Shibuya Hoppmann L500A V2 Instruction Manual

TM

L500A V2 High

Speed Labeler

Installation/Maintenance

Manual

Publication Version, Revision 1, All rights reserved.

© 2011 Shibuya Hoppmann Corporation

13129 Airpark Drive, Suite 120 • Elkwood, Virginia 22718 • USA

Tel: (540) 829-2564 • Fax: (540) 829-1726 • E-mail: [email protected]

Duplication of this manual, in whole or in part, requires written consent of Shibuya Hoppmann Corporation.

Model Name: Model Inventory Number:

Refer all servicing to qualied personnel.

This manual is intended for use by qualied

mechanic and electricians who install or service

the L500A V2 High Speed Labeler.

Please copy this information from

the L500A V2 High Speed Labeler’s

serial plate.

L500A V2 High Speed Labeler Manual

2 3

About This Manual

Who Should Read

This manual is intended for those who need to install and/or operate the

label applicator. The manual is not intended to meet the training needs of

persons new to labeling; nor is it intended to meet the needs of person‑

nel who wish to completely overhaul the unit. These needs will require

assistance of experienced personnel and are outside the scope of this

manual.

Note:

Please carefully read this entire manual before operating your label ap‑

plicator.

Caution Symbols

Caution symbols and messages in this manual call attention to

and Messages

hazardous voltages, moving parts, and other hazardous conditions.

The exclamation point caution symbol denotes possible personal injury

and/or damage to the equipment.

The lightning bolt caution symbol denotes possible personal injury and/

or damage to the equipment from electrical hazards.

Quick Start

Equipment Improvements & Shibuya Hoppmann Corporation (SHC) continually improves its products, and reserves the right to change

DocumentRevisionsNotice ordiscontinuespecicationsanddesignsshowninthismanualwithoutnoticeandwithoutincurringobligation.

SHC has made every effort to verify the information contained in this manual, but reserves the right to correct

any error at the time of the manual’s next revision. This manual is subject to change without notice. 02/11

2 3

Quick Start

2 About This Manual

3 Table of Contents

6 TermsandDenitions

Description and

7 The Label Applicator

Specications

11 ApplicatorSpecications

Figures/Tables:

8 Figure 1‑1. Label Applicator

9 Figure 1‑2. Side View of L500A V2 Labeler

10 Figure 1‑3. Back View of L500A V2 Labeler

11 Table1‑1.ApplicatorSpecications

Safety Precautions

13 Warnings and Conditions

Figures:

13 Figure 2‑1. Additional Warning Labels

Applicator Installation

15 Unpacking and Inspection

15 Applicator Positioning

20 Remote Electrical Enclosure/Interface Panel

21 Power Supply

Figures/Tables:

16 Figure 3‑1. Correct/Incorrect Positioning

17 Figure 3‑2. Rotation Adjustment

18 Figure 3‑3. U‑Arm

19 Figure 3‑4. Adjustments for T‑Stand and U‑Arm

20 Figure 3‑5. Interface Panel

Applicator Setup

23 Label Threading

28 Light Tower (Optional)

29 Low Label Sensor (Optional)

30 Rewind Clutch Adjustment

31 Product Sensor

32 Lion LRD 2100 Label Sensor

35 Setting the Labeling System

37 Right‑Hand to Left‑Hand Conversion

Table of Contents

ChapterPage

1

2

3

4

L500A V2 High Speed Labeler Manual

4 5

Applicator Setup

Figures/Tables:

23 Table4‑1.LabelandWebSpecications

24 Figure 4‑1. Web Path/Label Threading Path

25 Figure 4‑2. Unwind Assembly/Installing New Labels

26 Figure 4‑3. Lockout Knobs and Nip Rollers

27 Figure 4‑4. Rewind Assembly/Threading

27 Figure 4‑5. Light Tower

28 Figure 4‑6. Low Label Sensor

30 Figure 4‑7. Rewind Clutch Adjustment

31 Figure 4‑8. Product Sensor Setup

32 Figure 4‑9. Sensor Adjustments

34 Figure4‑10.LRD2100RetroreectiveModeAlignment

35 Figure 4‑11. Labels Through LRD2100 Sensor

38 Figure 4‑12. Wiper Arm Assembly Removal

38 Figure 4‑13. Sliding Out Wiper Arm Assembly

39 Figure 4‑14. Side Cover Removal

39 Figure 4‑15. Back Panels

39 Figure 4‑16. Torque Fork Assembly‑Hex Nut Removal

39 Figure 4‑17. Torque Fork Assembly‑Hex Nut Locations

40 Figure 4‑18. Unwind Assy./Dancer Arm Assy. Removal

40 Figure 4‑19. Retaining Ring, Shim and Shaft

41 Figure 4‑20. Belt Tensioner/Motor Mounting Plate

42 Figure 4‑21. Rewind Flange Removal

42 Figure 4‑22. Rewind Assembly Bearing Plate

43 Figure 4‑23. Side Standoff Location

43 Figure 4‑24. Standoff Locations

44 Figure 4‑25. Rewind Clutch Assembly Installation

44 Figure 4‑26. Drive Belt Threading

45 Figure 4‑27. Dancer Arm Spring (Rear of Labeler)

46 Figure 4‑28. Unwind Flange Shaft Key

46 Figure 4‑29. Dancer Arm Bumpers

47 Figure 4‑30. Reversing Brake Control Arm

47 Figure 4‑31. Removing the Brake Belt

47 Figure 4‑32. Reverse the Control Arm

ChapterPage

4

4 5

Table of Contents

Operator Interface

53 Operator Interface Map

53 Operator Interface Operation

53 Operating Mode

54 Main Screen

55 Parameter Display Screen

56 Operational Modes ‑ Jog

56 Operational Modes ‑ Label Auto‑Teach

58 Operational Modes ‑ Auto‑Center Teach, Auto‑Center &

Encoder‑Value Teach

60 Operational Modes ‑ Wipe‑On Mode

61 Operational Modes ‑ Tamp‑On, Blow‑On, Tamp‑Blow

62 Operator Screens

62 Parameter Group Screen

63 Parameter Menu ‑ Wipe

69 Parameter Menu ‑ Tamp

71 Parameter Menu ‑ Blow

73 Parameter Menu ‑ Jog

74 Parameter Menu ‑ Setup

78 Diagnostics

79 Program Number

Figures:

51 Figure 5‑1. Mapping of the Operator Interface

54 Figure 5‑2. Main Screen

55 Figure 5‑3. Parameter Display Screen

57 Figure 5‑4. Label Auto‑Teach

59 Figure 5‑5. Auto‑Center Teach Screen

60 Figure 5‑6. Wipe‑On Mode Screen

61 Figure 5‑7. Tamp‑On Screen

62 Figure 5‑8. Parameter Group Screen

78 Figure 5‑9. Diagnostics Screen

Maintenance

81 Preventive Maintenance

and Troubleshooting

81 Controller Maintenance

82 Troubleshooting

Figures:

82 Figure 6‑1. Stepper Drive Motor Fault Display

6

ChapterPage

5

L500A V2 High Speed Labeler Manual

6 7

Terms and Denitions

Term Equivalent Terms, Denition or Abbreviation

Blow-On Module

Blow Module; Label Blow‑On Applicator Module

Tamp-On Module

Tamp Module; Label Tamp‑On Applicator Module

FR Filter

Combination Pneumatic Pressure Regulator and Secondary Particle

Filter

Peeler Plate

Peeler Bar

Product

Any medium to which labels are applied (Boxes, Bottles, etc.)

Web

Webbing, Backing, Label Strip, Label Stock, Label Ribbon, Waste,

Continuous Backing

Flag

Before the label is completely removed from the webbing, the part of

labelwiththeadhesiveexposed,istheaggedpartofthelabel

Labeler

Applicator

ChapterPage

7

Replacement Parts

85 How to Order Spare Parts

86 L500A V2 Recommended Replacement Parts List

Figures:

88 Figure 7‑1. L500A V2 Labeler ‑ Views with Parts Callouts

Appendix

91 Warranty

Figures:

89 Figure 8‑1. Wiring Diagram

90 Figure 8‑2. Wiring Diagram

8

6 7

The Label Applicator

Thank you for purchasing a label applicator. The applicator will meet the

needs of the single label, the stand alone applications or the integration

into an inline product handling system.

The applicator's patented head design has one of the lowest drive inertias

in the industry. This means less wear and more accuracy and repeatabil‑

ity.

The following are some of the features of the label applicator:

aRapidcongurationandchangeoverofapplicatormodules.

aAccommodates a 15" (381mm) supply roll diameter to minimize down

time for reloading.

aLabelheadisconvertedfromleft‑handtoright‑handjustiedwithout

any additional parts.

aGear powered label drive and torque clutch adjustable rewind.

aOne button auto‑teach for fast, easy, repeatable changeover.

aSpeed matching of label and product.

aEasy access to main components for maintenance and changeover.

