2

Throughout this manual are special at-

tention statements.

DANGER!

A statement preceded by the trian-

gular attention symbol and the word

“DANGER” indicates an imminently

hazardous situation which, if not

avoided, WILL result in death or seri-

ous injury!

WARNING!

A statement preceded by the trian-

gular attention symbol and the word

“WARNING” indicates a potentially

hazardous situation which, if not

avoided, COULD result in death or

serious injury.

CAUTION!

A statement preceded by the word

“CAUTION” contains information that

should be acted upon to avoid dam-

age to the machine.

IMPORTANT!

A statement preceded by the word

“IMPORTANT” is one that possesses

special signicance.

NOTE:

A statement preceded by the word

“NOTE” contains information that is handy

to know and may make your job easier.

Attention Statements

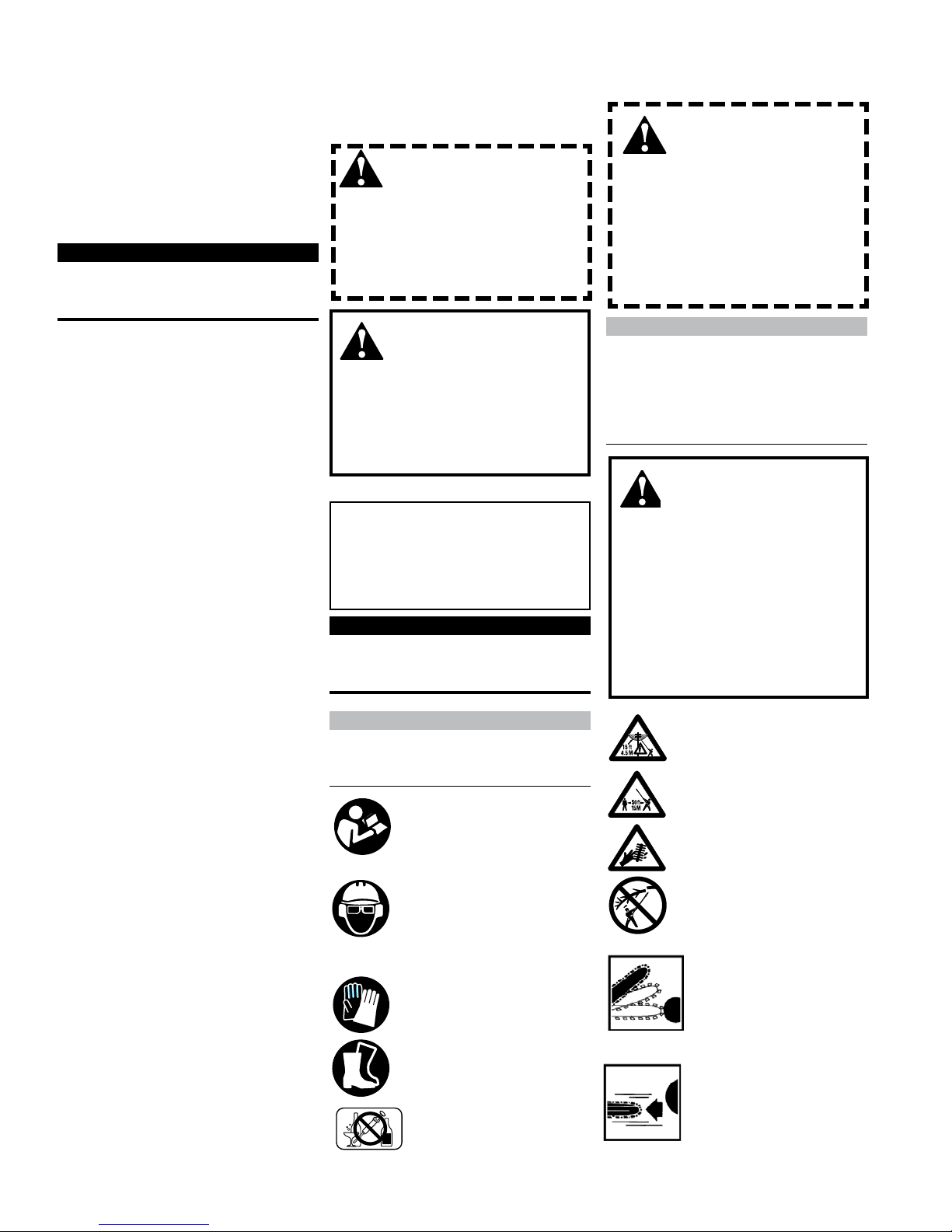

Introduction Safety Precautions

Read and follow this manual, make sure

anyone using the trimmer does likewise.

Failure to do so could result in serious

personal injury or machine failure. Keep

this manual for future reference.

