SICK UE402 User manual

O

P E R A T I N G IN S T R U C T I O N S

Operating Instructions

2©SICK AG • Industrial Safety Systems • Germany • All rights reserved 8 009 874/31-03-03

This document is protected by the law of copyright, whereby all rights established therein remain with the com-

pany SICK AG. Reproduction of this document or parts of this document is only permissible within the limits of the

legal determination of Copyright Law. Alteration or abridgement of the document is not permitted without the

explicit written approval of the company SICK AG.

Operating Instructions

8009 874/31-03-03 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 3

1.1 Function of this document ........................................................................................5

1.2 Target group...............................................................................................................5

1.3 Depth of information .................................................................................................5

1.4 Abbreviations .............................................................................................................6

1.5 Symbols used.............................................................................................................6

! "

2.1 Specialist personnel ..................................................................................................8

2.2 Applications of the device .........................................................................................8

2.3 Correct use.................................................................................................................8

2.4 General protective notes and protective measures ................................................9

2.5 Protection of the environment ..................................................................................9

# $

3.1 Special features.......................................................................................................10

3.2 Operating principle of the device............................................................................10

3.2.1 Principle of the device.................................................................................10

3.3 Configurable functions ............................................................................................10

3.3.1 Bypass..........................................................................................................11

3.3.2 PSDI mode ...................................................................................................12

3.3.3 Teach-in........................................................................................................16

3.4 Operating modes .....................................................................................................16

3.4.1 Scope of configurable functions.................................................................16

3.4.2 Functions that cannot be combined ..........................................................18

3.5 Display elements .....................................................................................................19

%

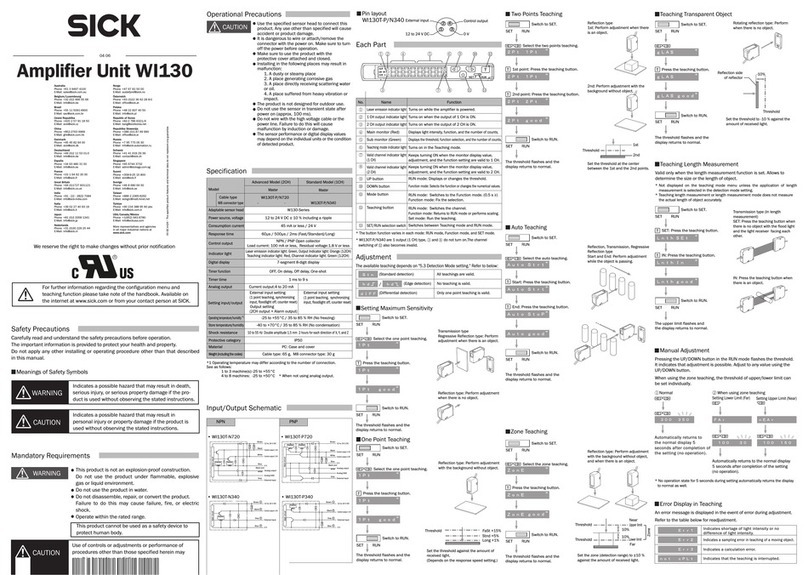

5.1 Connections of the UE 402.....................................................................................21

5.2 Operating mode selector switch .............................................................................23

5.3 Key-operated pushbutton for bypass .....................................................................23

5.4 Teach-in key-operated switch..................................................................................24

5.5 Machine-cycle contacts ...........................................................................................24

& ' &

( ' (

7.1 Preparing the configuration ....................................................................................27

" ) "

8.1 What to do in case of faults ....................................................................................28

8.2 SICK Support............................................................................................................28

8.3 Error displays of the diagnostics LEDs ...................................................................29

8.4 Additional error displays of the 7-segment display of the C 4000 .......................29

8.5 Extended diagnosis .................................................................................................30

Operating Instructions

4©SICK AG • Industrial Safety Systems • Germany • All rights reserved 8 009 874/31-03-03

* + #

9.1 Data sheet ............................................................................................................... 31

9.2 Dimensional drawing .............................................................................................. 32

##

10.1 Delivery .................................................................................................................... 33

10.2 Accessories.............................................................................................................. 33

,#

11.1 Declaration of conformity ....................................................................................... 34

11.2 List of tables............................................................................................................ 35

11.3 List of illustrations................................................................................................... 35

Operating Instructions Chapter

8009 874/31-03-03 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 5

Please read this chapter carefully before working with this documentation and the UE 402.

)

These operating instructions are designed to address the technical personnel of the

machine manufacturer or the machine operator in regards to safe mounting, installation,

configuration, electrical installation, commissioning, operation and maintenance of the

switching amplifier UE 402 in connection with the safety light curtain C 4000.

These operating instructions do not provide instructions for operating machines on which

the UE 402 resp. the safety light curtain is, or will be, integrated. Information on this is to

be found in the appropriate operating instructions of the machine.

+

These operating instructions are addressed to planning engineers, developers and the

operators of plant and systems which are to be protected by one or several safety light

curtains C 4000 in connection with the switching amplifier UE 402. It also addresses

people who integrate the UE 402 into a machine, initialise its use, or who are in charge of

servicing and maintaining the unit.

# -

These operating instructions contain information on:

installation and mounting

electrical installation

putting into operation and

parameterization

fault, error diagnosis and

troubleshooting

part numbers

conformity and approval

of the switching amplifier UE 402 in connection with the safety light curtain C 4000.

Planning and using protective devices such as the C 4000 also require specific technical

skills which are not detailed in this documentation.

When operating the UE 402 in connection with the safety light curtain C 4000, the na-

tional, local and statutory rules and regulations must be observed.

General information on health and safety at work and accident prevention using opto-

electronic protective devices can be found in the brochure “Safe machines with opto-

electronic protective devices”.

We also refer you to the SICK homepage on the Internet at

www.sick.com

Here you will find information on:

sample applications

alist of Frequently Asked Questions about the C 4000 in connection with the UE 402

these operating instructions in different languages for viewing and printing

certificates on the prototype test, the EC declaration of conformity and other documents

.

Chapter Operating Instructions

6©SICK AG • Industrial Safety Systems • Germany • All rights reserved 8 009 874/31-03-03

/

Electro-sensitive protective equipment (e.g. C 4000)

SICK Configuration & Diagnostic Software = software for configuration and diagnostics on

the UE 402

Bottom dead centre. Indicates that the bottom dead centre has been reached on a press

External device monitoring

Machine cycle contact. Indicates that a certain point in the machine cycle has been

reached on a press

Output signal switching device

Presence sensing device initiation = PSDI mode

Stop control contact = Run-on monitoring. Indicates the end of the expected stopping path

on a press

Top dead centre. Indicates that the top dead centre has been reached on a press

!

