooling device ........................ 25

3.8 Electrical installation........................................................................... 28

3.9 After installation.................................................................................... 28

WORLD CLASS WINCHES

RELIABLE - DEPENDABLE - UNCOMPLICATED

2

4 Winch basics ................................................................................................. 29

4.1 Hydraulic System Basic Information............................................ 29

4.1.1 General .................................................................................................... 29

4.1.2 Outline Diagram for Installation of Winch Hydraulics........... 30

4.1.3 Hydraulic Oil .......................................................................................... 32

4.1.4 Power Supply ........................................................................................ 33

4.1.5 Hydraulic Function Diagram............................................................ 34

4.1.6 Pressure setting of the control valve PVG32........................... 44

4.2 How to calculate required pulling force ...................................... 46

4.3 How to improve rope spooling ....................................................... 48

4.4 Wire rope selection............................................................................. 49

4.5 Dimensioning of rope sheaves ...................................................... 52

4.6 Rigging instructions ............................................................................ 53

5 Operating instructions............................................................................ 59

5.1 General .................................................................................................. 59

5.2 Pull out rope.......................................................................................... 61

5.3 Attaching the load ............................................................................. 63

5.4 Engage the rope drum ..................................................................... 64

5.5 Pull the load ......................................................................................... 65

5.6 Unhook the load.................................................................................. 66

5.7 Spool the rope back on the drum................................................. 67

6 Maintenance ................................................................................................ 68

6.1 Gear drive ............................................................................................. 68

6.2 Drum brake .......................................................................................... 69

6.3 Service and maintenance ................................................................ 71

6.4 Free-spool clutch ............................................................................... 79

6.5 Wire rope .............................................................................................. 81

7 Troubleshooting ......................................................................................... 82

8 Technical information ............................................................................. 86

8.1 General .................................................................................................. 86

8.1.1 Noise........................................................................................................ 86

8.1.2 Vibration ................................................................................................. 86

8.2 Design standard................................................................................... 86

8.3 EC declaration of conformity........................................................... 89

WORLD CLASS WINCHES

RELIABLE - DEPENDABLE - UNCOMPLICATED

3

1 Introduction

1.1 General

SEPSON’s objective, focus and single purpose is to build reliable, dependable and

uncomplicated winches that require a minimum of maintenance and are simple to

repair if this is ever needed. They are quickly and easily attached on any vehicle

chassis.

SEPSON hydraulic vehicle recovery winches from the product groups

– SEPDURANCE, SEPMATIC, FORCEMATIC as well as the worm gear driven

SEPGAIN series, meet all rescue and recovery requirements.

The SEPDURANCE winches represent the core of our range of drum winches and

are characterized by the following features.

All drum winches:

• have drum and housing made of nodular cast iron for added strength and

structural integrity

• have the free spooling feature to easily allow a manual unspooling of the wire

rope. A unique 2-speed feature controlled by a hydraulic valve system is also

standard on all models with a pulling force of 150 kN and above

• are equipped with a spring-applied, pressure-release multi-disk brake and the

optimal drum-to-wire-rope diameter ratio of minimum 10:1 which signicantly

increases the useful life of the rope and reduces operating expenses.

The SEPMATIC winches are the next step up on the ladder to higher performance

and feature an integrated automatic rope-spooling device.

The FORCEMATIC range is our most advanced family of winches. They have been

equipped with a unique feature that maintains a constant pulling force on the wire

rope regardless of its layer on the rope drum.

Documentation is available in English, French and German. All required translations

into the language of the Purchaser will be the responsibility of the Purchaser; both

as regards compliance with the European Union’s Machinery Directive and local

requirements.