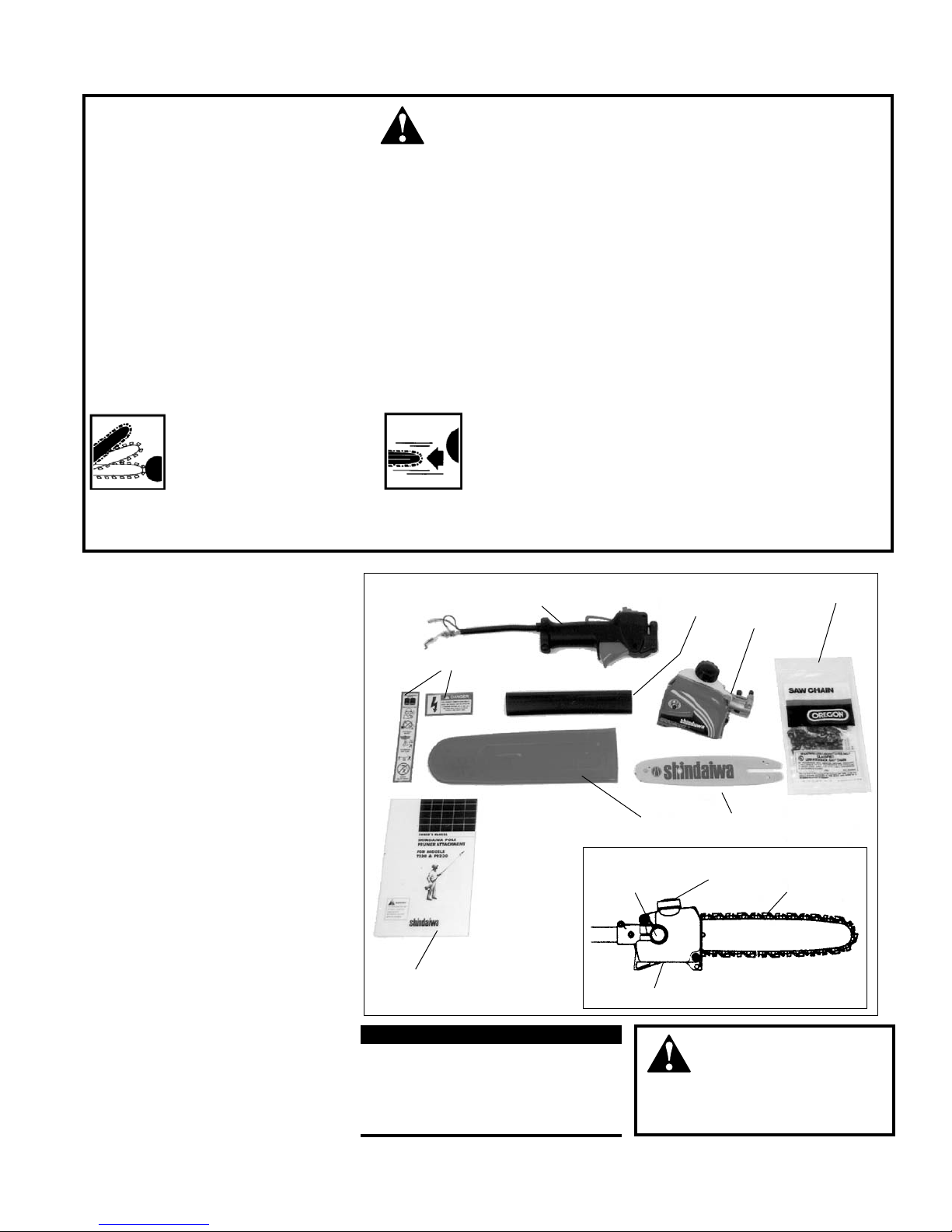

Always wear a hard hat to reduce the risk

of head injuries during operation of this

machine.

In addition, always wear eye and hearing

protection. Shindaiwa recommends wearing

a face shield as additional face and eye

protection.

Wear heavy duty, non-slip gloves.

Safety tip shoes or boots with non-slip

sole should be worn.

