SHAKTI PUMPS KUSPC 2.0 Manual

SHAKTI PUMPS (INDIA) LIMITED

Plot No. 401, 402, & 413, Industrial Area, Sector - 3, Pithampur - 454774,

Dist. - Dhar, (M.P.) - INDIA, E-mail: [email protected],

Visit us at : www.shaktipumps.com

INSTALLATION & OPERATING INSTRUCTIONS

Oct./2023-24/L2/00 VC : 0000 SAP No. : 2000020887

13 Oct 2023/ R10

KALPAVRIKSHA UNIVERSAL

SOLAR PUMP CONTROLLER 2.0

CHAPTER 1: SAFETY INSTRUCTIONS............................................

1.1 Pre-Installation Safety Measures..................................

1.2 Installation Safety Measures.........................................

1.3 Safety during Operation..................................................

Attention...........................................................................................

CHAPTER 2: INTRODUCTION..........................................................

2.1 Product Overview.............................................................

2.2 Storage Instructions........................................................

2.3 Receiving and Inspection...............................................

CHAPTER 3: PACKAGE CONTENTS................................................

CHAPTER 4: SPECIFICATIONS........................................................

CHAPTER 5: INSTALLATION............................................................

5.1 Mounting Method ............................................................

5.2 Installation Position........................................................

5.3 Mounting Procedure........................................................

CHAPTER 6: CONNECTIONS AND

CONNECTING PROCEDURE.............................................

6.1 Rear Panel........................................................................

6.1.1 PV Input Connectors........................................................

6.1.2 PV DC Disconnect Switch...............................................

6.1.3 Procedure for connecting three-phase induction

motor with KUSPC:

6.1.4 Procedure for connecting single-phase induction

motor with KUSPC

6.1.5 Operation of KUSPC with Single-phase Load

6.1.6 WIFI/GPRS DB9 Connector............................................

6.1.7 SHAKTI RMS/IoT DONGLE .........................................

ModBus Address Table....................................................

6.1.8 AC Output Connector.......................................................

6.1.9 Pressure Relief Vent........................................................

6.1.10 Aux Input/ Output & RS485

Communication Connectors..........................................

CHAPTER 7: OPERATION OF UNIT..................................................

7.1 Display Module Description...........................................

7.2 Button Description and Operation................................

7.3 LCD Operation..................................................................

CHAPTER 8: NUMERICAL DISPLAY INFORMATION.....................

8.1.1 Display Information..............................................................

CHAPTER 9: TROUBLESHOOTING..................................................

9.1.1 Fault information and description in detail.......................

CHAPTER 10: RECYCLING & DISPOSAL.......................................

WARRANTY CERTIFICATE

WARRANTY CARD

CONTENT

01

01

01

02

03

03

03

04

04

05-06

07

08

08

08

09-10

11

11-12

13-14

15

15

16-18

19

19

20-21

22-29

30

30

30-32

33

33

34-41

42

43-46

46

47-48

49

PAGE NO.

02

INSTALLATION & OPERATING INSTRUCTIONS INSTALLATION & OPERATING INSTRUCTIONS

01

CHAPTER 1 : SAFETY INSTRUCTIONS

WARNING! Ignoring the following instructions can cause physical injury or

damage to the equipment or death.

1.1 Pre-Installation Safety Measures

1. Before using the unit, read all instructions and cautionary markings

on the unit and all the sections of this manual.

2. The gross weight of the equipment is close to 20 Kg. Kindly lift the

USPC carefully to avoid any physical injury.

3. Please check the package for any sign of damage to ensure personal

safety. Don't use the damaged or incomplete USPC .

4. Customers are NOT authorized to open the USPC or to do any kind of

modification, or repair; otherwise, there is a danger of shock and loss

of warranty.

5. To store the USPC, kindly follow instructions given in Chapter 2

"INTRODUCTION".

1.2 Installation Safety Measures

1. Installation should be done in presence of a professional technician.

Safety equipment like safety shoes, helmets, and gloves should be

used by the technician. Only licensed person, who has been trained

in design, installation, commissioning, and operation of USPC is

permitted to operate this equipment.

2. To prevent risk of shock during installation and maintenance, please

make sure that all AC and DC terminals are plugged out.

3. Installation of the universal controller should be carried out on a

solar structure with proper ground clearance & specified nuts & bolts.

4. Install the USPC on metal or other non-flammable

material, and keep it away from any combustible material.

5. The USPC should not be installed inside a closed chamber. Ventilation

is required to ensure proper heat dissipation. Ignoring this will result

in malfunctioning of the unit and loss of warranty.

6. Before starting wiring and connections make sure that PV panels,

USPC , motor and all other accessories are properly fitted on their

designated place.

7. Ensure that the USPC, motor, and adjoining equipment are properly

earthed to reduce electromagnetic emission and interference.

8. Unit must be earthed using appropriate wire size diameter and its

diameter should be equal to or higher than that input power supply

wires (refer regional safety standard specific to your location).

9. Make sure that the voltage grade of the power supply is consistent

with the USPC 's voltage. Also, note that all PV panels are connected in

series or parallel as per system's requirement in order to have

required voltage fed to the drive.

10. There must not be any loose connection. Make sure that all

insulations are proper in order to prevent any damage/injury. Also

periodically inspect insulation in case of a bad weather.

11. Check whether the wiring is correct and firm, there should not be any

short circuit in the peripheral equipment's circuit.

12. Ensure that the output of the USPC is turned off while

setting all the required parameters.

13. Ensure that no unauthorized filter is connected to the output of the

USPC It may cause loss of warranty.

1.3 Safety during Operation

1. Make sure that the ratings of the pump, motor, PV panels, and

USPC comply with each other.

2. The heat sink should not be touched otherwise there is a danger of

getting burnt.

3. Do not operate or touch the USPC with the wet hand.

4. Do not put any of your belongings like mobile etc. on the USPC .

5. Disconnect PV power from the USPC under the

supervision or presence of a trained electrician.

6. Before opening the housing, the USPC must be disconnected from

PV.

7. After the input is disconnected from the USPC , wait for

at least five minutes so as to allow the internal capacitors to get

discharged for the safety of operation.

8. Ensure polarity, tightness and wire size are correct, before energizing

the USPC.