Introduction

WORLD CLASS WINCHES

RELIABLE - DEPENDABLE - UNCOMPLICATED

4

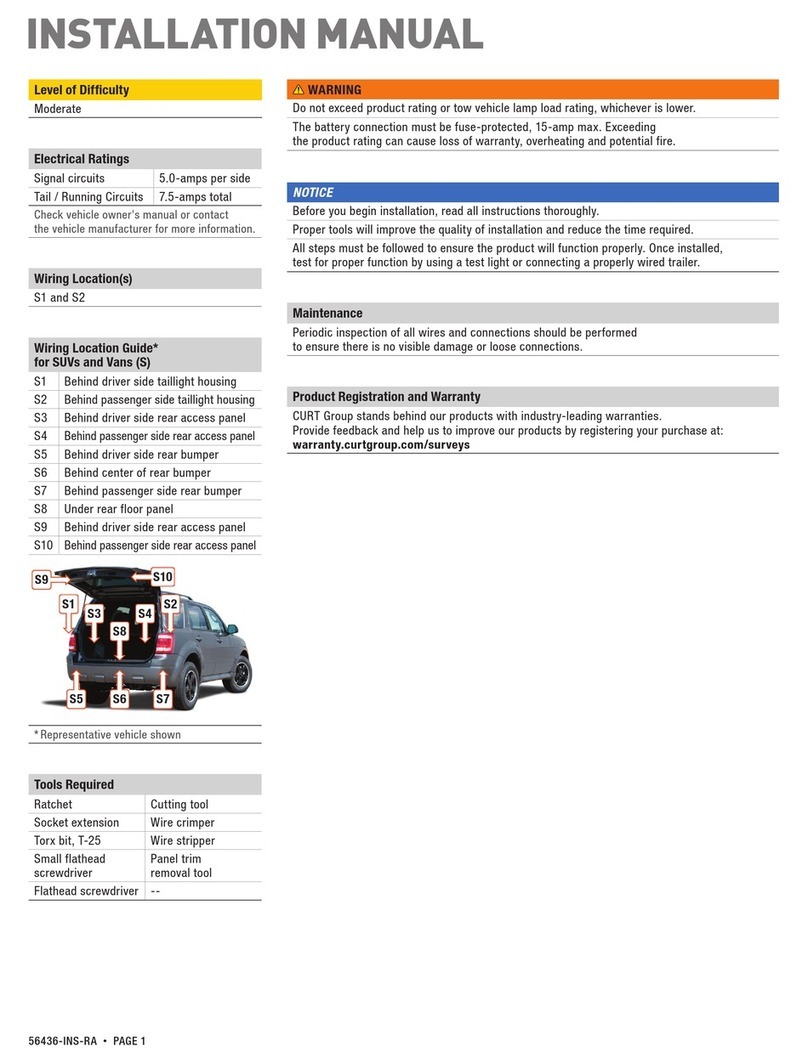

This warning symbol alerts to a clear and present danger and must be

observed and understood at all times. Do not proceed with the winching

operation if there is any doubt about the meaning of this warning!

WARNING

This symbol indicates that the information in a relevant paragraph must be

observed and understood. Please contact SEPSON if there is any doubt

regarding a “caution” or “warning” frame.

Caution

1.2 About this manual

This manual contains important data concerning the maintenance, installation and

operation of SEPSON winches.

Should anyone assigned the task to attach the winch on a vehicle be uncertain

about how to perform the task, please contact SEPSON.

The information in this manual is based on current information available to SEPSON

at this time. Under no circumstance, should this information override or replace

national or international statutory instructions, regulations and safety precautions.

Introduction

1.3 Warranty

The warranty is valid in the following cases:

The winch and accessories have been used as intended regarding ”Technical data”.

All instructions in the manual have been followed.

Maintenance and inspection procedures have been followed.

Repairs have been carried out by skilled personnel.

The installation of the winch is made in accordance with Sepson’s instructions.

WORLD CLASS WINCHES

RELIABLE - DEPENDABLE - UNCOMPLICATED

5

2 Safety

2.1 Introduction

This introduction describes and explains the safety precautions that must be

observed and provides useful and necessary information.

Read this chapter very carefully. It is important to fully understand its content and

purpose. It concerns your safety as well as the safety of others around you in the

working area of the rescue and recovery operation and the safe utilization of the

winch.

Familiarize yourself with the winch by practising its use before attempting to save

or rescue a vehicle. This is important and will help you understand its different

functions and ensure that you will be able to operate the equipment with optimal

safety.

The winch must only be used for vehicle recovery and loading.

