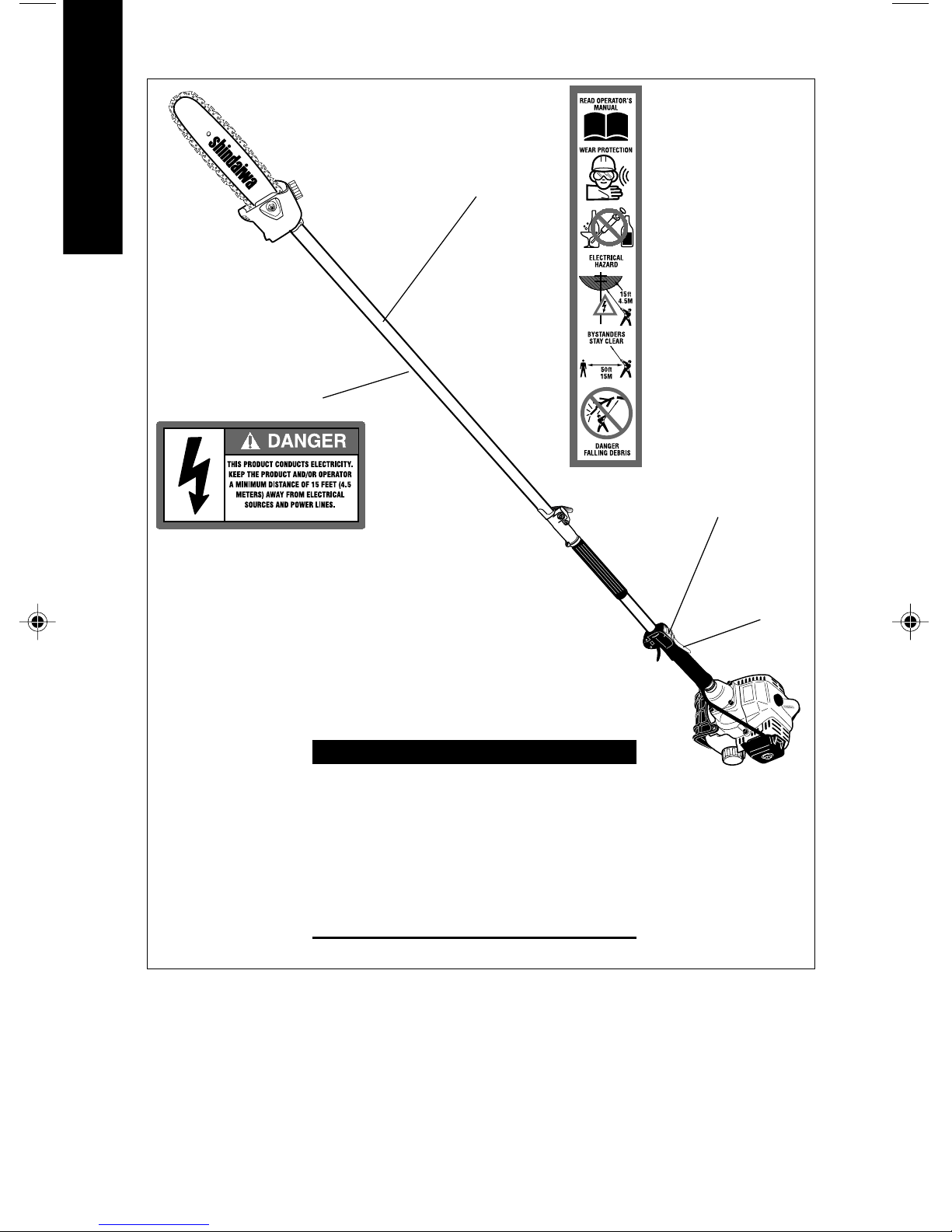

Operating Precautions

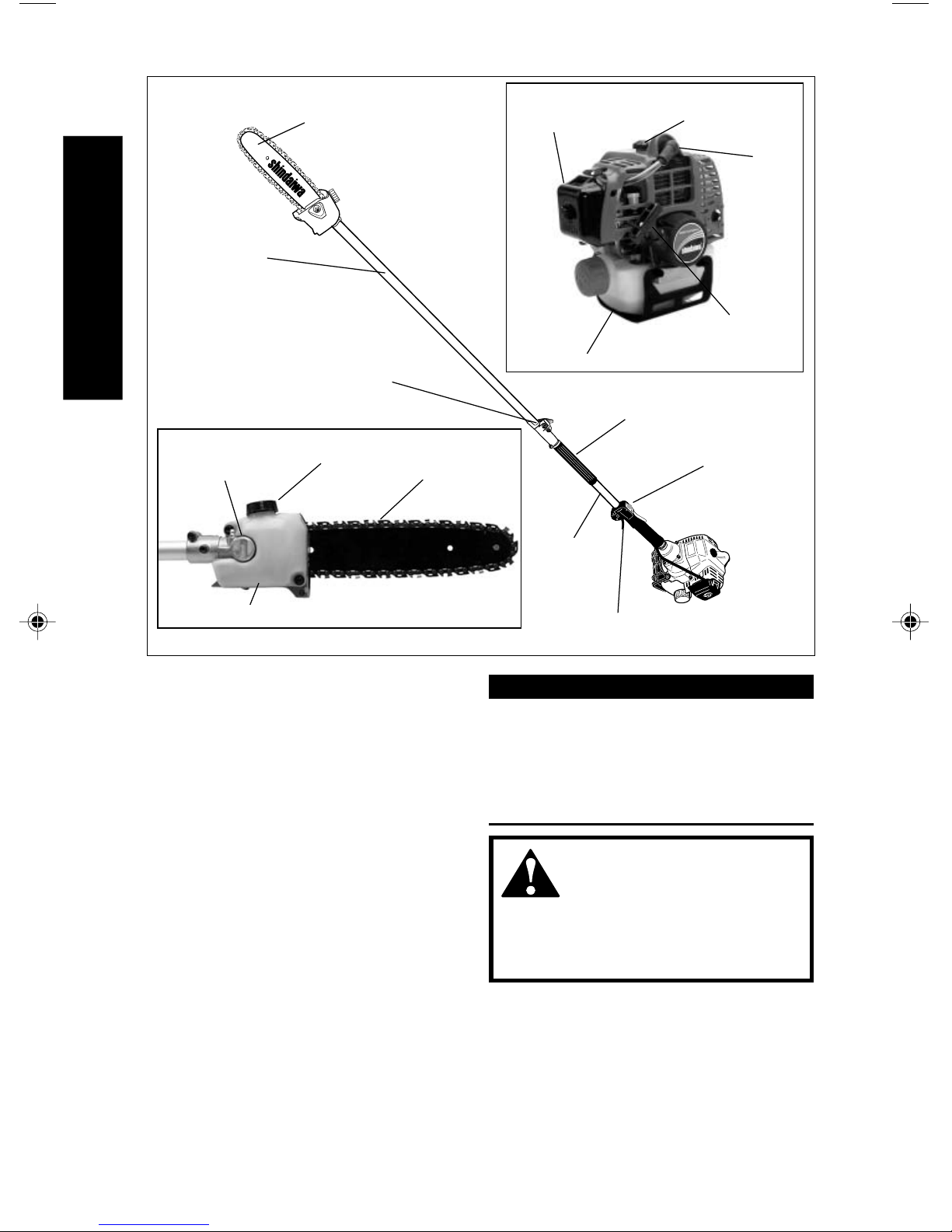

■Make sure the chain and

sprocket are correctly adjusted

before operating the pruner

(see page 15 for adjustment

procedures). Never attempt

chain adjustment with the

engine running!

■Always make sure the cutting

attachment is properly

installed and firmly tightened

before operation.

■Never use a cracked or

warped guide bar: replace it

with a serviceable guide bar

and make sure it fits properly.

■If a saw blade should bind fast

in a cut, shut off the engine

immediately. Push the branch

or tree to ease the bind and

free the blade.

■Make sure there are no missing

or loose fasteners, and that the

ignition switch and throttle

controls are working properly.

■Before starting the engine,

make sure the saw chain is

not contacting anything.

■Make sure there is always

good ventilation when operat-

ing the pruner. Fumes from

engine exhaust can cause

serious injury or death. Never

run the engine indoors!

■Do not operate the pole pruner

with the muffler removed.

■When cutting a limb that is

under tension, be alert for

springback so that you will not

be struck by the moving limb.

■Always stop the engine

immediately and check for

damage if you strike a foreign

object or if the unit becomes

tangled. Do not operate with

broken or damaged equipment.

■Stop the unit immediately if it

suddenly begins to vibrate or

shake. Inspect for broken,

missing or improperly in-

stalled parts or attachments.

■Never transport the pruner

nor set it down with the

engine running. An engine

that’s running could be

accidentally accelerated

causing the chain to rotate.

7

WARNING!

Use Good Judgement

SAFETY

WARNING!

Minimize the Risk of Fire

■NEVER smoke or light fires

near the unit.

■ALWAYS stop the engine and

allow it to cool before refuel-

ing. Avoid overfilling and wipe

off any fuel that may

have spilled.

■ALWAYS move the unit to a

place well away from a fuel

storage area or other readily

flammable materials before

starting the engine.

■ALWAYS inspect the unit for

fuel leaks before each use.

During each refill, check that no

fuel leaks from around the fuel

cap and/or fuel tank. If fuel leaks

are evident, stop using the unit

immediately. Fuel leaks must be

repaired before using the unit.

■NEVER place flammable

material close to the engine

muffler.

■NEVER run the engine without

the spark arrester screen in place.

P230_OM_62887-94011_01EC 8/18/05, 15:327