SGI-DNA BIOXP 3200 User manual

BioXp™3200 System

User's Guide

REV. 5.0 01.08.19

Part number 40010

LEGAL NOTICES

Limited Use Label License Except as otherwise agreed in writing by our authorized representative, this product is for INTERNAL RESEARCH USE

ONLY AND NOT FOR HUMAN, ANIMAL, THERAPEUTIC OR DIAGNOSTIC USE. For additional information about your

rights under this research license, please see our website at sgidna.com.

Limited Warranty a) SGI-DNA's entire liability and your exclusive remedy if the Product fails to conform to the following warranty (a

“Nonconforming Product”) shall be, at SGI-DNA's sole option, either repair or replacement of such Nonconforming

Product, or, if neither is practicable, a refund of the fees paid for the Product. The warranty for the repaired or

replaced Product is limited to the scope and remaining duration of the original warranty for the Nonconforming

product or, if longer, for 30 days after the date of shipment to you of the repaired or replaced Product. The warranty

is contingent upon proper use of the Product in accordance with the User's Guide and does not apply to any Product

that is subjected to unusual physical or electrical stress, misuse, neglect, improper testing or storage, modication or

unauthorized repair or upgrade.

b) SGI-DNA warrants that the product, as delivered, will be free from defects in material and workmanship for a

period of one year from the date it is delivered to you (“the Warranty Period”).

c) This warranty gives you specic legal rights and you may have other legal rights which vary from state to state.

This warranty is non-transferable.

d) OTHER THAN AS EXPRESSLY SET FORTH ABOVE, SGI-DNA MAKES NO WARRANTIES, EXPRESS, STATUTORY,

IMPLIED, OR OTHERWISE. NO DISTRIBUTOR, AGENT OR EMPLOYEE IS AUTHORIZED TO MAKE ANY MODIFICATIONS,

EXTENSIONS OR ADDITIONS TO THIS WARRANTY.

e) You shall indemnify, defend and hold harmless SGI-DNA from any costs, expenses, damages, or other losses arising

out of i) any warranty of greater scope or duration than that set forth in this SGI-DNA Limited Warranty; and ii) failure

to disclaim implied warranties and limit remedies and liabilities, by and on behalf of SGI-DNA.

Trademark Information TipOne® is a registered trademark of USA Scientic, Inc.

Gibson Assembly® is a registered trademark and BioXp™, Oligo Vault™, and Bio360™ are trademarks of SGI-DNA.

E. cloni® is a registered trademark of Lucigen Corporation.

TransforMax™ and EPI300™ are trademarks of Epicentre, Madison, Wisconsin.

Gene Pulser® is a registered trademark and Xcell™ is a trademark of Bio-Rad Laboratories, Inc.

Qubit® is a registered trademark and Nunc™ is a trademark of Thermo Fisher Scientic Inc.

Q5® and OneTaq® are registered trademarks of New England BioLabs, Inc.

Regulatory Statement For Research Use Only

Statement of Proprietary

Information

Copyright in this work is vested in SGI-DNA and the document is issued in condence for the purpose only for

which it is supplied. It must not be reproduced in whole or in part except under an agreement or with the consent

in writing of SGI-DNA and then only on the condition that this notice is included in any such reproduction. No

information as to the contents or subject matter of this document or any part thereof arising directly or indirectly

there from shall be given orally or in writing or communicated in any manner whatsoever to any third party being an

individual rm or company or any employee thereof without the prior consent in writing of SGI-DNA.

Terms and Conditions IMPORTANT- This agreement (the “Agreement”) is a legal agreement between you and SGI-DNA. By installing or

otherwise using the BioXp™ 3200 System (referred in this agreement as the “Product”), you agree to be bound by the

terms of this Agreement. If you do not wish to be bound by the terms of this Agreement, do not use the Product and

promptly return the unused, unopened Product to the place of purchase for a full refund. The user is prohibited from

reverse engineering the software or output les generated from the BioXp™ 3200 system.