The label applicator is offered as a stand‑alone unit or as a module

which can be integrated into a product handling system. In either case,

the applicator includes a controller, operator LCD interface and product

detector.

Description and Specications

1

L500A V2 High Speed Labeler Manual

8 9

Figure 1-1. The Label Applicator

IDLER

ROLLERS

REWIND

ASSEMBLY

TORQUE

FORK

ASSEMBLY

IDLER

ROLLERS (4)

IDLER

ROLLER

IDLER

ROLLERS

IDLER

ROLLER

IDLER

ROLLER

IDLER

ROLLER HMI

TOUCHSCREEN

(CONTROL PANEL)

DANCER ARM

ROLLERS

DANCER ARM

ASSEMBLY

UNWIND

ASSEMBLY

DRIVE ROLLER

(HIDDEN BY

COVER PLATE)

NIP ROLLERS (2)

(HIDDEN BY

COVER PLATE)

LABEL

SENSOR

8 9

Figure 1-2. Side View of the L500A V2 Labeler

Chapter 1 Description and Specications

REWIND

ASSEMBLY

PEELER

PLATE

(BOTTOM OF

WIPER ARM)

HMI

TOUCHSCREEN

(CONTROL PANEL)

UNWIND

ASSEMBLY

DRIVE

ROLLER

NIP ROLLER

LOCKOUT CAM

FOR NIP ROLLERS

DRIVE

MOTOR

LABEL

SENSOR

DANCER ARM

ROLLERS

L500A V2 High Speed Labeler Manual

10 11

Figure 1-3. Different Views of the L500A V2 Labeler (Back View)

TORQUE FORK

ASSEMBLY

HMI

TOUCHSCREEN

(CONTROL PANEL)

UNWIND

ASSEMBLY

IDLER

ROLLER

DANCER ARM

ASSEMBLY

DRIVE

MOTOR

REWIND

ASSEMBLY

PEELER

PLATE

(BOTTOM OF

WIPER ARM)

10 11

Chapter 1 Description and Specications

Table1-1.ApplicatorSpecications

Applicator Specications

Themanufacturerordistributormayhavechangedspecicationstomatch

yourapplication.PleaserefertoTable1‑1forapplicatorspecications.

Applicator Specications

Accuracy ±0.02" (±0.5mm) depending on the application module

Controls Dual processor

Product Detection Photo sensor

Label Sensor Capacitance

Power Requirements 115 VAC, 60 Hz, single phase, 6 Amp

Shop Air (For Modules Only) 80 psi minimum, 100 psi maximum to the lter/regulator

Environment 41-104˚F (5 to 40˚C) operating temperature

Relative Humidity 25-85% relative non-condensing humidity

Label Supply Roll 14" (356mm) outer diameter with 3" (76mm) spool inner diameter

Overal Dimensions of Applicator 30.9" wide x 28.5" tall x 18" deep (784.9mm x 723.9mm x 457.2mm)

Weight Approximately 150 lbs (68kg)

L500A V2 High Speed Labeler Manual

12 13

Notes

12 13

Warnings and Conditions

Turn Off Power!

Before servicing, make sure you have turned off the

compressed air and electrical power in a way which prevents accidental

reactivation. Padlock and clearly tag the appropriate electrical and pneu‑

matic disconnects. Wait at least two (2) minutes after disconnecting the

electrical power to discharge the motor start capacitor before performing

any electrical servicing with the rear cover removed.

Dress Appropriately!

Reduce the risk of injury from moving parts by

securing loose sleeves and other clothing. Do not wear loose jewelry or

neckties near the machine.Wear safety glasses or other protective eyewear

at all times. Never place hands or tools near the tamp, corner wrap, print

head, or any other movable parts when the machine is operating.

Install Safety Covers!

Make sure the machine remains safe to operate.

Be sure all safety covers have been installed before operating this ma‑

chine. Safety covers include any covers installed by your direct supplier,

as well as the main cover and the print engine cover. Each helps protect

the operator from potential pinch points and moving parts.

Avoid Pinch Points!

Exposed pinch points include the unwind and take

up assemblies, air tamp, and corner wrap modules. Pinch points exposed

when the main cover is removed include the dual clutch assemblies.

