4 | Page

TABLE OF CONTENTS

INTRODUCTION ........................................................................................................................................................ 5

Read this Manual....................................................................................................................................................................5

Safety Considerations and Requirements ......................................................................................................................5

Contacting Assistance ..........................................................................................................................................................6

Temperature Reference Sensor Device ..........................................................................................................................6

Engineering Improvements..................................................................................................................................................6

RECEIVING YOUR UNIT ............................................................................................................................................7

Inspect the Shipment............................................................................................................................................................. 7

Orientation................................................................................................................................................................................8

Recording Data Plate Information.................................................................................................................................... 11

INSTALLATION .........................................................................................................................................................13

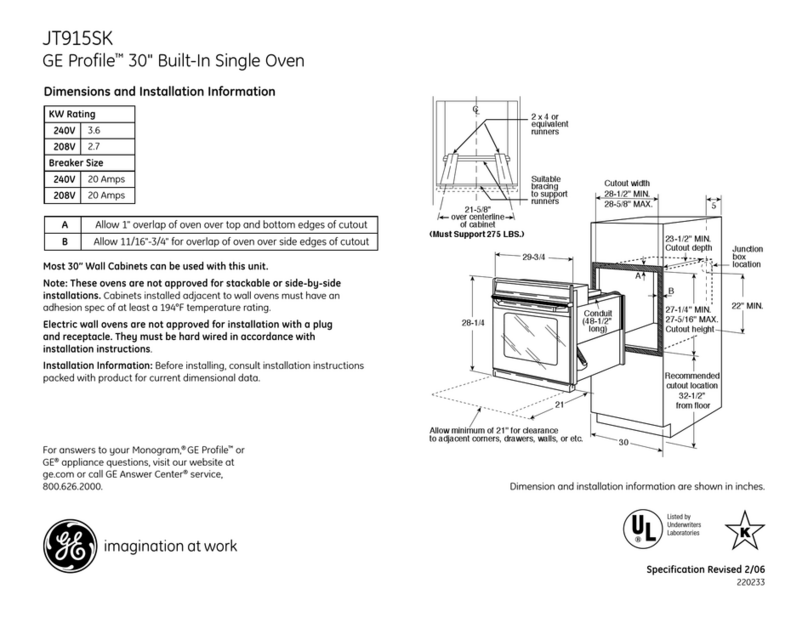

Hardwire Requirement........................................................................................................................................................ 13

Installation Checklist ........................................................................................................................................................... 13

Required Ambient Conditions........................................................................................................................................... 14

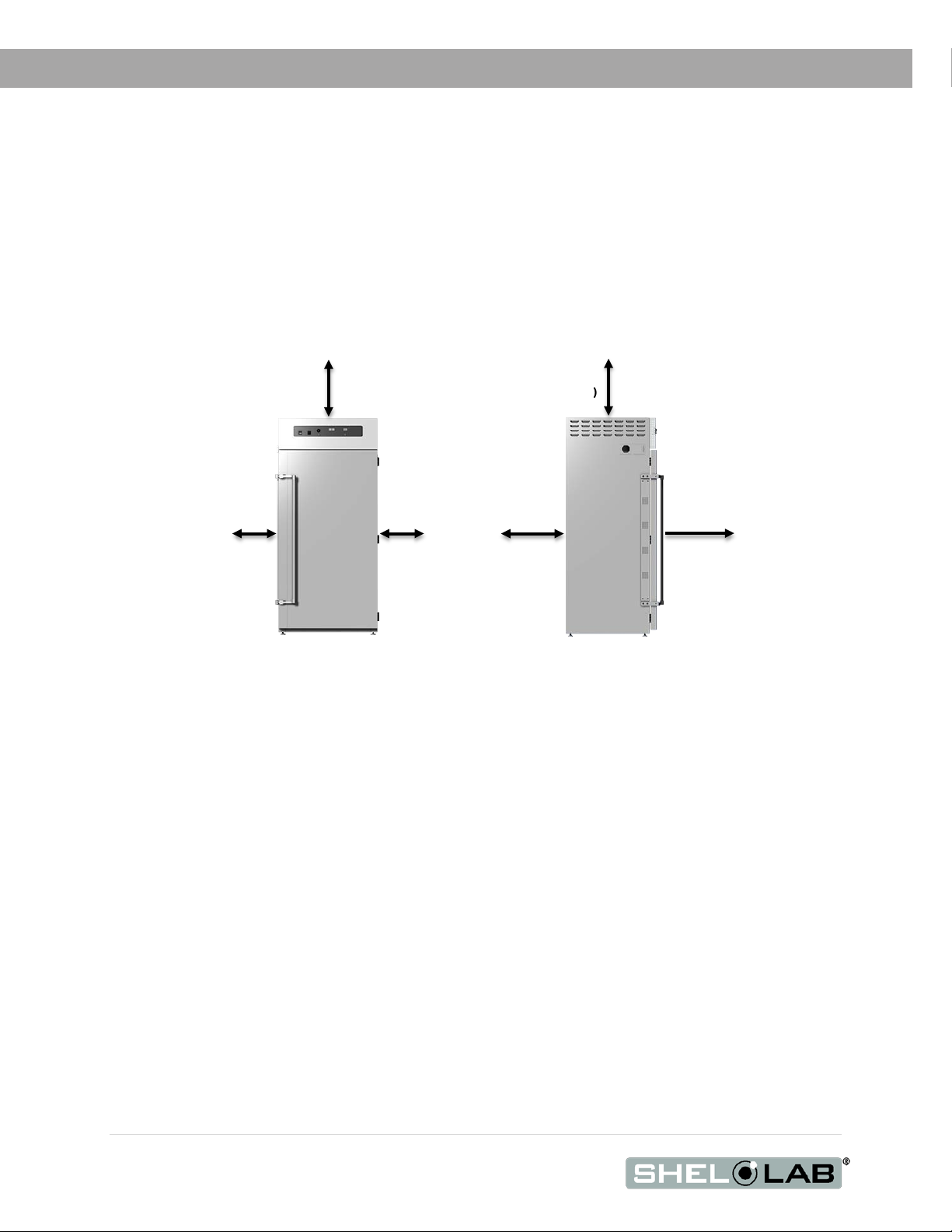

Required Clearances........................................................................................................................................................... 14

