SICK UE403 User manual

OPERATING INSTRUCTIONS

UE403

Switching amplifier

GB

Operating Instructions

UE403

2©SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010854/WP71/2012-11-28

Subject to change without notice

This document is protected by the law of copyright, whereby all rights established therein remain with the

company SICK AG. Reproduction of this document or parts of this document is only permissible within the limits

of the legal determination of Copyright Law. Alteration or abridgement of the document is not permitted without

the explicit written approval of the company SICK AG.

Operating Instructions

UE403

8010854/WP71/2012-11-28 © SICK AG • Industrial Safety Systems • Germany • All rights reserved i

Subject to change without notice

Update

Update

Please take note of the following updates to this document!

Based on Machinery Directive 2006/42/EC, we have added the following supplementary

data or change notices on our product to the following document.

Scope

This document is an original document.

Cited standards and directives

The standards and directives cited in these operating instructions might have changed.

The following list indicates the standards and directives that might have been cited and

their successive versions.

Kindly replace the standards and directives cited in these operating instructions with the

successive versions listed in the table.

Previous standard or directive Successive standard and directive

Machinery Directive 98/37/EC Machinery Directive 2006/42/EC

Directive 93/68/EEC Directive 93/68/EC

EMC directive 89/336/EEC EMC directive 2004/108/EC

Low Voltage Directive 73/23/EC Low Voltage Directive 2006/95/EC

DIN 40050 EN 60529

IEC 536:1976 EN 61140

DIN EN 50178:1998-04/

VDE 0160:1998:04

EN 50178

EN 775 EN ISO 10218-1

EN 292-1 EN ISO 12100-1

EN 292-2 EN ISO 12100-2

EN 954-1 EN ISO 13849-1

EN 418 EN ISO 13850

EN 999 EN ISO 13855

EN 294 EN ISO 13857

EN 811 EN ISO 13857

EN 1050 EN ISO 14121-1

IEC 68, part 2-27 or IEC 68 EN 60068-2-27

IEC 68, part 2-29 EN 60068-2-27

IEC 68, part 2-6 EN 60068-2-6

prEN 50100:1EN 61496-1

ANSI B11.19-1990 ANSI B11.19:2003:04, Annex D

WARNING

Operating Instructions

UE403

ii ©SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010854/WP71/2012-11-28

Subject to change without notice

Update

Technical specifications

Safety-related parameters according to EN ISO 13849, EN 62061, IEC 61508:

General system data

Type Type 4 (EN 61496:1)

Safety Integrity Level1) SIL3 (IEC 61508)

SIL claim limit1) SILCL3 (EN 62061)

Category Category 4 (EN ISO 13849:1)

Performance Level1)PL e (EN ISO 13849:1)

PFHd (mean probability of a

dangerous failure per hour)

10×10–9(in connection with M4000 Advanced,

M4000 Advanced A/P)

TM(mission time) 18 years (EN ISO 13849)

1) For detailed information on the safety design of your machine/system, please contact your local SICK

representative.

Operating Instructions

UE403

8010854/WP71/2012-11-28 © SICK AG • Industrial Safety Systems • Germany • All rights reserved iii

Subject to change without notice

Update

EC declaration of conformity

The following declaration of conformity replaces the declaration of conformity that might

bedepicted in these operating instructions.

EC declaration of conformity

(page 1)

Operating Instructions

UE403

iv ©SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010854/WP71/2012-11-28

Subject to change without notice

Update

EC declaration of conformity

(page 2)

Operating Instructions

UE403

8010854/WP71/2012-11-28 © SICK AG • Industrial Safety Systems • Germany • All rights reserved v

Subject to change without notice

Update

Checklist for the manufacturer

Checklist for the manufacturer/installer for the installation of electro-

sensitive protective equipment (ESPE)

Details about the points listed below must be present at least during initial commissioning — they are, however,

dependent on the respective application, the specifications of which are to be controlled by the manufacturer/installer.

This checklist should be retained and kept with the machine documentation to serve as reference during recurring

tests.

1. Have the safety rules and regulations been observed in compliance with the directives/standards applicable to

the machine?

Yes No

2. Are the applied directives and standards listed in the declaration of conformity? Yes No

3. Does the protective device fulfil the required PL/SILCL and PFHd according to EN ISO 13849-1/EN 62061 and

the type according to EN 61496-1?