04

INSTALLATION & OPERATING INSTRUCTIONS INSTALLATION & OPERATING INSTRUCTIONS

03

9. At over 2,000 metres altitude, the USPC 's heat dissipation function

deteriorates, therefore, use proper derating.

10. Untrained workers are banned to check the signals in the running

stage.

11. Remove the PV power supply only after the electric machine stops

running.

Attention

1. The DC connection terminals PV+ and PV- carry a dangerous DC

voltage of up to 800V.

2. At the USPC input, the photovoltaic cells generate DC voltage even at

low intensity of sunlight.

3. While cabling, make sure that it does not come in the path of any

other work e.g. harvesting or digging.

4. If there is any abnormality contact customer care.

5. USPC and its heat sink may be relatively at high

temperature than the atmosphere.

6. Improper wiring and utilization or unauthorized alteration may result

in damage to USPC and other equipments. Users will

be responsible for the cause and there will be a loss of warranty.

7. The KUSPC product is not recommended for elevators, ICU, life

saving products etc.

CHAPTER 2 : INTRODUCTION

2.1 Product Overview

Kalpavriksha Universal Solar Pump Controller (KUSPC 2.0) is a solar

converter designed for maximum utilization of solar power available at the

site throughout the year. Multiple applications such as Water Pumping,

Atta Chakki, Deep Freezer, Thresher etc. can be operated from this single

solar powered product. The KUSPC automatically supports the application

selected by the user from the graphical display.

The product comes with IP65 rating and thus is suitable to be installed in

an external environment. All the protection features for various

applications are inbuilt. An option to monitor and control the KUSPC

remotely using a mobile APP or a website is also available.

2.2 Storage Instructions

The USPC should be stored properly in the original shipping package or

crate when not in use especially for extended period of time to retain

warranty.

Measures to be taken for USPC’s storage

a Storage area should be clean, dry, and free from direct sunlight or

corrosive fumes.

a Storage area has an ambient temperature range of -20 °C to 60 °C.

a Storage area has a relative humidity range of 0% to 90% and non-

condensing environment.

a Storage area has an air pressure range of 85kPA to 107kPA.

DO NOT store

rIn an area with the rapid change in temperature (condensation and

frost may be caused).

rIn a place with significant water leakage.

rIn a place which has a high risk of fire ignition.

NOTE: If storage of drive is for more than 3 months then ensure that

0

temperature should not be more than 30 C. Storage for more than a

year may reduce the lifespan of the product.

2.3 Receiving and Inspection

The USPC has gone through rigorous quality control tests before shipment.

After receiving the drive, please check if the part no. indicated on the name

plate corresponds with part no. of your order.

= Serial Number Explanation

Serial Number for the Batch Date of Manufacturing

XX - XXXX - X - XX - XX - XX Year of

Manufacturing

Model Number Month of Manufacturing

Batch Number

06

INSTALLATION & OPERATING INSTRUCTIONS INSTALLATION & OPERATING INSTRUCTIONS

05

CHAPTER 3 : PACKAGE CONTENTS

Inspection

Note: Never install or operate any unit which is damaged or has missing

components. Doing so can result in injury.

Check the following items when unpacking the Inverter:

1. Inspect the entire exterior of the Inverter to see if there are any

scratches or other damage resulting from shipping.

2. Ensure there is operation manual and warranty card in the packing

box.

3. Ensure the nameplate is correct as ordered.

4. Ensure the optional parts are as per order, if ordered.

5. Contact the customer care if there is any damage to the unit or the

optional parts.

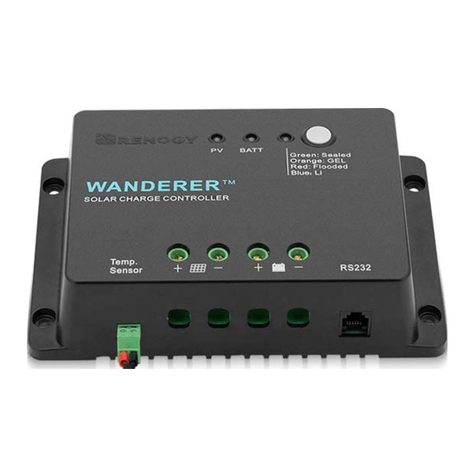

Fig. 3.1 Kalpavriksha Universal Solar Pump controller (KUSPC 2.0)

Fig. 3.2

A

H

B, F, G

I

C

J, K

D E

M

Following is the list of items in the packaging.

L

Table 3.1 List of Items

Fig. 3.2 Images of list of Items in KUSPC 2.0 Packaging

S.No. Name Qty. Unit Manufacturer Manufacturer Name

A1 Set

BMOUNTING PLATE STRIP KALP_H 371x24x2.4MM 1 EA

C1 EA

DPV CONNECTOR MC4 MALE WITH TERMINAL 2 EA ESC-4 (MALE) ELCOM INTERNATIONAL PVT.L

EPV CONNECTOR MC4 FEMALE WITH TERMINAL 2 EA KF2EDGK-5.08-02P Cixi Kefa Electronics Co., Ltd.

FFAB SHEETMETAL BKT WALLMOUNT KALP H RHS 1 EA

GFAB SHEETMETAL BKT WALLMOUNT KALP H LHS 1 EA

HSCREW HEX HEAD SELF TAP WTH GRIP M5.5X35 4 EA ESC-4 (FEMALE) ELCOM INTERNATIONAL PVT.L

ICONN. DRY CONTACT EXTERN 2 POS 320V 12A 1 EA

JPAN HEAD PHILLIPS DRIVE M4X10MM+WASHER 2 EA

KPHILIP PAN HEAD SCREW M6X16 W.WASHER(SS 4 EA

LCONN. DRY CONTACT EXTERN 3 POS 320V 12A 4 EA MSTB 2,5/ 3-ST-5 PHOENIX CONTACT

MMANUAL KALPAVRIKSHA USPC 1 EA

Part number

Universal Solar pump controller

SHAKTI RMS DONGLE WITHOUT WIFI

07 08

INSTALLATION & OPERATING INSTRUCTIONS INSTALLATION & OPERATING INSTRUCTIONS

CHAPTER 4 : SPECIFICATIONS CHAPTER 5 : INSTALLATION

Mounting Method, Installation Position and Mounting Procedure

of the USPC is illustrated as follows:

5.1. Mounting Method

1. The equipment employs natural convection cooling, and it can be

installed indoor or outdoor.

