(14) Remove the regulator parts from the cleaning solution. Blow all internal passageways dry with clean, dry

compressed air.

(15) Inspect the bores in which the piston O-rings move for corrosion or wear. If the bores are leaking air because

of wear, replace the parts. If some corrosion deposits persist, carefully wipe them away with a plastic scrubbing cloth.

Blow any resulting dust out of the regulator parts.

(16) Inspect the orifice sealing surface located inside the body where the small tip of the piston seals when the

regulator is assembled. Any nicks, scratches or corrosion at the top of the cone can allow air to pass, which will result

in creeping hose pressures.

Polish the defects out using a fine abrasive polishing stick or pencil eraser. When polishing, apply a light

pressure to prevent excessive wear on the or if ice cone. Use compressed air to blow away any dust created by the

polishing process.

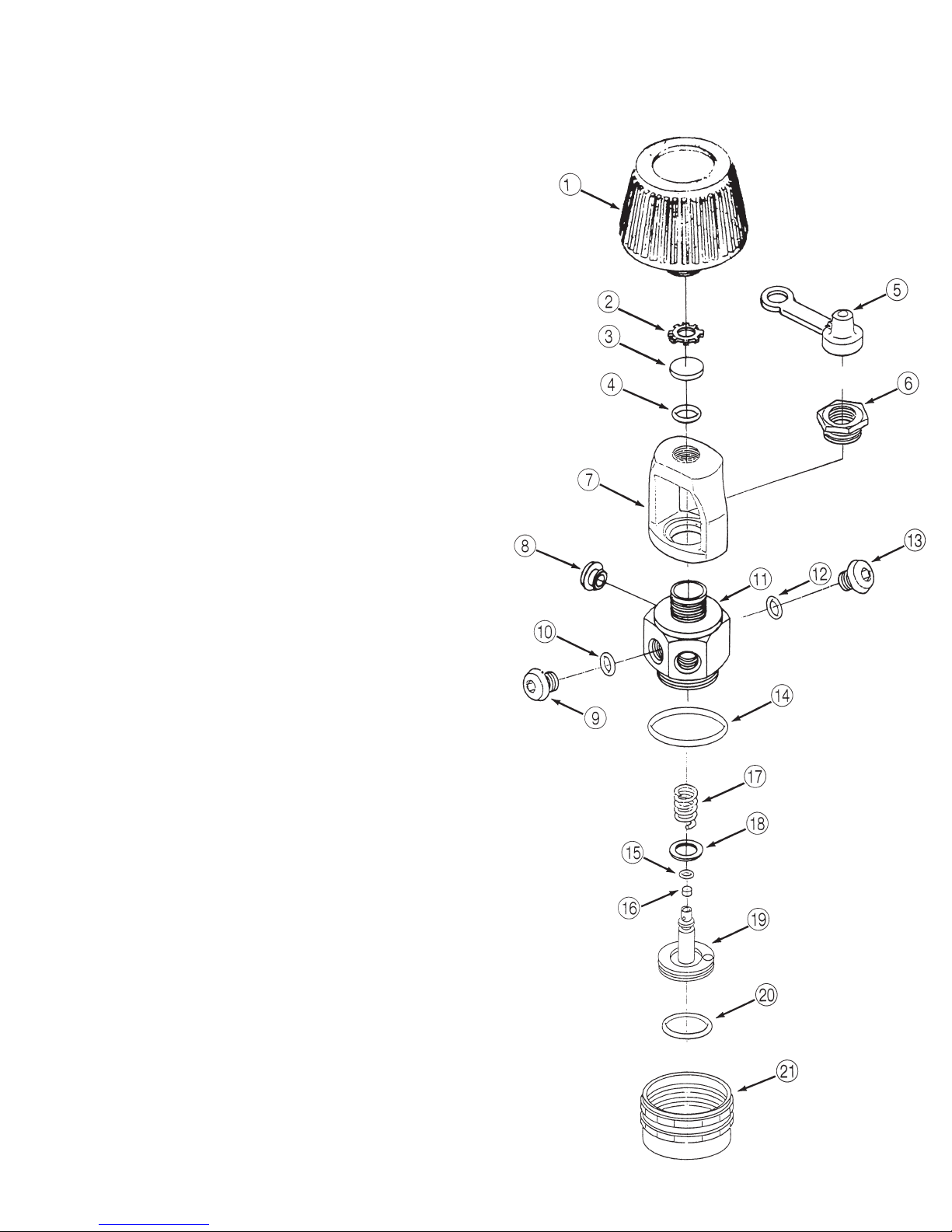

ASSEMBLY OF FIRST STAGE

(1) The minimum parts to be replaced at every annual service interval can be found in the Minimum Parts

Replacement Kit for the Brut regulator (p/n 4000-1).

(2) Before installing new O-rings on the piston, lubricate them with one of the recommended lubricants (see

"Specifications" section of this manual). Installation of the small O-ring (item 15) on the piston is made much easier

by using the brass-colored Sherwood O-ring installation cone (p/n TL106). Place the cone over the tip of the piston.

Slide the lubricated O-ring over the cone until it slips into the piston groove.

(3) Place the new piston seat on a clean piece of paper on a hard flat surface. Press the piston tip firmly over

the seat until it is fully installed. The piston is now rebuilt and ready for installation.

(4) Using a greased soft probe, lightly lubricate the first 1/8" of the small bore in the body (item 11) where the

small piston O-ring seals.