Yes No

4. Is the access to the hazardous area/hazardous point only possible through the protective field of the ESPE? Yes No

5. Have appropriate measures been taken to prevent (mechanical protection) or monitor unprotected presence in

the hazardous area when protecting a hazardous area/hazardous point and have these been secured against

removal?

Yes No

6. Are additional mechanical protective measures fitted and secured against manipulation which prevent reaching

under, over or around the ESPE?

Yes No

7. Has the maximum stopping and/or stopping/run-down time of the machine been measured, specified and

documented (at the machine and/or in the machine documentation)?

Yes No

8. Has the ESPE been mounted such that the required safety distance from the nearest hazardous point has been

achieved?

Yes No

9. Are the ESPE devices correctly mounted and secured against manipulation after adjustment? Yes No

10. Are the required protective measures against electric shock in effect (protection class)? Yes No

11. Is the control switch for resetting the protective device (ESPE) or restarting the machine present and correctly

installed?

Yes No

12. Are the outputs of the ESPE (OSSDs, AS-Interface Safety at Work) integrated in compliance with the required

PL/SILCL according to EN ISO 13849-1/EN 62061 and does the integration comply with the circuit diagrams?

Yes No

13. Has the protective function been checked in compliance with the test notes of this documentation? Yes No

14. Are the given protective functions effective at every setting of the operating mode selector switch? Yes No

15. Are the switching elements activated by the ESPE, e.g. contactors, valves, monitored? Yes No

16. Is the ESPE effective over the entire period of the dangerous state? Yes No

17. Once initiated, will a dangerous state be stopped when switching the ESPE on or off and when changing the

operating mode, or when switching to another protective device?

Yes No

18. Has an information label for the daily check been attached so that it is easily visible for the operator? Yes No

This checklist does not replace the initial commissioning, nor the regular inspection by qualified safety personnel.

Operating Instructions

UE403

vi ©SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010854/WP71/2012-11-28

Subject to change without notice

Update

Operating Instructions

UE403

8010854/WP71/2012-11-28 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 3

Subject to change without notice

Contents

Contents

1 About this document.........................................................................................................5

1.1 Function of this document....................................................................................5

1.2 Target group ..........................................................................................................5

1.3 Depth of information.............................................................................................5

1.4 Scope .....................................................................................................................6

1.5 Abbreviations.........................................................................................................6

1.6 Symbols used ........................................................................................................6

2 On safety.............................................................................................................................8

2.1 Qualified safety personnel....................................................................................8

2.2 Applications of the device.....................................................................................8

2.3 Correct use ............................................................................................................8

2.4 General safety notes and protective measures ..................................................9

2.5 Environmental protection .....................................................................................9

2.5.1 Disposal ...............................................................................................9

2.5.2 Separation of materials ....................................................................10

3 Product description.........................................................................................................11

3.1 Special features ..................................................................................................11

3.2 Operating principle of the device .......................................................................12

3.2.1 Principle of the device.......................................................................12

3.3 Application example............................................................................................13

3.4 Status indicators .................................................................................................14

4 Mounting ..........................................................................................................................15

4.1 Mounting on the M4000 multiple light beam safety device ............................15

4.1.1 Mounting on the rear of the M4000 ................................................15

4.1.2 Mounting on the side of the M4000................................................16

4.2 Mounting on the system .....................................................................................16

5 Electrical installation......................................................................................................17

5.1 System connection M12×5 ...............................................................................18

5.2 Connections for muting sensors M12×5..........................................................19

5.3 Connection muting lamp M12×5 ......................................................................20

5.4 Reset/override/additional signal C1/belt stop connection M12×5 ...............21

5.5 Configuration connection M8× 4 (serial interface) ...........................................22

6 Connection diagrams......................................................................................................23

6.1 M4000 Advanced with UE403 and UE10>30S..................................................23

6.2 M4000 Advanced A/P with UE403 and UE10>30S ..........................................24

6.3 M4000 Advanced A/P with UE403 and relay ...................................................25

7 Commissioning ................................................................................................................26

8 Configuration ...................................................................................................................27

8.1 Preparing the configuration................................................................................27

8.2 Configuration memory ........................................................................................28

9 Fault diagnosis ................................................................................................................29

