Sharpe 310596G Parts list manual

Instructions/Parts

Dryaire Membrane

Air Drying System 310596G

ENG

Model 6770

Maximum Working Pressure: 175 psi (1.2 MPa, 12 bar)

System Includes:

•Air Filter w/Overnight Drain (Part No. 22601)

•Coalescer w/Overnight Drain (Part No. 22605)

•Air Regulator Assembly (Part No. 22604)

•Membrane Air Dryer (Part No. 1-6770-3)

System Description

Sharpe’s DRYAIRE Membrane Air Drying System

is the painter’s insurance for removing dirt, water, oil, and uncondensed moisture from compressed air lines. It

provides clean dry compressed air while reducing overall costs and minimizing waste.

Sharpe’s 3-Stage Point-of-Use System comes assembled and is simple to install.

Approved for Paint Company warranty programs when applying today’s state-of-the-art refinish materials.

Ideal for protecting moisture sensitive tools.

Advanced Membrane Technology

•Point-of-Use air dryer

•Optimize overall drying costs

•Effective even at low flow rates

•No chemicals to dispose of

•Transparent operation

•Continuous, effective air drying

•No maintenance on Stage 3

•No electricity

•No additional hookups or connections

•Easy installation

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

Model 6770 Membrane Air Drying System

DRYAIRE MEMBRANE AIR DRYING SYSTEM

2

Specifications

STAGE 1: Air Filter w/Overnight Drain (Part No. 22601)

Provides removal of water and contaminants down to 5 microns.

Air Inlet 1/2 in. F.P.T.

Air Outlet 1/2 in. F.P.T.

Air Flow Capacity 115 cfm (3.2 m3/min.)

Max. Operating Pressure 175 psi (1.2 MPa, 12 bar)

Max. Temperature 150°F (65°C)

STAGE 2: Coalescer w/Overnight Drain (Part No. 22605)

Provides removal of oil and sub-micronic particles down to .01 microns.

Air Inlet 1/2 in. F.P.T.

Air Outlet 1/2 in. F.P.T.

Air Flow Capacity 70 cfm (2.0 m3/min.)

Max. Operating Pressure 175 psi (1.2 MPa, 12 bar)

Max. Temperature 150°F (65°C)

STAGE 3: Membrane Air Dryer (Part No. 1-6770-3)

Provides removal of uncondensed moisture.

Air Inlet 1/2 in. F.P.T.

Air Outlet 1/2 in. F.P.T.

Air Flow Capacity 30 cfm (0.85m3/min.)

Max. Operating Pressure 175 psi (1.2 MPa, 12 bar)

Max. Temperature 175°F (79°C)

Warning

Installation

1. Install Air Drying System as close as possible to the point where the air is being used.

2. Install main shut-off valve (part no. 22695) upstream of air system to allow maintenance of the unit.

3. Install system with air flow through filters in the direction noted on top of units.

4. Minimum 1/2 in. npt piping is recommended. Avoid using many fittings, couplings, etc. that restrict air flow.

5. Maximum operating pressure and operating temperature of system is: 160 psi (1.1 MPa, 11 bar) and 150°F (65°C).

Relieve the pressure when you stop spraying and

before cleaning, checking, or servicing equipment.

DRYAIRE MEMBRANE AIR DRYING SYSTEM

3

Operation

After the system is installed and ready to use:

1. Attach air hose(s) to outlet valve (part no. 34700).

2. Open main shut-off valve upstream of system.

3. Adjust regulator to desired setting by turning T-handle adjusting screw in or out.

4. Open outlet valve (part no. 34700) to supply air to spray guns or tool being used.

5. With air flowing, readjust air pressure at regulator if necessary.

6. Be sure to turn off unit when not in use.

Maintenance

1. Check system at least once per shift to ensure proper drainage.

2. Before performing maintenance on system, close main shut-off valve located upstream. Bleed off residual air in

system.

New Membrane Technology

wet air enters

membrane module

water vapor purges clean, dry air exits

module

water vapor permeates through

hollow membrane fibers

SHUT-OFF VALVE

(22695)

FILTER

(22601)

COALESCER

(22605)

MEMBRANE

AIR DRYER

(1-6770-3)

AIR REGULATOR

(22604)

OUTLET VALVE

(34700)

DRYAIRE MEMBRANE AIR DRYING SYSTEM

4

Air Filter w/Overnight Drain (Part

No. 22601)

Maintenance

To maintain maximum filtering efficiency and to avoid

excessive pressure drop, the filter must be kept clean.

Bowl drainage is automatic with the overnight drain;

however, manual draining can also be done by removing

the bowl. A visible coating of dirt on the filter element

surface or an excessive pressure drop is an indication

that cleaning is necessary.