Limitation of Liability SGI-DNA'S LIABILITY ARISING OUT OF OR RELATING TO A PRODUCT SHALL NOT EXCEED THE AGGREGATE AMOUNTS

YOU PAID TO SGI-DNA FOR THE PRODUCT. IN NO EVENT WILL SGI-DNA BE LIABLE FOR LOST USE, PROFITS, REVENUE,

COST OF PROCUREMENT OF SUBSTITUTE GOODS, OR ANY OTHER SPECIAL, INDIRECT, RELIANCE, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES, HOWEVER CAUSED AND UNDER ANY THEORY OF LIABILITY. THE FOREGOING

LIMITATIONS SHALL APPLY REGARDLESS OF WHETHER SGI-DNA HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES AND NOT WITHSTANDING THE FAILURE OF ESSENTIAL PURPOSE OF ANY LIMITED REMEDY.

Disclaimer The material in this manual is for informational purposes only and is subject to change without prior notice at any

time. SGI-DNA and/or its aliates assume no responsibility for any errors that may appear in this document.

INDICATIONS FOR USE The BioXp™ 3200 System is a device which is intended for the processing of DNA materials. The system is not

approved for use other than that stated above.

Technical Services For technical assistance, please contact technical services at techser[email protected]om or 1-855-474-4362.

SGI-DNA

sgidna.com

©2019 SGI-DNA. All rights reserved.

Gibson Assembly®: US Patent Nos. 7,776,532, 8,435,736, and 8,968,999.

010819

Table of Contents

BioXp™ 3200 Instrument Guide 3

Instrument Ordering Information 3

Safety Information 3

Manual Symbols 3

Precautions 3

Marking Symbols on the Equipment 3

Safety Warnings 4

Equipment Specications 6

System Components 6

Technical Specications 6

Installation Guide 6

System Location 6

Unpacking, Set up, and Power Up 8

Getting to Know the System 9

Starting the BioXp™ System 10

Ethernet Set Up 10

Start the BioXp™ System 10

Quick Start Guide: Performing an Instrument Run 11

BioXp™ Tiles and Libraries Quick Start 11

BioXp™ Cloning Quick Start 12

Operational Features of the BioXp™ System 15

Delay Start 15

Tracking Progress During a Run 16

Canceling a Job During Delay Start 17

Canceling a Job During a Run 17

Shutting down the BioXp™ System 17

Conguring the BioXp™ System 18

Instrument Troubleshooting 19

General Instrument Troubleshooting 19

Deck Inspection 19

Error Messages 19

Cleaning and Maintenance 20

Cleaning Instructions 20

Calibration 20

Preventative Maintenance 20

Repair 20

Recommended Separation Distances 20

Equipment Disposal 21

WEEE Compliance 21

Regulatory Statements 22

FCC Compliance Statement 22

Guidance and Manufacturer’s Declaration: Emissions 22

Guidance and Manufacturer’s Declaration: Immunity 22

1

BioXp™ Tiles, Libraries, and Clones 23

Product Ordering Information 23

Overview 23

Receiving an Order 23

Required materials (not included in the product order) 24

Specications 24

Consumables and Reagents 25

Instrument Operation 26

Preparing for a BioXp™ 3200 System run 26

Load the instrument 27

Begin the Run 28

During the Run 28

After the Run 28

Analyzing BioXp™ Tiles, Libraries, and Clones 30

Gel Electrophoresis 30

Next Steps– BioXp™ Tiles and Libraries 31

Quantication 31

Cloning BioXp™ Tiles 31

Multi-fragment Assembly 31

PCR Amplication (Optional) 32

Colony Screening (Optional) 33

Next Steps– BioXp™ Clones 34

Transformation 34

Full-length Clone (EFC) Analysis 36

Screening colonies 36

Reference Material 38

pUCGA 1.0 Amp clone map 38

Troubleshooting 39

2

3

BioXp™ 3200 Instrument Guide

Instrument Ordering Information

Product Description Cat. No.