Safety

WORLD CLASS WINCHES

RELIABLE - DEPENDABLE - UNCOMPLICATED

6

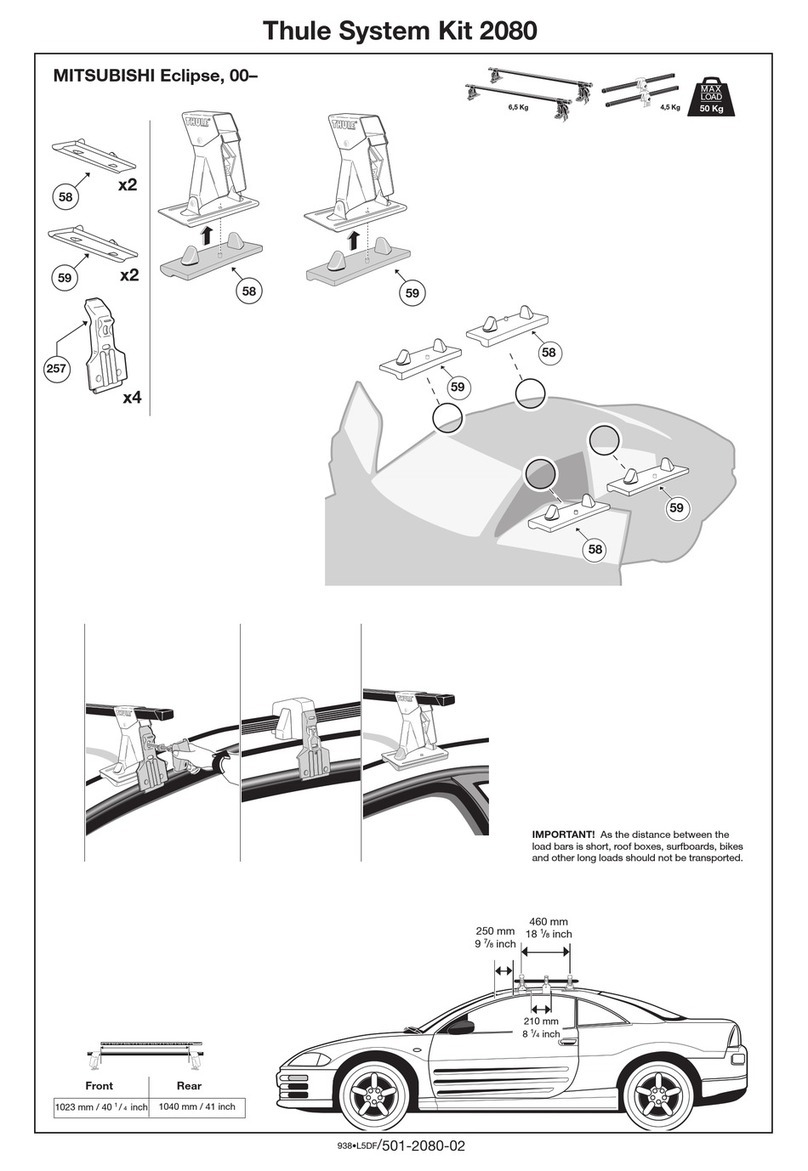

Signs with the symbols below shall be attached on or near the winch operating

device(s). If a remote control is used the symbols shall be attached on the hand

held control unit.

2.2 Safety symbols

General warning

Eye protection must be used

Head protection must be used

Hand protection must be used

Safety boots must be used

Read the manual before operating the winch

Safety

WORLD CLASS WINCHES

RELIABLE - DEPENDABLE - UNCOMPLICATED

7

IN

Winching out (attached at the direction control valve - remote control).

Winching in (attached at the direction control valve - remote control).

Free-spool clutch (attached at the free-spool control).

Sepson supplies a sheet with self gluing symbols with the winch to be attached on

the operating device by the winch installer.

OUT

A label showing drum rotation when spooling in the rope on the drum

is attached on the winch by Sepson prior to shipment.