Recommendations are designed to give you some assistance in your decision-making

process with respect to a certain function or a technical measure.

Refer to notes for special features of the device.

Display indicators show the status of the 7-segment display of sender or receiver:

Constant indication of characters, e.g. U

Flashing indication of characters, e.g. 8

Alternating indication of characters, e.g. L and 2

The depiction of numbers on the 7-segment display can be rotated by 180° with the aid of

the CDS. In this document the depiction of the 7-segment display is however always in the

normal, non-rotated position. Please consult the C 4000 operating instructions for a de-

tailed description of the C 4000 indicators.

LED symbols describe the state of a diagnostics LED. Examples:

Yellow The yellow LED is illuminated constantly.

Yellow The yellow LED is flashing.

Yellow The yellow LED is off.

Instructions for taking action are shown by an arrow. Read carefully and follow the instruc-

tions for action.

0 1

Awarning notice indicates an actual or potential risk or health hazard. They are designed

to help you to prevent accidents.

Read carefully and follow the warning notices!

Software notes show the location in the CDS (Configuration & Diagnosis Software) where

you can make the appropriate settings and adjustments. Go to the menu View,Dialog box

of the CDS and activate the item File cards to view the named dialog fields as required.

Alternatively, the Software Assistant will guide you through the appropriate setting.

The software notes contained in the operating instructions of the safety light curtain

C 4000 apply accordingly in connection with the UE 402. Depending on the scope of the

respective function (see page 16 of this document) you will find the corresponding setting

in the CDS below the select System or Operating mode of the CDS configuration dialog.

$

'-

2-'

-3

3''

-

$-%

''

+-'

4

.

5

6

66

6,6

66

6,

6

66

6

Take action …

WARNING

Operating Instructions Chapter

8009 874/31-03-03 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 7

/

In drawings and diagrams, the symbol denotes the C 4000 sender and the symbol

denotes the C 4000 receiver.

+7 8

The dangerous state (standard term) of the machine is always shown in the drawings and

diagrams of this document as the movement of a machine part. In practical operation,

there may be a number of different dangerous states:

machine movements

electrical conductors

visible or invisible radiation

a combination of several risks and hazards

Chapter Operating Instructions

8©SICK AG • Industrial Safety Systems • Germany • All rights reserved 8 009 874/31-03-03

!

!

This chapter deals with your own safety and the safety of the equipment operators.

Please read this chapter carefully before working with the UE 402 or with the machine

protected by the safety light curtain C 4000 in connection with the UE 402.

The switching amplifier UE 402 must be installed, commissioned and serviced only by

specialist personnel. Specialist personnel are defined as persons who

have undergone the appropriate technical training

and

who have been instructed by the responsible machine operator in the operation of the

machine and the current valid safety guidelines

and

who have access to the operating instructions of the UE 402 and of the safety light

curtain C 4000.

/

The switching amplifier UE 402 is a SICK safety light curtain C 4000 accessory. It extends

the technical application possibilities of the C 4000. The physical resolution, the maximum

protective field width and the realizable protective field height of the C 4000 are not

changed by deploying the UE 402.

It may be necessary to install additional mechanical protective devices when using the

C4000 in connection with the UE 402.

# '

The switching amplifier UE 402 must be used only as defined in chapter 2.2 “Applications

of the device”. It must be used only by qualified personnel and only on the machine where

it has been installed and initialised by qualified personnel.

If the device is used for any other purposes or modified in any way – also during mounting

and installation – any warranty claim against SICK AG shall become void.

Operating Instructions Chapter

8009 874/31-03-03 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 9

!

9 / /

!

Please observe the following procedures in order to ensure the correct and safe use of the

safety light curtain in connection with the UE 402.

Please observe the notes in the chapter titled “General protective notes and protective

measures” of the C 4000 operating instructions.

Moreover, it may be necessary to observe the following standards, among other things,

for your particular application:

–EN 692: Mechanical Presses, Safety

–EN 693: Hydraulic Presses, Safety

The C 4000 and UE 402 operating instructions must be made available to the operator

of the machine, with which the safety light curtain C 4000 is used in connection with the

UE 402. The machine operator is to be instructed in the use of the device by specialist

personnel and must be instructed to read the operating instructions.

The UE 402 must be connected to the same external voltage supply as the safety light

curtain. The voltage supply must be capable of buffering brief mains voltage failures of

20 ms as specified in EN 60204-1. Suitable power supplies are available as accessories

from SICK (Siemens type series 6 EP 1).

$/

The switching amplifier UE 402 has been designed to minimise environmental impact. It

uses only a minimum of power and natural resources.

At work, always act in an environmentally responsible manner. For this reason please note

the following information on disposal.

-

Always dispose of unserviceable or irreparable devices in compliance with local/national

rules and regulations with respect to waste disposal.

We would be pleased to be of assistance on the disposal of this device. Contact your local

SICK representative.

WARNING

.

Chapter #Operating Instructions

10 ©SICK AG • Industrial Safety Systems • Germany • All rights reserved 8 009 874/31-03-03

$

#$

This chapter provides information on the special features and properties of the UE 402. It

describes the construction and the operating principle of the device, in particular the dif-

ferent operating modes in connection with the safety light curtain C 4000.

Please read this chapter before mounting, installing and commissioning the device.

The functions of the UE 402 can only be used in conjunction with the C 4000 safety light

curtain Standard or C 4000 Advanced with the following entry on the type label in the field

Software version:3.00 or later.

#

The switching amplifier UE 402 extends the application possibilities of the safety light

curtain C 4000:

6operating modes are predefinable (see page 16)

PSDI mode (see page 12)

protective field evaluation bypass (see page 11)

teach-in mode: Adjusting the blanked-out areas directly on the device through the

corresponding objects in the protective field (see page 16)

# /

# $/

The UE 402 is an electronic module. It processes certain signals of the safety light curtain

C4000 or the cascading C 4000 and merges them with the signals of other connected

systems. These systems may include:

an operating mode selector switch

ateach-in key-operated switch

akey-operated pushbutton for bypass

machine cycle contacts, e.g. for the top and bottom dead centres of a press

The UE 402 is usually installed in the control cabinet.

## '

This chapter describes the functions of the safety light curtain C 4000 which are select-

able via software, which can only be used in connection with switching amplifier UE 402.

The functions can be partially combined with the other configurable functions of the safety

light curtain.