BioXp™ 3200 System, includes 1 year warranty Standard Ethernet conguration of

BioXp™ Instrument

BX 3200-02 and

BX 3200-02 EU

BioXp™ 3200 System Service Contract, 1 year Covers parts and labor for instrument

failure for 1 year, renewable annually

BX 3200-05 and

BX 3200-05 EU

Safety Information

Manual Symbols

This manual describes the use and maintenance of the SGI-DNA BioXp™ 3200 Instrument. Read this

manual completely before putting the instrument into service. The following icons are used in this

manual:

Electrical Safety Warning: Failure to follow these instructions can cause

harm to operators or subjects.

Important Note: Failure to follow these instructions can lead to damage of

the system or unexpected results.

Precautions

• The BioXp™ System conforms to the following standards: IEC 61010-1:2001 2nd Edition to include

EN61010-1:2001, IEC/EN 61010-2-010, IEC/EN 61010-2-081.

• The radiation exposure hazard is non-critical.

Covers and exterior components which the operator may come in contact

with during routine maintenance or calibration, shall operate at a voltage

no greater than 25 V AC or 60 V DC.

Marking Symbols on the Equipment

Warning: Indicates a warning concerning operations that may lead to

personal injury or potential damage to the instrument if not performed

correctly.

Caution, Hot Surface, Do NOT Touch.

Conformité European: This mark is a declaration by the manufacturer

that the respective component complies with the relevant directives and

standards as issued by the European Union.

Alternating Current.

Waste Electrical and Electronic Equipment (WEEE) Directive: Do not

dispose symbol. See "Equipment Disposal" on page 21 for additional

information.

Consult instructions for use.

4

Safety Warnings

Installation

The BioXp™ System is heavy. Do not attempt to lift or move the instrument without

the assistance and supervision of colleagues. Be certain to use appropriate moving

equipment and proper lifting techniques (including but not limited to making certain

that you have a secure grip on the instrument before lifting, keeping your spine in

a neutral position while lifting with your legs, and coordinating lifting and moving

movements with all appropriate personnel). Improper lifting can cause permanent back

injury.

Use this product only as specied. If the instrument is used in a manner not specied

by SGI-DNA, the protection provided by the instrument may be impaired, resulting in

personal injury or damage to the instrument.

Ground Circuit Protection

Check the mains electricity supply plug, voltage, and frequency to conrm that the

supply corresponds to the values shown on the instrument label.

Ensure that the supply of power to the instrument is via a socket tted with a protection

device, such as a circuit breaker of the correct rating, to provide automatic power cut-o

in the cause of an insulation fault.

Conrm that the mains wiring is grounded. SGI-DNA declines all responsibility for any

damages due to instrument non-grounding.

Main Power Switch

Do not position the instrument such that it is dicult to operate the main power switch.

Hazardous Chemical Warning

Chemicals used with the instrument may be hazardous.

Always wear protective gear including safety goggles, gloves, and a lab coat when

handling chemicals.

Exercise caution when handling ammable liquids.

Take precautions, including but not limited to installing proper ventilation systems, to

ensure that the BioXp™ System laboratory is safe and that operators of the instrument

will not be exposed to hazardous levels of harmful chemicals.

Follow all national, state, and local health and safety regulations and laws.

Use proper waste disposal in accordance with all relevant regulations.

Refer to applicable Material Safety Data Sheets (MSDSs).

Flammable Liquids: Instrument Warning

Exercise caution when using ammable liquids in the BioXp™ System to minimize the risk

of re.

Do not use any ammable liquids in the instrument except for the liquids required in the

included procedure.

Provide adequate ventilation for the instrument to prevent the accumulation of

ammable vapors.

All sources of ignition, such as open ame or electrical spark, are not permitted near the

instrument or in areas where ammable vapors may travel.

Ensure that the instrument, all neighboring equipment, and users of the instrument are

appropriately grounded to minimize the generation of static electricity.

Do not use the Ethanol Reservoir if it is cracked.

5

Flammable Liquids: Solution Handling Warning

Keep ammable liquids in covered containers when not in use.

Provide means to promptly and safely dispose of any ammable liquid leaks or spills.

Do not transfer liquids using air pressure.

Read applicable MSDSs.

