shelolab SMO5HP-2 User manual

Installation and

Operation Manual

SMO5HP-2

Previously designated as

HF4-2

High-Performance Oven 220 - 240 Voltage

2 | P a g e

Shel Lab Oven High Performance 220 - 240 Voltage

Installation and Operation Manual

Part Number (Manual): 4861706

Revision: September 22, 2015

This oven requires permanent connect wiring (also known as hardwiring). It does not connect to a

wall power source using a conventional plug-in power cord.

Purge Valve

The SMO5HP-2 can be built with a purge valve located on the back of the unit. The valve can be

connected to a cylinder of nitrogen (N2) or other neutral gas to purge the oven chamber. This option

must be ordered prior to the construction of the oven.

These units are TÜV listed as high performance ovens for professional, industrial, or educational

use where the preparation or testing of materials is done at an ambient air pressure range of 22.14

–31.3 inHg (75 –106 kPa), with no flammable, volatile, or combustible materials being heated.

CAN/CSA C22.2 No. 61010-1:2012

CAN/CSA C22.2 No. 61010-2-010:2004 Reaffirmed: 2014-07

UL 61010-1:2012-05

UL 61010A-2-010:2002-03

EN 61010-1:2010

EN 61010-2-010:2014

Supplemented by: UL 61010-2-010:2015

3 | P a g e

TABLE OF CONTENTS

INTRODUCTION...........................................................................................................................................4

General Safety Considerations.................................................................................................................4

Engineering Improvements .......................................................................................................................5

Contacting Assistance...............................................................................................................................5

Temperature Reference Sensor Device ...................................................................................................5

RECEIVING YOUR OVEN............................................................................................................................6

Inspecting the Shipment............................................................................................................................6

Recording Data Plate Information.............................................................................................................6

Orientation.................................................................................................................................................7

INSTALLATION............................................................................................................................................9

Required Ambient Conditions ...................................................................................................................9

Power Source Requirements..................................................................................................................10

Power Feed Wiring..................................................................................................................................10

Lifting and Handling ................................................................................................................................11

Leveling...................................................................................................................................................11

Install the Oven .......................................................................................................................................11

Initial Cleaning.........................................................................................................................................11

Shelving Installation ................................................................................................................................12

GRAPHIC SYMBOLS.................................................................................................................................13

CONTROL PANEL OVERVIEW.................................................................................................................14

OPERATION...............................................................................................................................................15

Operating Precautions ............................................................................................................................15

Theory of Operations ..............................................................................................................................16

Preparing the Oven for Use ....................................................................................................................18

Set the Over Temperature Limit..............................................................................................................19

Set the Temperature Controller Set Point...............................................................................................19

First Use Burn In .....................................................................................................................................20

Temperature Accuracy Verification.........................................................................................................21

Closed Vents...........................................................................................................................................23

Over Temperature Limit Active ...............................................................................................................23

Programmed Operations.........................................................................................................................24

Positive Venting of Exhaust ....................................................................................................................24

USER MAINTENANCE...............................................................................................................................26

Cleaning and Disinfecting .......................................................................................................................26

Door Latch and Electronics.....................................................................................................................27

Door Gaskets ..........................................................................................................................................27

Removing the Chamber Liner .................................................................................................................28

Calibrate the Temperature display..........................................................................................................30

UNIT SPECIFICATIONS.............................................................................................................................34

Weight .....................................................................................................................................................34

Dimensions..............................................................................................................................................34

Capacity ..................................................................................................................................................34

Shelf Capacity by Weight........................................................................................................................34

Temperature............................................................................................................................................35

Airflow Performance................................................................................................................................35

Power ......................................................................................................................................................35

REPLACEMENT PARTS............................................................................................................................36

4 | P a g e

INTRODUCTION

Thank you for purchasing a Sheldon Manufacturing High Performance Oven. We know that in

today’s competitive marketplace, customers have many choices when it comes to constant

temperature equipment. We appreciate you choosing ours. Our continued reputation as a leading

laboratory product manufacturer rests with your satisfaction. Sheldon Manufacturing, Inc. stands

behind our products, and we will be here if you need us.

These ovens are intended for professional, industrial, and educational applications requiring

horizontal shelf space airflows. The ovens are not designed for use at hazardous or household

locations.

Before you use your oven read this entire manual carefully to understand how to install, operate,

and maintain the oven in a safe manner. Keep this manual available for use by all oven operators.

Ensure that all operators are given appropriate training before the oven begins service.

GENERAL SAFETY CONSIDERATIONS

Note: Failure to follow the guidelines and instructions in this manual may create a protection

impairment by disabling or interfering with the unit’s safety features. This can result in injury

or death.

Your oven and its recommended accessories have been designed and tested to meet strict safety

requirements. For continued safe operation of your oven, always follow basic safety precautions

including:

Follow all local or regional ordinances in your area regarding the use of this unit. If you

have any questions about local regulations, please contact the appropriate agency.

