Sermatec SMT-10K-TL-TH User manual

10kW All-in-one Hybrid Inverter User Manual

Important Notice

In order to protect the legitimate rights and interests of users, please read our operating procedures and

safety instructions carefully before using this equipment. Please operate the equipment according to the

operating procedures and safety instructions.

Once using this device, you are deemed to have read, understood, endorsed, and accepted all terms

and contents of the device's operating procedures and safety instructions. The User is committed to

being responsible for his or her actions and all consequences arising therefrom.

The User undertakes to use the device solely for legitimate purposes and agrees to these Terms and

any relevant national policies or guidelines.

In using this equipment, please strictly observe and implement the requirements, including but not

limited to the operating procedures and safety instructions. All personal injury, accident, property

damage, legal disputes, and other adverse events that cause conflicts of interest caused by violations of

the user instructions or force majeure indicated by the safety instructions are the responsibility and loss

of the User. Our company will not assume any responsibility.

Copyright, all rights reserved. The content is subject to change without notice.

Caution!

Failure to observe a warning indicated in this manual may result in injury.

The danger of high voltage and electric shock!

Refer to the operating instructions

Signals danger due to electrical shock and indicates the time (5 minutes) to

allow after the inverter has been turned off and disconnected to ensure

safety in any installation operation.

The danger of hot surface!

Protective earth

Installation Risk Notification

Warning

Wear protective gloves when handling equipment by hand to

prevent cuts from sharp objects.

Attention

Make sure the cable label is correct before connecting the

cable.

Dangerous

Construction operation of high-voltage lines may cause fire or

electric shock. The area through which the AC cable is

connected and routed must comply with local regulations and

specifications.

Please carry out construction following relevant construction safety regulations and standards to avoid

safety accidents. The person in charge of this product must undergo strict training, master the correct

installation method of the system and various safety precautions before proceeding with the equipment.

The installation location should avoid the location of low-lying water accumulation and should be kept at

a safe distance from the surrounding fire-explosive facilities and underground pipelines. The installation

location should be away from open flames, high temperature, dust, and corrosive environment. The

protection grade of the selected product enclosure should be compared with the installation environment

adapt.

The installation position strength must meet the requirements; all fixing bolts should be tightened.

Otherwise, there is a risk of falling and dumping. Install the selected cables, terminals, and other

components to meet the current requirements. Before and after installation, ensure that all wiring related

to the charging equipment is tight, well insulated, wired correctly, no wear and crush damage. Otherwise,

there is a risk of fire and electric shock.

Before powering the device, confirm that the device is well-grounded to avoid electric shock. If any part

is damaged during installation, it should be repaired and replaced in time to avoid damage.

Operation and maintenance risk notification

Dangerous

There is dangerous voltage in the equipment when the system runs,

and non-professionals should not operate and maintain it.

Dangerous

Before maintaining the system clean, electrical connection, and

ground connection, be sure to cut off power. Otherwise, there is a risk

of electric shock and fire.

Equipment operation and maintenance must comply with electrical safety operating procedures.

Otherwise, there is a risk of fire and electric shock.

The personnel responsible for the operation and maintenance of this product must have the

qualifications of high voltage and alternating current, etc.,

He must undergo strict training, master the correct operation method of the system and various safety

precautions, and then carry out various equipment operations; otherwise, there may be a risk of electric

shock.

The energy storage equipment shall not be maintained when the power is not disconnected. Otherwise,

there will be a risk of electric shock.

It is strictly forbidden to wear conductive objects such as watches, bracelets, rings, etc., on the wrist

during operation.

There shall be no flammable and combustible materials around the energy storage equipment, and the

operation and maintenance personnel shall clean up in time. Otherwise, there is a fire risk.

Operation risk notification

Do not use the system in the event of equipment failure. Do not operate without authorization when the

equipment is abnormal.

Please strictly follow the operating procedures and instructions on the energy storage equipment and

comply with the industry's safety regulations. Otherwise, there will be electric shock and fire risks.

Accidents such as fires, flooding of energy storage facilities, etc., are strictly forbidden to be close to

energy storage equipment. Please inform personnel familiar with the equipment and emergency

treatment methods for emergency treatment.