+// ! 1

Each time the configuration is changed you must test the effectiveness of the entire pro-

tective device (see chapter titled “Test notes” in the operating instructions of the safety

light curtain C 4000).

.

WARNING

Operating Instructions Chapter #

8009 874/31-03-03 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 11

$

## 2!

In some applications it is at times necessary to mute the protective field evaluation of

the safety light curtain. This could be, e.g., in a safe machine setup mode, in which the

machine can be operated only at walking speed. When the bypass is active, the safety light

curtain displays Green and the 7-segment display of the receiver displays .

!5! 1

While the bypass function is active, the safety light curtain will not detect any intervention

in the protective field. You must ensure that other protective measures are forcibly acti-

vated during the bypass, e.g. the safe machine setup mode, so that the machine cannot

endanger persons or parts of the machine during the bypass function.

The bypass function may only be activated by a key-operated switch with an automatic

reset and two levels or by two input signals that are independent of each other, e.g. two

positioning switches.

It must be possible to view the entire hazardous point when pressing the key-operated

switch.

When you activate the bypass function, you can only connect a teach-in key-operated

switch (see page 24) directly to the C 4000, because the corresponding terminals of the

UE 402 are occupied by the key-operated pushbutton for bypass.

It is not possible to combine the bypass and PSDI mode functions.

The safety light curtain terminates the bypass function automatically, when …

–the operator starts a teach-in procedure.

–the operator changes the operating mode.

–there is a signal change at the Emergency Stop input on the C 4000.

– a system error (lock-out) occurs.

200 ms after switching off the bypass, the system is again in a safe status (latency time).

Device symbol C4000 Host (receiver),context menu Configuration draft,Edit,selection of

the operating mode,file card General,option Bypass.

The connection of the key-operated pushbutton for bypass is described in chapter 5.3

“Key-operated pushbutton for bypass” on page 23.

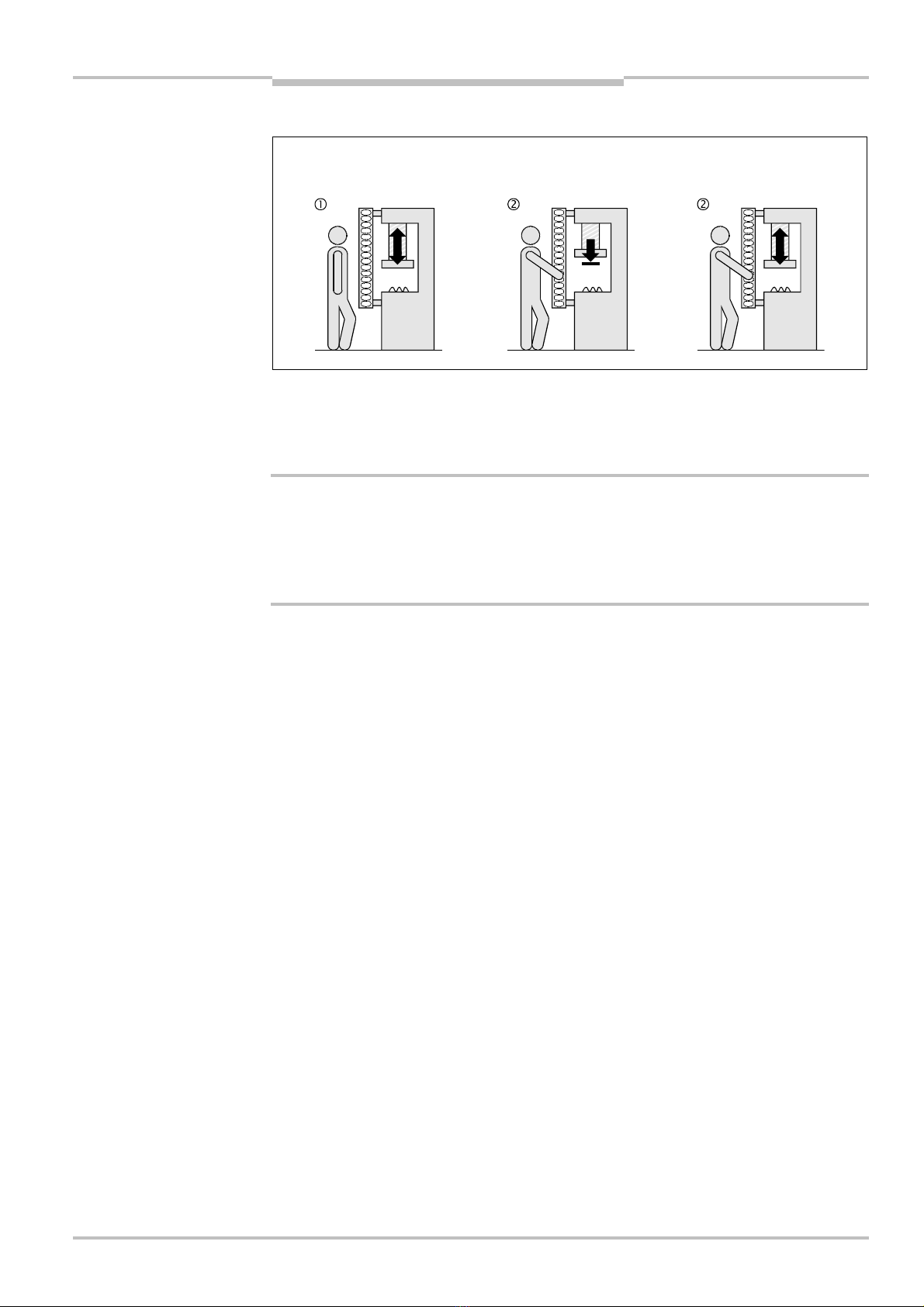

Fig.

1

:

Schematic layout of

the bypass function

WARNING

.

Bypass

inactive

Bypass

active

Chapter #Operating Instructions

12 ©SICK AG • Industrial Safety Systems • Germany • All rights reserved 8 009 874/31-03-03

$

## $-%

In the PSDI mode, the machine waits at the top dead centre for a defined number of inter-

ruptions by the operator. After a certain number of interruptions, the safety light curtain

automatically releases the dangerous movement. Dual mode PSDI means e.g., that the

safety light curtain causes the movement to block after the first interruption by the opera-

tor (). The safety light curtain does not release the movement until the operator has com-

pleted the second interruption ()().

The PSDI mode function can only be configured for light curtains with an effective opera-

ting resolution of 30 mm.

Device symbol C4000 Host (receiver),context menu Configuration draft,Edit,selection of

the operating mode,file card General,area PSDI mode.

$-%

In the case of active PSDI time monitoring, the maximum duration of an entire PSDI is

limited to 30 seconds.