Safety

WORLD CLASS WINCHES

RELIABLE - DEPENDABLE - UNCOMPLICATED

8

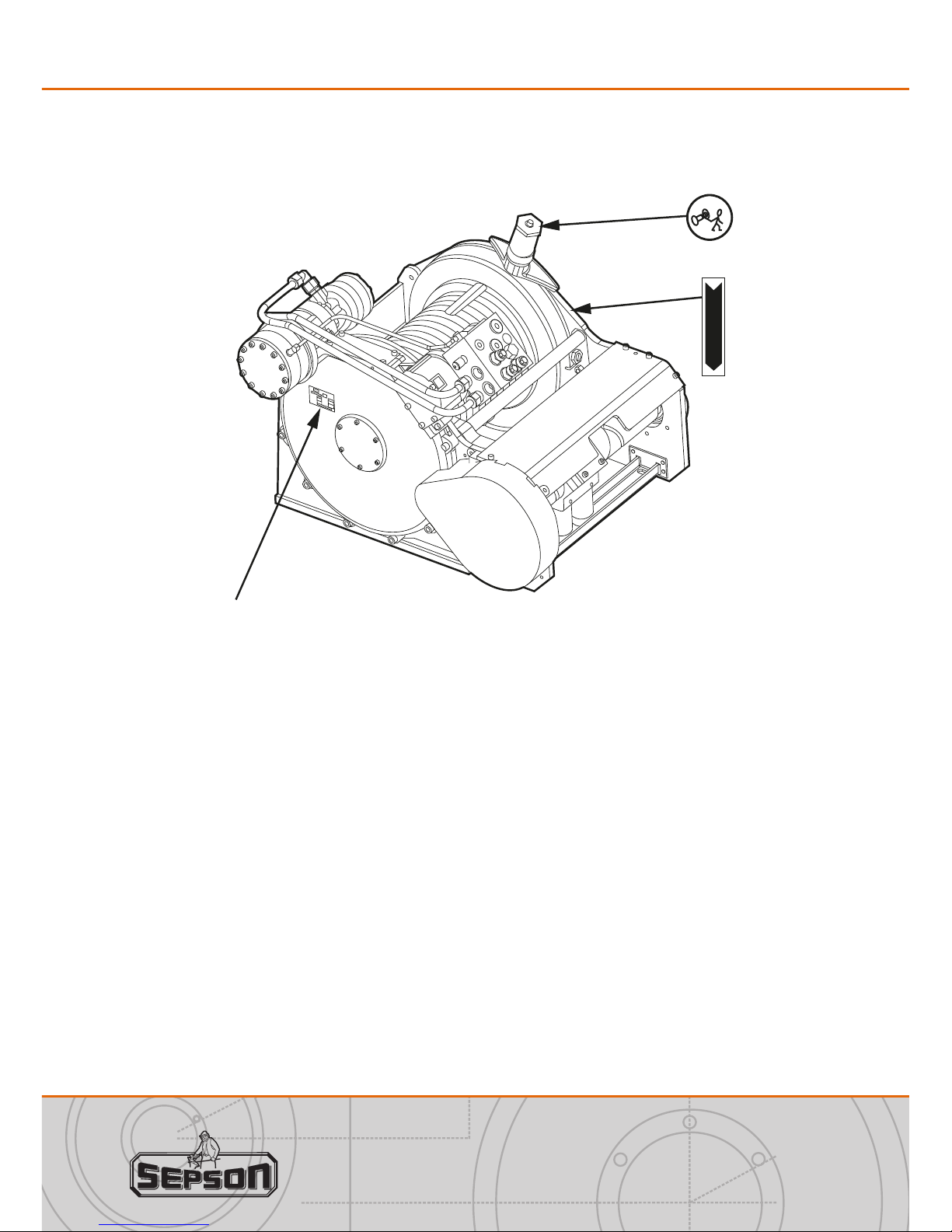

2.3 Winch markings

Machine plate (See 2.4 Machine plate).

The placement of the markings varies between different winch models.