Cleaning

To clean, it is not necessary to remove the complete filter

from the line. Disassembly is simple and does not require

tools. Before disassembly, shut off the air supply and

depressurize filter. Clean all parts with cleaning solvent

and blow out filter body before reassembly. Wash filter

element in cleaning solvent and blow out from the inside.

Overnight Drain

The overnight drain (part no. 22631) is simple in design

and operation. When the filter bowl is pressurized, the

piston travels down against the spring and closes the

drain opening. When the bowl is depressurized (i.e.:

overnight when system is shut down), the spring lifts the

piston from the seal allowing the bowl to drain.

NOTE: The overnight drain can be operated manually at

anytime by pushing the piston stem up.

Parts

22638

22645

22640

22631

push to

manually drain

(open)

Part No. Description

22631 Overnight Drain

22632 Mounting Bracket

22638 O-Ring

22640 Baffle Kit

22645 Filter Element

DRYAIRE MEMBRANE AIR DRYING SYSTEM

5

Coalescer w/Overnight Drain

(Part No. 22605)

Installation

It is always recommended that a SHARPE air filter be

installed upstream of the coalescing filter to remove 5

micron and larger size particles and separate large

droplets of moisture from the air line.

Maintenance

Never let the liquid level in the bowl reach the base of the

coalescing element.

Cleaning

To clean, it is not necessary to remove the complete filter

from the line. Disassembly is simple and does not

require tools. Before disassembly, shut off the air supply

and depressurize coalescer. Clean all parts with

cleaning solvent and blow out body before reassembly.

Replace coalescing element (part no. U23075).

Pressure Drop Indicator

The differential pressure drop indicator on this unit is

designed to provide early detection of a clogged

coalescing filter element. As the filter element becomes

clogged the red indicator will start to rise while air is

flowing through the unit. When the pressure drop across

the element reaches 10-12 psi (0.07-0.08 MPa, 0.7-0.8

bar) the red indicator will be in full view and the element

should be replaced. Failure to replace the element when

the pressure drop exceeds 10 psi (0.07 MPa, 0.7 bar)

will affect your air quality and tool efficiency.

Overnight Drain

The overnight drain (part no. 22631) is simple in design

and operation. When the filter bowl is pressurized, the

piston travels down against the spring and closes the

drain opening. When the bowl is depressurized (i.e.

overnight when system is shut down), the spring lifts the

piston from the seal allowing the bowl to drain.

NOTE: The overnight drain can be operated manually at

anytime by pushing the piston stem up.

Parts

Part No. Description

22631 Overnight Drain

22632 Mounting Bracket

22647 O-Ring

22650 Pop-up Indicator Repair Kit

U23075 Coalescer Element

22650

22647

U23075

22631

push to

manually drain

(open)