(5) Place the O-ring (Item 4) into the main body (yoke end). Place the inlet filter (item 3), rough side up, on top

of the O-ring. Place the star washer (Item 2) on top of the filter. Use Sherwood's filter installation tool (p/n TL115) to

push against the star washer with the short round center section of the tool until the flat part of the handle comes in

contact with the end of the regulator body. This ensures that the filter has been installed squarely to the proper depth,

without distorting the filter.

(6) Install the piston (item 19) squarely into the cap (item 21). If any shims were found when the regulator was

disassembled, place them over the piston stem. Then place the main spring (Item 17) over the piston stem.

(9) Replace the lightly lubricated O-ring (Item 14) on the body.

(10) Install the cap assembly onto the body. Hand-tighten the assembly as tightly as possible, then install the

Sherwood regulator support handle into one of the low pressure ports. Using a Sherwood combination wrench or

bench vise to hold the cap, tighten the cap onto the body until it bottoms on the thread. Do not tighten further.

(11) Using your index finger, install the clean and dry one-way bleed valve (item 8) into the body.

Note: If you use the bleed valve with the Sherwood logo molded into it P/N you will notice a “dot”molded near

the right side of the logo. Install the bleed valve with the “dot”oriented closet to the inlet of the regulator

(toward the yoke).

(12) Lightly lubricate the body yoke nut threads with grease, and install the yoke (item 7) and the yoke nut (Item

6) onto the body.

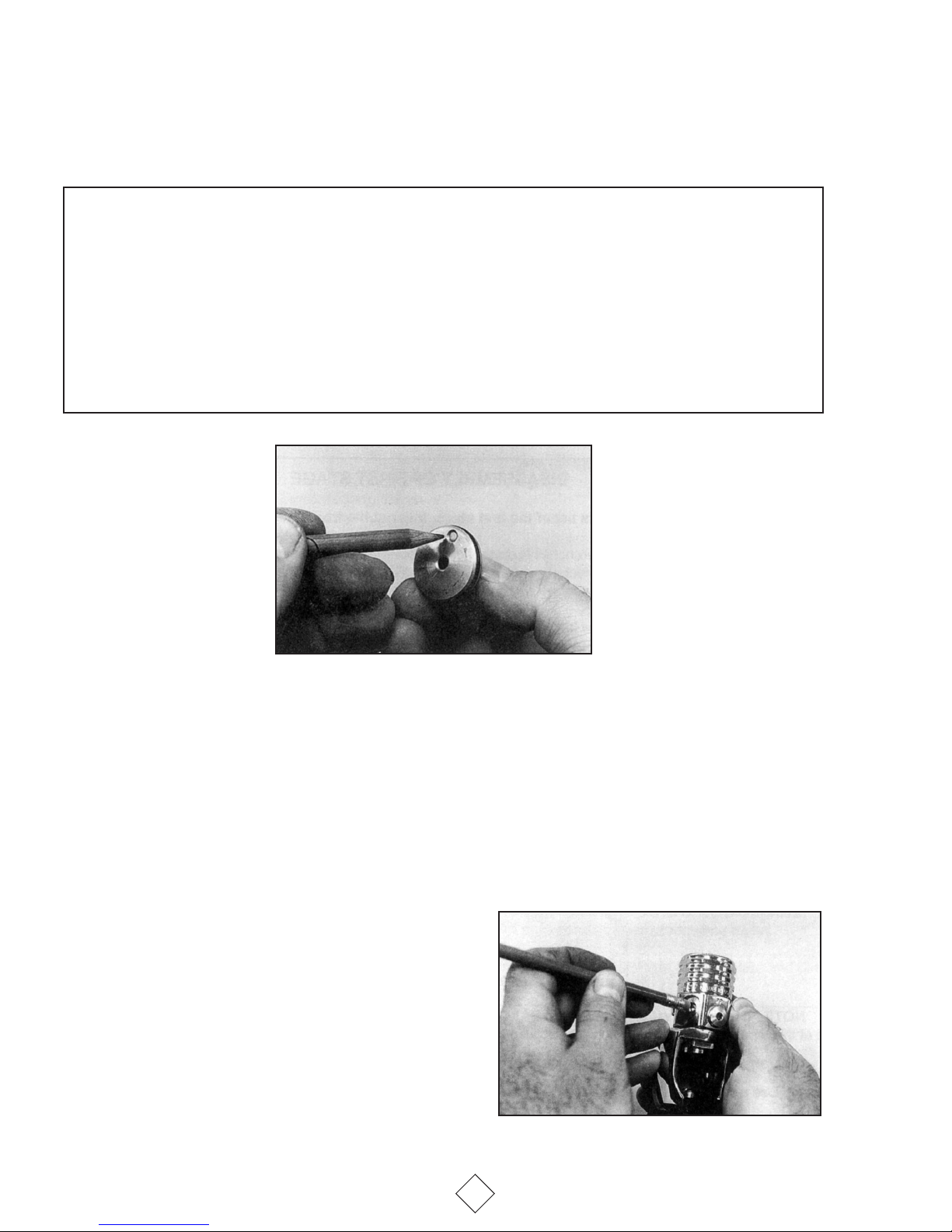

(13) Using the regulator support handle (p/n TL113) in one of the L. P. pressure ports of the body and a

Sherwood combination wrench or 15" adjustable wrench, tighten the yoke nut snugly (see Photo #1).

(14) Install the handwheel (Item 1) and the dust cap (item 5) onto the yoke.

5