9.1 In the event of faults or errors............................................................................29

9.2 SICK support........................................................................................................29

9.3 Error displays of the LEDs...................................................................................30

9.4 Extended diagnostics..........................................................................................30

Operating Instructions

UE403

4©SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010854/WP71/2012-11-28

Subject to change without notice

Contents

10 Technical specifications ................................................................................................ 31

10.1 Data sheet........................................................................................................... 31

10.2 Dimensional drawings ........................................................................................ 34

10.2.1 UE403 ............................................................................................... 34

10.2.2 Muting lamp, version with incandescent lamp ...............................35

10.2.3 Muting lamp, version with LED ........................................................ 35

11 Ordering information ...................................................................................................... 36

11.1 Part number and delivery................................................................................... 36

11.2 Accessories ......................................................................................................... 36

12 Annex................................................................................................................................ 38

12.1 EC declaration of conformity.............................................................................. 38

12.2 Manufacturer’s checklist ................................................................................... 39

12.3 List of tables ....................................................................................................... 40

12.4 List of illustrations .............................................................................................. 41

Operating Instructions Chapter 1

UE403

8010854/WP71/2012-11-28 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 5

Subject to change without notice

About this document

1About this document

Please read this chapter carefully before working with this documentation and the UE403

switching amplifier.

1.1 Function of this document

These operating instructions are designed to address the technical personnel of the

machine manufacturer or the machine operator in regards to safe mounting, installation,

configuration, electrical installation, commissioning, operation and maintenance of the

UE403 switching amplifier in connection with the M4000 Advanced multiple light beam

safety device.

These operating instructions do not provide instructions for operating machines on which

the UE403 switching amplifier or the M4000 Advanced multiple light beam safety device

is, or will be, integrated. Information on this is to be found in the appropriate operating

instructions for the machine.

1.2 Target group

These operating instructions are addressed to planning engineers,machine designers and

operators of plants and systems which are to be protected by one or several M4000

Advanced multiple light beam safety devices in connection with a UE403 switching

amplifier. It also addresses people who integrate the UE403 into a machine, initialise its

use, or who are in charge of servicing and maintaining the device.

1.3 Depth of information

These operating instructions contain the following information on the UE403 switching

amplifier in connection with the M4000 Advanced multiple light beam safety device:

•mounting

•electrical installation

•commissioning and configuration

•fault, error diagnosis and

troubleshooting

•part numbers

•conformity and approval

Planning and using protective devices such as the M4000 Advanced also require specific

technical skills which are not detailed in this documentation.

When operating the UE403 in connection with the M4000 Advanced multiple light beam

safety device, the national, local and statutory rules and regulations must be observed.

General information on accident prevention using opto-electronic protective devices can

be found in the brochure “Safe Machines with opto-electronic protective devices”.

We also refer you to the SICK homepage on the Internet at

www.sick.com

Here you will find information on:

•sample applications

•a list of Frequently Asked Questions regarding the M4000 in connection with the UE403

switching amplifier

•these operating instructions in different languages for viewing and printing

•EC Declaration of Conformity

Note

Chapter 1Operating Instructions

UE403

6©SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010854/WP71/2012-11-28

Subject to change without notice

About this document

1.4 Scope

These operating instructions are only applicable to the UE403 switching amplifier with the

following entry on the type label in the field Operating Instructions:8010851_WP71. This

document is part of SICK part number 8010851 (operating instructions “UE403 —

Switching amplifier” in all available languages).

For the configuration and diagnostics of these devices you require CDS (Configuration &

Diagnostic Software) version 3.1.0 or higher. To determine the software version, select the

Module-Info... option in the ?menu.

1.5 Abbreviations

Application diagnostic output = configurable signal output that indicates a specific status

of the protective device

SICK Configuration & Diagnostic Software = software for the configuration of your UE403

External device monitoring

Enhanced function interface = safe SICK device communication

Electro-sensitive protective equipment (e.g. M4000 or C4000)

M4000 Advanced multiple light beam safety device

Output signal switching device = switching output that drives the safety circuit

Programmable logic controller

Safety Data Link = SICK safety interface (connection for OSSD and EFI of an ESPE)

1.6 Symbols used

Recommendations are designed to give you some assistance in your decision-making

process with respect to a certain function or a technical measure.