Avoid Dangerous Conditions!

The standard labeler should not be placed

in washdown environments. Dry conditions are critical for long life.

Normal operator inherently causes static electricity to build up. Avoid

explosive or potentially explosive environments.

Safety Precautions

Figure 2-2. Additional Safety Warning Labels - Hand Crush, Finger Cut, Hand in Gears.

2

L500A V2 High Speed Labeler Manual

14 15

Notes

14 15

This chapter covers unpacking, inspection, positioning and power hookups

for the label applicator.

Unpacking and Inspection

Step 1.

Check the Shipping Container. The shipping container protects the ap‑

plicator under most circumstances. Visually inspect the outside of the

shipping container. Report any crate or equipment damage to the ship‑

ping carrier immediately.

The Applicator can weigh in excess of 150 lbs (68kg).

Step 2.

Unpack the Applicator. Remove the top and sides of the shipping crate

to expose the Applicator. Remove the packing material. Inventory the

container.

Applicator Positioning

The standard mounting procedure uses the two mounting holes that are

located on each side of the applicator. The optional U‑arm supports the

applicator at those mounting locations. The mounting holes are tapped

to M12 x 60.

Positioning of the labeler may vary if an application module was pur-

chased with your unit.

Applicator Installation

3

L500A V2 High Speed Labeler Manual

16 17

The labeler must be positioned so that labels are applied to the product

with the proper orientation. Once the correct orientation is obtained,

the labeler is ready to be placed into position. The product and labeling

surface should be parallel with each other at point of contact. (Refer to

Figure 3‑1.)

Figure 3-1. Correct/Incorrect Positioning

PRODUCT PRODUCT

THE TWO

SURFACES

SHOULD BE

PARALLEL NOT

PARALLEL

CORRECT INCORRECT

16 17

Chapter 3 Applicator Installation

Figure 3-2. Rotation Adjustment

Rotation adjustment of the wiper arm and peeler tip (refer to Figure 3‑2)

shouldbemadetolocatetheagofthelabelasclosetotheproductas

possible. The peeler tip should be located just above the product. A ref‑

erenceof0˚(zerodegrees)fromtheproductissuggestedonthewiper

arm. Then, rotate the peeler tip as needed.

Note: Theagofthelabelistheamountoflabelprotrudingpastthepeeler

tip.

Placing the peeler tip in the path of the product may cause damage to

the applicator.

The applicator needs to be mounted in such a way that there is mini-

mum vibration and rotation, or else the accuracy of the labeling may

be compromised. It is also suggested that ne tuning adjustments be

made after mounting.

PRODUCT

PEELER

TIP

WIPER ARM

90˚

103˚

L500A V2 High Speed Labeler Manual

18 19

U-Arm & T-Stand

If a T‑stand and/or U‑arm is purchased with your unit, refer to Figures

3‑3 and 3‑4 for proper positioning.

To pivot the applicator up or down, loosen the large hex nut which fastens

the U‑arm to the T‑stand. This allows the unit to rotate the peeler tip up

or down. Tighten the same nut to secure the applicator's position. (Refer

to Figure 3‑4.)

The applicator may also be positioned for top, side, or bottom panel

labeling. Loosen the two large socket head bolts that fasten the U‑arm

to the labeler. Rotate the applicator into a position where the application

module is parallel to the surface of the product to be labeled.

Figure 3-3. U-Arm

SOCKET HEAD ADJUSTMENT

SOCKET HEAD

ADJUSTMENT

MOUNTING HOLE

MOUNTING

BOSS

18 19

Chapter 3 Applicator Installation

Figure 3-4. Adjustment for T-Stand and U-Arm

Use the handle at the top of the T‑stand to raise or lower the applicator to

the desired height relative to the product. (Refer again to Figure 3‑4.)

To change the horizontal position of the unit, simply unlock the casters

on the bottom of the T‑stand and roll the unit to the desired location. Lock

the casters down once in position.