Store ammable liquids in cool, well-ventilated areas away from corrosives, oxidizers, and

ignition sources.

Label containers and cabinets as "ammable materials" where applicable.

Use only approved safety vessels for ammable liquid storage.

Ground and bond ammable liquid containers to prevent static charge build-up.

Never pour ammable liquids down a drain or sink.

Dispose of empty ammable containers in an approved manner.

Electrical Safety Warnings

Do not attach the power cord to an extension cord or to a multiple portable socket.

Doing so may compromise shielding and/or grounding.

This equipment should not be used adjacent to or stacked with other equipment. If it

becomes necessary to use the BioXp™ System under these conditions, the unit should be

observed to verify normal operation in this condition.

Use only grounded mains outlets for instrument supply.

Use only grounded mains outlets to supply instrument.

Do not remove any panels. Panels should be removed only by trained service personnel.

The AC power cord is the primary disconnection device for the instrument. Ensure that

the point of connection is easily accessible and free of any obstructions.

Important Warning: Moving Parts

Do not override the door lock. When the door is locked, the moving parts of the

instrument are operational. Never attempt to physically restrict movement of instrument

components.

Interfering with moving parts may cause personal injury. Keep hands clear of moving

parts while operating the instrument.

Do not move or shift the instrument during operation.

If the instrument shows evidence of corrosion or wear, do not attempt to manipulate or

tamper with components of the instrument.

Important Warning: Disconnecting the Instrument

Disconnect power to the system before cleaning or performing maintenance.

DO NOT remove any panels; panels should be removed only by qualied service

personnel.

Do not disassemble unit.

6

Equipment Specications

System Components

Use of other parts or materials other than those supplied with the instrument can degrade

system performance and may cause safety hazards. Use only SGI-DNA approved or supplied

components.

Use only SGI-DNA supplied Power Supply Cord. Use of other power cords may compromise

electrical protection and could create a hazard.

Components of the BioXp™ System

BioXp™ 3200 Instrument

Power Cord

RJ45 Ethernet Cable

Reagent and Recovery Plate Thermal Covers

Ethanol Reservoir

Technical Specications

Product Name BioXp™ 3200 System

Power Input Voltage 100–240 V

Power Input Current 8.3 A Max

Operating Temperature Range 16°C to 40°C

Storage Temperature Range −18°C to 60°C

Operating and Storage Humidity Range 10% to 90% (non-condensing relative humidity)

Operating Altitude To 2000 m

Water Ingress Non-immersion, protection for damp wipe only

Weight 63.4 kg

Dimensions (W,H,D) 66 cm × 53 cm × 74 cm

Installation Guide

The following section is included for reference purposes only. As standard practice, SGI-DNA will install

the BioXp™ System.

CAUTION: Read the entire Installation Guide before unpacking the BioXp™ System. Be sure to read and

adhere to the "Safety Warnings" on pages 4 and 5. Contact SGI-DNA immediately if you have any

concerns or questions.

System Location

The BioXp™ 3200 System has a compact footprint and is designed to be used in the typical laboratory

environment. Install the instrument in a location that meets the following requirements:

• Lab bench space that is 87 cm (35 inches) wide and 74 cm (29.2 inches) deep to accommodate the

instrument and allow for 10 cm of clearance on the sides for proper ventilation.

• Clearance of 79 cm (31 inches) above the lab bench to allow the door to open upward properly

• An available AC power outlet present within 2 meters of the instrument

• Available internet connection through a wired Ethernet connection

7

Setup Precautions

Place the instrument on a clean, dry, at surface capable of holding the

weight of the system.

Allow 10 cm of clearance on both sides of the instrument for proper

ventilation.

Make certain that the power cord connection point is free and clear of

obstructions so that it is easily accessible.

The intended location must be stable so that the instrument will not move

or vibrate excessively when in use.

Avoid dusty areas.

Avoid areas where the instrument would sit in direct sunlight or near a

heat source.

Do not set the instrument up where liquids or chemicals are used. Ensure

that no liquids are spilled into the instrument.

8

Unpacking, Set up, and Power Up

WARNING! Using the BioXp™ System in a manner not specied by SGI-DNA may result in damage to the

equipment and/or personal injury.

