Sesino RAS Series User guide

USE AND MAINTENANCE Self contained cooling

unit RAS

SELF-CONTAINED COOLING UNITS OF RAS SERIES

Since water resources being not sufficiently available, more and more frequently it becomes indispensable to cool the oil with

air. In some cases it is not possible to connect the air-oil heat exchanger on the oil’s return line due to the presence of pressure

picks in the circuit. This is why we were forced to realize a separate circuit with autonomous circulation pump, separate pipes,

thermo-switch and electric circuit wiring.

For such cases, which are oftener and oftener, Sesino technicians have foreseen to design and launch into series production

self-contained cooling units of RAS series, which in the best way performs the task of cooling the oil independently from

primary hydraulic system of presses, injection molding machines, machine tools stations and other types of hydraulic

equipment.

RAS autonomous cooling groups are made by an air-oil cooler, a ventilator fitted with a power-driven pump and a thermal

adjustable electronic switch.

Trough a electric cabinet assembled with the group and an adjustable electronic switch and it’s thermostatic probe, it’s possible

to regulate the desired temperature of oil in the reservoir .

Generally, the oil temperature is set between 30°C and 90°C, in any case the setting temperature should be over than

environment temperature.

Maximum working pressure inside the standard cooling element is 10 bar.

The group is made with an high quality components, in order to guarantee a long life time and a low noise level.

One of the actual big problems is the energy saving. Using water for the cooling purposes we loose the heat that oil has give

to the water.

If we use the air emerging from RAS group it’s possible to make re-use of the heat donated by oil by warming the area where

the RAS is installed.

Presently, the cost for water industrial usage are very high, and some companies are forced to install a closed loop chillers

for water refrigeration and the majority of them are refrigeration machines.

Energy consumption in these cases is considerably high and normally power waste is about 30%.

With RAS group series application it’s possible to decrease the energy consumption at 6%, with a considerable energy saving

and consequently less working cost, plus the cheaper initial cost of equipment.

Each RAS group is manufactured in accordance with the actual accident prevention measurement standard and also in

accordance with European regulation for electrical equipments.

USE AND MAINTENANCE Self contained cooling

unit RAS

INSTALLATION, START UP, MAINTENANCE

INSTALLATION

Working place

Cooler must be installed in a position where the air is not impeded in its current either in come in and come out processes.

To optimize cooler’s thermal performance is better to avoid any recycle of hot air between outlet and inlet.

Indoor installation of the cooler

It’s indispensable to have a good air recycle in the room where the cooler is installed, in order to avoid warming of environment

air , decreasing, thus, the thermal performance of heat exchanger in general.

RAS cooling element is put in the upper side of the group, air comes out directly from the radiator core. In this way we avoid

to bother the worker by warm air flow.

Outdoor installation of the cooler

In this case, power-driven pump & electrical ventilator must be protected from bad weather conditions.

Put the group under the roof, in order to protect the cooler from direct rain.

During winter time, in case of long stand by, oil temperature inside the cooler decreases a lot and consequently the oil viscosity

increases considerably.

For a proper re-start up of the system and also to avoid any back pressure on the radiator, it’s possible to install (by User’s

concern) an oil thermostatic recycling system, so that oil temperature does not go under a certain minimum level.

When the place of installation is too dusty it causes the spoilage of radiator core which provokes decreasing of thermal

performances. This is why, in cases when RAS is installed in a place of high pollution, is necessary to keep clean the radiator

regularly (see maintenance section).

ASSEMBLING

Hydraulic system

SESINO’s self-contained RAS series must be connected with flexible hoses with BSPP connectors (possible with cutting

edge ring) to oil’s tank in order to keep cooled.

Suction hoses must have the same or bigger size than the cooler’s port; otherwise is possible to have cavitation problems

with noise level increase and bad pump performance.

For the above same reason and also to avoid an increase of Delta-P, it’s recommend to use straight hoses without tortuosity,

size reduction and so on.

With a self-filling gear pump, it’s possible to fit the cooler under the tank with a maximum height of 2 meters under the oil level.

Applying bigger height, pump could be cavitation problems.

Thermostatic probe connection

Thermostatic probe must be put inside the oil tank to maintain the temperature. It’s necessary to have a female ½” BSPP

port for a correct installation, where the probe itself will be afterwards be screw on.