The 30 seconds start by the machine being stopped at the top dead centre.

When the final PSDI interruption of an entire PSDI is not terminated within this time, the

safety light curtain remains red and waits until the reset button has been pressed.

PSDI time monitoring has been configured by default and can be deactivated.

Device symbol C4000 Host (receiver),context menu Configuration draft,Edit,selection of

the operating mode,file card General,option PSDI time monitoring active.

$-%

You can determine the section of the protective field in which the safety light curtain can

interpret an interruption as a PSDI. This section of the protective field is called the PSDI

window.

If you configure a PSDI window as shown in Fig. 3, the safety light curtain only interprets

as a valid PSDI interruption.

You can only define one PSDI window. This also applies to a cascading system.

At least one beam must be free between the PSDI window and adjacent blanked-out

areas.

If you do not define a PSDI window, all areas of the protective field that have not been

blanked out are PSDI windows.

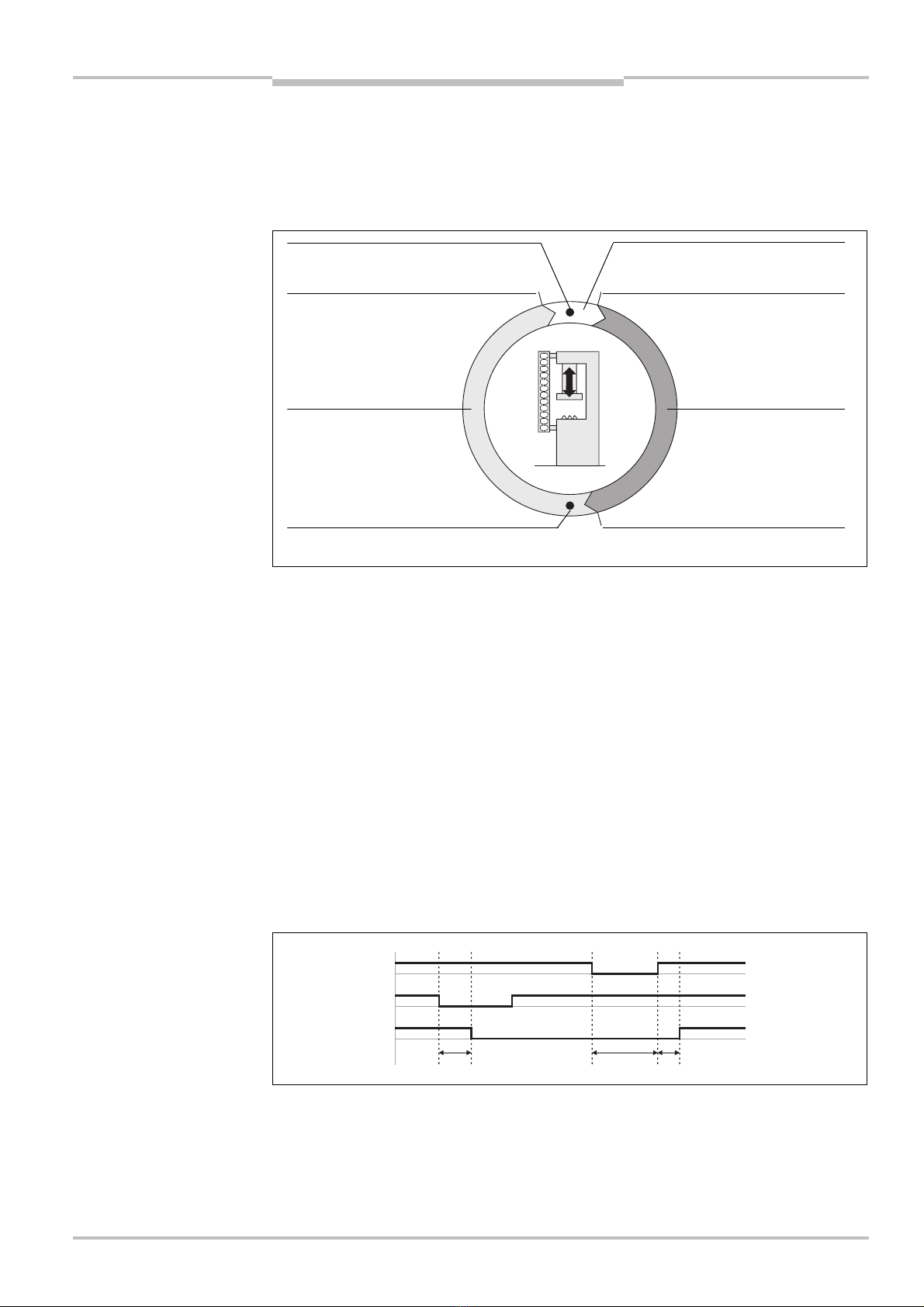

Fig.

2

:

Schematic layout of

the dual mode PSDI

.

Fig.

3

:

Function of the PSDI

window

.

PSDI window PSDI window

Invalid cycle

interruption

Valid PSDI

interruption

Operating Instructions Chapter #

8009 874/31-03-03 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 13

$

Device symbol C4000 Host (receiver),context menu Configuration draft,Edit,selection of

the operating mode,file card General,option PSDI window.You must then specify the

beginning and the size of the PSDI window on file card Host or Guest of the system in

question.

! $-%

To ensure that the PSDI mode operation is safe and true to the application, C 4000 in con-

nection with UE 402 evaluates three machine signals:

run-on monitoring (SCC)

Run-on monitoring evaluation is optional.

bottom dead centre (MCC-BDC)

top dead centre (MCC-TDC)

On the basis of the three machine signals, the safety light curtain can identify the

machine’s current cycle phase:

Downward movement of the press. This cycle phase involves danger.

Upward movement of the press. This cycle phase does not involve danger for all

machines.

Stopping the press. This cycle phase does not involve danger provided the “Run-on

monitoring” machine signal is not followed.

The figure below clarifies the process in time with the aid of an example of the single PSDI

mode:

aMax. 150 ms after reaching the machine cycle contact MCC-TDC, the output signal

switching devices (OSSDs) fall away.

bThe operator reaches into the protective field for at least 100 ms. The protective device

therefore recognizes the interruption as the PSDI.

cThe protective contacts close again no longer than 200 ms after the last PSDI.