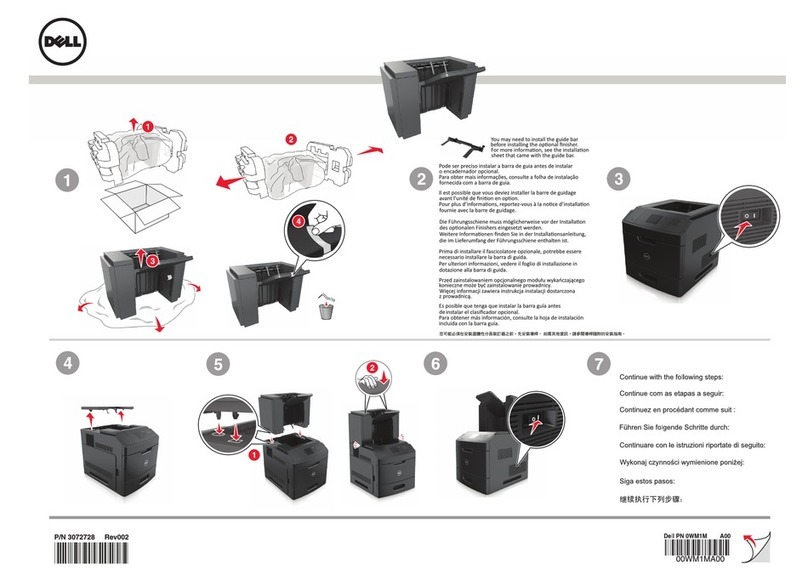

1. Remove the crate from the BioXp™ System by positioning two people across from each other. Carefully

lift the box upward while leaving the instrument stationed on the foam cushions on the pallet as

shown in the following illustrations:

2. Remove the foam packaging materials from the top of the instrument.

3. Carefully coordinate lifting the BioXp™ System o of the pallet with at least two people using proper

lifting technique:

4. Making certain the path is clear, carry the instrument and place it on the site prepared according to the

stipulations outlined in "System Location" on page 6.

5. After removing the power cord from packaging, connect it to the power inlet located on the right rear

side panel of the instrument.

6. Check that the power switch located above the power cord inlet is in the “o” position (0).

7. Connect the instrument to a grounded power outlet.

Note: We recommend connecting the instrument to a 1500 VA/900 W uninterruptible power supply.

9

Getting to Know the System

Hardware Overview

Figure 1. Front and side view of the BioXp™ 3200

System.

Figure 2. The BioXp™ 3200 System Deck.

Figure 3. Deck Map.

1– Heated Lid

2– Thermocycler

3– Purication Module

4– Thermal Cover

5– Reagent Chiller

6– Recovery Chiller

7– Reservoir Retainer

8– Strip Well Holder

9– Tip Tray Retainer 1

10– Tip Tray Retainer 2

11– Tip Tray Retainer 3

12– Tip Tray Retainer 4

13– Waste Bin

Instrument Ports and Power Switch

Location Label number Port/Inlet Used to

12345

1 USB Do not use

Note: The USB port is for instrument

diagnostics and is for authorized service

personnel use only.

2 Ethernet Connect to sgidna.com for system operation

3 Fuse Do not use

4 Power

switch

Switch power to the instrument on or o.

Note: We recommend leaving the

instrument on continuously.

5Power inlet Power the instrument

Figure 4. Power On/O switch and communications ports.

10

Starting the BioXp™ System

Ethernet Set Up

The BioXp™ System requires an internet connection. Prior to connecting the instrument to the internet, be sure to

test the connection. Connect the provided RJ45 Ethernet Cable to the Ethernet port located on the rear of the unit

to an available Ethernet wall jack.

Start the BioXp™ System

1. Turn the instrument on using the power switch located on

the side of the instrument.

The BioXp™ System will initiate a self-check process to verify the correct functionality of motion control

and other internal systems of the instrument. If the instrument is unable to perform a successful self-check

it will alert the user to the problem and will prevent the instrument from operating until the problem has

been addressed. The self-check process has been carefully developed to ensure that the BioXp™ System is

operating within optimal calibration ranges and that all systems are functioning correctly before initiating

a run.