Refer to notes for special features of the device.

Display indications reflect the state of the 7>segment display on an ESPE connected

(e.g. the M4000):

Alternating indication of characters, e.g. t and 2

Please consult the operating instructions of the ESPE for a detailed description of the

indicators.

LED symbols describe the status of an LED:

The LED is constantly illuminated.

The LED is flashing.

The LED is off.

Instructions for taking action are shown by an arrow. Read carefully and follow the

instructions for action.

WARNING

Warning!

Awarning indicates an actual or potential risk or health hazard. They are designed to help

you to prevent accidents.

Read carefully and follow the warning notices!

Note

ADO

CDS

EDM

EFI

ESPE

M4000

OSSD

PLC

SDL

Recommendation

Note

,

,

Take action …

Operating Instructions Chapter 1

UE403

8010854/WP71/2012-11-28 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 7

Subject to change without notice

About this document

Software notes show the location in the CDS (Configuration & Diagnostic Software) where

you can make the appropriate settings and adjustments.

The software notes contained in the operating instructions for the M4000 Advanced

multiple light beam safety device apply accordingly in connection with the UE403.

Sender and receiver

In drawings and diagrams, symbol denotes the sender and symbol denotes the

receiver of an electro-sensitive protective equipment.

The term “dangerous state”

The dangerous state (standard term) of the machine is always shown in the drawings and

diagrams of this document as a movement of a machine part. In practical operation, there

may be a number of different dangerous states:

•machine movements

•electrical conductors

•visible or invisible radiation

•a combination of several risks and hazards

Chapter 2Operating Instructions

UE403

8©SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010854/WP71/2012-11-28

Subject to change without notice

On safety

2On safety

This chapter deals with your own safety and the safety of the equipment operators.

Please read this chapter carefully before starting to work with the UE403 or with

machinery protected by the M4000 Advanced multiple light beam safety device in

connection with the UE403.

2.1 Qualified safety personnel

The UE403 switching amplifier must only be installed, commissioned and serviced by

qualified safety personnel. Qualified safety personnel are defined as persons who …

•have undergone the appropriate technical training

and

•who have been instructed by the responsible machine operator in the operation of the

machine and the current valid safety guidelines

and

•have access to the operating instructions of the UE403 and have read and familiarised

themselves with them

and

•have access to the operating instructions for the M4000 Advanced multiple light beam

safety device connected to the switching amplifier and are familiar with them.

2.2 Applications of the device

The UE403 switching amplifier is an accessory for the SICK M4000 Advanced multiple

light beam safety device. It extends the technical application possibilities of the M4000

Advanced.

The UE403 switching amplifier is only intended for use in industrial environments. When

used in residential areas it can cause interference.

Additional mechanical protective measures may be required when using the M4000

Advanced in connection with the UE403.

2.3 Correct use

The UE403 switching amplifier must be used only as defined in chapter 2.2 “Applications

of the device”. It must be used only by qualified personnel and only on the machine where

it has been installed and initialised by qualified safety personnel in accordance with these

operating instructions.

If the device is used for any other purposes or modified in any way — also during mounting

and installation — any warranty claim against SICK AG shall become void.

Operating Instructions Chapter 2

UE403

8010854/WP71/2012-11-28 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 9

Subject to change without notice

On safety

2.4 General safety notes and protective measures

WARNING

Safety notes

Please observe the following procedures in order to ensure the correct and safe use of the

M4000 Advanced multiple light beam safety device in connection with the UE403.

•Please observe the notes in the chapter titled “General safety notes and protective

measures” of the M4000 Advanced operating instructions.

•The M4000 Advanced and UE403 operating instructions must be made available to the

operator of the machine with which the M4000 Advanced multiple light beam safety

device is used in connection with the UE403. The machine operator is to be instructed

in the use of the device by qualified safety personnel and must be instructed to read the

operating instructions.

•Changes to the configuration of the devices can degrade the protective function. After

every change to the configuration you must therefore check the effectiveness of the

protective device.

The person who makes the change is also responsible for the correct protective function

of the device. When making configuration changes, please always use the password

hierarchy provided by SICK to ensure that only authorised persons make changes to the

configuration. The SICK service team is available to provide assistance if required.