Use only approved accessories. Do not modify system components. Any alterations or

modifications to your oven may be dangerous and will void your warranty.

Always hardwire the unit’s power feed to an earth grounded electrical source that conforms

to national and local electrical codes. If the unit is not grounded, parts such as, knobs and

controls may conduct electricity and cause serious injury.

Avoid damaging the power feed. Do not bend it excessively, step on it, place heavy objects

on it. A damaged power feed can easily become a shock or fire hazard. Never use a power

feed after it has been damaged.

Do not position the equipment in such a manner as to make it difficult to disconnect or

uncouple the power feed.

Do not attempt to move the unit while in operation or before the unit has cooled.

5 | P a g e

INTRODUCTION (CONTINUED)

ENGINEERING IMPROVEMENTS

Sheldon Manufacturing continually improves all of its products. As a result, engineering changes

and improvements are made from time to time. Therefore, some changes, modifications, and

improvements may not be covered in this manual. If your unit’s operating characteristics or

appearance differs from those described in this manual, please contact your Shel Lab dealer or

customer service representative for assistance.

CONTACTING ASSISTANCE

If you are unable to resolve a technical issue with the oven, please contact Sheldon Technical

Support. Phone hours for Sheldon Technical Support are 6am –4:30pm Pacific Coast Time (west

coast of the United States, UTC -8).

Please have the following information ready when calling or emailing Technical Support: the model

number and the serial number. These will be found on the unit’s data plate, which is located on

the back of the unit at the top right, next to the power supply as mandated by regulatory

requirement.

640-1366

TEMPERATURE REFERENCE SENSOR DEVICE

The oven does not come with a temperature reference device. A reference sensor device must be

purchased separately for performing accuracy verifications and calibrations of the oven

temperature display.

The reference device must be accurate to at least 2°C, and should be regularly calibrated,

preferably by a third party.

For best results, use a digital device with wired-connected temperature sensing probe. For

example: a wire thermocouple probe that can be introduced into the oven chamber, leaving the

device outside. Readings taken from outside the unit avoid chamber door openings during

verifications and calibrations, and eliminate subsequent waits for the chamber temperature to re-

stabilize before proceeding.

Select a probe suitable for the application temperature you will be calibrating or verifying the display

accuracy at.

Alcohol thermometers are insufficient for conducting accurate verifications and calibrations. Do not use a

mercury thermometer. Never place a mercury thermometer in the oven chamber.

6 | P a g e

RECEIVING YOUR OVEN

Before leaving our factory, all High Performance Ovens are packaged in high-quality shipping

materials to provide protection from transportation-related damage. When an oven leaves our

factory, safe delivery becomes the responsibility of the carrier. Damage sustained during transit is

not covered by the oven’s warranty. When you receive your High Performance Oven, inspect it for

concealed loss or damage to its interior and exterior. If you find any damage to the oven follow the

carrier’s procedure for claiming damage or loss.

INSPECTING THE SHIPMENT

Carefully inspect the shipping carton for damage. Report any damage to the carrier service that

delivered the oven. If the carton is not damaged, open the carton and remove the contents. The

unit should come with an Installation and Operation Manual, warranty card, a Certificate of

Compliance, and the Programming Guide –Watlow EZ-Zone Heating Profiles.

Verify that the correct number of shelves, shelf slides, and leveling feet have been included (see

the following table for quantities).

Included accessories

Shelves (2)

Shelf Slides (4)

Leveling Feet (4)

Carefully check all packaging before discarding. Save the shipping carton until you are certain that

the unit and its accessories function properly.

RECORDING DATA PLATE INFORMATION

Locate the data plate on the back of the oven next to the power inlet. The data plate contains the

oven model number and serial number. Enter this information below for future reference.

Date Plate Information

Model Number

Serial Number

7 | P a g e

Figure 2: Orientation Photo

Figure 1: SMO5HP-2 Oven

RECEIVING (CONTINUED)

ORIENTATION

Fuse

Holders

External Power Outlet

Permanent Connect Wire Braid

14 gauge, 6 inches (15 cm)

Intake Vent

Exhaust

Vent

Control Panel

Power Switch

Intake Vent Valve

Control

Exhaust Vent

Valve Control

Outer Door

Gasket

Chamber

Ceiling Liner

Right Wall

Chamber Liner

Left wall

Chamber Liner

Door Latch

Door Latch

Chamber

Gasket

Note: The external

power outlet type

varies by country and

voltage.

Power Panel (Back)

8 | P a g e

GRAPHIC SYMBOLS (CONTINUED)

This page left blank

9 | P a g e

INSTALLATION

Installation of an SMO5HP-2 requires permanent connect wiring (commonly known as hardwiring),

and must be performed by a qualified electrical technician. All other installation steps can be

performed by the end user.

