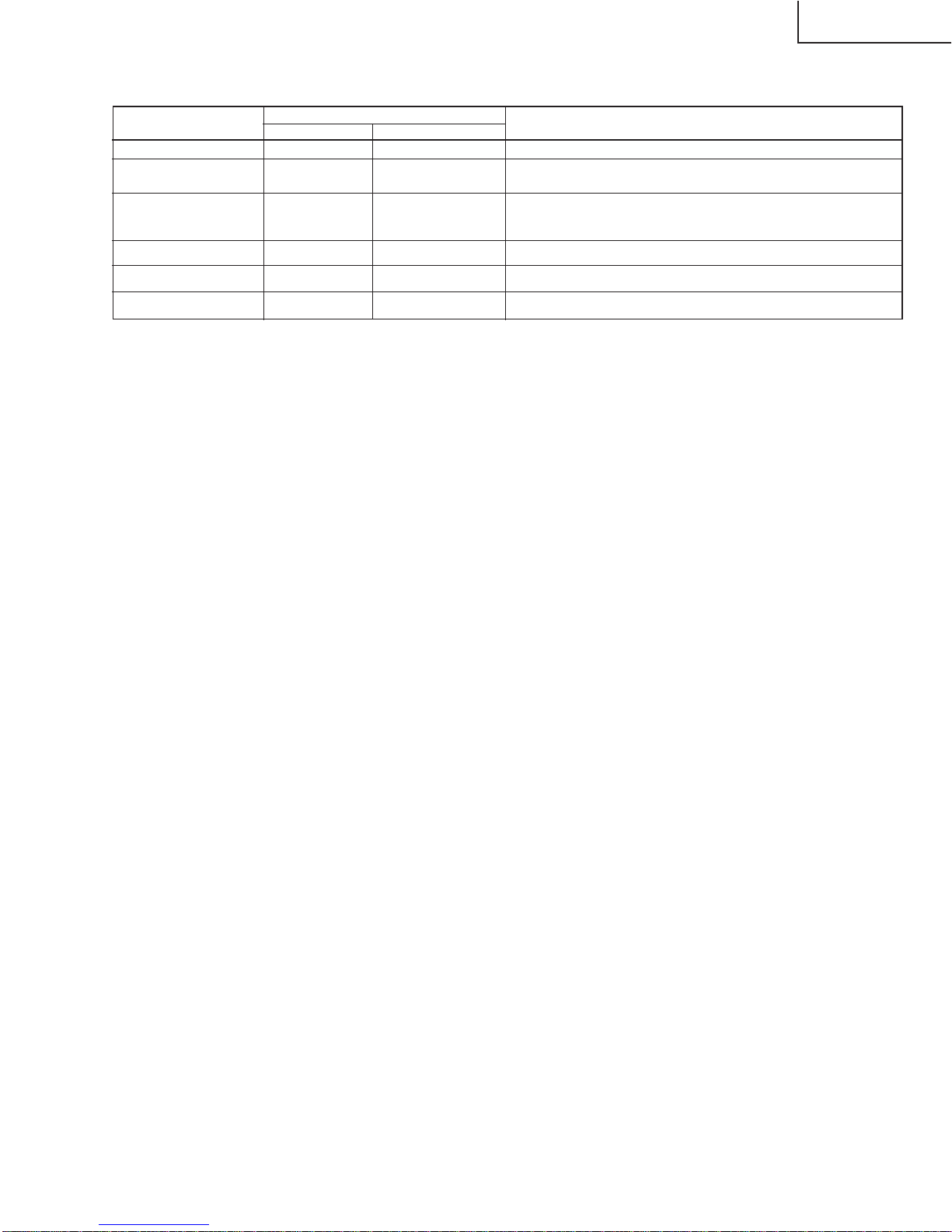

7

32C530

SERVICE

NUMBER

DATA

ADJUSTMENT ITEM

INITIAL VALUE

RANGE NOTE

V01 PICTURE 0-15 (00h-0Fh) 8 (08h)

V02 TINT 0-127 (00h-7Fh) 66 (42h)

V03 COLOR 0-127 (00h-7Fh) 56 (38h)

V05 BRIGHT 0-127 (00h-7Fh) 64 (40h)

V06 R CUT-OFF 64-255 (40h-FFh) 64 (40h)

V07 G CUT-OFF 64-255 (40h-FFh) 64 (40h)

V08 B CUT-OFF 64-255 (40h-FFh) 64 (40h)

V09 G/R DRIVE 0-127 (00h-7Fh) 64 (40h)

V10 B DRIVE 0-127 (00h-7Fh) 64(40h)

V11 Y-MUTE/V-STOP 0-2 0 (00h) Y-Mute / Holizontal "–"

