Shenzhen Nowforever Electronics Technology E100S1R5 User manual

DK00 Series

Inverter

User Manual

V1.3

Contents

Inspectio

n

......................

.1

Sofeware

up

dated

descriptio

n

.....

.3

1

Summariz

e

.....................

.4

1.1

D

esc

r

ipt

i

on

o

f

N

a

mep

l

at

e

......

.

4

1.2

S

ele

c

tio

n

gu

i

d

e

...............

.

5

1.3

T

ech

n

olo

gy

C

riter

io

n

..........

.

6

1.4

F

eat

u

res

......................

.

8

2

Installa

t

io

n

..................

10

2.1

I

nst

a

lla

t

ion

Env

i

ron

m

en

t

......

10

2.2

I

nst

a

lla

t

ion

dir

e

cti

on

and

s

p

ace

11

2.3

I

nst

a

lla

t

ion

dimensions

of

i

nve

r

ter

..................................

12

2.4

Ins

t

all

a

tio

n

dimension

o

f

k

eyb

o

ard

..................................

14

3 wiring

........................

15

3.1

C

onn

e

cti

on

o

f

Pe

r

ipe

r

al

devices 15

3.2

W

iri

ng

D

i

agr

a

m

................

16

3.2.1

Des

c

rip

t

ion

o

f

ma

i

n

ci

r

cui

t

term

i

nal

s

....................

16

3.2.

2

Ju

m

per

s

of

con

t

rol

cir

c

ui

t

17

3.2.3

Des

c

rip

t

ion

o

f

C

o

ntr

o

l

Ci

r

cui

t

Term

i

nal

s

....................

18

4 Operation

.....................

20

4.1

K

eyp

a

d

D

e

scr

i

pti

on

............

20

4.1.

1

Key

fu

n

cti

on

d

e

scr

i

pti

on

21

4.1.

2

In

d

ica

t

or

l

igh

t

de

s

cri

p

tion

.............................

22

4.2

O

per

a

tio

n

process

.............

23

4.2.

1

Fast-monitoring

........

24

4.2.

2

Fu

n

cti

on

codes

set

t

in

g

.

25

4.2.

3

In

f

orm

a

tio

n

Qu

e

r

y

......

25

4.2.

4

Fau

lt

A

lar

m

Re

s

e

t

......

26

4.2.5

K

eyb

o

ard

d

i

git

a

l

set

t

ing

m

o

dif

y

rapi

d

........................

26

4.3

Q

uic

k

de

bugg

i

ng

...............

27

5

Detailed

Function

Descriptio

n

..

28

5.1 P0

F

u

nct

i

on

G

rou

p

.............

28

5.1.

1

Ba

s

ic

F

unc

t

io

n

.........

28

5.1.2

S

imp

l

e

vec

t

or

co

n

trol

p

ara

m

eter

.............................

34

5.1.

3

Input

t

erm

i

nal

s

........

37

5.1.

4

Ou

t

put

ter

m

ina

l

s

.......

41

5.1.

5

Ke

y

boa

r

d

s

e

tti

ng

.......

44

5.1.

6

Start

and Stop

Con

t

ro

l

.

45

5.1.

7

Pr

o

tec

t

fu

n

cti

on

.......

46

5.1.

8

Mu

l

ti-

s

tep

speed

.......

50

5.1.

9

PI

D

Co

n

tro

l

............

51

5.1.10

T

r

ave

r

se

f

req

u

enc

y

se

t

ting

.............................

55

5.1.11

Se

rial

Comm

u

nic

a

tion

Set

t

ings

.............................

56

5.1.12

B

u

ilt

-

in

PLC Run

M

od

e

.

57

5.2 P1

F

u

nct

i

on

G

r

oups

(

F

unc

t

ion

C

od

es

modi

f

y

S

e

tti

ng

)

..................

64

5.3 P2

F

u

nct

i

on

G

rou

ps

(

r

ese

r

ved

)

65

5.4 d0

f

u

nct

i

on

g

rou

ps

(

r

ead

only)

65

6 Fault and

trouble shooting

.....

66

6.1

F

aul

t

and

Al

a

r

m

...............

66

6.1.

1

F

a

ul

t

I

n

dic

a

tio

n

and

Fau

lt

R

eset

.............................

66

6.1.

2

A

l

ar

m

I

n

dic

a

tio

n

and

Ala

r

m

R

eset

.............................