REQUIRED AMBIENT CONDITIONS

This oven is intended for use indoors, at room temperatures between 15C and 40C (59F and

104F), at no greater than 80% Relative Humidity (at 25C / 77F).

Allow a minimum of 12 inches (30cm) between the oven and any walls or partitions, and 24

inches (60cm) of vertical headspace clearance above the top of the oven for unobstructed airflow

and cooling. If the oven exhaust will be vented from the workspace through a duct or other

channeling, 12 inches (30cm) of vertical clearance will suffice. Make sure the intake and exhaust

vent remain unobstructed. Do not place objects on top of oven, aside from the power exhaust

accessory described in this manual.

Operating the unit outside these conditions may adversely affect the oven’s temperature

range, uniformity, and stability. For conditions outside of those listed above, please contact your

distributor or Shel Lab Sales to explore other ovens suited to your production of laboratory

environment.

When selecting a location to install the oven, consider all conditions that can affect temperature

performance. For example:

Ovens, autoclaves, and any device that produces significant radiant heat

Heating and cooling ducts, or other sources of fast moving air currents

High-traffic areas

Direct sunlight

10 | P a g e

INSTALLATION (CONTINUED)

POWER SOURCE REQUIREMENTS

When selecting a location for the oven, check that each of the following requirements are satisfied:

The oven must be positioned so that all operators have access to the power feed

disconnect in case of emergencies.

oThe Disconnect must be in close proximity to the equipment and within easy reach

of the operator.

oThe Disconnect must be marked as the disconnecting device for the equipment.

The power source must be single (1) phase and protective earth grounded.

The power source must match the voltage and ampere requirements listed on the oven

data plate. This oven is intended for 220 - 240 volt, 50/60 Hz applications at 12 Amps.

The power source for the oven must conform to all national and local electrical codes.

Supplied voltage must not vary more than 10% from the data plate rating. Damage to

the oven may result if supplied voltage varies more than 10%. A separate circuit is

recommended to prevent possible loss of product due to overloading or failure of other

equipment on the same circuit.

A switch or circuit-breaker must be used in the building installation. The required

circuit-breaker is 20 Amps

Fuses: The oven is provided with (2) two 20 amp fuses. These are located in holders adjacent to

the power feed braid on the back power panel of the unit. The fuses protect against overcurrent

conditions related to the operation of the oven. If one fuse blows, the oven will shut down. For safe

operation, the cause of a blown fuse should be determined prior to replacing it.

The oven is also provide with a pair (2) of 2 amp fuses installed adjacent to the external power

outlet. Please see the Orientation photo on page 7. The fuses protect against overcurrent

conditions related to the operation of the outlet and an attached power exhaust blower. If one fuse

blows, the outlet will depower. The cause of a blown fuse should be determined prior to replacing it.

POWER FEED WIRING

The oven comes provided with an integral 6 inch (15 cm) wire braid of two 14 gauge high-

temperature (300°C) hot wires and a 14 gauge earth ground. See the Orientation Picture on page

7.

The wires for power source connection should be Green/Yellow –Earth; Black –Hot; Red –Hot.

The oven must be earth grounded using the protective conductor terminal (green with yellow

stripe wire. Do not remove the protective conductor (earth connection). Removing the protective

conductor will negate the oven’s protections against potentially dangerous electric shocks and

create a possible fire hazard.

11 | P a g e

INSTALLATION (CONTINUED)

LIFTING AND HANDLING

The oven is heavy. Use appropriate lifting devices that are sufficiently rated for these loads. Follow

these guidelines when lifting the oven:

Lift the oven only from its bottom surface.

Doors, handles, and knobs are not adequate for lifting or stabilization.

Restrain the oven completely while lifting or transporting so it cannot tip.

Remove all moving parts, such as shelves and trays, and secure the door in the closed

position during transfers to prevent shifting and damage.

LEVELING

The oven must be level and stable for safe operation. Each Clean Room Oven ships with four

leveling feet. Insert one leveling foot into each of the four holes in the bottom corners of the oven.

Stand the oven upright. Then, adjust the foot at each corner until the oven stands level and solid

without rocking. To raise a foot, turn it in a counterclockwise direction; to lower a foot, turn it in a

clockwise direction.

Note: To prevent damage when moving the oven, turn each of the four leveling feet completely

clockwise.

INSTALL THE OVEN

Install the unit in a workspace location that meets the criteria discussed in the previous entries of

the Installation section. After wiring the oven to its power source, only energize the unit for brief

periods as necessary to test the wiring power feed and source.

INITIAL CLEANING

The unit was cleaned at the factory, but not sterilized. Additionally, it may have been exposed to

contaminants en route during shipping. See the Cleaning and Disinfecting topic in the User

Maintenance section (page 26) for more information on how to clean and disinfect the oven

chamber.

Remove all wrappings and coverings from shelving prior to cleaning and installation.