MOUNTING BOSS FOR

OPTIONAL LEVELING FEET

LOCKING

CASTERS

SOCKET HEAD

BOLTS FOR

TOP OR SIDE-

PANEL

LABELING

ADJUSTMENTS

HEX NUT

FOR PEELER

TIP MOVEMENT

CAM

LOCK

HANDLE FOR

VERTICAL

MOVEMENT

L500A V2 High Speed Labeler Manual

20

Remote Electrical Enclosure /Interface Panel

Connections for the interface panel are found on the remote electrical

enclosure (see to Figure 3‑5.) These connections are easily accessible

for quick changeover between modes of operation. The following is an

explanation of each device:

Figure 3-5. Interface Panel on Remote Enclosure

ON

OPERATOR

INTERFACE

ENCODER

LABEL

SENSOR

PRODUCT

SENSOR

LOW LABEL

SENSOR

OPERATOR INTERFACE: Plug in which the Operator Panel

is connected. Cycling power is required when connected or

disconnected.

ENCODER: Plug in which an optional encoder is connected. The

encoder is used for synchronous mode labeling, which can apply

the label at the speed the product is traveling. It is recommended

to use an incremental encoder with at least 1024 increments.

LOW LABEL SENSOR: Plug in which the low label sensor is

connected. The low label sensor is found behind the unwind

assembly wheel.

PRODUCT SENSOR: Plug in which the product sensor is

connected.

LABEL SENSOR: Plug in which the label sensor is connected.

The label sensor is found on the wiper arm assembly.

DISCONNECT SWITCH:

Allows the operator to

complete disconnect power

to the labeler, or connect

power. Turn ON to connect

power; Turn to OFF to

disconnect power.

Table of contents

Popular Label Maker manuals by other brands

CAB

CAB Hermes C Series Service manual

Brother

Brother QL 570 - P-Touch B/W Direct Thermal Printer Setup & operation guide

Avery Dennison

Avery Dennison ALS 230 user manual

Dymo

Dymo 1752265 user guide

Intermec

Intermec EasyCoder E4 Linerless user guide

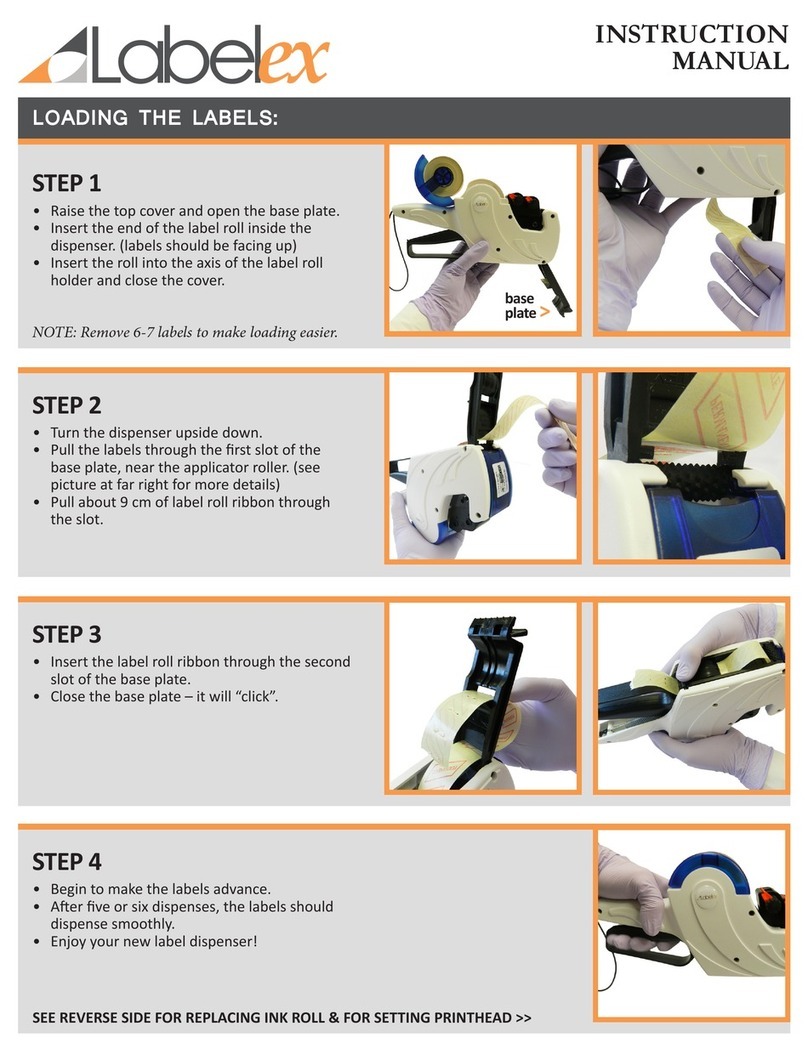

Duraline Systems

Duraline Systems Labelex instruction manual