67

6.2

F

aul

t

and

Trouble

Sh

o

oti

ng

....

67

6.3

Common

F

a

ult

s

and

So

l

uti

on

s

...

70

6.3.

1

No

dis

p

lay

aft

e

r

power

on

:

70

6.3.

2

M

o

to

r

do

esn

’

t

mo

v

e

a

fte

r

inverter

running

.............

71

7 Maintenance

...................

73

7.1

Inspect

t

he

i

nve

r

ter

per

i

odi

c

all

y73

7.2

R

epl

a

cem

e

nt

o

f

w

e

ari

ng

p

a

rt

s

..

74

8

List

of

F

unction

Parameter

s

....

75

8.1 P0

fu

n

cti

on

g

rou

p

s

(

use

r

s

setup

f

unc

ti

on

codes

)

...........................

75

8.2 P1

f

unc

t

ion

g

rou

p

s(f

u

nct

i

on

c

od

es

modi

f

y

s

e

tti

ng

)

...................

90

8.3 d0

Fu

n

cti

on

Gro

u

ps

(

fau

lt

inf

o

rma

ti

on

of

h

i

sto

ry

)

......................

90

8.4 d1

Fu

n

cti

on

Groups (

i

nve

r

t

er

info

r

mat

i

on

)

.....................

91

8.5 d2

function groups

(

Inverter

run

n

i

ng

state

)

...........................

92

8.6 d3

f

unc

t

ion

g

roups

(

users

i

n

ter

f

ace

state

)

...........................

93

9

MODBUS

C

o

mmunication

Protoco

l

..

95

9.1

M

ODBU

S

C

o

mmu

n

ica

t

ion

Mod

e

s

....

95

9.2

I

nfo

r

mat

i

on

f

orm

a

t

............

96

9.3

E

xam

p

les

of

M

ODBU

S

I

n

for

m

ati

on

100

9.3.

1

To read

the

co

n

ten

t

s

o

f

st

o

rag

e

register

....................

100

9.3.

2

Te

s

t

c

i

rcu

it

..........

101

9.3.

3

W

r

it

e

in

t

o

m

ult

i

-st

o

rag

e

register

....................

102

9.3.

4

Da

t

a

saved

ins

t

ruc

t

io

n

103

9.3.

5

Bro

adc

a

st

m

ode

l

se

n

t

d

a

t

a

103

9.4

I

nve

r

ter

for

sla

v

e

...........

104

9.4.

1

In

s

tru

c

tio

n

Da

t

a

......

104

9.4.

2

Mo

n

ito

r

ing

Data

.......

105

9.4.

3

Se

t

Da

t

a

..............

105

9.4.

4

Te

s

t

D

a

t

a

.............

105

9.5

I

nve

r

ter

for

mas

t

e

r

..........

106

9.6

M

ODBU

S

C

o

mmu

n

ica

t

ion

Err

o

r

C

o

de

s

107

9.7

Back-check

o

f

no

r

esp

o

nse

fault

f

or

slav

e

............................

107

Chart Index

....................

109

I

ns

p

ec

ti

on

1

Inspection

Check the following items when unpacking the

inverter,

1. Ensure there is operation manual and warranty card in the

packing box.

2. Inspect the nameplate and ensure it is what you ordered.

3. Ensure the optional parts are what you need if have ordered

any optional parts.

Please contact the local agent if

the

re is any damage in the

inverter or optional parts.

Warranty

description

The manufacturer warrants its products from the date of

leaving factory. Manufacturer is responsible only for quality

problems is caused by product design and production process, it is

not responsible for the products were damaged in the course of

transportation or discharge box. For the incorrect installation and

I

ns

p

ec

ti

on

2

use,such as temperature, dust, corrosion and other non-compliance

of the working conditions and overload operation , manufacturer is

irresponsible.

3

S

of

e

wa

r

e

upd

at

e

d

de

scr

i

p

t

ion

Sofeware updated

description

Firmware version updated for X902,mostly add “interior

PLC run mode” relative to X901 version. Please refer

to“5.1.12 built-in PLC run mode”.

4

S

um

m

ar

i

ze

MOD

L

E:

A100S1R5B

INPUT: 1PH

AC220V 50HZ

/6

0

HZ

O

UTPU

T

:

8A

S

/

N:

Ba

r

Code

SHENZHEN

NOWFOR

E

VER

1

Summarize

Please check the following items when unpacking the

inverter, the nameplate and ensure it is what you ordered,the entire

exterior of the inverter to ensure there are no scratches or other

damage caused by the transportation, ensure there is operation

manual and warranty card in the packing box.