12 | P a g e

INSTALLATION (CONTINUED)

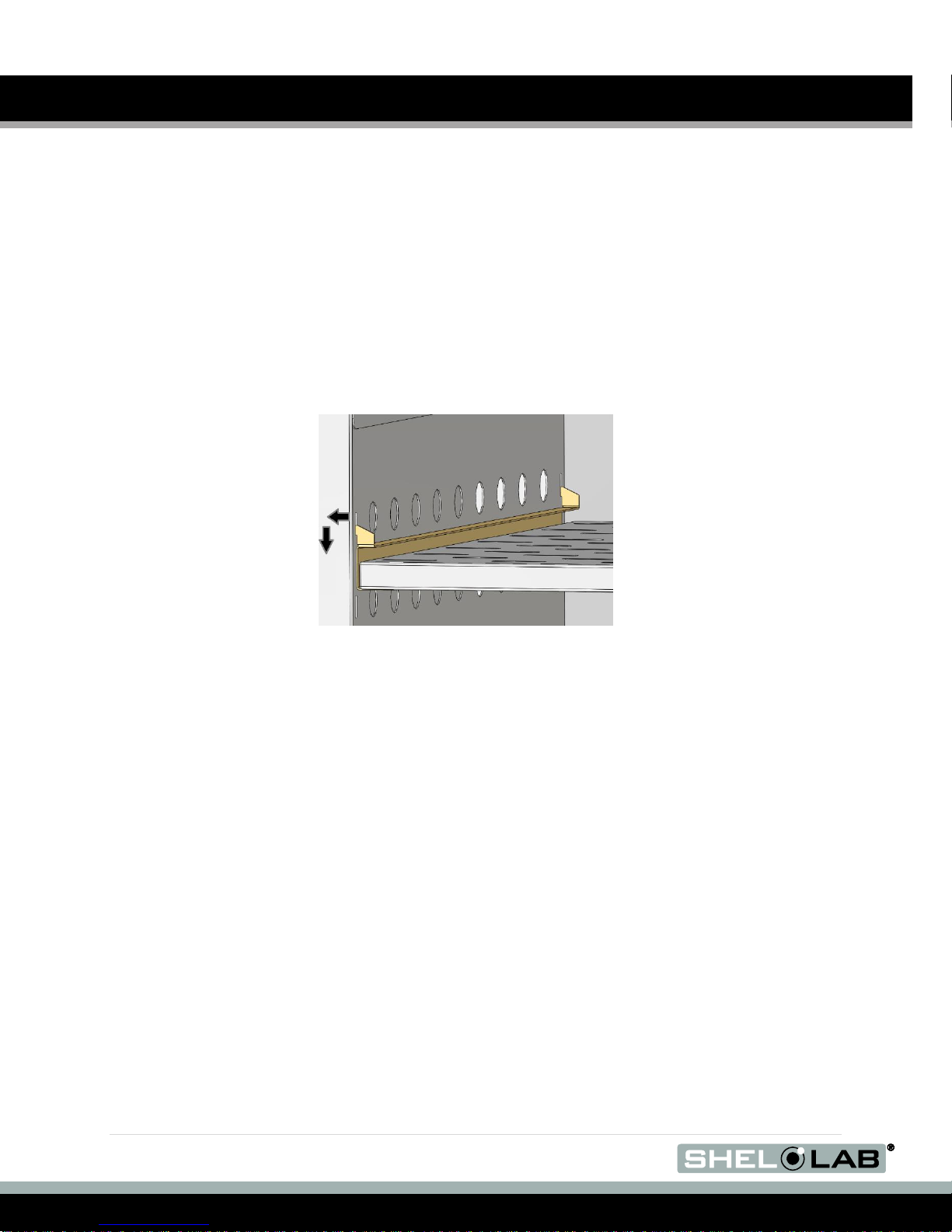

SHELVING INSTALLATION

The horizontal airflow within the chamber moves from the air duct on the right-hand side of the

chamber, to the large holes on the left side. Place the shelves so they do not obstruct the duct duct

holes in order to maximize airflow across the shelf space.

1. Install shelf slide hangers on opposites of the oven by inserting the slider’s tabs into the

chamber’s mounting slots, then pushing down gently to secure the slider.