DRYAIRE MEMBRANE AIR DRYING SYSTEM

6

I

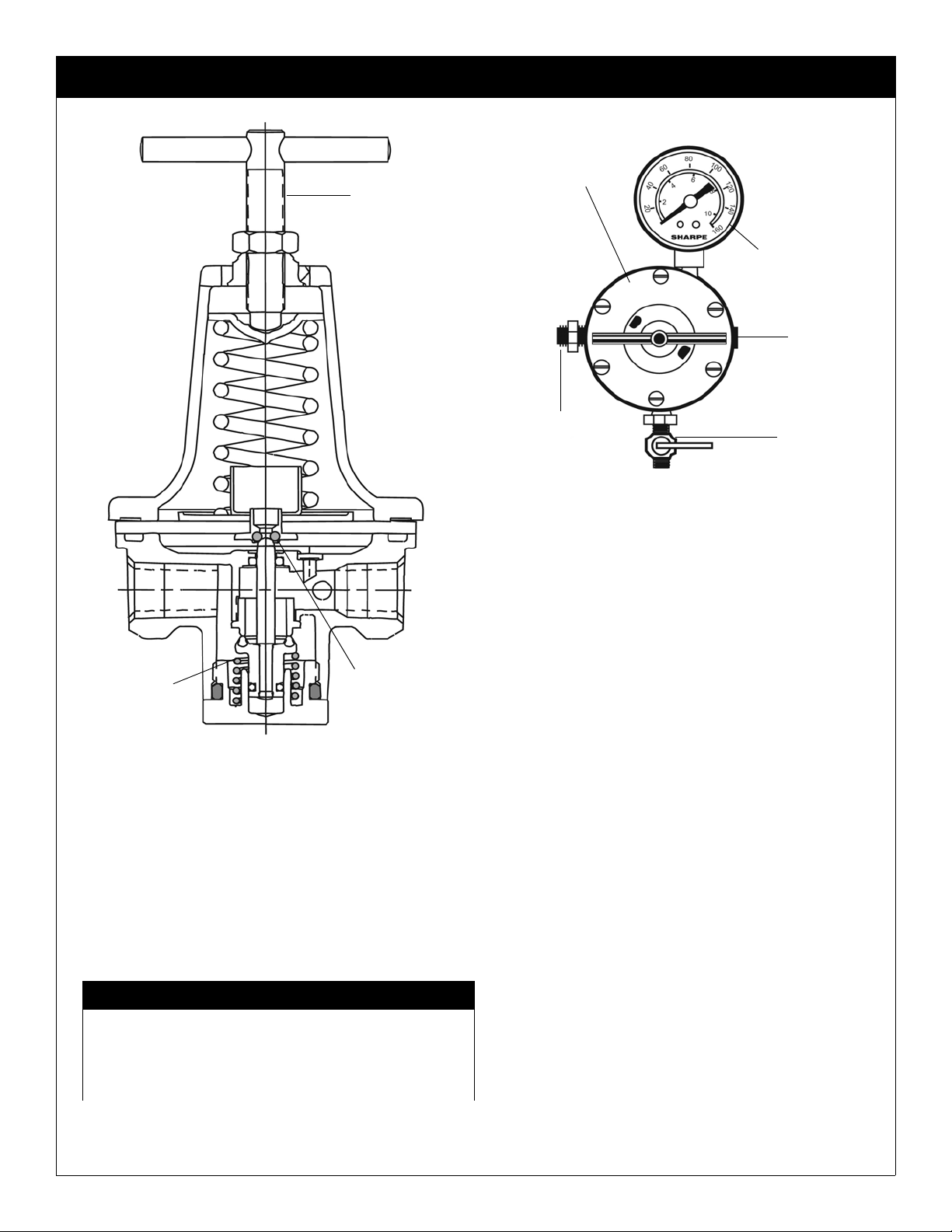

S e l f - R e l i e v i n g A i r R e g u l a t o r

(Part No. 22604)

Maintenance

If the air supply is kept clean, this regulator will provide

long periods of uninterrupted service. Erratic regulator

operation or loss of regulation is most always due to dirt

in the diaphragm area and cleaning is in order.

Cleaning

Depressurize regulator, remove bottom plug, spring

valve, and diaphragm. Clean parts with denatured

alcohol, wipe off seat and blow out body with

compressed air. Reassemble parts as a unit and screw

into regulator before tightening bottom plug Make sure

disc is in center hole in body. Should regulator continue

to malfunction, obtain diaphragm/valve repair kit (part

no. 22680) and replace parts provided.

22682

22680

22685

Specifications

Air Inlet 3/8 in. F.P.T.

Air Outlet 1/4 in. F.P.T. (3 EA.)

Air Flow Capacity 100 cfm (2.8 m3/min.)

Max. Operating Pressure 160 psi (1.1 MPa, 11 bar)

Max. Temperature 150°F (65°C)

Parts

Part No. Description

8230 Air Pressure Gauge

10028 Plug

22680 Diaphragm/Valve Repair Kit

22682 T-Handle Adjusting Screw

22685 Bottom Spring

AIR REGULATOR

(22604)

AIR PRESSURE

GAUGE (8230)

NIPPLE

(22687)

PLUG

(10028)

OUTLET

VALVE

(34700)