0078-01

Safety

WORLD CLASS WINCHES

RELIABLE - DEPENDABLE - UNCOMPLICATED

9

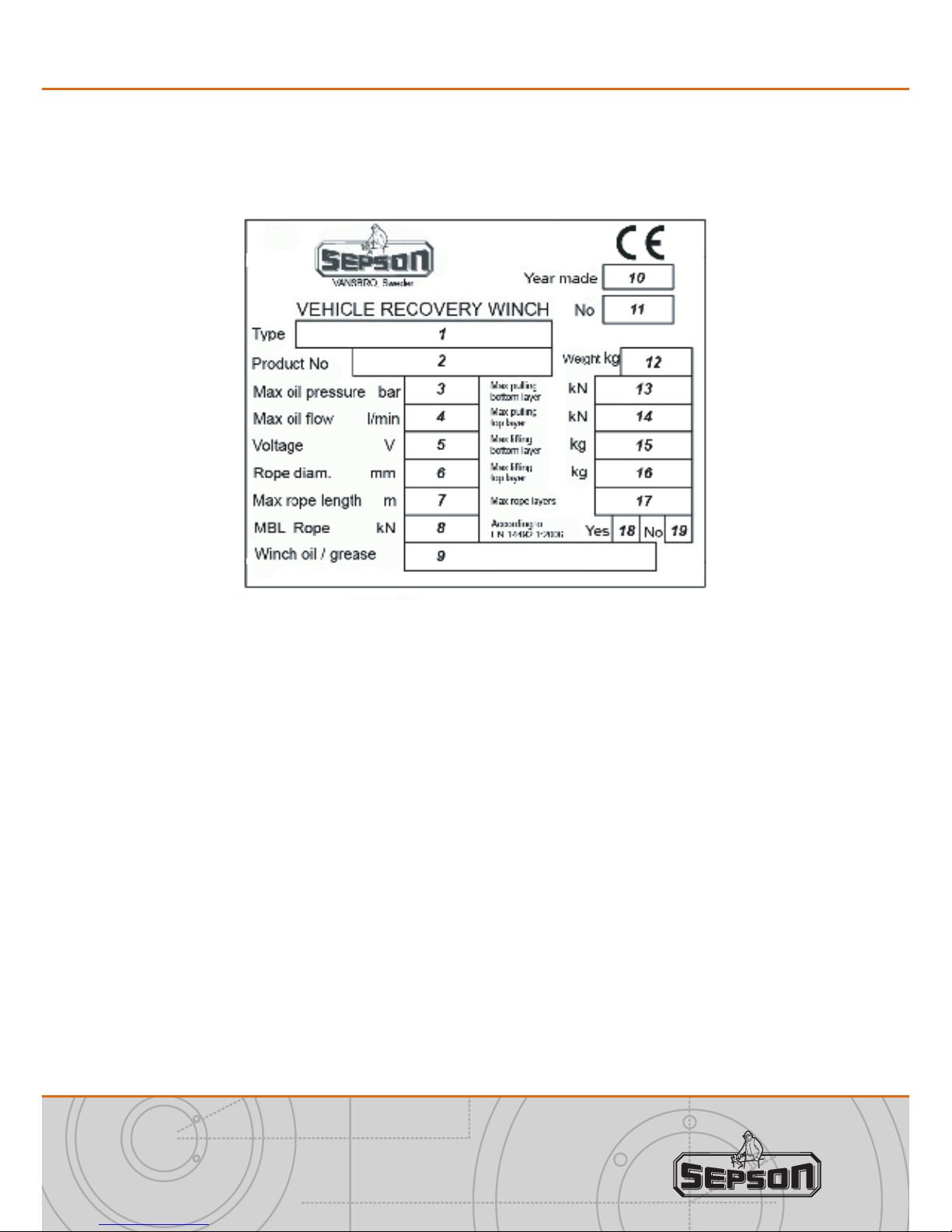

2.4 Machine plate

1. Winch model – Sepdurance, Sepmatic, Forcematic or Sepgain.

2. Product number.

3. Maximum allowed oil pressure to the winch. A higher pressure can

seriously damage the winch and give excessive pulling force. If the pressure is

higher than our specication the warranty is not valid.

4. Maximum allowed oil ow to the winch. A higher oil ow can seriously

damage the winch.

5. Required electrical current for the winch if applicable.

6. Diameter of steel wire rope.

7. Maximum length of steel wire rope on the winch.

8. Minimum breaking load (MBL) for the winch wire rope stated by the wire

rope manufacturer.

9. Recommended oil or grease for the winch.

Safety

WORLD CLASS WINCHES

RELIABLE - DEPENDABLE - UNCOMPLICATED

10

10. Manufacturing year.

11. Manufacturing number.

12. Weight of winch excluding steel wire rope.

13. Maximum pulling force on the bottom rope layer.

14. Maximum pulling force on the top rope layer.

15. Maximum allowed load weight when lifting on the bottom rope layer.

16. Maximum allowed load weight when lifting on the top rope layer.

17. Maximum allowed number of rope layers on the winch drum.

18. Complies with EU-standard.

19. If No is stated, the specied wire rope does not comply with EU standards and

the winch is delivered for use in countries outside the European Union with

other safety standard.

Safety

WORLD CLASS WINCHES

RELIABLE - DEPENDABLE - UNCOMPLICATED

11

Operation of the winch requires a skilled operator.

WARNING

2.5 General information

Any use of the winch may create risks of injuries to the operator and the general

safety of people in the area as well as damage to the winch itself and other

equipment used in connection with its operation.

It is only the operator’s awareness of the necessary safety precautions and his/her

sound judgment that can eliminate or reduce the risks of personal injuries.

It is the responsibility of the operator to ensure that all appropriate precautions are

taken as required by the working environment and conditions in each individual

case.

Neither this document nor observing and applying its instructions absolve the

operator or owner from their joint responsibilities to ensure the actual

implementation of all precautions or the observance of all warnings.

If anyone becomes aware of any SEPSON supplied product or SEPSON originated

design that can create a risk to an individual working with or within the vicinity of the

product, it is an obligation to contact SEPSON immediately.

It is the user’s responsibility to make all relevant hazard identications and risk

assessment of all activities associated with the use of both the product and this

document.

It is solely the user’s and the owner’s joint responsibility to provide a safe working

environment and to provide the necessary safety equipment and ensure that

everybody who is depending on this document, understands the instructions,

warnings and caution and that they are able to operate the equipment in

accordance with these instructions.

Should an operator lack the knowledge, experience or skills to work in accordance

with the safety or other instructions in this document, immediate assistance should

be requested from SEPSON. Technical assistance sought from SEPSON will be

subject to SEPSON terms and conditions.

Safety

WORLD CLASS WINCHES

RELIABLE - DEPENDABLE - UNCOMPLICATED

12

2.6 Personal Protective Equipment

It is absolutely essential that the operator uses the appropriate and required safety

equipment when working with the equipment.

Protective clothing should protect the operator(s) against oil and shield from

accidental contact with the wire rope. Avoid loose clothing that may be caught in the

winch or the wire rope and cause serious injury.

Personal safety equipment does not eliminate the risk of injury but reduces the risk

and effects in case of an accident. It is only the user’s awareness of all safety risks

and his/her own judgment that will provide the necessary safety margins against

personal injury.