2. Please install the equipment under the guidance of Figure 5.1.

Vertical installation on floor level is recommended. Mount vertically or

tilted backwards by max. 15°. Never install the inverter tilted

forwards, sideways, horizontally or upside down.

3. Install the USPC at eye level for convenience when checking the LCD

display and possible maintenance activities.

4. When mounting the USPC, please consider that disassembly for

service work may be required.

5.2. Installation Position

Do not expose the USPC to direct solar

irradiation as this could cause power

derating due to overheating. The

ambient temperature should be

between -25°C ~ 60°C (-13°F ~

140°F) to ensure optimum operation.

Choose locations with sufficient air

e x c h a n g e . E n s u r e a d d i t i o n a l

ventilation, when necessary. To make

sure the installation spot is suitably

ventilated, if multiple units are

installed in same area, the following

safety clearance shall be followed for

proper ventilation conditions. Fig. 5.2

Fig. 5.1

3 HP 5 HP 7.5 HP 10 HP

PV Voltage Range

Max. PVCurrent

MPPTRange 220 - 450 VDC 220 - 650 VDC 220 - 450 VDC 220 - 720 VDC

Nominal PV Voltage 370 VDC 580 VDC 370 VDC 580 VDC

Number of PV Inputs

Max. Power 3000 W 5500 W 7500 W 10000 W

PV Start Voltage

Voltage Range 0 - 460 VAC

Max. Current

Operating Frequency Range

Power Factor Range

Motor Types

Peak Efficiency

Protection

Voltage Range

Motor Type

Max. Current 5A 8.5 A 10A 17 A

Nominal Frequency

Operating Frequency Range

Power Factor Range

MPPT Accuracy

Peak Efficiency

Total Harmonic Distortion (THDv)

Protection

DISPLAY & COMMUNICATION

Display Type

Status Indicator

Aux Ports

Remote Monitoring

WiFi

PHYSICAL

L X W X H

Net Wt. / Gross Wt.

OTHER INFO

Pollution Degree

Over Voltage Category

Protection Class

Operating Temperature

Relative Humidity

Altitude

IP Degree of Protection

Cooling

Standards

Air Forced Cooling

3

357 x 431 x 263 mm

PARAMETERS

Serial Communication

200 - 770 VDC

200 VDC

0 - 200 Hz

0.75 - 1

IPMSM, PMSM, S4RM, ACIM

Shortcircuit, Dryrun, Overtemperature, Overload etc

0-52 Hz (Through Constant V by F)

0.75 - 1

415VAC ± 5%

ACIM

48-50Hz

>99%

>93%

<3% (at nominal power)

Output voltage low, Output frequency low/high,

Over Current, Peak Torque overload etc.

Class I

0

-10 to 50 C

0~95% RH (Non-condensing)

3000 m (> 2000 m power derating)

LEDs

RS232 & RS485

MODBUS

1 Output port, 2 Digital port, 2 Analog port

Yes (Optional)

Graphical LCD

IP 65 (Indoor & Outdoor Installation)

Yes (Optional)

PD3

Category II

18.5kg/20kg

26 A

2

16 A

PV INPUT

MOTOR-PUMP OUTPUT

13 A

1

12 A

OTHER APPLICATION OUTPUTS (4 NOs)

>95%

Follows MNRE guide line.

>93% >93% >93%

KUSPC 2.0

09 10

INSTALLATION & OPERATING INSTRUCTIONS INSTALLATION & OPERATING INSTRUCTIONS

5.3. Mounting Procedure for KUSPC 2.0

This section provides the mounting procedure and drawings for lower power

KUSPC 2.0 Model.

1. Connect the mounting plate strip to the mounting brackets and then

mark the Positions of the Drill Holes of the wall mount bracket.

The mounting position should be marked as shown in Figure 5.3.

2. Drill Holes and Place the Expansion Tubes

According to the guides, drill 4 holes in the wall (in conformity with position

marked in Figure 5.4 ) and then place expansion tubes.

3. Mount the KUSPC 2.0

Carefully mount the USPC to the mounting bracket following the steps

shown in figure 5.5 Make sure that the rear part of the equipment is closely

mounted to the mounting bracket .

Fig. 5.3 Mounting Brackets for KUSPC 2.0

Fig. 5.4 Drilling drawing for KUSPC 2.0 Fig. 5.5 Mounting Procedures for KUSPC 2.0

STEP 3:

After installation put

the 4 nos. of M6 screws

in the side holes

(A)

STEP 1:

Place the mounting

bracket using 4 screws

(B)

STEP 2:

Hold the unit gently &

hook the unit to the

wall mount brackets.

12

INSTALLATION & OPERATING INSTRUCTIONS

11

INSTALLATION & OPERATING INSTRUCTIONS

Rear Panel view with cover & Dongle Connected

Fig. 6.2

Rear Panel view without cover

Note: Please refer section 6.1.3 & 6.1.4 for output wire connection.

Marking Description

1 PV Input Connectors

2 PV DC Disconnect Switch

3 WIFI/GPRS DB9 Connector

4 Connection for sine output (out 1-4)

5 VFD Motor Connection (out 5)

6 Pressure Relief Vent

7 Aux Input/ Output Connectors

Fig. 6.3

Table 6.1

CHAPTER 6 : CONNECTIONS AND CONNECTING PROCEDURE

6.1. Rear Panel

Rear Panel view with covers

Fig. 6.1

14

INSTALLATION & OPERATING INSTRUCTIONS

13

INSTALLATION & OPERATING INSTRUCTIONS

DC connector is made up of a positive connector and a negative

connector as shown in figure 6.4 & 6.5

1. Insulated Enclosure 2. Lock Screw

1. Insulated Enclosure 2. Lock Screw

6.1.1 PV Input Connectors

Table 6.2

1 2

1 2

Fig. 6.4 Positive Connector

Fig. 6.5 Negative Connector

Connecting Procedure

1. Tighten the lock screws on positive and cathode connector.

2. Use specified strip tool to strip the insulated enclosure of the

positive and cathode cables with appropriate length.