Modification record

The Document version A00 (2019.03.04)

The First release

The Document version A01 (2019.05.07)

1.2 Modify Working Mode

2.3.2 Add electrical connection diagram

3.1 Update pictures of APP

3.6.2 Note about Battery Lower Limit SOC

4.2 Add Software upgrade

5.3 Update Trouble Shooting

The Document version A02 (2019.08.20)

2.2.2 Modify Working Mode

2.3.2.4 Modify Software update

The Document version A03 (2019.08.28)

2.3.2.5 Add Figure 2-27

The Document version A04 (2019.08.30)

1.2 Update Working Mode

2.3.2.4. Update Communication cable connection

The Document version A05 (2019.11.27)

2.3.2. Hybrid Inverter System Connection Diagram

2.3.2.4 Modify communication cable connection

2.3.2.5 Modify DRED cable connection (Option)

The Document version A06 (2020.05.30)

2.2.1 Update Figure 2-1, Figure 2-2

2.3.2.4 Update Figure 2-23

5.2 Update state description of WIFI LED

The Document version A07 (2021.04.28)

3 Sum mate APP

4 System Commissioning

The Document version A08 (2021.09.22)

Delete 3 Summate APP context

Add Parallel system

Contents

1 Summary.................................................................................................................................. 1

1.1 The description of the model........................................................................................1

1.2 Compose and Operating Principle.............................................................................. 1

2 Installation............................................................................................................................... 8

2.1 Safety regulations..........................................................................................................8

2.2 Installation preparation................................................................................................8

2.3 Installation................................................................................................................... 12

2.4 Installation check........................................................................................................ 23

3 Sermatec APP.......................................................................................................................23

3.1 Software acquisition....................................................................................................23

3.2 Connect to internal Wi-Fi...........................................................................................23

4 Parallel connecting..............................................................................................................24

4.1 Battery connection...................................................................................................... 24

4.2 Smart meter................................................................................................................. 25

4.3 Parallel wiring............................................................................................................. 26

4.4 Grid connection........................................................................................................... 26

4.5 Backup load connection..............................................................................................26

4.6 PV................................................................................................................................. 26

4.7 APP setting...................................................................................................................27

4.8 Parallel parameter display......................................................................................... 29

5 Product Maintenance..........................................................................................................31

5.1 Routine Maintenance..................................................................................................32

5.2 LED Status...................................................................................................................33

5.3 Trouble Shooting.........................................................................................................34

6 Technical Parameters.........................................................................................................45

1

1 Summary

The 10kW all-in-one hybrid inverter (hereinafter referred to as the Hybrid Inverter) can realize

Hybrid Inverter for photovoltaic charging, DC terminal battery charging, and discharging, and AC

terminal grid-connected applications.

This chapter describes the model, composition and configuration, and working principle of the

Hybrid Inverter.

1.1 The description of the model

Take 10kW inverter for example for model description.

Hybrid Inverter model: SMT-10K-TL-TH

The model description is shown as below:

SMT 10K TL TH

Three phases

Transformer less

Power (W)

Product Series

Figure1-1 10kW Hybrid Inverter all-in-one model description

1.2 Compose and Operating Principle

The Hybrid Inverter is composed of a power unit (battery charging and discharging circuit, boost

and buck circuit, inverter circuit, auxiliary power source, filter circuit), system control unit, and a

system monitoring unit (including a system communication unit), etc.

This product generally applies to solar storage systems; the system is mainly composed of PV

panels, battery, hybrid inverter, local load, Grid, etc. The system can realize the functions of

transmitting PV power to Grid, supplying backup load by PV or/and Battery, charging Battery by

PV or/and Grid, etc. After carefully research, five work modes are well designed to meet most

scenarios, ensure the PV power generation effectively, supply the backup load reliably, preserve

the service time of the battery as long as possible, etc.

2

The schematic diagram of the primary circuit of the Hybrid Inverter is as follows:

Figure1-2 The Hybrid Inverter principle topology

Work Modes:

Five working modes: General mode, Energy Storage mode, Micro-grid model, Peak-Bottom mode,

and AC coupling mode. The Inverter must be configured in APP before startup :working

parameters (Grid standard, DC side battery type, battery protocol, meter protocol.), working mode

(working mode, utility power price, period setting), and other parameters if neccessary. As shown

in the figures below:

Figure1-3

3

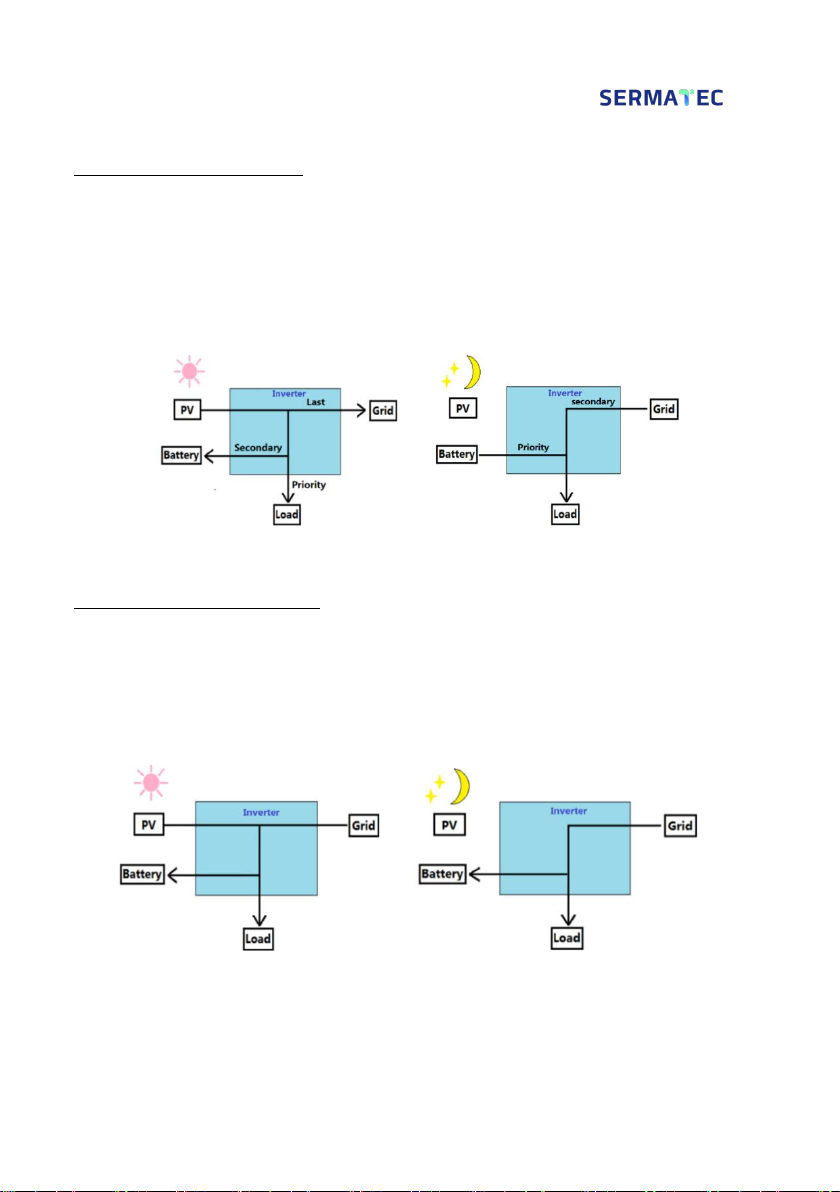

Mode 1: General mode (Default)

Suitable for Areas with Stable Grid

1. If PV power is sufficient, PV power will supply to the load, then charge the battery, feeding into

grid at last if still surplus power (Anti-backflow is forbidden). (Figure1-5)

2. When PV power is insufficient, batteries and the grid supply power to the load together with

insufficient PV. (Figure1-6)

3. Anti-backflow is default disabled..

Typical application scenarios:

Figure1-4 Figure1-5

Mode 2: Energy Storage mode

Suitable for Areas with Unstable Grid

1. PV and grid supply power to load and charge batteries together. (Figure1-7)

2. When the Grid is normal, the battery SOC is always in full state.

3. Batteries discharge only when the grid is abnormal.

4. Anti-backflow default to enable.

Typical application scenarios:

Figure1-6 Sunny Day Figure1-7 Grid is normal

4

Figure1-8 Grid is abnormal

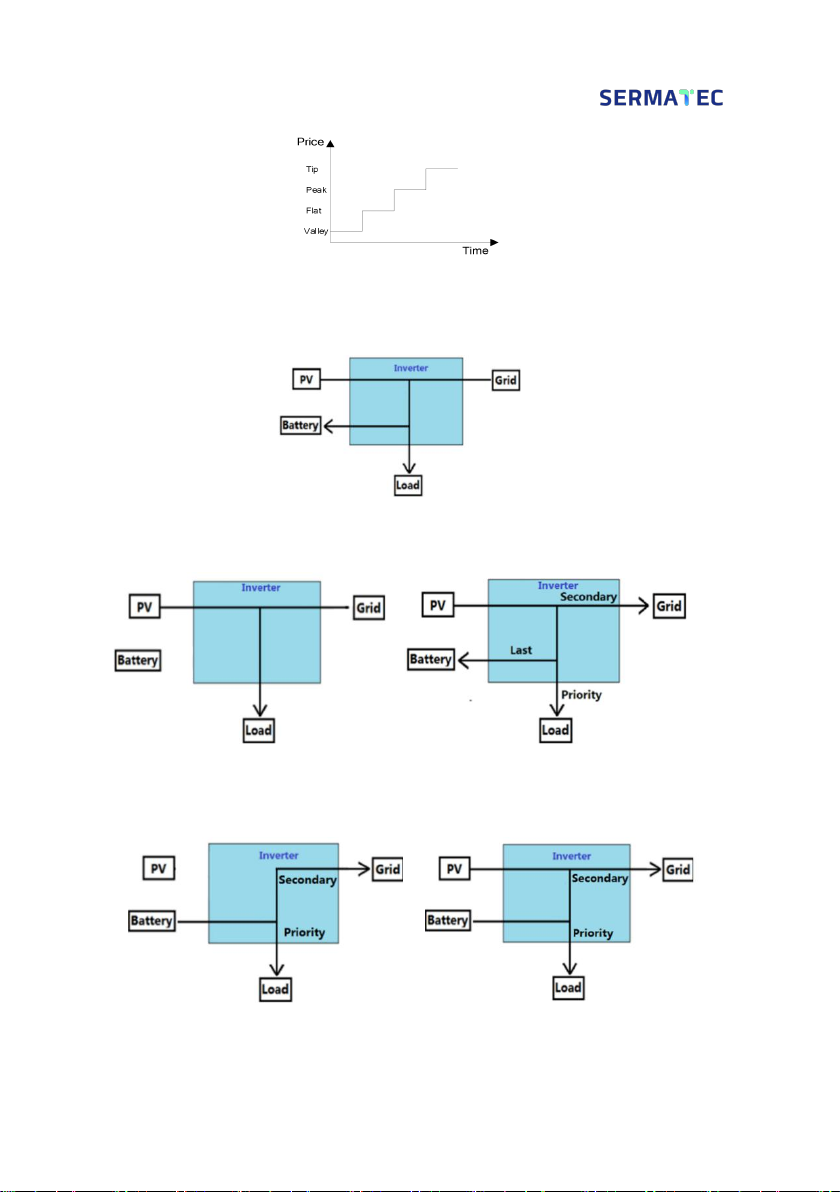

Mode 3: Micro-grid mode

Suitable for Areas without Grid

1. The Micro-grid power source comes from PV, battery.

2. If PV is sufficient, PV power priority supply to the load, then charge the battery. (Figure1-10)

3. When PV is insufficient, Batteries supply power to the load. (Figure1-11)

Typical application scenarios:

Figure1-9 Sunny day Figure1-10 Night

Mode 4: Peak-Bottom mode

Suitable for Areas with Changing Electricity Price

According to the electricity price of utility, the whole day can be divided into four periods (most of

the place): tip, peak, flat, and bottom price.

1. During the price of bottom period, the grid or/and PV charge the batteries and supply to loads

together to storage the electric power,battery never discharge at this stage.

2. During the price of flat period, when the PV is sufficient, it provides power in the sequence of

load,battery and grid.

3. During the price of tip and peak period, the battery and PV provides power to the laod, if more

energy will sell to Grid to obtain profit. Battery never charges at this stage.

Typical application scenarios:

5

Figure1-11 Grid price

In Bottom Time Period:

Figure1-12

In Flat Time Period:

Figure1-13 PV is insufficient Figure1-14 PV is sufficient.

In Tip and Peak Time Period:

Figure1-15 PV is insufficient Figure1-16 PV is sufficient

6

Mode 5: AC coupling mode

Suitable for the scenario that grid-tied inverter already there

Cooperate with the existing grid-tied inverter to build a storage system to get more profit. The joint

point is the Grid side or AC terminal.

1. Inverter communicates with CT (smart meter), CT is used to detect the on-gird power;

2. When PV surplus, battery with low SOC(less than 100%): Surplus PV will firstly provides to

loads(backup loads and AC grid loads),then charge the battery ,lastly sell to grid;

3. When PV surplus, battery with full SOC: PV supply power to the load firstly, and then the rest

power of PV will feed into the grid;

4. When PV insufficient: Battery and PV supply power to the load simultaneously; Battery and grid

supply power to the load simultaneously when battery with lower limit of SOC or discharge power

not enough;

5. Off-grid: Battery supply power to backup load;

6. APP will display: Battery charge/discharge power; Backup load power; AC grid load power, and

on-grid power.