Protective clothing

Head protection (Hard hat)

Eye protection (Goggles)

Hand protection

(Heavy duty gloves when handling the

rope and rubber gloves when working

with oil)

Safety boots

(Steel tipped and slip resistant sole)

Safety

WORLD CLASS WINCHES

RELIABLE - DEPENDABLE - UNCOMPLICATED

13

LR

R

R

R

R

R

R

2.7 Precautions

Before starting the winch operation, always make sure that no unauthorized

personnel are in the danger zone indicated in the diagram below.

Safety

Danger zone

Distance (R)

Attachment point

Rope length (L)

SEPSON cannot exclude the risk of danger outside the above zone in the event of

material breakdown.

Length L: paid-out rope Distance R

Smaller than 3 m not permissible –

3 m to 5 m 2.0 x L

6 m to 30 m 1.5 x L

30 m to max. possible distance 1.1 x L

WORLD CLASS WINCHES

RELIABLE - DEPENDABLE - UNCOMPLICATED

14

Keep hands clear of the wire rope and all attaching components during

installation, pulling process and when spooling the wire rope in or out of

the drum. Always handle the wire rope by the rope end when spooling out

the rope by hand.

WARNING

The rst step is to create a safe working environment for each specic pull.

There are several aspects to consider depending on restrictions imposed by the

surroundings and the locations of the vehicles.

– Remove any objects that may be blocking the operation or prevent a clear view of

the pull path.

– Try to place the winch in a straight line in front of the load.

– Never try to pull the load sideways.

– If necessary, use snatch blocks or other devices to change the pulling direction or

its angle to the winch.

– Take all necessary time to plan the pulling operation and gather available

information such as the load (weight) and the surroundings (surface condition)

before the operation takes place.

– Consider all important issues that might impact the winching operation and which

may be important factors in calculating the pull and in determining the need for

special equipment.

Safety

Always follow and observe SEPSON’s and the vehicle manufacturer’s advice and

instructions with regards to the recommended location of the winch.

The hydraulic system and its applications require care and cleanliness. Always

observe and respect SEPSON assembly and installation instructions.

Never use the winch to move people and never use it as a hoist to lift

objects.

WARNING

WORLD CLASS WINCHES

RELIABLE - DEPENDABLE - UNCOMPLICATED

15

Always handle the wire rope with gloves and pull on any device attached

to the rope end when spooling in or out by hand.

WARNING

When pulling out the rope, always leave at least the length of four (4)

revolutions on the drum.

WARNING

Always pull out the wire rope manually with the drum in the free spooling

position. Never run out the rope under power.

Caution

Never hook the wire rope on to itself, it will cause damage.

Caution

Never ll the hydraulic oil tank with more than 80% of capacity to leave 20%

space for heat expansion of the liquid.

Caution

Safety

– Always wear heavy duty protective gloves when handling the rope and never let

it slide through the palm of your hands while spooling, because wire strands may

cause painful injury.

– If a remote control is installed, always keep the control unit with you when leaving

the winch unattended.

– Always attach the wire rope to a point on the object that will support the winch’s

maximum capacity.

WORLD CLASS WINCHES

RELIABLE - DEPENDABLE - UNCOMPLICATED

16

Always put a load on the rope when spooling to the drum otherwise the rope will

not spool correctly.

Caution

Always inspect the wire rope’s attaching point at the load side and its

condition before operating the winch.

WARNING

Make sure that the rope is slack before unhooking after the pull. There is a

clear danger of injury from the rope’s rotation.

WARNING

Always stand clear of the rope and respect the danger zone. Make sure

everybody is aware of your intention to pull the load, in and outside the

danger zone.

WARNING

Damaged wire ropes or attaching devices must be replaced before the

pull.

WARNING

Safety

WORLD CLASS WINCHES

RELIABLE - DEPENDABLE - UNCOMPLICATED

17

3 Installation

The winch is designed for pulling operations in recovery and rescue and is designed

for mounting on a vehicle chassis only. Please refer to the technical information for

more detailed specication on this particular winch model.

3.1 General

3.2 Mounting on vehicle

The winch is either mounted with a mounting plate or directly to the vehicle’s

chassis.

When a mounting plate is required, the plate must support the force of at

least 1,25 times the maximum pulling force of the winch.

Refer to instructions about the use and dimensions of a mounting plate in the

Technical information for your winch. If in doubt, always seek the advice and

instructions from both SEPSON and the vehicle’s manufacturer.

– The emergency stop shall cut out the power supply to the winch(es).

– Never mount an operating device close to the exhaust pipe(s).

– Handholds and platform for maintenance work shall be installed if needed for

safe work.