V12 SHARP 0-63 (00h-3Fh) 50 (32h) 32

V13 DC RESTORATION 0-3 (00h-03h) 2 (02h) 02

V14 BLACK STRETCH 0-3 (00h-03h) 2 (02h) 02

V15 ABL START POINT 0-3 (00h-03h) 3 (03h) 03

V16 ABL GAIN 0-3 (00h-03h) 2 (02h) 02

V17 γPOINT 0-3 (00h-03h) 0 (00h) 00

V19 ENERGY SAVE 0-63 (00h-3Fh) 63 (3Fh) Offset 3F

V24 LOW-G 0-255 (00h-FFh) 12 (0Ch) Color Temp. F4

V25 LOW-B 0-255 (00h-FFh) 241 (F1h) Color Temp. E6

V26 ML-G 0-255 (00h-FFh) 0 (00h) Color Temp. FD

V27 ML-B 0-255 (00h-FFh) 247 (F7h) Color Temp. F8

V28 HIGH-G 0-255 (00h-FFh) 2 (02h) Color Temp. 01

V29 HIGH-B 0-255 (00h-FFh) 8 (08h) Color Temp. 06

V30 WPL 0-1 1 (01h) 01

V31 RGB CONTRAST 0-63 (00h-3Fh) 59 (3Bh) 3B

V34 VSM GAIN 0-3 (00h-03h) 1 (01h) 01

V36 BPF/TOF-INPUT 0-1 0 (00h) External Input 00

V37 CORING 0-1 0 (00h) 00

V38 VSM PHASE 0-1 0 (00h) 00

V39 COLOR γ0-1 0 (00h) 00

V40 SHARP-INPUT 0-63 (00h-3Fh) 44 (2Ch) External Input 2C

V41 TINT-INPUT 0-127 (00h-7Fh) 62 (3Eh) External Input 3E

V42 PICTURE-COMPONENT 0-15 (00h-0Fh) 6 (06h) Component Input

V43 TINT-COMPONENT 0-127 (00h-7Fh) 62 (3Eh) Component Input 3E

V44 COLOR-COMPONENT 0-127 (00h-7Fh) 72 (48h) Component Input 48

V45 BRIGHT-COMPONENT 0-127 (00h-7Fh) 84 (54h) Component Input

V46 R CUT OFF-COMPONENT 64-255 (40h-FFh) 64 (40h) Component Input

V47 G CUT OFF-COMPONENT 64-255 (40h-FFh) 64 (40h) Component Input

V48 B CUT OFF-COMPONENT 64-255 (40h-FFh) 64 (40h) Component Input

V49 G/R DRIVE-COMPONENT 0-127 (00h-7Fh) 64 (40h) Component Input

V50 B DRIVE-COMPONENT 0-127 (00h-7Fh) 64 (40h) Component Input

V51 SHARP-COMPONENT 0-63 (00h-3Fh) 44 (2Ch) Component Input 2C

V52 TINT-S 0-127 (00h-7Fh) 62 (3Eh) S terminal input. 3E

V53 C-TRAP 0-1 (00h-01h) 0 (00h) 00

V59 AUTO FLESH 0-1 (00h-01h) 0 (00h) 00

V60 SHARP P F 0-1 (00h-01h) 1 (01h) 01

V61 CD MATRIX 0-3 (00h-03h) 2 (02h) 02

V62 B-Y ATT 0-1 (00h-01h) 0 (00h) 00

V63 R-Y ATT 0-1 (00h-01h) 0 (00h) 00

V64 CD MATRIX-COMPONENT 0-3 (00h-03h) 0 (00h) Component Input 00

V65 B-Y ATT-COMPONENT 0-1 (00h-01h) 0 (00h) Component Input 00

V66 R-Y ATT-COMPONENT 0-1 (00h-01h) 0 (00h) Component Input 00

V67 BUZZ 0-1 (00h-01h) 1 (01h) 01

V68 RGB ABCL 0-1 (00h-01h) 1 (01h) 01

R01 RF-AGC 0-63 (00h-3Fh) 36 (24h)

R03 RF-AGC REF 0-255 (00h-FFh) 170 (AAh)

Standard value for the self-adjustment

AA

D01 V POSITION 0-7 (00h-07h) 0 (00h) 00

D02 H POSITION 0-31 (00h-1Fh) 15 (0Fh)

D03 V SIZE 0-127 (00h-7Fh) 89 (59h)

D04 H SIZE 0-63 (00h-3Fh) 36 (24h)

D05 V-LINEARITY 0-15 (00h-0Fh) 8 (08h)

D06 V-S CORRECTION 0-15 (00h-0Fh) 12 (0Ch) 0C

D07 EW PARABOLA 0-63 (00h-3Fh) 43 (2Bh)

D08 EW TRAPEZIUM 0-63 (00h-3Fh) 36 (24h)

D10 AFC GAIN 0-3 (00h-03h) 2 (02h) 02

D11 V EHT 0-7 (00h-07h) 6 (06h) 06

D12 H EHT 0-7 (00h-07h) 6 (06h) 06

D13 EW CORNER 0-31 (00h-1Fh) 8 (08h) 08

A. VCJ IC ADJUSTMENT

FIXED VALUE

(HEX)