Note: CT must be installed under AC-coupling working mode, CT self-checking default enabled,

the device will not start if the CT self-checking(meter detection) failed.

Meter/CT here only communicates with hybrid inverter, so if you enable anti-backflow it works for

hybrid inverter only, cannot work on grid-tied inverter as Sermatec inverter cannot control the grid-

tied inverter.

7

Figure 1-17 AC Coupling System Diagram

8

2 Installation

This chapter describes the installation and wiring of the Hybrid Inverter. Please strictly follow the

instructions in this chapter to install and wire connection.

2.1 Safety regulations

The Hybrid Inverter has high voltage and large current inside. To ensure personal safety, the

following regulations should be noted at all times.

The Hybrid Inverter can only be installed by personnel who have received training in the Hybrid

Inverter and have a good knowledge of the Hybrid Inverter. During the installation process, always

observe the safety precautions and local safety regulations before the catalog of this manual;

Do not operate or maintain the inside of the system during thunderstorms or wet weather to

prevent electric shock;

If operating inside the Hybrid Inverter, make sure the system is not powered on.

If the hybrid Inverter is equipped with an anti-theft lock, please be sure safekeepingof the key.

2.2 Installation preparation

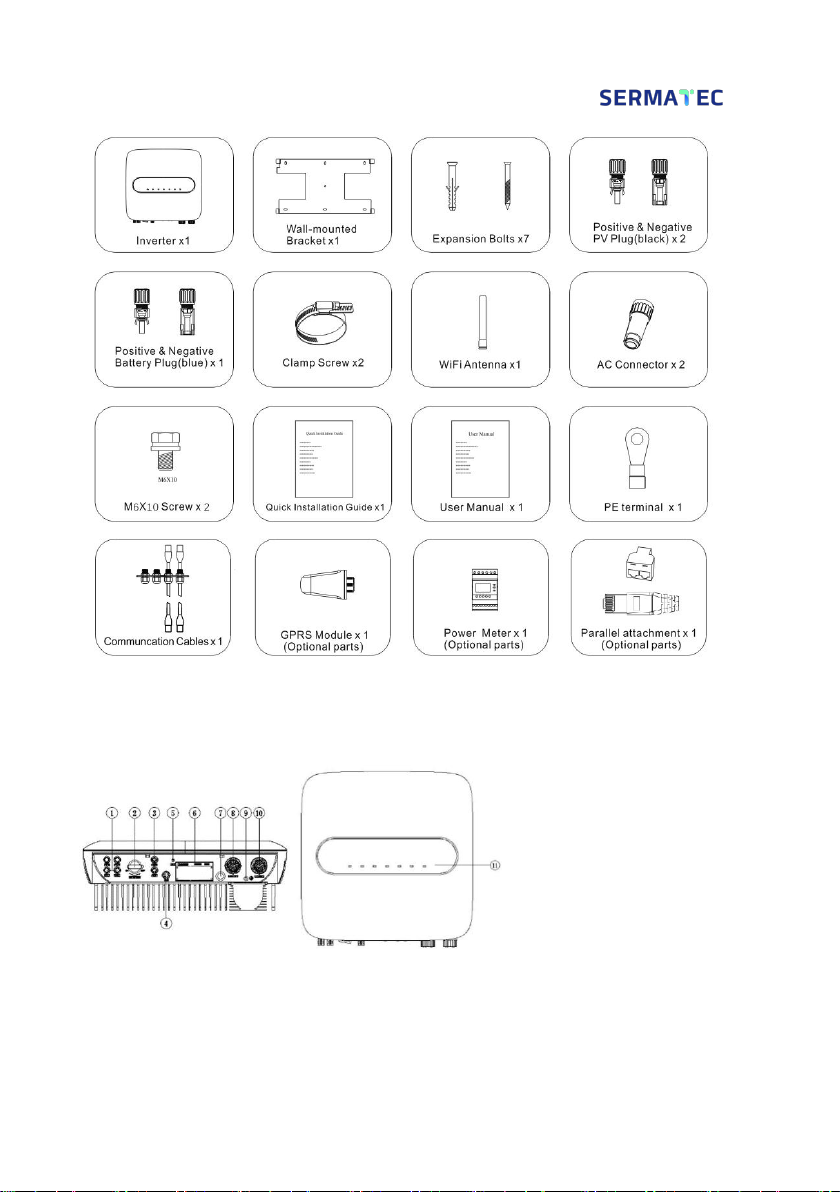

2.2.1 Unpacking inspection

Only when the goods arrive at the installation site can the unpacking box be allowed to be

inspected. The inspection is completed by the customer's representative and the supplier's

representative. Unpack the package, review the checklist.