3. Feed the positive and cathode cables into corresponding lock

screws.

4. Put the metal positive and cathode terminals into positive cable and

cathode cable whose insulated enclosure has been stripped, and

crimp them tightly with a wire crimper. Make sure that the

withdrawal force of the pressed cable is bigger than 400N.

5. Plug the pressed positive and cathode cables into relevant

insulated enclosure, a "click" should be heard or felt when the

contact cable assembly is seated correctly.

6. Fasten the lock screws on positive and negative connectors into

respondent insulated enclosure and make them tight.

7. Connect the positive and cathode connectors into positive and

negative DC input terminals of the inverter, a"click" should be heard

or felt when the contact cable assembly is seated correctly.

Fig. 6.6 Connecting Cables

1. Positive Cable 2. Cathode Cable

Fig. 6.7

1. Connection Port

1

2

Cross - Sectional Area of Cables (mm )

Scope

4.0-6.0

Recommended Value

4.0

Outside Diameter of the

Cables (mm)

4.2 ~5.3

1

16

INSTALLATION & OPERATING INSTRUCTIONS

15

INSTALLATION & OPERATING INSTRUCTIONS

KUSPC 2.0 provides a feature to operate three phase as well as single phase

Induction motors. In KUSPC 5 types of three phase motors can be connected

at a time out of which any one motor operates at a time. The motor to be

operate is selected via display settings.

Notation to connect three-phase motor to KUSPC is given below:

6.1.2 PV DC Disconnect switch

This switch is provided to isolate the PV DC input from the USPC during

servicing of the inverter or any other maintenance work on the PV panels.

R Y B

Drive Motor

R Y B

The connection diagram with changeover switch is shown in fig. 6.8

Fig 6.8 Change over switch connection of three-phase motor with KUSPC

6.1.4 Operation of KUSPC 2.0 with Single phase IM:

In order to connect single-phase induction motor with KUSPC follow below

mentioned procedure.

= Connect single-phase motor to single-phase utility supply.

= Measure the voltage across main winding and the auxiliary winding.

= The winding having voltage equal to the supplied voltage is the main

winding. (nearly 230 V)

= The other winding measuring voltage between 200-400 V is the

auxiliary winding.

= Enter the values of main and auxiliary winding voltage in the USPC

parameters along with the motor type and poles.

= Remove the start capacitor from the motor (If present).

= Connect KUPSC 2.0 as per the fig. 6.9

Fig 6.9 Connection diagram for Single phase IM to KUSPC

= Make sure that “B” wire of the drive connects to the “Common

(C) / junction of main and Aux winding” of the motor.

The controller makes VRB = Main winding voltage and VYB = Aux winding

voltage.

= If someone wants to use the motor with the utility supply as well as USPC.

A shakti changeover switch is required to switch the input power

connection. The overall connection diagrams are shown in Fig 6.10a and

Fig 6.10B, wherein the start capacitor should be connected on the utility

side of changeover box.

6.1.3 Procedure for connecting three-phase induction motor with KUSPC 2.0:

18

INSTALLATION & OPERATING INSTRUCTIONS

17

INSTALLATION & OPERATING INSTRUCTIONS

Fig 6.10a Connection diagram with cut-off switch connected to Aux winding

Fig 6.10b Connection diagram with cut-off switch connected to main winding

The changeover switch connections are shown in Fig 6.11a and Fig 6.11b

Make sure that start capacitor does not come into picture when the motor

is operated from KUSPC.

Fig 6.11a Changeover switch connection corresponding to Fig 6.10a

Fig 6.11b Changeover switch connection corresponding to Fig 6.10b

NOTE: To change the direction of motor rotation, go to USPC PARAMETERS >> Direction.

20

INSTALLATION & OPERATING INSTRUCTIONS

19

INSTALLATION & OPERATING INSTRUCTIONS

6.1.7 SHAKTI RMS/IoT DONGLE

Step2:

Insert SIM card as per the correct direction marked.

Step3:

Put the motherboard back into the enclosure.

Figure 4

Step 4:

Insert the dongle into DB9 port and use two M3x10 screws

to fix the dongle along with gasket.

Figure 3

Figure 1

Status

Indicator

DB9 serial

port

Status Indicator:

2. Installation and Connection:

For installing the SHAKTI IoT dongle.

Follow these steps :

Step1: Remove the cover and take out the motherboard.

1. Product Appearance

Figure 2

3. Configuration

Step1: Connect the "Shakti IoT dongle" to the main device and check the "pulse LED"

(green) blinking in every second.

Step2:

If the sim card is present in the "Shakti Iot dongle" and 2G or 4G network is available in

1 2

that area, the Signal LED (RED) will be ON for 2G dongle and Pulse LED (GREEN) will

blink in every second for 4G dongle.

Remote Monitoring and Control

In-built Data Logger & RTC

Compatible with GSM, WiFi & Bluetooth

6.1.6 WIFI/GPRS DB9 Connector

Connect IoT dongle or RS 232 to USB USPC cable to this port for recording and

observing data from the USPC on online portal. When the dongle is connected it

sends recorded data of all the parameters used in operation of the unit. But if some

specific parameter is required to be observed RS 232 to USB converter cable can be

connected and data corresponding to a particular address according to the table 6.2

can be accessed.

Figure 6.8 RS232 Connector

Pin 1: +5V VCC (few milliamperes)

Pin 2: Received Data (RXD)

Pin 3: Transmit Data (DTR)

Pin 4: Not Connected (NC)

Pin 5: Ground (GND)

Pin 6: Not Connected (NC)

Pin 7: Not Connected (NC)

Pin 8: Not Connected (NC)

Pin 9: Not Connected (NC)

6.1.5 Operation of KUSPC 2.0 with Single-phase Load:

Single-phase load can be connected across thresher, aata chakki, chaff cutter or deep

freezer. Load type is selected from the USPC parameters in the factory setup.