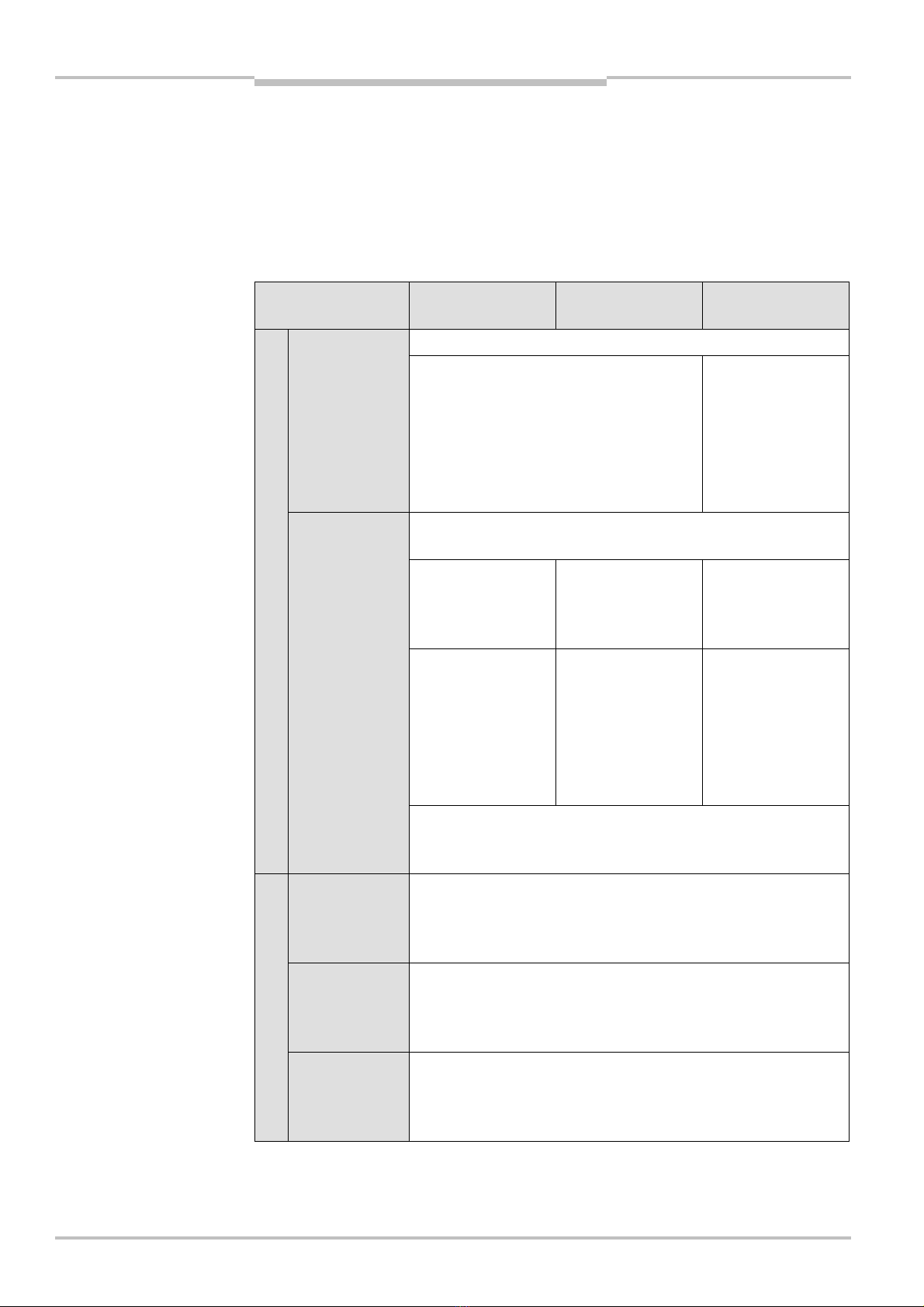

Fig.

4

:

Schematic layout of

the machine cycle for PSDI

mode operation for the

example of a press

Fig.

5

:

Time-process diagram

for single PSDI mode

Machine cycle contact at

top dead centre (MCC-TDC)

Run-on monitoring (SCC)

Machine cycle contact at bottom

dead centre (MCC-BDC)

Cycle phase :

downward

movement of the

press

Cycle phase :

upward movement of the

press

Cycle phase :

stopping path of the press

Top dead centre (TDC)

Bottom dead centre (BDC)

Protective field

MCC-TDC

OSSDs

cba

Unoccupied

Occupied

Closed

Open

Closed

Open

Chapter #Operating Instructions

14 ©SICK AG • Industrial Safety Systems • Germany • All rights reserved 8 009 874/31-03-03

$

The C 4000 does not offer control and monitoring functions for reverse operations or

single-stroke safety. In other words,the safety light curtain cannot detect any reverse

movement of the machine.

The electrical connection of the machine cycle contact is described in chapter 5.5

“Machine-cycle contacts” on page 24.

:;$-% <

The UE 402 support three start sequences in PSDI mode:

/

;738<

0

=

The machine cycle contact MCC-TDC must be connected.4:

The internal restart interlock of the

C4000 must be activated.

The internal restart

interlock of the

C4000 is

deactivated.

An external restart

interlock must be

available.

You have just switched on the machine or have switched the

machine to an operating mode with the PSDI mode.

The Yellow LED

of the host system

is illuminated

constantly.

The Yellow LED

of the host system

is flashing.

The Yellow LED

of the host system

is illuminated

constantly.

Reach once or

twice into the

protective field

according to the

PSDI mode.

Press the reset

button.

Press the reset

button.

Reach once or

twice into the

protective field

according to the

PSDI mode.

Reach once or

twice into the

protective field

according to the

PSDI mode.

:

$

The machine runs until it reaches the top dead centre and waits

there for the cycle. The Yellow LED of the host receiver is then

illuminated constantly.

%

/;<

The safety light curtain changes to red.

%

/;<

The behavior of the safety light curtain depends on the PSDI

control (see “Eccentric press mode” further below).

$-% !

%

;<

First interruption: PSDI starts

Last interruption: PSDI ends. The safety light curtain reverts to

Green as soon as the protective field interruption is ended.

.

Tab.

1

:

Possible start

sequences in PSDI mode

Operating Instructions Chapter #

8009 874/31-03-03 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 15

$

4 $-%

You can release the PSDI control in two different ways:

Limited: The safety light curtain only evaluates interruptions within the stopping phase

as a PSDI, i.e. if the machine cycle contact was made for the top dead centre (MCC-TDC)

and has also fallen away again.

Not limited: The safety light curtain also evaluates interruptions within the upward and

stopping phases as PSDIs if the machine cycle contact is made for the top dead centre

(MCC-TDC) and has not yet fallen away again. This configuration makes higher clock

speeds possible.

$-% !