2. After the self-check, one of the following screens is displayed:

If reagents from previous jobs are on the

instrument deck, a Remove Materials

Screen is displayed. Open the door,

remove the materials from previous jobs,

and then close the door.

If you are ready to load the instrument and

begin a run, refer to the appropriate deck

loading instructions for your system run.

11

Quick Start Guide: Performing an Instrument Run

After installing and setting up the BioXp™ System, the instrument is ready for operation. The following instructions are

intended for experienced users. If this is your rst time operating the BioXp™ System or if you are unfamiliar with operating

the instrument, refer to the detailed instructions on pages 23–29.

BioXp™ Tiles and Libraries Quick Start

The instructions on this page are specic for building BioXp™ Tiles and Libraries. See page 12–14 for instructions for

loading the instrument for building BioXp™ Clones.

Each BioXp™ Tiles kit includes Module A (+4°C) and Module B (−20°C). Refer to the Loading Map shipped with your BioXp™

Reagents for the most up-to-date loading instructions.

1. If the door is closed, select "Unlock Door" from the instrument LCD screen and open the door

2. Thaw the DNA Assembly Reagent Plate (at 25°C for 1 hour or on ice for at least 3 hours)

3. Load tips by aligning the tip tray notch with the upper left corner of each Tip Tray Retainer

Load 3 x 50 µL tips

Load 1 x 200 µL tips

4. Add a minimum of 12 mL freshly prepared 70% ethanol to the reusable Ethanol Reservoir

Load Ethanol Reservoir in the right-most Reservoir Retainer position of the instrument deck

Note: Do not discard the Ethanol Reservoir after the run; keep for future use

5. Load plates stored at 4°C:

Load the Recovery Plate onto the Recovery Chiller with the notch in the upper left corner

Load the Oligo Vault™ Plate so that the notch is positioned in the upper left corner of the Thermocycler

6. Briey spin the DNA Purication Strip

Load the black DNA Purication Strip into the #1 position (left-most) with the strip pinhole closest to the front

of the instrument

7. Secure strips with the spring-loaded arms while holding strips securely in place

8. Spin the thawed DNA Assembly Reagent Plate for 1 minute at 500 rpm. Visually inspect the wells to ensure that they

are completely thawed before loading the plate.

Load DNA Assembly Reagent Plate onto Reagent Chiller, notch in the lower left corner

Note: Be certain that the plate is properly seated within the chiller and that the barcode is on the right

9. Refer to the photo in the lower left panel below. Conrm that all components are securely seated. Close the door.

10. After the deck inspection, press Start Now or Delay Start (no more than 2 hours) to begin the run.

Loaded Deck at Beginning of Run Deck at Run Completion

Oligo Vault™

Thermal Cover DNA Assembly

Reagent Plate

Recovery

Plate

Ethanol

Reservoir

50 μL tips 50 μL tips

50 μL tips 200 μL tips

black strip

Oligo Vault™

Recovery Plate

Location of BioXp™ Tiles after the run

After the instrument run, BioXp™ nal products are located in Wells A1–H4 of the Recovery Plate within the Thermocycler.

BioXp™ Tiles and Libraries are provided in 45L TE Buer. The expected yield is >200 ng of puried, linear DNA. If you will not

be using the nal products immediately, seal the Recovery Plate and store at 2°C to 8°C for up to one week or at −20°C for up

to one year.

12

BioXp™ Cloning Quick Start

The following instructions are intended for experienced users only. For additional instructions, see:

• The BioXp™ Custom Cloning Vector Preparation Guide available at sgidna.com.

• Detailed loading instructions on pages 23–29.

Guidelines for preparing the BioXp™ custom vector strip

1. After you have prepped your vector according

to the protocols and guidelines in the BioXp™

Custom Cloning Vector Preparation Guide available

at sgidna.com, adjust the prepared vector

concentration according to the table:

Vector Size (kb) Concentration (ng/µL)

3–5 15–20

5–7 20–25

7–9 25–30

9–12 30–35

2. Determine the volume of prepared linear vector

you will add to wells A, C, E, and Gof a BioXp™

Vector strip.