For example if single phase load is connected across thresher go to: FACTORY

SETUP<<USPC PARAMETERS<< THRESHER<< LOAD TYPE<<SINGLE PHASE LOAD

Single-phase load connects across YB terminals of the drive as shown in the fig. 6.12

Fig 6.12 Connection diagram of drive with single-phase load

NOTE: The Pins 1 & 5 of the

DB9 Connector are the source

p i n s o f 5 V a t f e w

milliamperes current. These

pins cannot be used as sink

even for a single milliampere

current.

NOT

CONNECTED

SINGLE PHASE

LOAD

DRIVE

R Y B

Pulse LED (GREEN)

Constant ON/OFF

Blink 1time in 2sec

Blink in every second

Blink 2 times in 1sec

Blink 4 times in 1 sec

ON

Blink in every second

OFF

Constant ON

Constant OFF

ON/Blink

OFF

Abnormal1

No Sim detected 2

Normal1 /No Internet

2

Internet connected2

Data transfer in process2

Signal LED (RED)1Normal1/ GPS location fixed 2

GPS (RED) 2Getting GPS location 2

Abnormal(Signal low)1/ GPS off

2

NETWORK LED (GREEN) 24G Connectivity 2

2G Connectivity 2

Wi-Fi LED (YELLOW)1Normal1

No WiFi Network 1

Here 1 & 2 indicates 2G & 4G Dongle respectively

22

INSTALLATION & OPERATING INSTRUCTIONS

21

INSTALLATION & OPERATING INSTRUCTIONS

Figure 6

Step3:

To configure the Wi-Fi follow these steps:3.1)

Turn ON Wi-Fi on your Mobile and select

"SHAKTI_DONGLE and connect it with the

password "shakti123".

An HTML page will open in your browser

otherwise browse http://192.168.4.1. You

will get the HTML page like this:

3.2) Now "Configure Wi-Fi" now

new page will open like this:

3.3) Select your preferred WiFi with

proper password and then save. In case

your WiFi network is not visible in the list

scan again.

Figure 8

Figure 7

On successful configuration, WiFi LED (yellow) will be ON.

* NOTE*

a) Shakti IoT Dongle is designed to work with GSM on priority, WiFi is always secondary.

b) For using Wi-Fi remove SIM card then connect shakti dongle.

c) On successful TCP connection WI-FI yellow LED will blink in every second.

4. Troubleshooting

1) If Pulse LED is constantly ON/OFF, check main device power supply or restart the

device.

2) If signal LED not glowing, check sim card / signal strength.

3) If Wi-Fi LED not glowing, check Wi-Fi network / reconfigure Wi-Fi settings.

5. Contact Shakti to integrate IoT Dongle to other products & solutions.

S.No. Configuration Parameters OFFSET Unit

1 FACTORY MODE 256 1 0 1 1 1 NA

2 LANGUAGE 257 1 0 0 0 1 NA

3 INSTALL DATE 259 1 1 31 1 1 NA

4 INSTALL MONTH 260 1 1 12 1 1 NA

5 INSTALL YEAR 261 1 18 99 21 1 NA

6 LCD CONTRAST 262 1 27 39 33 1 NA

7 ENERGY_ERASE_FLAG 263 1 0 2 2 1 NA

8 ON_HOUR_MOTOR 264 1 1 12 1 1 NA

9 ON_MINUTE_MOTOR 265 1 0 59 1 1 NA

10 OFF_HOUR_MOTOR 266 1 1 12 1 1 NA

11 OFF_MINUE_MOTOR 267 1 0 59 1 1 NA

12 RS232 BAUD RATE 268 1 1 6 2 1 NA

13 RS485 BAUD RATE 269 1 1 6 2 1 NA

14 AUTOROLL ENABLE 270 1 1 2 1 1 NA

15 MODBUS ADD RS232 271 2 1 99 1 1 NA

16 MODBUS ADD RS485 273 2 1 99 1 1 NA

17 DISPLAY MODE 277 1 1 2 1 1 NA

18 PRIMARY HEALTH CHECK 278 1 0 1 0 1 NA

19 TRIP ZONE ENABLE 279 1 1 2 1 1 NA

20 USPC APPLICATION 280 1 1 5 1 1 NA

21 RUNFROMSS_ENABLE 283 1 0 1 0 1 NA

22 FLAG PARK 284 1 0 1 1 1 NA

23 DISPLAY LOCK 285 1 1 2 1 1 NA

24 DISPLAY LOCK PASSWORD 290 2 0 999 345 1 NA

MODBUS

ADDRESS

(DEC)

Item

min

Item

Max

Item

Default

Scale

Factor

* Applicable on some models.

24

INSTALLATION & OPERATING INSTRUCTIONS

23

INSTALLATION & OPERATING INSTRUCTIONS

S.No. VFD Parameters OFFSET Unit

1MASTER ON OFF 1000 1 0 1 0 1 NA

2CONTROL MODE 1001 1 1 4 2 1 NA

3DIRECTION 1002 1 1 2 1 1 NA

4APPLICATION 1003 1 0 0 0 1 NA

5LOCK_UNLOCK 1004 1 0 1 0 1 NA

6CONTROL TYPE 1005 1 0 1 0 1 NA

7MIN POWER VFD 1006 2 100 9999 700 1 W

8MAX CURRENT 1008 2 50 250 160 10 A

9OVER CURRENT VFD 1010 2 5 23 16 1 A

10 DRY RUN CURRENT 1012 2 1 10 5 1 A

11 DRY RUN POWER 1014 2 100 9999 200 1 W

12 DC BUS OVER VOLTAGE 1016 2 500 850 800 1 V

13 OVER TEMPERATURE VFD 1018 2 70 108 108 1 °C

14 THERMAL DERATING 1020 2 0 100 100 1 %

15 MAX FREQ 1022 2 1 400 200 1 Hz

16 Retry_time_Minutes 1034 2 1 30 10 1 NA

MODBUS

ADDRESS

(DEC)