1

If you wish to set the release of the PSDI control to Not limited,then you must make

sure at the machine side that the machine stops automatically at the top dead centre.

For this you must always observe the standards that apply for your specific applica-

tion/machine situation.

Device symbol C4000 Host (receiver),context menu Configuration draft,Edit,selection of

the operating mode,file card General,option Enable PSDI control.

4>

The purpose of run-on monitoring is to detect any failure of the machine brake at the top

dead centre. If you activate run-on monitoring, the UE 402 in front of the stroke release

monitors whether the SCC is still closed, i.e. whether the machine has actually stopped at

the top dead centre.

If the press exceeds the SCC before the operator has intervened once or twice depending

on the PSDI mode, the C 4000 switches to lock-out.

The SCC contact must be connected for run-on monitoring.

Device symbol C4000 Host (receiver),context menu Configuration draft,Edit,selection of

the operating mode,file card General,option Run-on monitoring active.

Eccentric presses must not be allowed to stop at the bottom dead centre because their

construction does not enable them to stop in this situation. In eccentric press mode, the

safety light curtain mutes the protective field function in this phase. The muting begins

when the machine cycle contact for the bottom dead centre is reached. You must ensure

that the machine cycle contact for the bottom dead centre is not made until after the end

of the dangerous movement. The muting ends when the machine cycle contact for top

dead centre is reached, but no longer than after 30 seconds.

When you configure the eccentric press mode you must also connect the machine cycle

contact for the bottom dead centre (MCC-BDC). The connection is described in chapter 5.5

“Machine-cycle contacts” on page 24.

$ 1

In eccentric press mode, you must take suitable measures to ensure that no dangerous

state can occur while muting is active.

Device symbol C4000 Host (receiver),context menu Configuration draft,Edit,selection of

the operating mode,file card General,option Eccentric press mode active.

WARNING

.

.

WARNING

Chapter #Operating Instructions

16 ©SICK AG • Industrial Safety Systems • Germany • All rights reserved 8 009 874/31-03-03

$

In eccentric press mode with release mode “not limited”, the safety light curtain only de-

tects an interruption during the total muting time as PSDI, if the interruption lasts longer

than the time it takes to reach the machine cycle contact for the top dead centre

(MCC-TDC).

### + >

The configurable Teach-in function has been realized in the safety light curtain C 4000 and

explained in the appropriate operating instructions. The electrical connection of the teach-

in key-operated switch on the UE 402 is described in chapter 5.4 “Teach-in key-operated

switch” of this document on page 24.

#

You can configure up to six operating modes with the aid of the CDS. The operator can

switch between these operating modes by means of an operating mode selector switch.

This section describes the scope of the configured functions and the possibilities for com-

bining them.

The operating mode selector switch must be a key-operated switch.

You can also set up fewer than six operating modes.

No electrical connection may be made for operating modes that are not in use.

Otherwise the safety light curtain will be completely blocked (lock-out).

'=///! /! 1

If you configure several operating modes, you must especially check the operation of the

protective device in each of these operating modes. To this end, you must observe the test

notes in the operating instructions of the safety light curtain C 4000.

Device symbol C4000 Host (receiver),context menu Configuration draft,Edit,area

Operating modes.You can find more information on setting up and storing an operating

mode in the C 4000 online help in the CDS.

The connection of the operating mode selector switch is described in chapter 5.2

“Operating mode selector switch” on page 23.

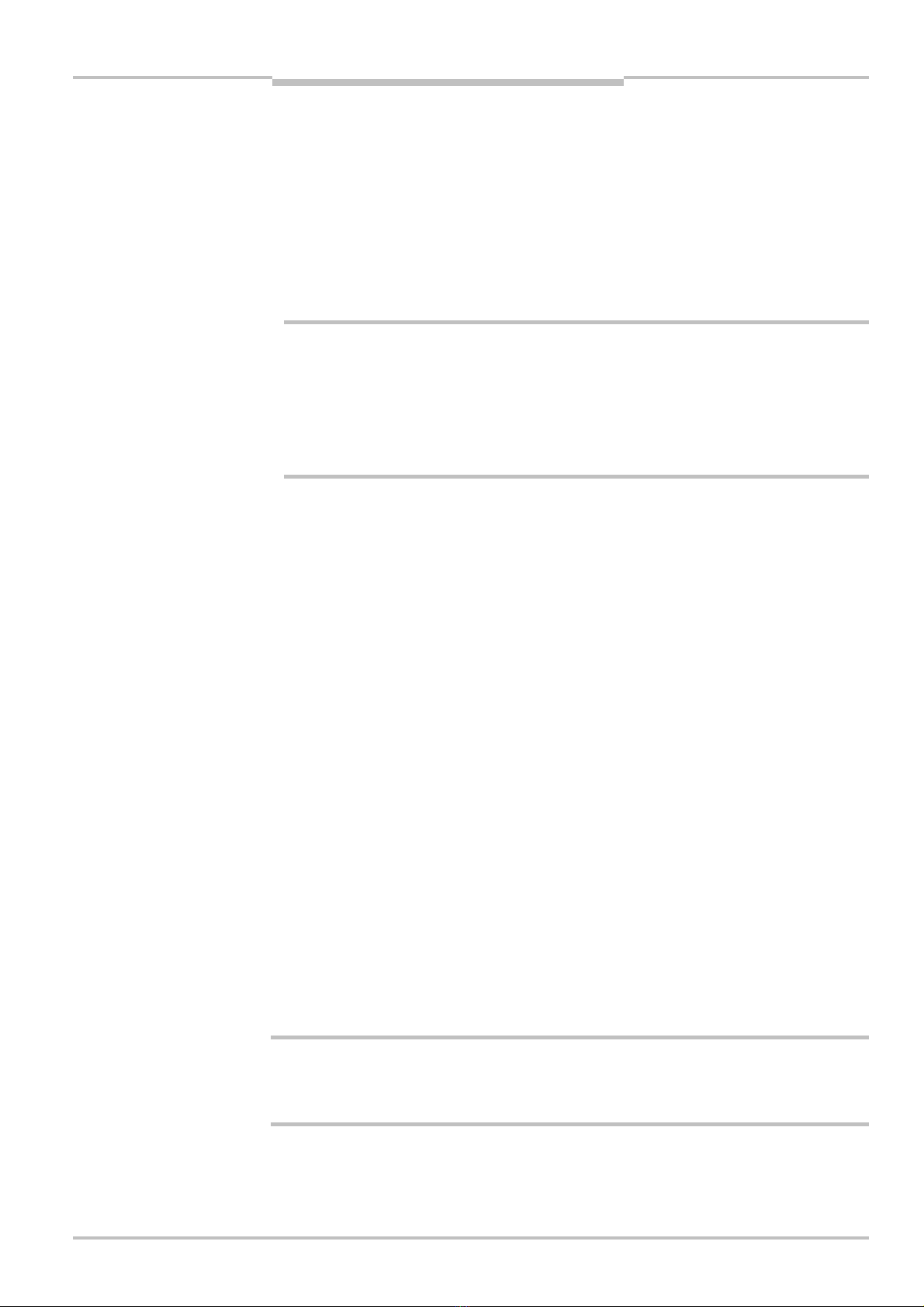

#

The configurable functions of the C 4000 have different scopes (cf. Tab. 2). The scope

depends on whether …

the function can be configured separately for every individual system in a cascade or

only for the entire cascade.

the function can be configured separately for every operating mode or only for the entire

application.

