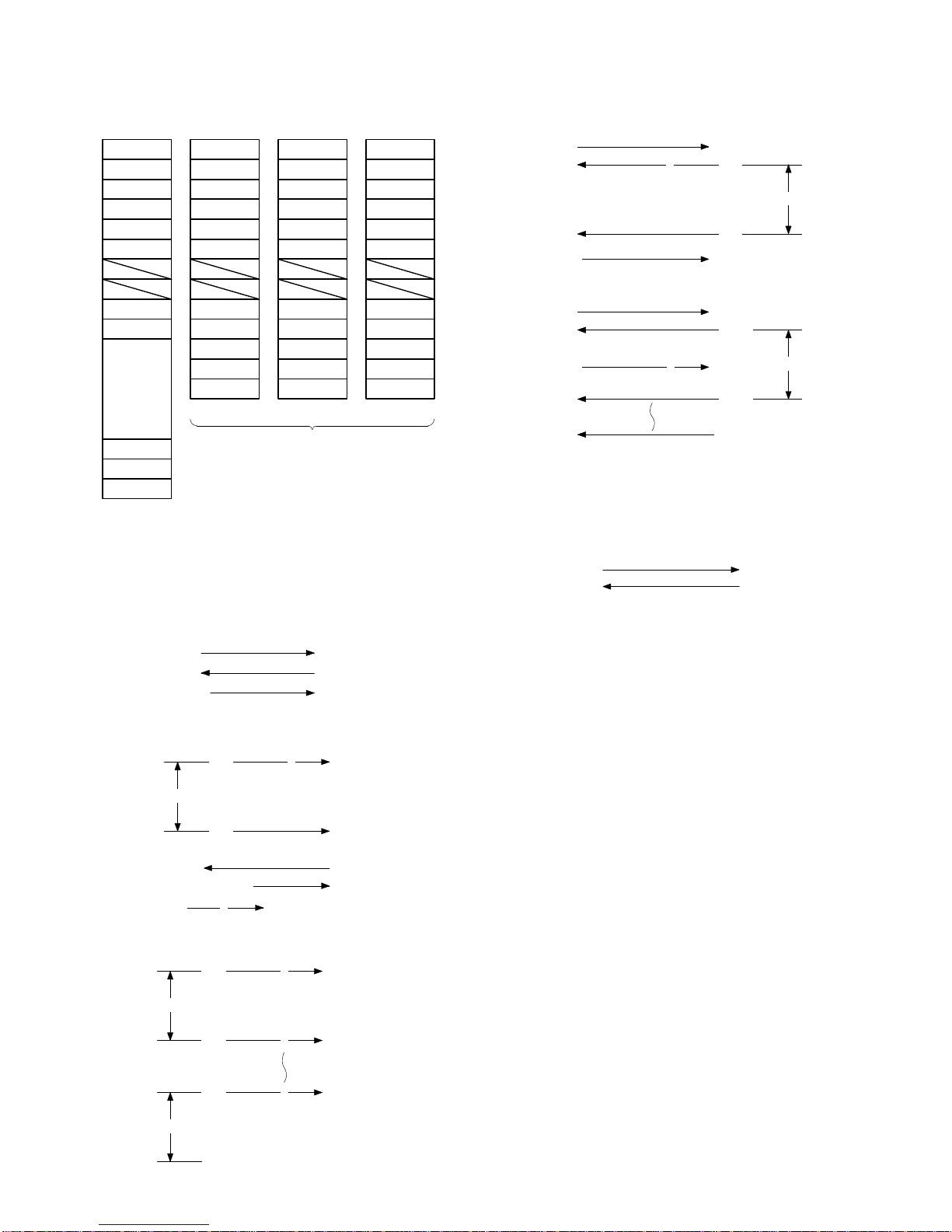

8. Packet Format

F

8 Bits 1Opening flag (8 Bits) (01111110) (7E)

DA

8 Bits 2Destination address (00-FEH)

(SRN Terminal Number)

SA

8 Bits 3Source address (00-FEH)

TYPE

8 Bits 4Packet type (DATA/ACK/RACK/NRDY)

CH NO

8 Bits 5Channel No. (01H = CH1; 02H = CH2)

DLS

8 Bits 6Circuit status: Buffer full, RE-transmit, Unable

7Dummy

BCL

8 Bits 8Number of bytes at the data unit

BCH

8 Bits

DATA

max.

270

bytes.

9DATA

Number of data bytes (270 Bytes)

CRC

8 Bits ΦCRC check code

CRC

8 Bits

F

8 Bits ΓClosing flag (8 Bits) (01111110) (7E)

Fig. 3-3 Packet format

1Opening flag (7E)

The open flag (7E) is sent at the beginning of each packet. As the

SRN control circuit (receiving side) receives the flag, it will start

the receiving operation.

NOTE: The packet begins with the open flag (8 Bits) and ends

with a closing flag (8 Bits).

2Destination address (00H – FEH)

The destination address indicates where the packet is addressed

(receiving unit) too. The terminal number of each unit is converted

into a hexadecimal number to be used for the destination address.

3Source Address (00H – FEH)

The source address indicates the sending unit (transmit unit). The

terminal number of each unit is converted into a hexadecimal

number to be used for the source address.

4Types of packets

There are four types of packets each are used to indicate the type

of packet to be transferred.

00: DATA packet

(summary and preset data)

01: ACK packet

The acknowledging packet that is sent to the transmitting

side from the receiving side to indicate that the packet was

received properly.

02: RACK packet

The acknowledging packet that will be sent to the receiving

side to indicate that the ACK packet has been properly

received by the sending side.