Item

min

Item

Max

Item

Default

DVT

Factor

S.No. Motor Parameters OFFSET Unit

1MOTOR TYPE 2000 1 0 2 2 1 NA

2TORQUE PERCENT 2001 2 0 200 200 100 %

3RATED CURRENT 2003 2 10 200 140 10 A

4RATED POWER 2005 2 3 10 10 10 W

5RATED VOLTAGE INDUCTiON 2007 2 40 560 456 1 V

6RATED VOLTAGE S4RM 2009 2 40 560 456 1 V

7RATED VOLTAGE PMSM 2011 2 40 560 360 1 V

8RATED FREQUENCY INDUCTION 2013 2 0 120 60 1 Hz

9RATED FREQUENCY S4RM 2015 2 0 120 60 1 Hz

10 RATED FREQUENCY PMSM 2017 2 0 250 120 1 Hz

11 NO OF POLES INDUCTION 2019 2 2 8 2 1 NA

12 NO OF POLES S4RM 2021 2 2 8 2 1 NA

13 NO OF POLES PMSM 2023 2 2 8 4 1 NA

14 REFERENCE SPEED 2025 2 100 4000 500 1 RPM

15 POWER FACTOR 2027 2 60 100 75 100 NA

16 LEAKAGE INDUCTANCE 2029 2 5 999 56 10000 H

17 MAGNETIC INDUCTANCE 2031 2 20 9999 881 10000 H

18 ROTOR RESISTANCE 2033 2 20 9999 33 100 Ohm

19 STATOR RESISTANCE 2035 2 20 9999 43 100 Ohm

20 START TIME 2037 2 1 60 15 1 Sec

21 STOP TIME 2039 2 1 60 15 1 Sec

22 MOTOR AUX VOLTAGE USPC2 2041 2 40 460 350 1 V

23 MOTOR AUX VOLTAGE USPC3 2043 2 40 460 350 1 V

24 MOTOR AUX VOLTAGE USPC4 2045 2 40 460 350 1 V

25 MOTOR AUX VOLTAGE USPC5 2047 2 40 460 350 1 V

26 USPC2 MOTOR TYPE 2049 1 0 2 0 1 NA

27 USPC3 MOTOR TYPE 2050 1 0 2 0 1 NA

28 USPC4 MOTOR TYPE 2051 1 0 2 0 1 NA

29 USPC5 MOTOR TYPE 2052 1 0 2 0 1 NA

30 SPEED DIRECTION SELECT USPC2 2053 1 1 2 1 1 NA

31 SPEED DIRECTION SELECT USPC3 2054 1 1 2 1 1 NA

32 SPEED DIRECTION SELECT USPC4 2055 1 1 2 1 1 NA

33 SPEED DIRECTION SELECT USPC5 2056 1 1 2 1 1 NA

34 SINGLE PHASE NON MOTOR LOAD USPC2 2057 1 0 1 0 1 NA

35 SINGLE PHASE NON MOTOR LOAD USPC3 2058 1 0 1 0 1 NA

36 SINGLE PHASE NON MOTOR LOAD USPC4 2059 1 0 1 0 1 NA

37 SINGLE PHASE NON MOTOR LOAD USPC5 2060 1 0 1 0 1 NA

MODBUS

ADDRESS

(DEC)

Item

min

Item

Max

Item

Default

DVT

Factor

26

INSTALLATION & OPERATING INSTRUCTIONS

25

INSTALLATION & OPERATING INSTRUCTIONS

S.No. PUMP Parameters OFFSET Unit

1 PUMP TYPE 3000 1 0 2 1 1 NA

2 PUMP HEAD 3001 2 5 999 50 1 m

3 POW1 3003 2 0 9999 1000 1 W

4 D1 3005 2 0 9999 80 1 LPM

5 POW2 3007 2 100 9999 2000 1 W

6 D2 3009 2 0 9999 150 1 LPM

7 POW3 3011 2 200 9999 3500 1 W

8 D3 3013 2 0 9999 250 1 LPM

9 POW4 3015 2 300 9999 5500 1 W

10 D4 3017 2 0 9999 400 1 LPM

11 POW5 3019 2 400 9999 7500 1 W

12 D5 3021 2 0 9999 500 1 LPM

MODBUS

ADDRESS

(DEC)

Item

min

Item

Max

Item

Default

DVT

Factor

S.No. USPC PARAMETERS OFFSET Unit

1RATED VOLTAGE THRESHER 4000 2 40 560 400 1 V

2RATED VOLTAGE ATTA CHAKKI 4002 2 40 560 400 1 V

3RATED VOLTAGE CHAFF CUTTER 4004 2 40 560 400 1 V

4RATED VOLTAGE DEEP FREEZER 4006 2 40 560 400 1 V

5RATED FREQUENCY THRESHER 4008 2 40 400 50 1 Hz

6RATED FREQUENCY ATTA CHAKKI 4010 2 40 400 50 1 Hz

7RATED FREQUENCY CHAFF CUTTER 4012 2 40 400 50 1 Hz

8RATED FREQUENCY DEEP FREEZER 4014 2 40 400 50 1 Hz

9RATED POLES THRESHER 4016 2 2 8 2 1 NA

10 RATED POLES ATTA CHAKKI 4018 2 2 8 2 1 NA

11 RATED POLES CHAFF CUTTER 4020 2 2 8 2 1 NA

12 RATED POLES DEEP FREEZER 4022 2 2 8 2 1 NA

13 RATED CURRENT THRESHER 4024 2 30 200 160 10 A

14 RATED CURRENT ATTA CHAKKI 4026 2 30 200 160 10 A

15 RATED CURRENT CHAFF CUTTER 4028 2 30 200 160 10 A

16 RATED CURRENT DEEP FREEZER 4030 2 30 200 160 10 A

17 OVER VOLTAGE THRESHER 4032 2 100 500 435 1 V

18 OVER VOLTAGE ATTA CHAKKI 4034 2 100 500 435 1 V

19 OVER VOLTAGE CHAFF CUTTER 4036 2 100 500 435 1 V

20 OVER VOLTAGE DEEP FREEZER 4038 2 100 500 435 1 V

21 UNDER VOLTAGE THRESHER 4040 2 50 350 250 1 V

22 UNDER VOLTAGE ATTA CHAKKI 4042 2 50 350 250 1 V

23 UNDER VOLTAGE CHAFF CUTTER 4044 2 50 350 250 1 V

24 UNDER VOLTAGE DEEP FREEZER 4046 2 50 350 250 1 V

25 OVER FREQUENCY THRESHER 4048 2 100 660 520 10 Hz

26 OVER FREQUENCY ATTA CHAKKI 4050 2 100 660 520 10 Hz

27 OVER FREQUENCY CHAFF CUTTER 4052 2 100 660 520 10 Hz

28 OVER FREQUENCY DEEP FREEZER 4054 2 100 660 520 10 Hz

29 UNDER FREQUENCY THRESHER 4056 2 100 500 200 10 Hz

30 UNDER FREQUENCY ATTA CHAKKI 4058 2 100 500 200 10 Hz

MODBUS

ADDRESS

(DEC)