Please contact the local agent if there is any damage in the

inverter or optional parts.

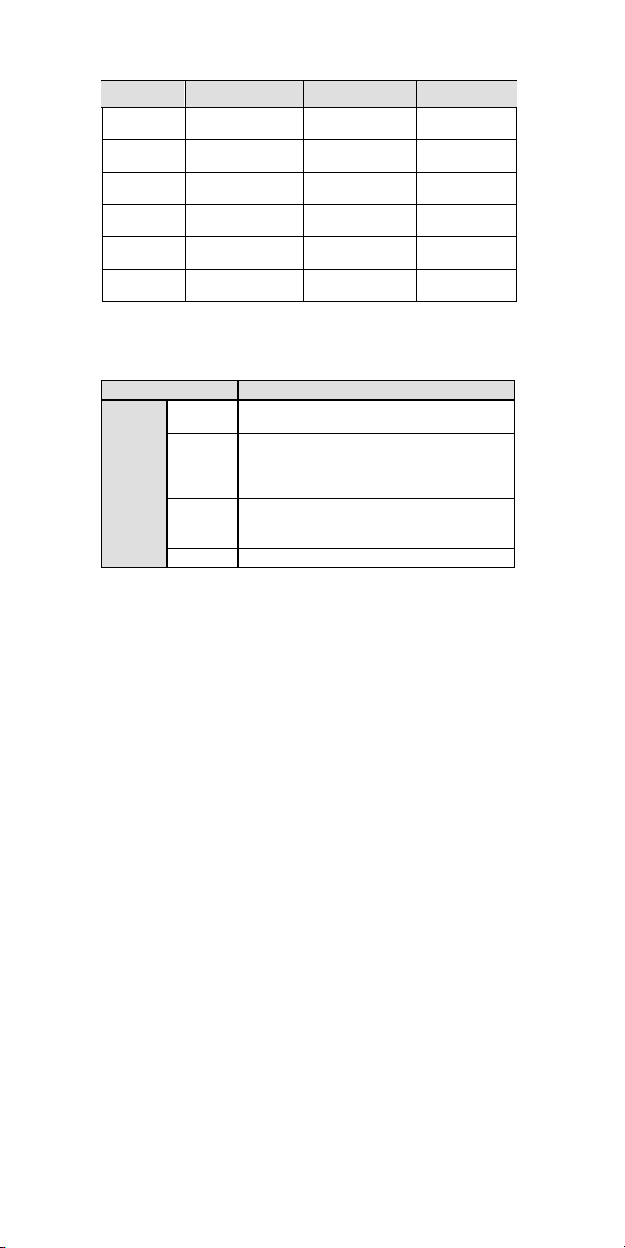

1.1 Description of Nameplate

Mod

el

Inp

u

t

Pow

er

rated

O

utput

Curr

e

nt

Chart 1-1

Nameplate

5

S

um

m

ar

i

ze

Se

r

i

e

s

:

si

m

p

le

T:Three

phase 380V

S:

S

ingle

phase

22

0V

E100 S 1R5

B

Po

w

er

E100S Parts

Description

B Basic

model

S Simple model(no serial communication

function)

E100T Model

Description

G:

G

Model

P: P

Model

GB: G Model (built-in braking

transistor)

PB: P Model (built-in braking

transistor)

Chart 1-2 Naming

rule

remark:may obtain the information of model and power in “d1

function groups”.

1.2 Selection guide

Model Rated output

power(KW)

Rated Output

Current(A)

Motor

Power

(

KW

)

E100S0R4

0.4

3.0

0.4

E100S0R7

0.75

5.0

0.75

E100S1R5

1.5

8.0

1.5

E100S2R2

2.2

10.0

2.2

Chart 1-3 220V series

description

Model

Rated output

Rated Output

Motor Power

6

S

um

m

ar

i

ze

power(KW)

Current(A)

(KW)