2. Hang the shelf from the two installed sliders.

Figure 3: Installed Sliding Shelf

13 | P a g e

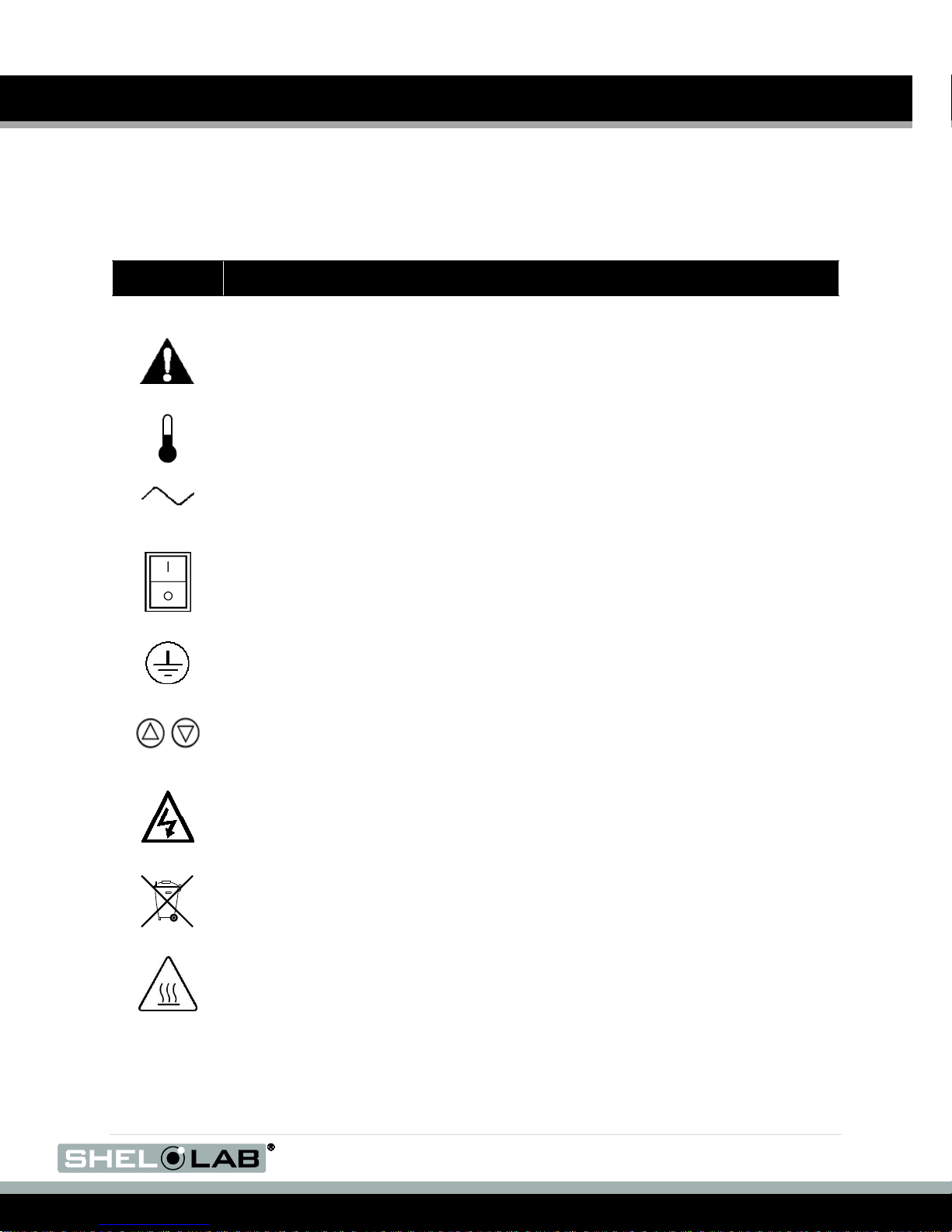

GRAPHIC SYMBOLS

The oven is provided with multiple graphic symbols on its external and internal surfaces. The

symbols identify hazards and the functions of the adjustable components, as well as important

notes found in the user manual.

Symbol

Definition

Indicates that you should consult your user manual for further instructions.

Indique que l'opérateur doit consulter le manuel d'utilisation pour y trouver les instructions

complémentaires.

Indicates Adjustable Temperature

Indique température réglable

Indicates AC Power

Repère le courant alternative

Indicates I/ON and O/OFF

I repère de la position MARCHE de l'interrupteur d'alimentation

O repère de la position ARRÊT de l'interrupteur d'alimentation

Indicates protective earth ground

Repère terre électrique

Indicates UP and DOWN respectively

Touches d e déplacements respectifs vers le HAUT et le BA

Indicates a Potential Shock Hazard

Signale danger électrique

Indicates the unit should be recycled (Not disposed of in land-fill)

Indique l’appareil doit être recyclé (Ne pas jeter dans une décharge)