Environmental Disruption Sources .................................................................................................................................. 14

Power Source Requirements ............................................................................................................................................ 15

Power Feed Wiring............................................................................................................................................................... 15

Lifting and Handling ............................................................................................................................................................ 16

Leveling................................................................................................................................................................................... 16

Install the Oven ......................................................................................................................................................................17

Installation Cleaning.............................................................................................................................................................17

Install the Shelving................................................................................................................................................................17

GRAPHIC SYMBOLS ................................................................................................................................................19

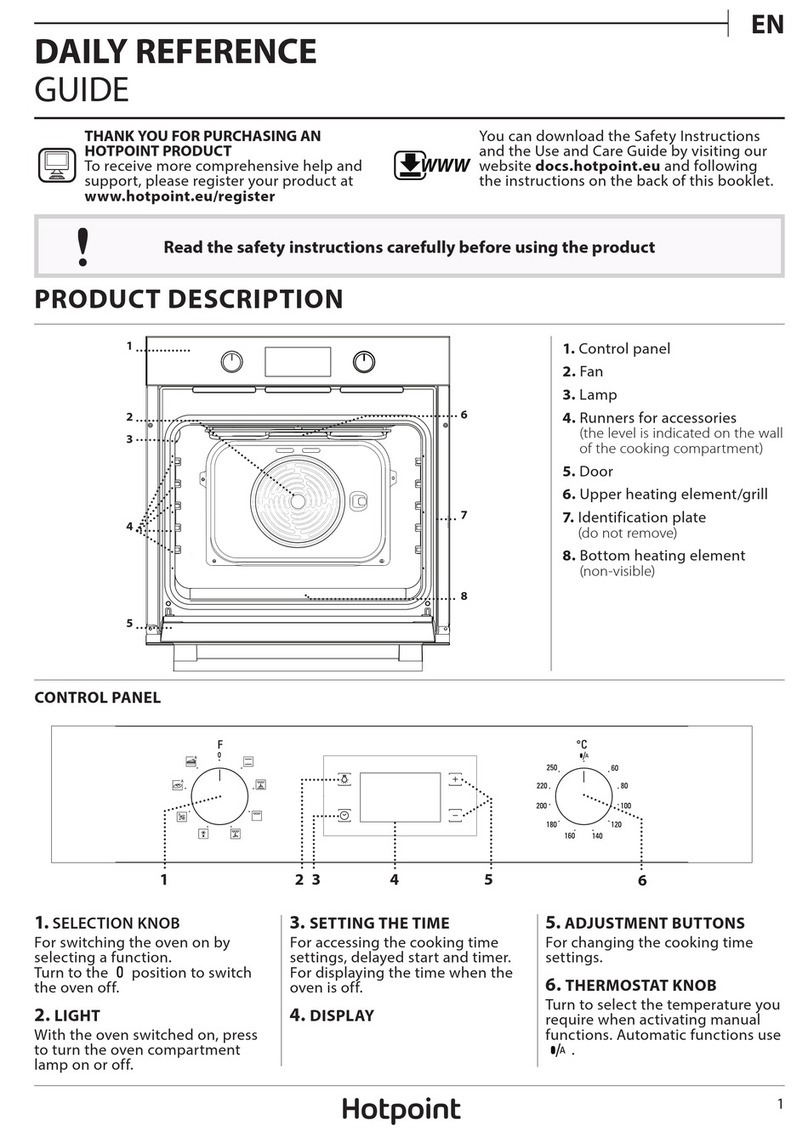

CONTROL PANEL OVERVIEW ...............................................................................................................................21

OPERATION.............................................................................................................................................................. 23

Operating Precautions....................................................................................................................................................... 23

Theory of Operation ........................................................................................................................................................... 24

Put the Oven into Operation ............................................................................................................................................ 26

Set the Temperature Set Point.........................................................................................................................................27

Set the Over Temperature Limit...................................................................................................................................... 28

Setting the Timer ................................................................................................................................................................. 29

Launch a Heating Profile.................................................................................................................................................... 31

Drying Racks and other Accessories............................................................................................................................. 32

USER MAINTENANCE............................................................................................................................................. 33

Cleaning and Disinfecting................................................................................................................................................. 33

Door Components............................................................................................................................................................... 34

Electrical Components....................................................................................................................................................... 34

Calibrating the Temperature Display ............................................................................................................................ 35

UNIT SPECIFICATIONS .......................................................................................................................................... 39

Weight..................................................................................................................................................................................... 39

Dimensions............................................................................................................................................................................ 39

Capacity ................................................................................................................................................................................. 39

Shelf Capacity by Weight.................................................................................................................................................. 40

Air Flow Performance......................................................................................................................................................... 40

Temperature .......................................................................................................................................................................... 41

Power....................................................................................................................................................................................... 41

PARTS LIST............................................................................................................................................................... 43