E100T0R7G

0.75

2.6

0.75

E100T1R5G

1.5

3.8

1.5

E100T2R2G

2.2

5.1

2.2

E100T3R7P

3.7

9.0

3.7

E100T3R7G

3.7

9.0

3.7

E100T5R5P

5.5

13

5.5

Chart 1-4 380V series

description

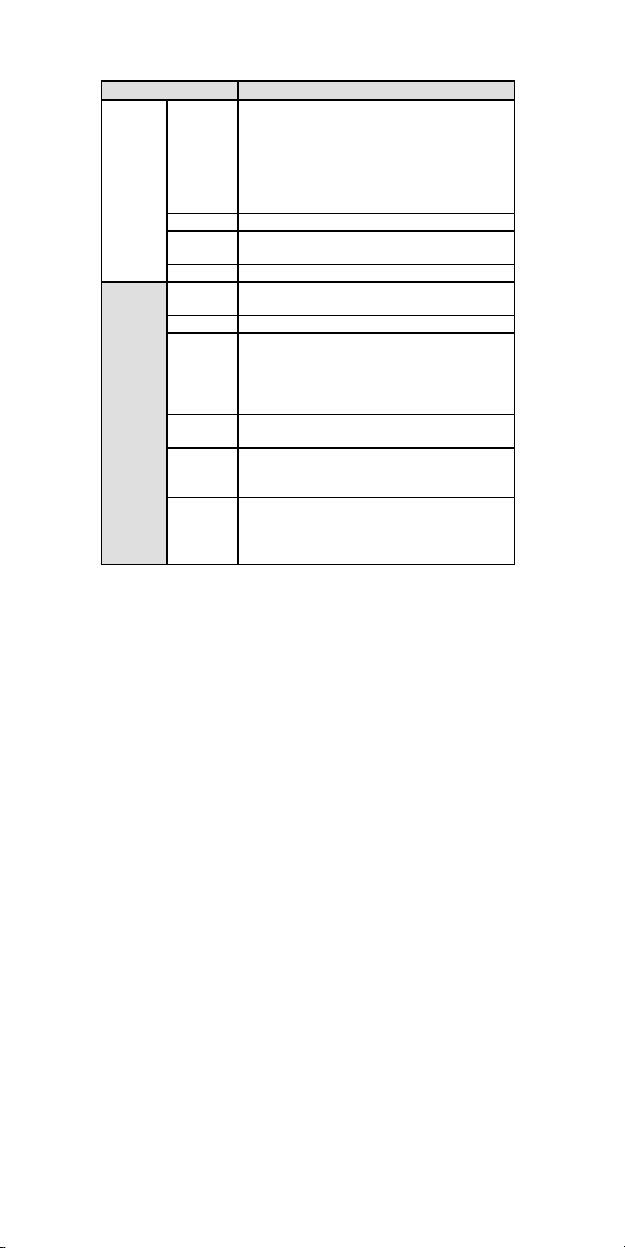

1.3 Technology Criterion

Items

Criterion

Performance

Frequency

range

0~600Hz

Precision of

output

frequency

0.01Hz

Distinguish

rate of setting

frequency

Digital setting:0.01Hz.

Analog setting : AD switch precision for one i

n

t

housand,linearity for +-5%.

Speed range

1:100

7

S

um

m

ar

i

ze

Items

Criterion

Overload

capability

E100S series:150%rated current 60s;180%rated current 2

s.

E100T series(G model):150%rated current 60s;180%rate

d

current 2s.

E100T series(P model):120%rated current 60s;150%rate

d

current 2s.

remark:may obtain the informations of model and power in

“d1 function groups”.

Control Mode

Open-loop simple vector control

Torque boost

Manual torque can be adjust;Auto-Torque upgrade the whol

e

frequency band.

Start up Torque

when0.5Hz, rated torque for 150%.

Function

descriptions

Acc and Dec

time

0.1~3200.0s

Jog function

Jog frequency:0.00~50.00h z;

Standard

functions

Simple vector control 、 torque boost 、 automatic sl

ip

compensation

(rev gain)、stop for DC braking、Restart after

power off instantaneous、auto fault reset、control over-curren

t

when accelerating speed、multi-step speed 4 run、traver

se

frequency function applies to textile、closed loop PID control

Run rule

3kinds control mode :keyboard control, analog termina

l

control, serial communication control

Frequency

Source

Selection

Digital setting, analog voltage setting, analog current setting

,

t

he serial communication port setting; can be combine

d

t

hrough a variety of ways to switch.

Input

Terminals

4digital input terminals, as many as 13 kinds of custo

m

features, is compatible with the active NPN input;

Two analog input terminals, can receive a voltage signal (0 ~

10V), or current signal (4 ~ 20mA);

This manual suits for next models

11

Table of contents