Indicates: Caution hot surface

Indique: Avertissement symbole de surface chaude

14 | P a g e

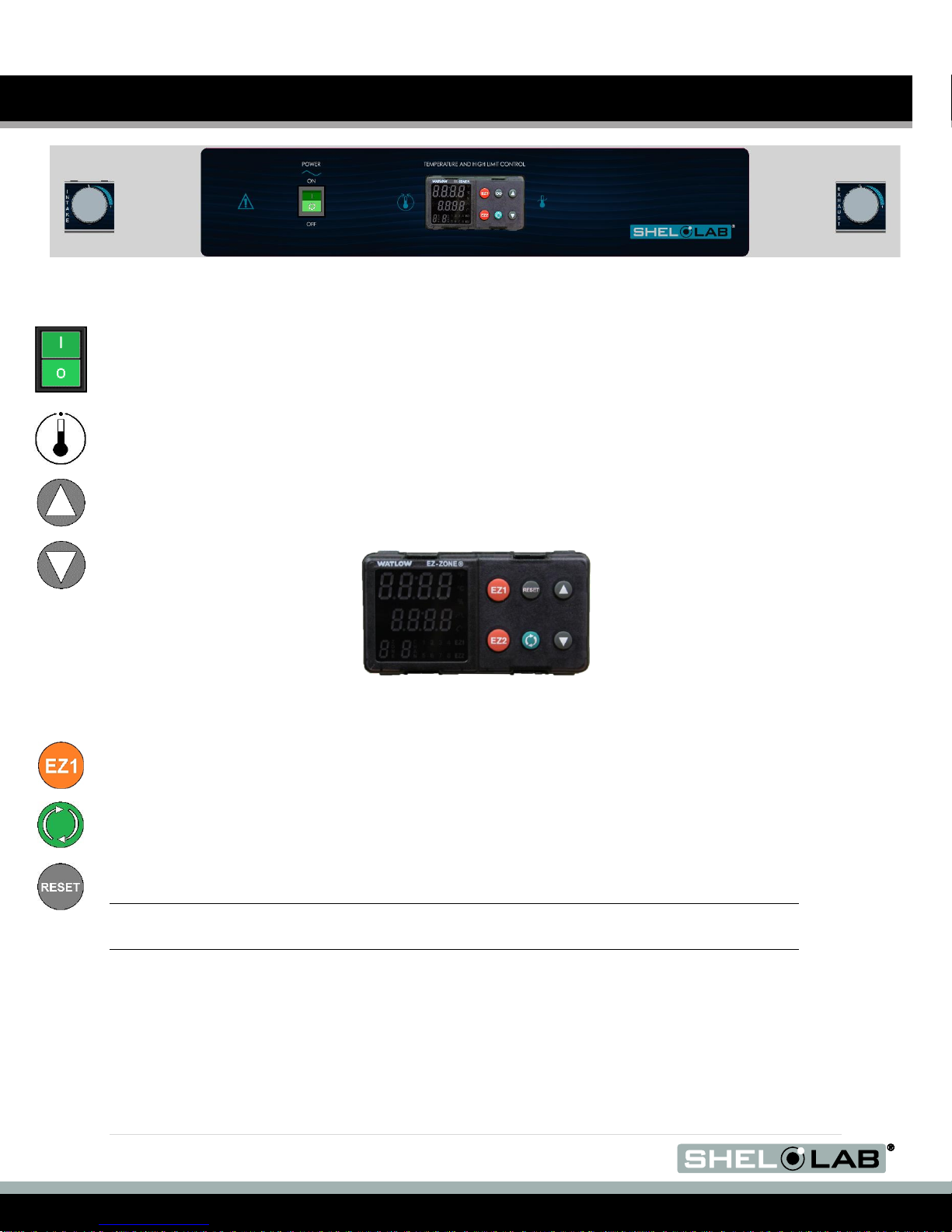

CONTROL PANEL OVERVIEW

Figure 3: Control Panel

Power Switch

The green, light up power switch controls all power to the oven. It must be in the illuminated I (ON)

position before any systems or components are operational.

Temperature, Profile, and OTL Controller

The temperature controller for the oven is labeled TEMPERATURE AND HIGH LIMIT CONTROL

and consists of a Watlow EZ-Zone Controller. The controlller is provided with a digital display and

Up and Down arrow keys. The keys are used to change the oven temperature set point, perform

calibrations, and program heating profiles. The arrow keys also control the operations of the Over

Temperature Limit system (OTL).

Figure 4: Temperature Controller

The EZ1 button is used to quick launch Profile 1 or abort any running heating profile (see the

Programmed Operations section on page 24). The EZ2 button does not have a function in the

SMO5HP-2.

The green advance button is used to scroll forward through menus and parameters lists.

The reset button is used to scroll the display back to a previous page or menu while programing

heating profiles. Pressing the reset button repeatedly returns the display to the home page.

Note: On some older Watlow Controllers the Reset button may be labeled with an infinite ∞symbol

rather than RESET.

A small flashing “2” toward the center bottom of the display indicates when the controller is

powering the oven’s heating elements. A small flashing “1” indicates internal communications

functions within the controller.

Vent Valves

The SMO5HP-2 comes provided with two vent valve controls on its front control panel. These open

or close the intake and exhaust valves located on the top of the unit.

15 | P a g e

OPERATION

OPERATING PRECAUTIONS

Warning: This SMO oven is not an explosion-proof unit!

Avertissement: Ce sont des fours pas résistants aux explosions.