Item

min

Item

Max

Item

Default

DVT

Factor

28

INSTALLATION & OPERATING INSTRUCTIONS

27

INSTALLATION & OPERATING INSTRUCTIONS

S.No. USPC PARAMETERS OFFSET Unit

31 UNDER FREQUENCY CHAFF CUTTER 4060 2 100 500 200 10 Hz

32 UNDER FREQUENCY DEEP FREEZER 4062 2 100 500 200 10 Hz

33 TORQUE BOOST THRESHER 4064 2 0 100 10 1000 NA

34 TORQUE BOOST ATTA CHAKKI 4066 2 0 100 10 1000 NA

35 TORQUE BOOST CHAFF CUTTER 4068 2 0 100 10 1000 NA

36 TORQUE BOOST DEEP FREEZER 4070 2 0 100 10 1000 NA

37 MAX FREQUENCY THRESHER 4072 2 1 68 55 1 Hz

38 MAX FREQUENCY ATTA CHAKKI 4074 2 1 68 55 1 Hz

39 MAX FREQUENCY CHAFF CUTTER 4076 2 1 68 55 1 Hz

40 MAX FREQUENCY DEEP FREEZER 4078 2 1 68 55 1 Hz

41 MAX CURRENT THRESHER 4080 2 50 220 200 10 A

42 MAX CURRENT ATTA CHAKKI 4082 2 50 220 200 10 A

43 MAX CURRENT CHAFF CUTTER 4084 2 50 220 200 10 A

44 MAX CURRENT DEEP FREEZER 4086 2 50 220 200 10 A

45 AUX_KP 4088 2 0 999 20 100 Sec

46 AUX_KI 4090 2 0 999 50 100 Sec

47 VDC KP USPC 2 4092 2 0 9999 500 10000 NA

48 VDC KP USPC 3 4094 2 0 9999 500 10000 NA

49 VDC KP USPC 4 4096 2 0 9999 500 10000 NA

50 VDC KP USPC 5 4098 2 0 9999 500 10000 NA

51 VDC KI USPC 2 4100 2 0 9999 5000 10000 NA

52 VDC KI USPC 3 4102 2 0 9999 5000 10000 NA

53 VDC KI USPC 4 4104 2 0 9999 5000 10000 NA

54 VDC KI USPC 5 4106 2 0 9999 5000 10000 NA

55 USPC2 START TIME 4108 2 1 60 15 1 Sec

56 USPC3 START TIME 4110 2 1 60 15 1 Sec

57 USPC4 START TIME 4112 2 1 60 15 1 Sec

58 USPC5 START TIME 4114 2 1 60 15 1 Sec

59 USPC2 STOP TIME 4116 2 1 60 15 1 Sec

60 USPC3 STOP TIME 4118 2 1 60 15 1 Sec

61 USPC4 STOP TIME 4120 2 1 60 15 1 Sec

62 USPC5 STOP TIME 4122 2 1 60 15 1 Sec

MODBUS

ADDRESS

(DEC)

Item

min

Item

Max

Item

Default

DVT

Factor

S.No. CONTROL PARAMETERS OFFSET DVT Factor Unit

1PSL 5000 2 0 1000 12 100 NA

2ISL 5002 2 0 1000 12 100 NA

3DRYRUN RPM LIMIT 5004 2 0 9999 2500 1 RPM

4TORQUE BOOST PER 5006 2 0 160 30 1000 %

5Id REF PMSM 5008 2 0 200 0 10 NA

6PMSM THETA FACTOR 5010 2 0 150 10 10 NA

7MIN RPM PMSM 5012 2 100 1000 500 1 RPM

8RAMP TIME PMSM 5014 2 30 400 90 10 Sec

9WC FCORR VDC 5016 2 10 4000 400 100 NA

10 WC MOD VDC 5018 2 10 4000 1000 100 NA

11 BOOST VOLTAGE REF 5020 2 550 700 620 1 V

12 PBC 5022 2 0 9999 10 10000 NA

13 IBC 5024 2 0 9999 2 1000 NA

14 IMP FACTOR 5026 2 0 100 25 100 NA

15 PBC SPL 5028 2 0 9999 10 10000 NA

16 IBC SPL 5030 2 0 9999 12 1000 NA

MODBUS

ADDRESS

(DEC)

Item

min

Item

Max

Item

Default

30

INSTALLATION & OPERATING INSTRUCTIONS

29

INSTALLATION & OPERATING INSTRUCTIONS

S.No. FLOAT PARAMETERS (Not for Server) OFFSET Unit

1 TOTAL TIME GSC 6000 3 NA NA NA 1 Hr

2 TOTAL TIME VFD 6004 3 NA NA NA 1 Hr

3 TOTAL ENERGY GSC 6008 3 NA NA NA 1 Kwh

4 TOTAL ENERGY VFD 6012 3 NA NA NA 1 Kwh

5 TOTAL FLOW 6016 3 NA NA NA 1 ML

6 MAX POWER VFD 6020 3 1000 9999 9600 1 W

7 MAX POWER USPC 6024 3 1000 9999 9600 1 W

MODBUS

ADDRESS

(DEC)

Item

min

Item

Max

Item

Default

DVT

Factor

6.1.8. AC Output (v/f sinusoidal)

There are at least 4 outputs of this category. The output voltages are 3 phase

balanced sinusoids with constant flux control. These outputs can be configured

via display, mobile application etc.. Any one output is functional at a time.

Typical loads like Thresher, Aatta Chakki, Deep Freezer, Chaff Cutter etc. can be

connected to these output terminals.

6.1.9 Pressure Relief Vent

Pressure relief vent releases the internal pressure.

6.1.10 Aux Input/output & Rs485 Communication Connectors

1. Remove the Aux terminal connector cover

by removing the screws.