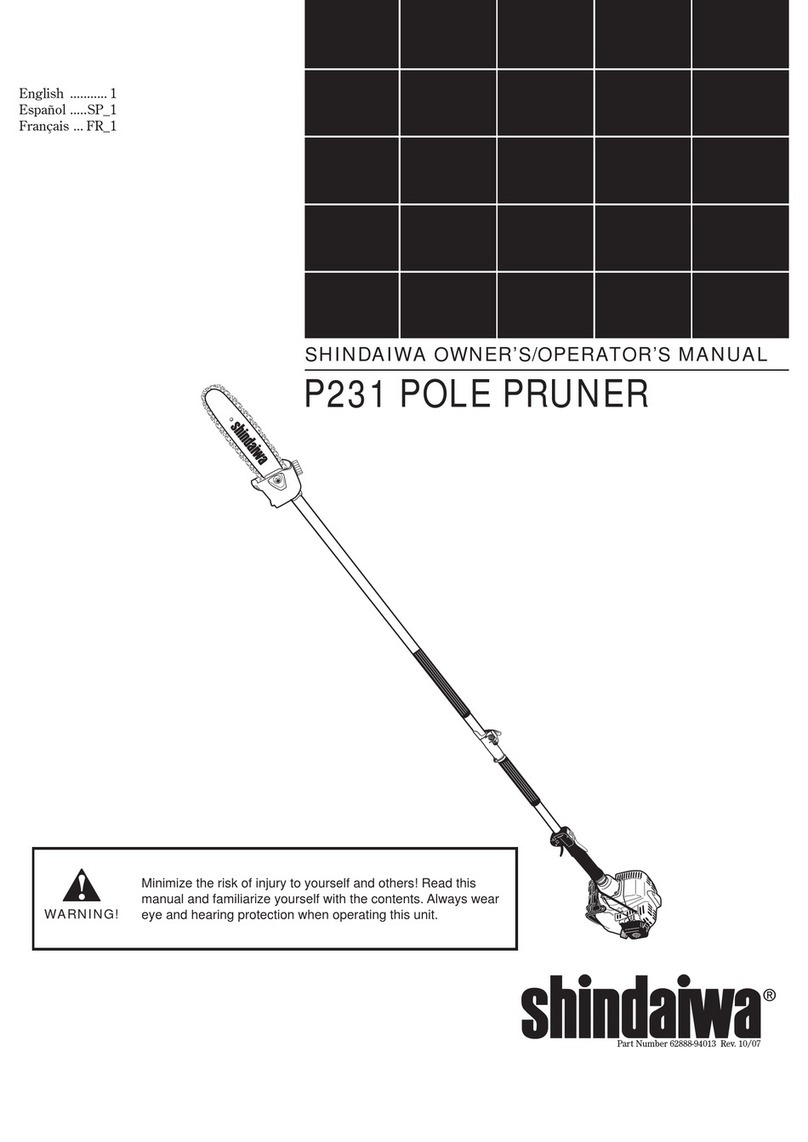

The Shindaiwa Pole Pruner Attachment

is designed and built to deliver superior

performance and reliability without

compromise to quality, comfort, safety or

durability.

As an owner/operator, you'll soon

discover for yourself why Shindaiwa is

simply in a class by itself!

While every attempt has been made to

provide the latest information about your

Shindaiwa product, there may be some

differences between your attach- ment

and what is described here. Echo, Inc.

reserves the right to make changes

to products without prior notice and

without obligation to make alterations to

components previously manufactured.

The procedures described in this manual

are intended to help you get the most

from your machine as well as to protect

you and others from harm. These pro-

cedures are guidelines for safe opera-

tion under most conditions, and are not

intended to replace any safety rules and/

or laws that may be in force in your area.

If you have questions regarding your

power tool, or if you do not under-

stand something in this manual, your

Shindaiwa dealer will be glad to assist

you.

You may also contact Shindaiwa at the

address printed on the back of this

manual.

NOTE:

For specic maintenance and safety infor-

mation about your T230/231, AH230/231,

or PB230, consult the owner's manual

provided with it. If it has been lost or

misplaced, contact a Shindaiwa dealer for

a replacement.

WARNING!

THE PRUNER IS NOT INSULATED

AGAINST ELECTRICAL SHOCK!

Approaching or contacting electrical

line with the pruner could cause

death or serious injury. Keep the

pruner at least 33 feet (10 meters)

away from electrical lines or branch-

es that contact electrical lines.

IMPORTANT!

The information contained in these

instructions describes components

available at the time of publication.

PAGE

Contents

WARNING!

A pole pruner runs at very high

speeds and has the potential to do

serious damage if misused, abused

or mishandled. To reduce the risk

of injury, you must maintain control

at all times, and observe all safety

precautions during operation. Never

permit a person without train-

ing or instruction to operate this

pruner!

Introduction ............................................ 2

Attention Statements ............................. 2

Safety Precautions.................................. 2

Operating Precautions .......................... 3

Safety Labels........................................... 4

Operating the Pruner ............................ 4

Product Description............................... 5

Specifications.......................................... 6

Assembly............................................... ..6

Filling the Chain Oiler Reservoir ......... 8

Maintenance ........................................... 9

Sharpening the Chain ......................... 10

Troubleshooting Guide ....................... 12

This product conducts electricity. Keep

the product and/or operator a minimum

distance of 15 feet (4.5 meters) away

from electrical sources and power lines.