1. The oven is not designed to safely contain combustible gasses.

2. Do not place explosive, combustible, or flammable materials into the chamber.

3. The bottom surface of the chamber should not be used as a work surface.

4. Do not operate the oven in an environment with noxious fumes.

5. The SMO oven is provided with a dampened exhaust vent. For safe and efficient oven

operation follow these precautions:

a. In normal heating the damper is closed.

b. Outgassed byproducts may be hazardous to or noxious for operating personal.

If either is the case, the oven exhaust should be positively ventilated to a

location outside workspace in accordance with national and local regulations.

6. Do not place sealed or filled containers in the oven.

7. Do not place mercury thermometers in the oven.

8. The SMO oven is not designed for use in Class I, II, or III locations as defined by the US

National Electric Code.

Warning: The vent dampers may be hot to the touch. These areas are marked with Hot Surface labels. Proper PPE should be

employed to minimize burn risk.

Avertissement:Les clapets d'aération peuvent être chauds au toucher. Ces zones sont marqués avec des étiquettes de

Surface chaude. Les EPI approprié devraient être employée pour réduire au minimum le risque de brûler.

16 | P a g e

OPERATION (CONTINUED)

THEORY OF OPERATIONS

To achieve the oven’s stated operation specs, the vents must be fully closed. Operating the oven

with the vents open impacts the oven chamber temperature uniformity and stability. This may or

may not speed drying rates, depending on the nature of your samples or product. During normal

operations the vents are intended to be opened only while the product or samples are cooling.

Running the oven with an active power exhaust blower attached to the exhaust vent will reduce the

oven chamber temperature.

Heating

The oven runs in either manual mode or an automatic heating profile. The oven comes from the

factory set to run in manual mode. When powered and running in manual mode, the SMO oven

chamber heats to and then indefinitely maintains the temperature set point shown on the home

page of the controller. The manual mode set point can be adjusted by the end-user using the Up

and Down temperature buttons. The oven will not heat if the temperature set point is set below its

operational temperature range.

When the oven is powered, the chamber air temperature cannot go below the ambient room

temperature plus the internal waste heat of the oven. Waste heat is generated primarily by the

operation of the air-circulating blower fan motor and the resulting air compression in the duct

spaces. In practice the temperature floor is ambient +15°C.

The oven heater controller (a Watlow EZ digital controller) stores the user-selected temperature set

point, along with any user-programed heating profiles. The controller monitors the oven chamber air

temperature using a solid-state probe located in the airstream on the right wall of the chamber.

When the processor detects that the chamber temperature has dropped below the current

temperature set point, it pulses power to a heating element in a recirculation air duct located above

the oven chamber.

The controller employs proportional-integral-derivative analytical feedback-loop functions when

measuring and controlling the chamber air temperature levels. PID-controlled heating pulse

intensities and lengths are proportional to the difference between the measured chamber

temperature and the current set point. The frequency of pulses are derived from the rate of change

in the difference. The integral function slows the rate of pulses when the temperature nears the set

point to avoid overshooting.

SMO ovens rely on natural heat radiation for cooling. The oven depends on the operation of its

blower fan to circulate air and maintain temperature uniformity and stability in the chamber.

The heating rates given in unit specification section of this manual are for a 25°C environment. The

ambient temperature of the workspace around the oven will affect heating and cooling.

17 | P a g e

OPERATION (CONTINUED)

Heating Profiles

The Watlow controller can store up to four heating profiles, each with ten steps. Please see the

Programed Operations section on page 24, and the Watlow EZ-Zone Profile Programing Guide

for more details. A profile can be launched whenever the unit is running in manual mode. Heating

profiles should allow adequate time for the oven chamber to heat to the first temperature in the

profile, prior to continuing to the second step of the profile.

Airflow and Applications

During normal operations, the internal blower fan motor pulls air out of the oven chamber through

perforations on the left chamber wall. The captured air is pulled up and blown across a heating

element in the recirculation duct immediately above the chamber, then forced down through a duct

on the right side of the chamber. The air exits the duct through small holes on the right chamber

wall. Upon leaving these holes, the heated air blows horizontally across the shelf space, helping to

create temperature uniformity and enhance drying. After crossing the shelves, the air enters a duct

on the left side of the chamber, and is then pulled back into the heater space above the oven

chamber.

If the intake and exhaust vents are opened, some air will exit through the open exhaust vent on the

top right of the unit. Lost air will be replaced through the intake vent. The rate of atmosphere

exchange depends on several variable factors. These include: ambient conditions, position of the

vent valves, the volume of material in the oven chamber, and if a power exhaust unit is connected

to the exhaust vent.

Over Temperature Limit

The Watlow controller contains a backup temperature control system with independent circuitry.

This system connects to a redundant temperature sensor probe inside the oven chamber. The over

temperature heating cutoff system is intended to be set 5°C above your application or process

temperature set point. In the event the oven chamber temperature exceeds the over temperature

limit setting, the backup system will depower the heating element. This provides redundant heating

control the event of a failure of the primary circuitry or the main temperature sensor probe.