Depending on the scope of the function in question, you can find the corresponding setting

in CDS under the System or Operating mode options of the CDS configuration dialog.

.

.

WARNING

Operating Instructions Chapter #

8009 874/31-03-03 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 17

$

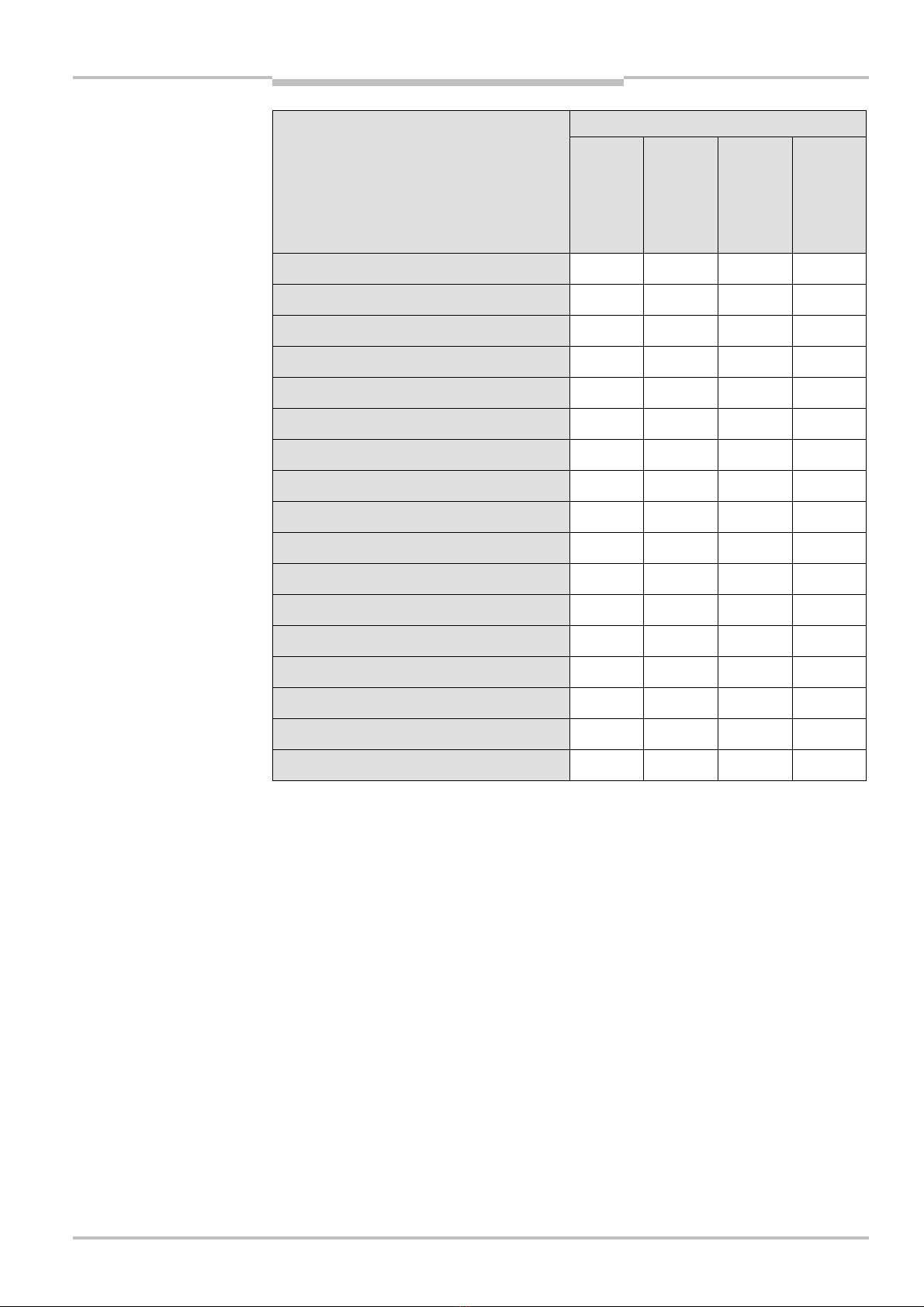

)

!

/

!

Rotation of the 7-segment display

PSDI mode

PSDI window

Beam coding

External device monitoring (EDM)

Reduced resolution

Scanning range

Type of bypass switch

Enable bypass

Emergency stop-input

Fixed blanking

Floating blanking

Teach-in

Type of restart interlock (internal/external)

Type of reset button

Connection site of the reset button

Signal output

Tab.

2

:

Scope of confi

gurable

functions

Chapter #Operating Instructions

18 ©SICK AG • Industrial Safety Systems • Germany • All rights reserved 8 009 874/31-03-03

$

# )

Several functions of the safety light curtain C 4000 cannot be combined.

You can configure two functions, each of which are applicable within one operating mode,

in two different operating modes of the same application, even if Tab. 3 indicates that they

cannot be combined.

'

Teach-in key-operated

switch on the extension

connection

Not with the Emergency Stop on the C 4000

Teach-in key-operated

switch on the UE 402

Not with Bypass

Emergency stop Not with the teach-in key-operated switch on the

extension connection of the C 4000

Bypass Not with PSDI mode

Not with PSDI window

Not with the teach-in key-operated switch on the UE 402

PSDI mode Not with Bypass

Not with fixed blanking with increased size tolerance

Not with floating blanking with partial object monitoring

Not with reduced resolution,if the effective resolution is

>30 mm

PSDI window Not with Bypass

Not with fixed blanking with increased size tolerance

Not with floating blanking

Not with reduced resolution

Reduced resolution

(effective resolution

>30 mm)

Not with fixed blanking with increased size tolerance

Not with floating blanking with partial object monitoring

Not with PSDI mode

Not with PSDI window

Floating blanking with

partial object monitoring

Not with fixed blanking with increased size tolerance

Not with reduced resolution

Not with PSDI mode

Not with PSDI window

Fixed blanking with

increased size tolerance

Not with floating blanking with partial object monitoring

Not with reduced resolution

Not with PSDI mode

Not with PSDI window

.