Probe maximum length is 2 meters. Since the probe is pre-set, it’s not possible either to shorten or to make it longer, in order

not to influence device performances.

For bigger length (not standard) please consult our Technical Department.

USE AND MAINTENANCE Self contained cooling

unit RAS

START UP

First of all, please check the voltage and power frequency supply; they must correspond to the data on the label, i.e. 400 V.

50 Hz.

Electrical connection to the terminal

Internal electrical connections are pre-assembled, it’s not necessary to make any other connections.

To connect the self-contained group to electrical supply it’s necessary to open the connection box, this is how You reach the

terminal.

Then connect the three phases of the current 400 V 50 Hz R-S-T respectively Black, Blue (or Grey) and Brown to the clamps

marked 1-2-3 respectively.

Then please connect the phase to clamp 4 and the neutral in low voltage (230 V) to clamp 5 for thermostat power supply.

Connect ) the NO thermostat contacts (red wires) with 12 V or 230 V to the clamp 6 & 7 (1 & 2 on smaller terminal).

An addition remote control switch must be connected to all the above connections (under Customer’s care).

In this way You will supply current to ventilator / power driven-pump and to thermostat switch.

On board electrical connections and all eventual electrical protections, are at Customer’s charge.

See ELECTRICAL SYSTEM.

Electronic thermostat switch setting

Electronic thermostat is already programmed by our operators during assembling process. No other

specific setting is required.

It’s simply necessary to set the desired temperature (oil temperature to keep inside the tank) by acting on touch-buttons or

arrows near digital display.

A special record will kept of temperature setting even when the system is switched off. In any

case for any technical complications, please follow these rules:

A. On having visualized the parameter to modify with touch-button SET and HYS, keep pressed for a while the

touchbutton ARROW UP in order to increase the value or ARROW DOWN to decrease it vice versa. Keeping the

buttons pressed, You can obtain a speed up of progressive variation of the value.

B. Touch-button SET. Pressing it when thermostatic switch is in the basic running, L1 symbol followed by the previous

assigned value appears for 2”. Achieving L1 from input side causes output commutation (switch over) of ON/OFF

on RL1.

Touch-button SET, if kept pressed during parameter’s programming records it immediately and thermostat switch

comes back to basic functioning. The same sequence automatically happens if in 6” no touch-button is pushed.

It’s sufficient to set the electronic thermostat switch on very low temperature value to obtain a ventilator / power drivenpump

nonstop running.

USE AND MAINTENANCE Self contained cooling

unit RAS

1) Cooling element

2) Frame

3) Fan

4) Pumo

5) Flange

6) Electric box

7) Motor

USE AND MAINTENANCE Self contained cooling

unit RAS

USE AND MAINTENANCE Self contained cooling

unit RAS

CONTROL /CHECKING

If the oil temperature is not stabilized at desired temperature but it continues to increase slowly time by time, it’s necessary to

proceed with the following verifications in order to find out the causes.

1. Ventilator / Power driven-pump speed and rotation sense.

2. Pump noise: if it’s high we are in presence of cavitation, which are always to avoid.

3. Inlet and outlet cooling air from radiator block.

4. Radiator block cleaning up on oil and air side.

5. Oil and air inlet temperature.

To obtain an optimum thermal performance of the unit it’s necessary to avoid any oil and air circulation difficulties as well as

installation in a very highly polluted areas.

MAINTENACE

This type of equipment doesn’t require any specific maintenance.

When they are installed in a highly polluted place it’s necessary to clean radiator block regularly.

Air side cleaning

It’s possible to execute with compressed air only. Air flow direction must be parallel with fins passing on radiator in order not

to damage them.

If the dirt is caused by oil or grease, cleaning must be done with a steam flow or hot water, paying particular attention to flow

direction. Cleaning procedure must be effected when the radiator core is disassembled from the unit.

Oil side cleaning

It’s necessary to disassemble the radiator core for this cleaning.

A low level of dirt could be removed with a detergent fluid circulation.

Running time of this operation depends of the level of spoilage and normally it takes between 10 and 30 minutes.

After this operation it’s necessary to remove all the fluid from radiator internal parts. The subject operation must be done with

compressed air.

During detergent fluid circulation it’s necessary to keep the fluid pressure at maximum 10 bar.