18 | P a g e

OPERATION (CONTINUED)

PREPARING THE OVEN FOR USE

Preform the following steps to prepare the oven for use after installing it in a new

workspace environment.

Optional: If you will be performing a temperature display accuracy verification as part of

your set up, Sheldon Manufacturing recommends introducing the temperature probe of

your temperature reference device into the oven chamber now, prior to powering the oven.

Please see the procedure (page 21) for probe placement instructions. Placing the probe

now offers significant times savings during the procedure. The probe must be rated for the

temperature you will be running the oven at during the burn-in (see page 20).

1. Open the intake and the exhaust vents on the oven to prepare for the initial burn-in

procedure.

2. Place the Power Switch in the ON position. The Temperature Display will illuminate, then

show the controller home page.

3. Set up the oven for use by carrying out the following procedures found in the Operation

section:

Set the Over Temperature Limit to 325°C (page 19) to prevent the OTL heating

cutoff from interfering with the following three procedures.

First User Burn-In (page 20)

oSet the Temperature Controller Set Point to the highest temperature you

will use the oven at to run the Burn-In procedure manually (page 19).

–Or –

oProgram a heating profile to automatically run the Burn-In. See pages 20 and

24, as well as the Programing Guide –Watlow EZ-Zone Controller Heating

Profiles, which came with the oven.

Optional: Perform a Temperature Display Accuracy Verification

(page. 21)

Set the Temperature Controller Set Point on the home page to your

application temperature, if you will be running the oven in its manual

mode (page 19). Otherwise, program a heating profile (page 24).

Set the Over Temperature Limit (page. 19)

oThis time set the control to 5°C above your application’s manual mode

temperature or the highest temperature of your heating profile. This prepares the

oven for normal use.

Load the oven with your product or samples.

End of procedure

Home Page

27°C Chamber air

temperature, 0°C

set point

19 | P a g e

OPERATION (CONTINUED)

SET THE OVER TEMPERATURE LIMIT

This procedure sets the Over Temperature Limit backup system. Normally the system is set 5°C

above the highest set point temperature you will be using during your current application or

process. Always set at least 5°C above the hottest temperature of a heating profile.

Note: If this is the first use of the oven, set the Over Temperature Limit to 325°C or higher to

prepare to help ensure the OTL system will not interfere with the Burn-In procedure.

1. Press the green Advance button until “Lh.S1” (Limit High Set Point) shows in the green-

colored mid-level display.

2. Use the Up and Down arrows to enter a temperature limit in the red top display.

3. After entering the temperature limit, press the Advance button. The red display will show

“SAFE”, indicating that the temperature limit has been set.

4. Press the Reset button to scroll the display back to the home page.

SET THE TEMPERATURE CONTROLLER SET POINT

This procedure sets a new temperature set point for the oven’s manual mode.

Note: Set the oven to the highest temperature you will run the oven at, if manually running the

First Use Filter Burn-In procedure (see page 20).This procedure may also be run by

programing and launching it as a heating profile.

1. On the home page, use the Up and Down Arrow keys to adjust the set point in the green

display to your baking application or process temperature set point.

a. Holding down an arrow key will cause the temperature to advance in

increments of ten (10) rather one (1).

2. Release the Arrow Button once you have reached your required set point. There may be

a brief pause before the oven starts heating.

a. A small flashing 2 in the Watlow display indicates the temperature controller

is calling for heat.

End procedure

Set Point at 0°C,

Chamber temp

27°C

Steps 1 and 2:

Limit set at 325°C

Step 3

Step 2: Set Point

adjusted to 280°C

20 | P a g e

OPERATION (CONTINUED)

FIRST USE BURN IN

The steps below help eliminate smoking from protective coatings on the heating elements, when

running above 150°C. Perform the burn-in at the highest temperature the oven will be used at.

1. Open the intake and exhaust vents. Oven exhaust should be positively vented outside of

the oven’s workspace during the Burn-In.

2. If you have not already done so, set the Over Temperature Limit to 325°C, and the

temperature set point the highest operating temperature the oven will be used at.

3. Run the oven for a minimum of one (1) hour at your highest operational temperature, until

smoke from the heating elements dissipates.

Other manuals for SMO5HP-2

2

Table of contents

Other shelolab Oven manuals

shelolab

shelolab SMO34HP-2 User manual

shelolab

shelolab SG02 User manual

shelolab

shelolab SMO5HP-2 User manual

shelolab

shelolab SMO10HP-2 Quick start guide

shelolab

shelolab SMO14-2 User manual

shelolab

shelolab SMO3 User manual

shelolab

shelolab E1310 User manual

shelolab

shelolab SMO14-2 User manual

shelolab

shelolab SMO5HP-2 User manual

shelolab

shelolab SMO1E User manual