Tab.

3

:

Functions that

cannot be combined

Operating Instructions Chapter #

8009 874/31-03-03 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 19

$

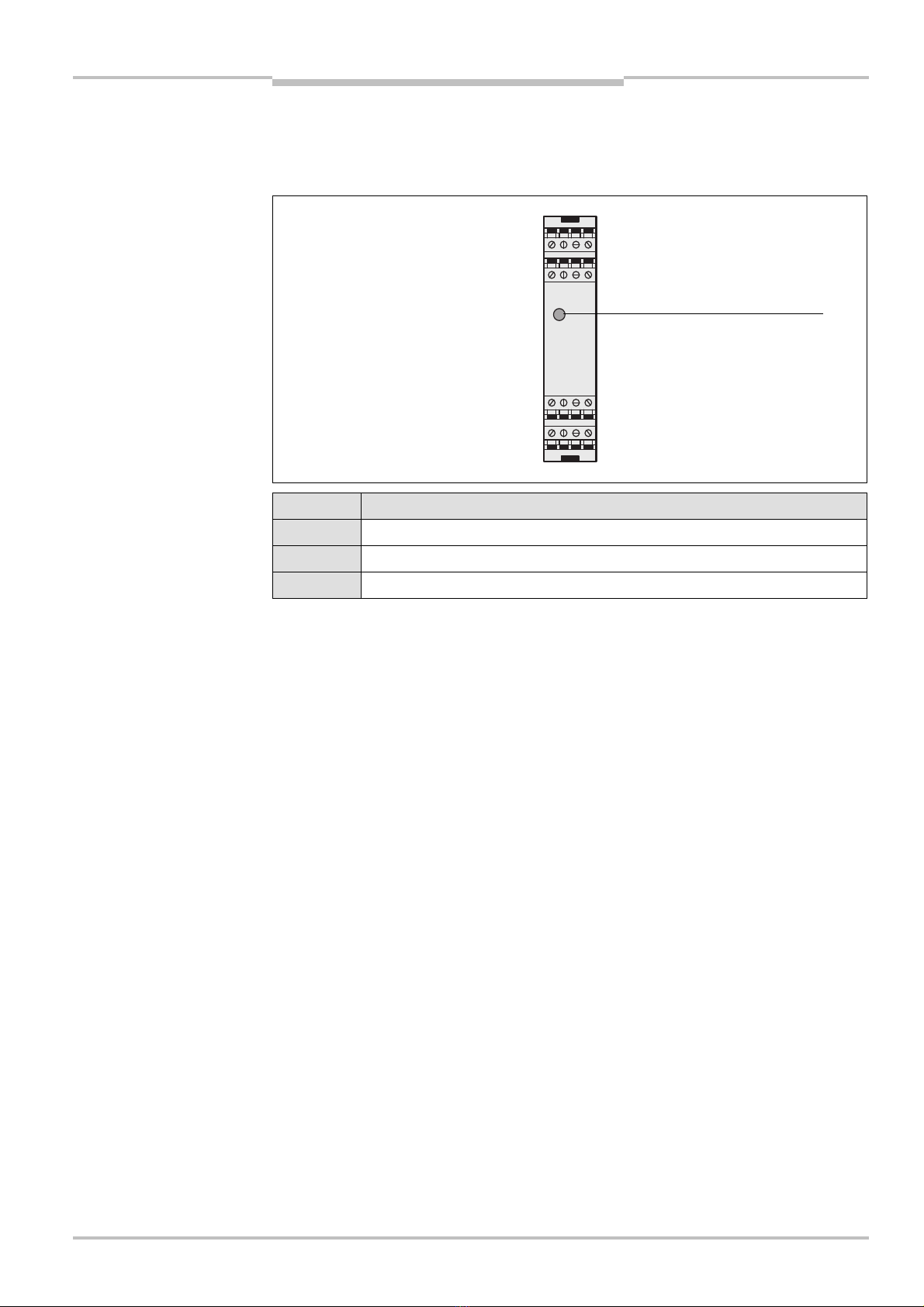

# - !

The UE 402 has a diagnosis LED. Moreover, all operational status indicators appear im-

mediately on the corresponding C 4000 sender and/or receiver.

- ! 3

Yellow LED off: no supply voltage

Yellow LED illuminated: device ready for operation

Yellow LED flashing: error (see section 8 “Fault diagnosis” on page 28)

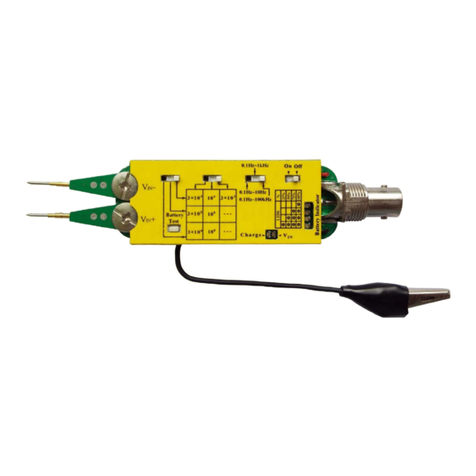

Fig.

6

:

Diagnostic LED of the

UE 402

Tab.

4

:

Me

aning of the

diagnostic LED of the UE 402

Diagnostic LED

Chapter Operating Instructions

20 ©SICK AG • Industrial Safety Systems • Germany • All rights reserved 8 009 874/31-03-03

%

%

The UE 402 has been designed for assembly on a mounting rail. The positioning place

must at least comply with enclosure rating IP 54.

The following steps are necessary after mounting and installation:

making the electrical connections (chapter 5)

testing the installation (To this end you should read the section titled “Test notes” in the

safety light curtain C 4000 operating instructions.)

Other manuals for UE402

1

Other SICK Amplifier manuals

Popular Amplifier manuals by other brands

Premier Hazard

Premier Hazard 9004 installation instructions

Crestron

Crestron High-Gain Line Amplifier SRD-AMP-1 installation guide

Herron Audio

Herron Audio VTPH-1 owner's manual

Analog Technologies

Analog Technologies ATNMA1.0 quick start guide

AUDIO TELEX

AUDIO TELEX DCM500 user manual

AUSTRALIAN MONITOR

AUSTRALIAN MONITOR AM1200 Operation manual