03: NRDY packet

The acknowledge packet that is sent to the sending side to

indicate that it is not ready to receive data.

5Channel No.

Indicates that channel of the packet. (Channel 1 or Channel 2)

6Circuit status

In the case of the NRDY packet, it indicates why the NRDY packet

was issued.

1) Unable to handle received data because the receiving side is

in the BUSY state.

2) Unable to handle received data because the receiving buffer is

full.

7Number of data bytes

Indicates the number of bytes of data, which is a data, packet

status that will be converted into hexadecimal numbers before

transmission. Maximum number of bytes is 270.

8Data

Transfer data is contained in this field. Size of data is limited to a

maximum of 270 bytes. It can only exist in the data packet.

9CRC check code

This check code is used to detect any errors in the transmit data.

A CRC code is generated from the sending side to be sent to the

receiving side.

At the receiving side, the CRC check code is generated on the

basis of the same formula as the sending side to verify it against

the CRC check code receive.

ΦClosing flag (7E)

The closing flag is sent at the end of the packet. When the IRC

control circuit at the receiving side receives the flag, it terminates

the operation.

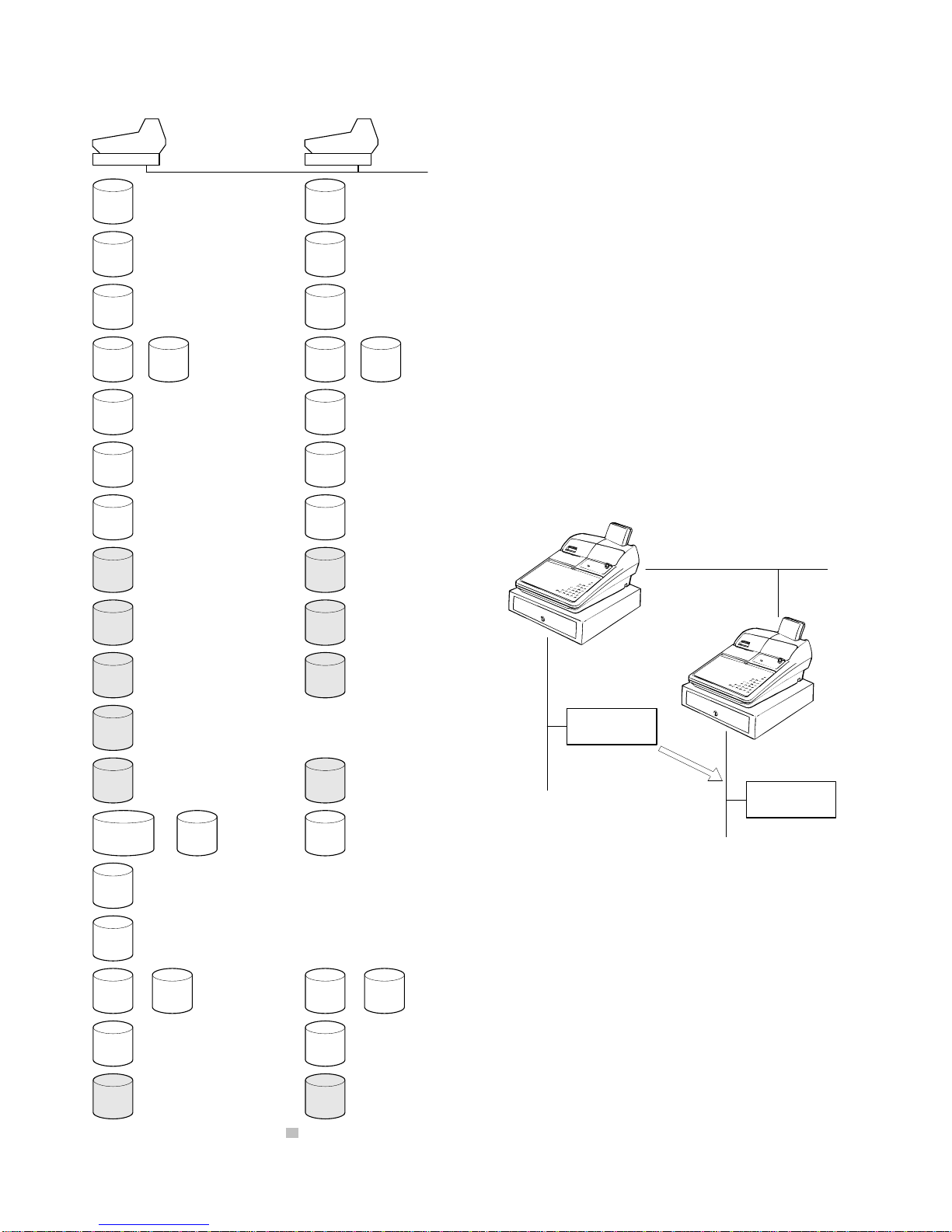

9. Type of packet

Two types of packet formats are available for the SHARP RETAIL

NETWORK. One is the data packet (the content of data is judged by

the host level). The other is the control packet which is responded to

by the controller level and has three types of packets: ACK packet,

RACK packet and NRDY (NOT READY) packet.

(1) DATA packet: is used for sending and receiving data. Its con-

tents are judged at the host level.

(2) ACK packet: is a response sent from the sink station to the

source station by the link level (of DATA packet) when the DATA

packet is properly received.

(3) NRDY (NOT READY) packet is a response packet of the link

level. It is used in case it is unable to receive in the host level or

no space is available in its receive buffer despite the the error

check CRC of the DATA packet is normal.

1 4