Note: Volume recommendations are subject to

change. Please contact us at

Number of BioXp™ Cloning Reactions Volume/

well

≤16 Reactions 12 µL

>16 Reactions 18 µL

3. Add 12 or 18 µL of prepared linear vector to wells

A, C, E and G of a BioXp™ Vector strip. Do not seal

the strip. Ensure that no air bubbles have been

introduced and that the resuspended vector is

at the bottom of the strip wells. Load the lled

custom strip on the deck with the pinhole closest

to the front of the instrument. A C E G

B

D

F

H

pinhole

EXAMPLE: For 8 cloning reactions, adjust the volume of a 10 kb vector to a nal concentration of 30–35 ng/µL. Add 12 µL of

the linearized, prepared vector to the four strip wells (A, C, E and G).

Total amount of required vector = 1.44 to 1.68 µg.

13

BioXp™ Cloning Quick Start: Loading the instrument

Each BioXp™ Cloning kit includes Module A (+4°C), Module B (−20°C), and Module C (−20°C).

1. If the door is closed, select "Unlock Door" from the instrument touch screen and open the door

2. Thaw −20°C components as directed below:

• DNA Assembly Reagent Plate (at 25°C for 1 hour or on ice for at least 3 hours)

• GA Cloning Strip and Vector Strip (30 minutes on ice)

3. Load tips by aligning the tip tray notch with the upper left corner of each Tip Tray Retainer

Load 3 x 50 µL tips

Load 1 x 200 µL tips

4. Add a minimum of 12 mL freshly prepared 70% ethanol to the reusable Ethanol Reservoir

Load Ethanol Reservoir in the right-most Reservoir Retainer position of the instrument deck

Note: Do not discard the Ethanol Reservoir after the run; keep for future use

5. Load plates stored at 4°C:

Load the Recovery Plate onto the Recovery Chiller with the notch in the upper left corner

Load the Oligo Vault™ Plate into the Thermocycler with the notch in the upper left corner

6. Briey spin the strips. Visually inspect the wells to ensure that they are completely thawed. Load in the order listed

and shown below, with the strip pinhole closest to instrument front

Load the black DNA Purication Strip into position #1

Leave position #2 empty

Load the purple GA Cloning Strip into position #3

Load the red pUCGA 1.0 or Custom Vector Strip into position #4

7. Secure strips with spring-loaded arms while holding the strips in place.

8. Spin the thawed DNA Assembly Reagent Plate for 1 minute at 500 rpm.

Visually inspect the wells to ensure that they are completely thawed.

Load DNA Assembly Reagent Plate onto Reagent Chiller,

notch in the lower left corner and barcode on the right

Note: Be certain that the plate is properly seated within the chiller.

9. Refer to the photo in the lower left panel below. Conrm that components are securely seated. Close the door.

10. After the deck inspection ends, press Start Now or Delay Start (no more than 2 hours) to begin the run.

Loaded deck at beginning of run

Oligo Vault™

Thermal Cover

DNA Assembly

Reagent Plate Recovery

Plate

Ethanol

Reservoir

50 μL tips 50 μL tips

50 μL tips 200 μL tips

black strip

purple strip

red strip

or

14

After the cloning run: nal DNA product location

Deck at run completion

Recovery Plate Oligo Vault™

keep keep

keep

keep

keep

Items to keep

DNA product Located within Storage instructions

Cloning Reaction

(wells A1–H4) Recovery Plate

Seal and store at 2°C to 8°C for up to one week or at −20°C for up to one year.

Uncloned Tiles

(wells A5–H8)

Oligo Vault™Plate

(foil covered)

Ethanol Reservoir

(empty and rinse for next use)

Recommendations

After the BioXp™ run is complete, cloning reactions are ready for transformation. We recommend diluting cloning

reactions 1:2 with molecular biology grade water before transformation.