DRYAIRE MEMBRANE AIR DRYING SYSTEM

7

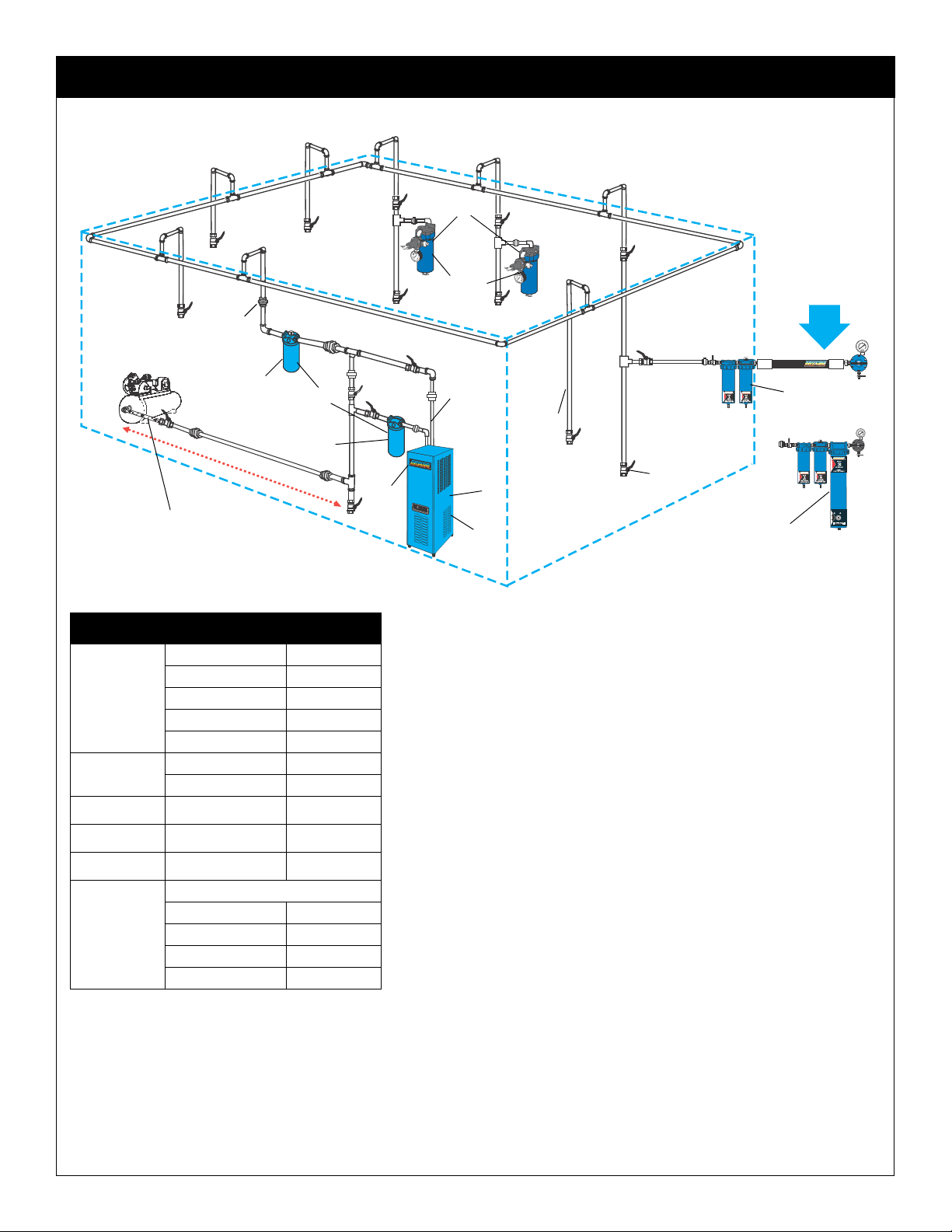

Ref. Letter Description Model No.

ASharpe 606 U06710

Sharpe 606A U06720

Sharpe 606B 6730

Sharpe 880A 6950

Sharpe F88 8130

B707C 6930

707F 6920

707FC 6910

CDryaire Membrane 6770

DDryaire Desiccant 6760

ERefrigerated Air Dryer

25CFM 6880

35CFM 6885

50CFM 6890

75CFM 6895

3!452!

4%$

./2-!

$%3)##!.4

Air Control Unit

or Air Filter

Refrigerated

Air Dryer

Dryaire Membrane

or Desiccant Air

Drying Systems at

Compressor

Model 707C

Oil Coalescer

Model 707F

Air Filter

Drain Leg

Ball Valve

Union

Air In

Air Out

Flexible Hose Between com-

pressor and Main Air Line

15ft.to20ft.

Main Air Line 1 in.

A

C

D

E

B

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 310596

SHARPE MANUFACTURING • P.O. BOX 1441, MINNEAPOLIS, MN 55440-1441

1-800-742-7731, www.sharpe1.com

Copyright 2006, Graco Inc. is registered to ISO 9001

Revised 02/2011

DRYAIRE MEMBRANE AIR DRYING SYSTEM

1 Year Limited Warranty

Sharpe warrants this product to the original user against defective material or workmanship for a period of 1 year from the

date of purchase.

Sharpe reserves the right to determine whether the part or parts failed because of defective material, workmanship, or

other causes. Failures caused by accident, alteration, or misuse are not covered by this warranty.

Sharpe, at its discretion, will repair or replace products covered under this warranty free of charge. Repairs or replacements

of products covered under this warranty are warranted for the remainder of the original warranty period.

Sharpe or its authorized service representatives must perform all warranty repairs. Any repair to the product by unauthor-

ized service representatives voids this warranty. The rights under this warranty are limited to the original user and may not

be transferred to subsequent owners.

This warranty is in lieu of all other warranties, expressed or implied, including warranties of merchantability and fitness for a

particular purpose. Some states do not allow the exclusion or limitations of incidental or consequential damages, so the

above limitations may not apply to you.

Sharpe Information

TO PLACE AN ORDER, contact your SHARPE distributor or call 1-800-742-7731 or visit our website at www.sharpe1.com.

Product Registration

Thank you for the purchase of your Sharpe®product. We greatly appreciate your business.

Important reasons to register your product:

•Registration enables Sharpe to notify you if there is a problem with your product.

•Improved Product Development - Your input helps us continue to design products that meet your needs.

For the most up-to-date information and to register your product, please go to www.sharpe1.com and click on “Register

Product.”

Table of contents

Other Sharpe Dehumidifier manuals