GENERIC ADVISES

SESINO’s RAS self-contained groups are projected exclusively to cool hydraulic oil and cannot be used to cool other fluid or

liquid.

Before proceeding with any maintenance operation IS MANDATORY TO SWICTH VOLTAGE OFF, because inside of this

unit there are some moving parts that may cause injury to the operator.

GUARANTEE LIMITATION

Product’s Warranty period covers max. 12 months from delivery date.

Warranty is limited to the defected component, when after checking, a real effective Manufacture responsibility arises.

Warranty on the product is always declined when improper maintenance or any damage occurs.

Table of contents

Popular Freezer manuals by other brands

Veripart

Veripart VRIEZER VPVR144NFE user manual

Marathon

Marathon MCF70GRD-1 owner's guide

Frigidaire

Frigidaire FFH17F7HW - 16.6 cu. Ft. Frost Free Upright... Guide d’utilisation et d’entretien

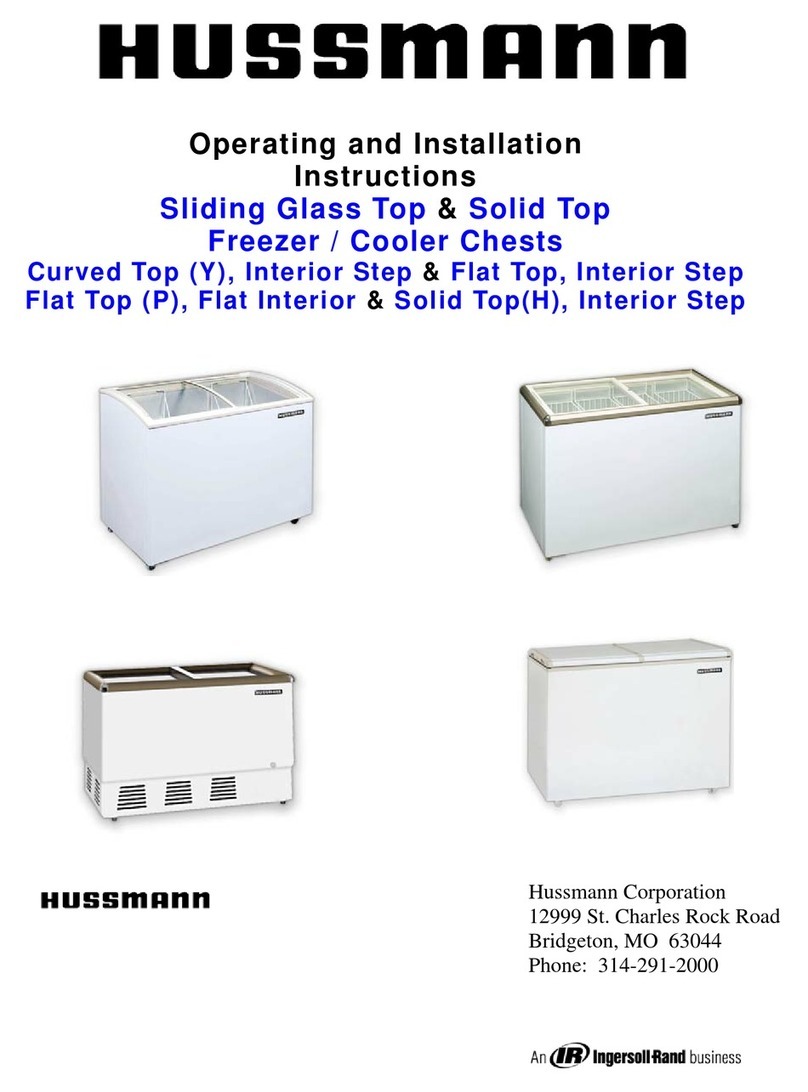

Hussmann

Hussmann HBD/BC-142 Operating and installation instructions

DSI

DSI V-3 manual

Brandt

Brandt BFK099EBW instruction manual

Rothenberger

Rothenberger ROFROST Turbo R290 Instructions for use

Beko

Beko ZA 630 Installation, operating & food storage instructions

Kelvinator

Kelvinator KFS220RGW Factory parts catalog

Midea

Midea COMPACT Series Service manual

ARDESTO

ARDESTO URM-85M60 instruction manual

Electrolux

Electrolux TF110 owner's manual