Analyze Tiles– We recommend evaluating the success of the assembly reaction by running a gel containing the

uncloned BioXp™ Tiles from the Oligo Vault™ Plate before transforming clones.

Transformation– We recommend using E. cloni 10G Chemically Competent Cells (LucigenCat.No.60107, free samples

available at Lucigen.com) or TransforMax™ EPI300™ Electrocompetent E. coli (LucigenCat.No.EC300110). If other cells

are used, use competent cells with a transformation eciency ≥1 × 109CFU/g pUC19.

15

Operational Features of the BioXp™ System

Delay Start

The Delay Start function is a useful tool enabling you to schedule instrument runs at your convenience.

Immediately after a Delay Start is scheduled (before the delay time period elapses), the instrument

initiates reagent mixing from the Reagent Strips and the Reagent Plate. Therefore, ensure that the

Reagent Strips and Reagent Plate have thawed completely before initiating a Delay Start. If you decide to

cancel a Delay Start, consider that you may need to replace the Reagent Strips and Reagent Plate and run

the job at a later date since the master mixes created from combining the contents of the Reagent Strips

and the Reagent Plate are thermolabile.

To perform a Delay Start:

1. After pressing Delay Start on the Job Initiation Screen, the system will display a

DelayTimerScreen:

2. Use the arrows to set the delay start time and press OK.

Note: We recommend using the Delay Start feature for short periods of time (less than 2 hours)

asnecessary.

3. After the delay time has been scheduled, the system will prepare reagents for the run. The system

displays a Delay Start Screen with a timer showing the length of time left until the run begins

(in hours : minutes : seconds) and the expected time of job completion (also in hours : minutes :

seconds):

4. After the system has prepared the reagents for the run, a new countdown screen is displayed. You

may opt to bypass the delay and start the run immediately by pressing Start Now. If no action is

taken, the instrument run will begin when the timer reaches 0:00.

16

Tracking Progress During a Run

Time to Completion

During a run, the instrument will display the projected time remaining for the run

(in hours : minutes : seconds) and the estimated Time of Completion, as shown in the following

illustration.

Ways to Track Progress

You can track the progress of your reaction in a number of ways:

Parameter Denition

Time to Completion The system estimates the time at which the run will be completed.

Time Remaining The system estimates the time remaining for completion.

Visual Progress The system provides a progress bar through the various steps to completion.

Note: The scale of each step is not linear. (i.e. Step 1 requires much more time

than Step 4 but both steps are each depicted with a similar sized time lapse

bar).

Color Indicators

The internal colored lights change during the run process. The colors indicate the status of the process

taking place. The background color of the screen changes to indicate the following:

Touchscreen

Background Color Indication

Blue Normal operation: run set up or run in progress

Yellow System check or prompt requiring user attention

Red Error message

Green Processing completed

17

Canceling a Job During Delay Start

To cancel a job after initiating a Delay Start, press Cancel Job .

The system will display a screen reminding you that materials may have already been compounded,

rendering reagents unusable at a future time.

Press To

NO (keep running) Continue with the delay start and

instrument run

YES (stop running) Cancel the delay start and abort

the job

Canceling a Job During a Run

IMPORTANT! You will not be able to reuse reagents if you cancel a job after the run has initiated and the

Reagent Plate Seal has been broken. Do not cancel a run unless absolutely necessary.

1. If you need to cancel a job during a run, slide

your nger to the right across the bar on the

bottom of the Display Screen during a Run.

Slide to cancel

2. After sliding to cancel, the system will display

a Conrmation To Cancel screen. Press YES

Cancel Job to end the run or No to continue

the run.

If you press YES Cancel Job, the instrument

will display a Canceling Job screen until the job

cancel is complete.

3. When prompted, remove all materials and

used or partially used consumables from the

instrument deck:

Shutting down the BioXp™ System

We recommend leaving the instrument on continuously. Only turn the instrument o when necessary,

such as when moving the instrument to another location. If the instrument must be turned o, toggle the

power switch located on the side of the instrument (near the power cord) to the OFF position.

Other manuals for BIOXP 3200

1

Table of contents