Keep bystanders at least 50 feet (15 me-

ters) away from the operating trimmer

to reduce the risk of being struck by

falling objects or thrown debris.

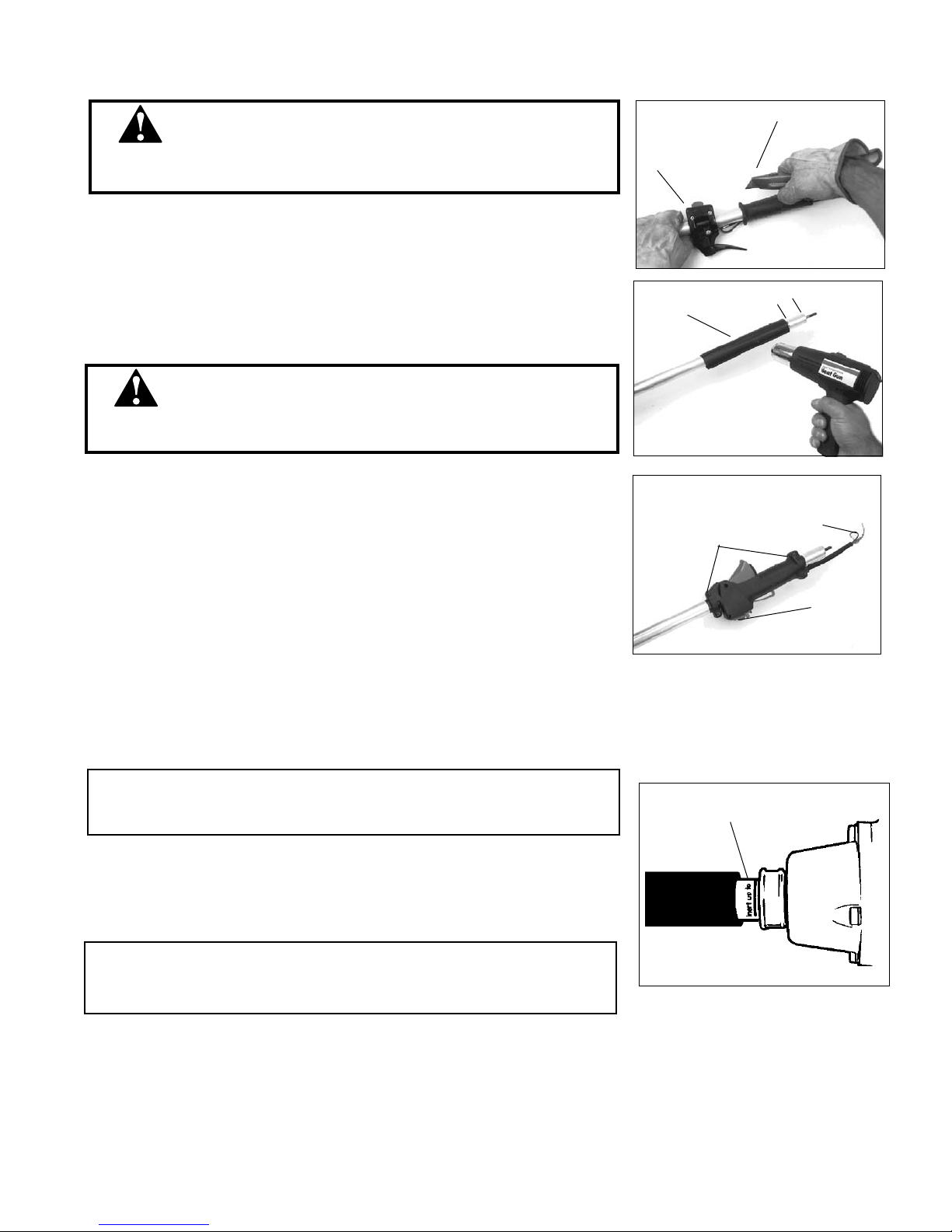

The blades / cutting attachments are

SHARP! Handle with care.

Be aware of the danger of falling debris.

Beware of pinching.

Pinching the saw along the tip of the

guide bar may force the bar back

rapidly toward the operator. Pinching

can occur whenever wood closes in

around the moving chain.

Beware of Kickback!

Kickback can occur whenever the

tip of the guide bar touches an object

while the saw is operating. Kickback

may force the bar up and back

toward the operator with lightning-

like speed!

Never operate power equipment of any

kind if you are tired or if you are under

the inuence of alcohol, drugs, medica-

tion or any other substance that could

affect your ability or judgement.