SEPSON is not liable for the winch installation on the vehicle.

Installation

WORLD CLASS WINCHES

RELIABLE - DEPENDABLE - UNCOMPLICATED

18

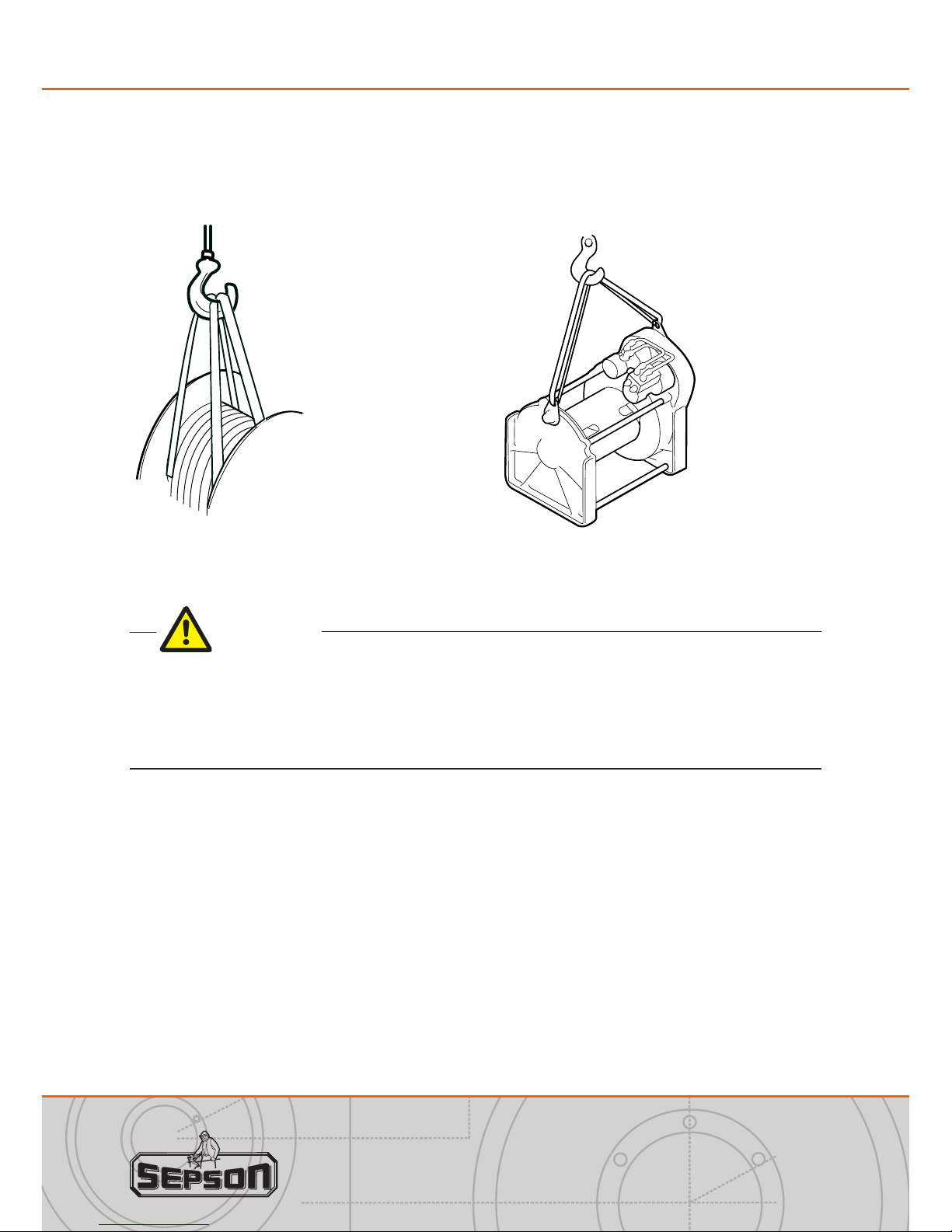

3.3 Lifting the winch

The winch is too heavy for handling by hand. Use an adequate lifting device

and do not place lifting straps around the hydraulic motor or the hydraulic valve

block. Please refer to the technical information to obtain the exact weight of this

winch.

Caution

1. Remove the rope from the drum and refer to instructions under rope installation.

2. Create a rope sling around the drum.

3. Place the loop sling into the lifting device.

4. Check the balance before lifting.

5. Lift the winch.

If the winch is supplied with thread bolt holes for lifting eyes use lifting eyes.

Lifting straps Lifting eye

Separate the straps on the drum

as much as possible.