2. Use wire gauge from 25 AWG to 20 AWG for

the connections to

Terminal blocks.

3. Pass the Aux/RS485 terminal block cable

through cable glands.

4. Connect the cable to terminal block

receptacle.

5. Ensure IP covers are installed back after

connections to ensure IP rating

compliance.

6. Tightly secure the terminal block cover

using the cover screws and do not disturb

the gaskets.

Following are the details of terminal blocks.

= Aux Output Ports

1. There are three Aux ports, two output (AUX

1 & AUX 2) & one input (D-I/P) are

provided.

2. The Aux Output ports are potential free

contacts, which would toggle based on the

configuration.

S.No. PV PARAMETERS OFFSET Unit

1MPPCR VFD 7000 2 50 5000 3600 1 NA

2MPPCR USPC 7002 2 100 9999 3600 1 NA

3VOLTAGE TOLERANCE 7004 2 0 300 50 1 NA

4CURRENT TOLERANCE 7006 2 0 4999 60 10 NA

5PVO FACTOR 7008 2 1 300 50 100 NA

6IVO FACTOR 7010 2 0 500 50 100 NA

7DVO FACTOR 7012 2 20 700 300 100 V

MODBUS

ADDRESS

(DEC)

Item

min

Item

Max

Item

Default

DVT

Factor

31 32

INSTALLATION & OPERATING INSTRUCTIONS INSTALLATION & OPERATING INSTRUCTIONS

=Aux Input Ports

1. Normally, Pin-1 & 2 are closed and based on configuration, Pin-1

would connect with Pin-3.

2. Aux Input port can trigger an event for the USPC by connecting

Pin-1 & 3 by some external circuit or means. The events which can

be triggered by Aux input port can be configured.

3. The Aux Input port can be also configured for firmware upgrade by

service personals.

=RS 485

1. The RS485 MOD BUS communication connection to the USPC can

be done by using RS485 terminal block.

2. Connect A to Pin-1, B to Pin-3 and Ground to Pin-2

Figure 6.12 Connections for Terminal Block

=FAN

Do not connect or use this port.

AUX1 AUX2 D-I/P RS-485 FAN

PIN 1

PIN 2

PIN 3

PIN 1

PIN 2

PIN 3

PIN 1

PIN 2

PIN 3

PIN 1

PIN 2

PIN 3

PIN 1

PIN 2

Figure 6.11 AUX Port

AUX PORT

33 34

INSTALLATION & OPERATING INSTRUCTIONS INSTALLATION & OPERATING INSTRUCTIONS

CHAPTER 7 : OPERATION OF UNIT

7.1 Display Module Description

Following figure 7.1 is indicates the outer look of Display. It has six buttons,

three LED indicators, one 128X64 pixel LCD Display.

Figure 7.1 LCD display layout

7.2.Button Description and Operation

7.3.LCD Operation

=Startup

Upon starting the unit for the first time, the LCD Display enters into Factory

Setup interface. In factory setup, the user gets an option to set various

parameter required for the proper functioning of the product which are

illustrated in the figure 7.2.

Scroll through various options displayed on the screen with the up & down

buttons and press Enter to set the parameter and Esc to exit the particular

option. For example in the language setting user has an option to choose

one language out of the four options available. The RTC Date is set in the

format DD/MM/YY and the RTC Time in HH:MM:SS format. Other options

are common to factory setup option in main menu therefore, is d iscus s e d

in section C of CONFIGURE. After the successful starting of the product or

whenever the LCD is not operated for a period of time, 11 status screens

appears in rolling until menu button is pressed.

A RPM page based on the NOB functionality can be accessed by long

pressing UP/DOWN button. The speed can be varied in multiples of 10, 50

and 100 using the same buttons.

Indiction LED 1 LED 1

Motor Running

Fault

Stand By

Green (Motor) Green (Motor)

Functionality

= To Turn ON the Motor*

= To Turn OFF the Motor*

= Previous Screen

= Used for Scrolling up

= For increasing the parameter values in

Configuration menu

= Used for Scrolling down

= For decreasing the parameter values in

Configuration menu

= Selection

Power On

Power Off

ESC

UP

ARROW

DOWN

ARROW

ENTER

35 36

INSTALLATION & OPERATING INSTRUCTIONS INSTALLATION & OPERATING INSTRUCTIONS

Figure 7.2 Startup menu tree

= Main Menu

In the main menu user can change the setting or get information by

transferring from one interface to another. The STATUS, CONTROL, and

CONFIGURE, are discussed separately in further sections. The Faults

occurring in the system is displayed in the FUALT LOGS. The information

regarding faults of different durations can be extracted from the LOG menu.

The ABOUT section provides the information of firmware version, serial

number, network details.

LANGUAGE

RTC DATE

RTC TIME

APPLICATION

INSTALL DATE

PROTECTION

SOLAR PARAMETERS

Round Robbin

Display

Status Screen

DATE

SOLAR

OUTPUT

MOTOR/ THRESHER/ATTA CHAKKI/CHAFF CUTTER/DEEP FREEZER

PUMP

POWER

ENERGY

RUN TIME

TEMP

Startup

Clear

EEPROM

YES

NO

NOTE: The highlighted 5 compulsory parameters

need to set before exiting the startup menu.

MADE IN INDIA

Main Menu

STATUS

SOLAR

VFD MOTOR

PUMP

USPC MOTOR

ENERGY & TIME

TEMPERATURES

LIMIT VAR

LOCATION

CONTROL

ON/OFF

CONTROL MODE

VFD DIRECTION

CONFIGURATION

APPLICATION

PROTECTION

LANGUAGE

DATE & TIME

DISPLAY

MODBUS CONFIGURATION

FACTORY SETUP

LOGS

FAULT LOGS

ABOUT

FIRMWARE

SERIAL NUMBER

NETWORK DETAILS

*3

*2

*1

GPS CONFIG

Figure 7.3 Main Menu tree

USPC PARAMETERS

PUMP PARAMETERS

CONTROL PARAMETERS

DONGLE DATA CONFIG

BOOT MODE OPTIONS

EEPROM RESET

RS232 EXTRACT

RS485 EXTRACT

Table of contents