9

Figure 2-1 Packing list

2.2.2 The Hybrid Inverter Overview

1. PV Connector

2. PV Switch

3. Battery connector

4. GPRS Module Interface

5. WIFI Antenna Interface

6. Communication Interface

7. Waterproof vent valve

8. AC Backup Load Connector

9. PE connection Point

10. AC Grid Connector

11. Indicator LED

Figure 2-2 The Hybrid Inverter Overview

10

2.2.3 Cable and Air switch preparation

Table 2-1 Wiring and cable requirements table

Serial

Cable Name

Recommended

model

cross-sectional

area(mm²)

Color of cable

Cable

OD(mm)

1

PV side DC positive

and negative input

PV1-F

4~6

Red, Black

ø4.5~

ø7.8

2

Battery side DC

positive and negative

input

PV1-F

6

Red, Black

ø4.5~

ø7.8

3

AC output

UL1015 10AWG

4~6

Yellow,

Green, Red,

Blue,

Yellow-Green

ø11~ø20

Note: Be sure all cables withstand voltage, temperature resistance, equal to or

better than the recommended model, and complying with relevant regulation of the

electrical industry.

Selection of switch

Table 2-2 Table 2-3

2.2.4 Installation Kit

1. Electric drill (drilling bit: ¢8mm)

2. Screwdriver (Philips screwdriver: M3, M6; Flathead screwdriver: M3)

3. Wire stripper (4,6mm²)

4. Wire crimper 1 (Model: H4TC0001; Manufacturer: Amphenol)

5. Wire crimper 2(OT terminal, 4~6 mm²)

6. Open-end wrench (Model: H4TW0001; manufacturer: Amphenol)

7. Multimeter

Recommended DC switch

PV(option)

Battery(optio

n)

Rated

voltage

≥1000V DC

≥800V DC

Rated

current

32A

32A

Recommended AC switch

AC backup Load

AC Grid

Rated

voltage

≥250V AC

≥250V

AC

Rated

current

32A

32A

11

2.2.5 Installation requirements

1. Wall bracket Installation

1) It is necessary to ensure that the installation position is flat and the thickness of the whole wall

exceeds 100mm;

2) Ensure the installation wall is vertical to the ground. If it is sloping, the tilt angle is only allowed

to be less than 15°

3) Ensure the installation wall is solid enough to meet the requirements of load-bearing for the

hybrid inverter.

4) The mounting position is supposed to avoid direct sunlight.

Figure 2-3 Perpendicularity requirement

2. Installation space requirements

Product installation position, leave 300 mm of space for maintenance and heat dissipation left,

right, and front

Figure 2-4 Mounting distance

12

2.3 Installation

2.3.1 Mounting

STEP 1: Mark mounting hole on the wall,drill hole with 8mm diameter of the bit. Ensure a depth

of 80mm.

Figure 2-5

STEP 2: Hammer expansion tube into the wall mount bracket on the wall, keep aligned with the

holes.

Figure 2-6

STEP 3: Mount the hybrid inverter on the bracket.

Figure 2-7

13

STEP 4: Secure the inverter with M6 screw on the right side.

Figure 2-8

STEP 5: Install anti-theft lock if necessary (Optional, equipped by user).

Figure 2-9

2.3.2 Electrical Connection

Hybrid Inverter System Connection Diagram

Figure 2-10

14

For AU/EN

Figure 2-11

For Other Countries

Figure 2-12

Other manuals for SMT-10K-TL-TH

1

Table of contents

Other Sermatec Inverter manuals

Popular Inverter manuals by other brands

MGE UPS Systems

MGE UPS Systems 3.5 to 21 kVA N+1 owner's manual

SMA

SMA Sunny String Monitor - Cabinet Installation and use

Schweizer

Schweizer Solrif Short installation manual

Wagan

Wagan 2406 user manual

Hitachi

Hitachi SJ2-CO instruction manual

Mitsubishi Electric

Mitsubishi Electric FR-A8AP instruction manual