0014-02

0070-01

Installation

WORLD CLASS WINCHES

RELIABLE - DEPENDABLE - UNCOMPLICATED

19

0066-01

V1

V2

V1

V2

3.4 Hydraulic installation

All seals must be in place to protect the operator and anybody else in the

area against an escape of high oil pressure.

WARNING

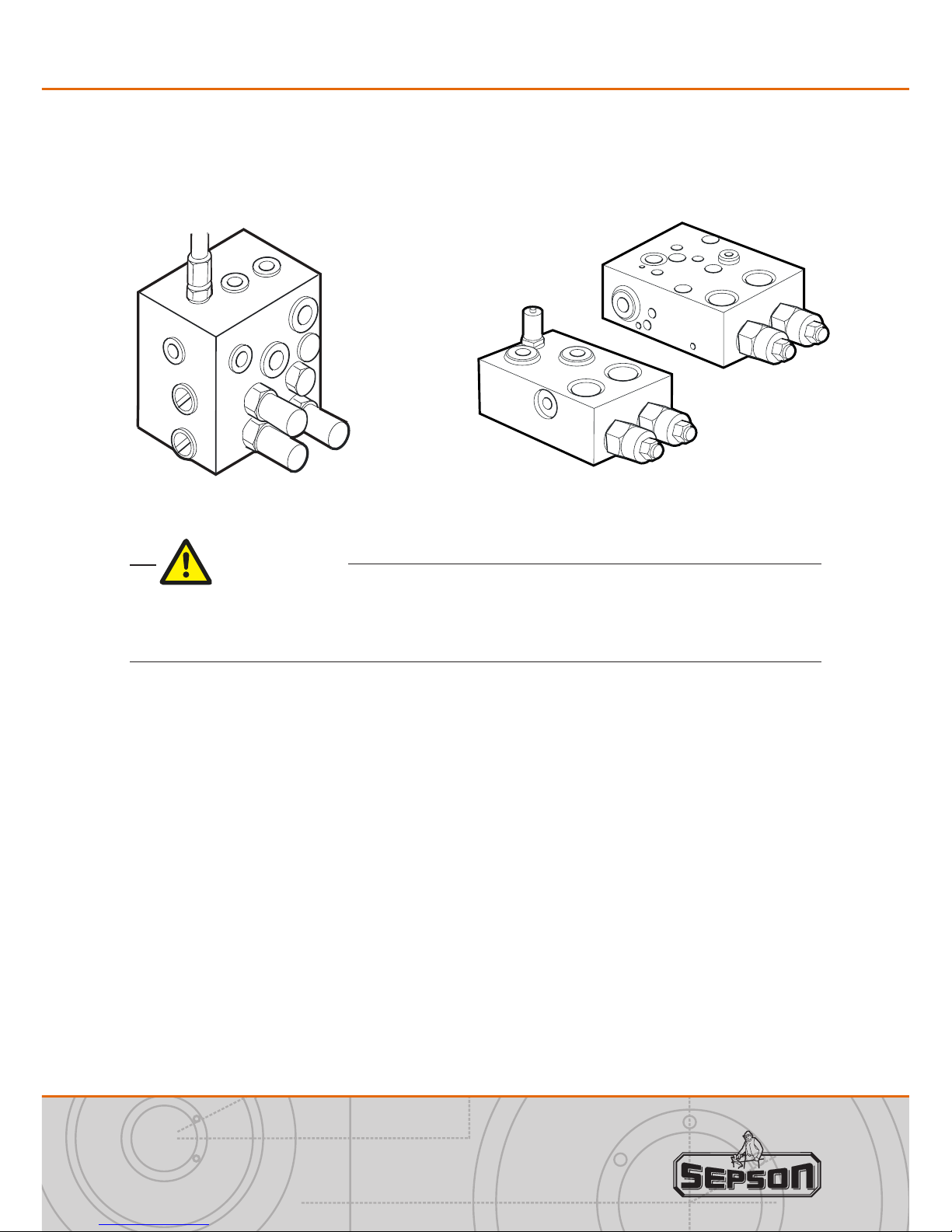

Auto 2-speed block Single speed block

0033-01

M

V1

V2

1. Connect the directional control valve and the winch by the ports V1 and V2 on

the hydraulic block.

2. Inspect and test all tubing, hoses and connection points for oil leakage.

If the directional control valve is attached to the winch, connect the pressure

hose/tube to the pressure inlet and the return hose/tube to the oil outlet on the

control valve.

For a hydraulic system with xed pump the directional control valve must have an

open centre; otherwise the winch safety brake will not operate properly or not at all.

If a load sensing hydraulic system is used contact Sepson for advice on choice of

control valve.

Make sure that the hydraulic system is set to not deliver higher oil pressure and oil

ow than listed in the technical information section for the winch.

Installation

This manual suits for next models

3

Table of contents