•The UE403 switching amplifier is connected directly to the M4000 Advanced multiple

light beam safety device and supplied with power from the M4000. Pay attention to the

related notes on the voltage supply in the operating instructions for the

M4000 Advanced.

2.5 Environmental protection

The UE403 switching amplifier has been designed to minimise environmental impact. It

uses only a minimum of power and natural resources.

At work, always act in an environmentally responsible manner.

2.5.1 Disposal

Unusable or irreparable devices should always be disposed as per the applicable national

regulations on waste disposal (e.g. European waste code 16 02 14).

•We would be pleased to be of assistance on the disposal of this device. Contact your

local SICK representative.

•Information on the individual materials in the UE403 is given in chapter 10 “Technical

specifications” on page 31.

Notes

Chapter 2Operating Instructions

UE403

10 ©SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010854/WP71/2012-11-28

Subject to change without notice

On safety

2.5.2 Separation of materials

WARNING

Only appropriately trained personnel are allowed to separate materials!

Caution is required when dismantling devices. There is a risk of injuries.

Before you send the devices for appropriate recycling, it is necessary to separate the

different materials in the UE403.

Separate the housing from the rest of the parts (in particular the circuit board).

Send the separated parts for recycling as appropriate (see Tab. 1).

Components Disposal

Product

Housing Metal recycling (aluminium)

Circuit boards, cable, connector and

electrical connecting pieces

Electronic recycling

Packaging

Cardboard, paper Paper/cardboard recycling

Tab.

1

:

Overview on disposal

by components

Operating Instructions Chapter 3

UE403

8010854/WP71/2012-11-28 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 11

Subject to change without notice

Product description

3Product description

This chapter provides information on the special features and properties of the UE403. It

describes the construction and the operating principle of the device in connection with the

M4000 Advanced multiple light beam safety device.

Please read this chapter before mounting, installing and commissioning the device.

3.1 Special features

Properties UE403

•RS>232 connection: access to the configuration/diagnostics either via M4000

Advanced or UE403

•IP 65 housing: flexible mounting to the M4000 Advanced or directly in the system

•M12 connection sockets with separate LED displays: I/O status display directly on the

UE403

•facility for connecting of:

– 2 to 4 muting sensors

–muting lamp

–reset/override control switch/additional external control signal

•1EFI connection for connection with the M4000 Advanced

•Storage of the configuration for the M4000 Advanced connected to the EFI in the

UE403. Automatic device detection after the replacement of an M4000 and transfer of

the saved configuration to the device. This makes easy replacement of an M4000

possible.

Chapter 3Operating Instructions

UE403

12 ©SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010854/WP71/2012-11-28

Subject to change without notice

Product description

3.2 Operating principle of the device

3.2.1 Principle of the device

The UE403 is a switching amplifier. It processes certain signals from the M4000 Advanced

multiple light beam safety device and combines them with signals from the

devices/systems that are connected to the UE403. Such signals can come from:

•muting sensors

•muting lamps

•control switches for e.g. reset or override

•external controls, e.g. signal for belt stop

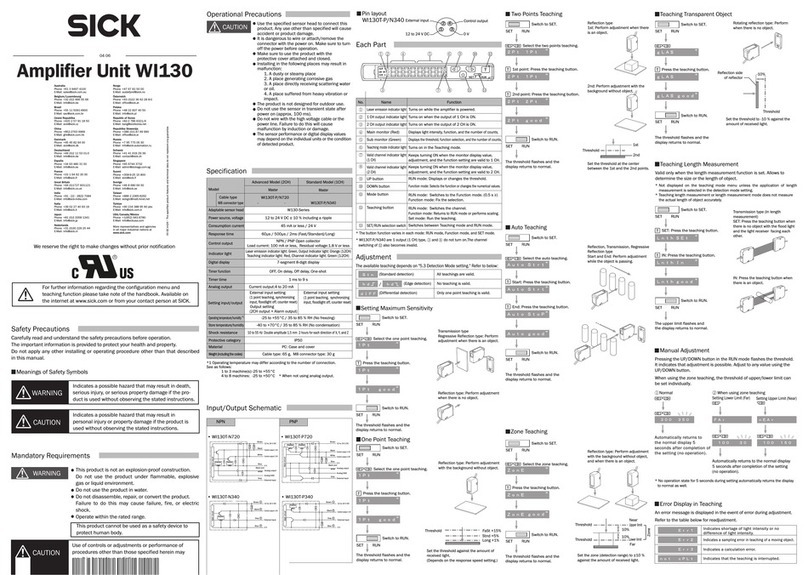

Fig. 1: Principle of the device

UE403

Muting

lamp

Muting

sensors

UE403

Reset/override

M4000

Advanced

EFI

connection

Configuration

connection UE403

Configuration

connection M4000

Operating Instructions Chapter 3

UE403

8010854/WP71/2012-11-28 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 13

Subject to change without notice

Product description

3.3 Application example

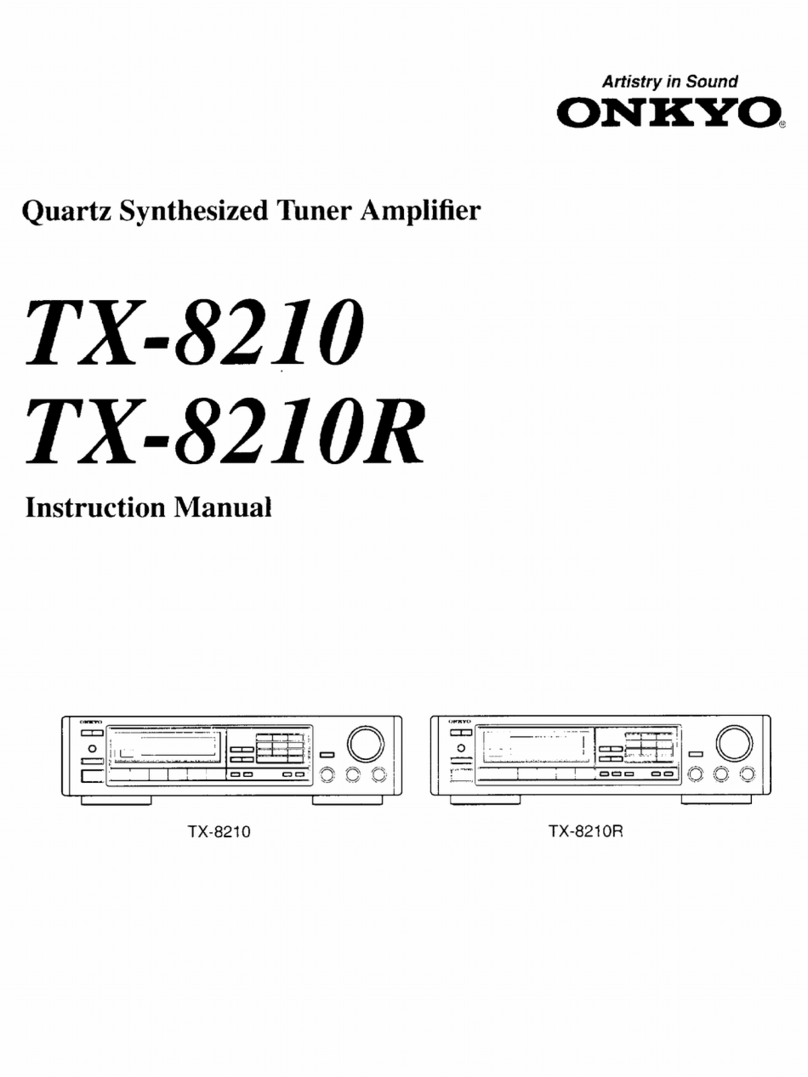

Muting application

Engine machining station with M4000 Advanced and UE403. The station entrance is

safeguarded with a 3-beam multiple light beam safety device together with the UE403

switching amplifier. 2 pairs of inductive muting sensors that are connected locally to the

UE403 detect the transport platform and trigger muting. The muting lamp signals the

muting state. The control switch for reset and override is also connected locally via the

UE403.

Fig. 2:Example for a muting

application

Muting

sensors

M4000 Advanced

+UE403

Muting

lamp

Control

switch

for

reset/override

Chapter 3Operating Instructions

UE403

14 ©SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010854/WP71/2012-11-28

Subject to change without notice

Product description

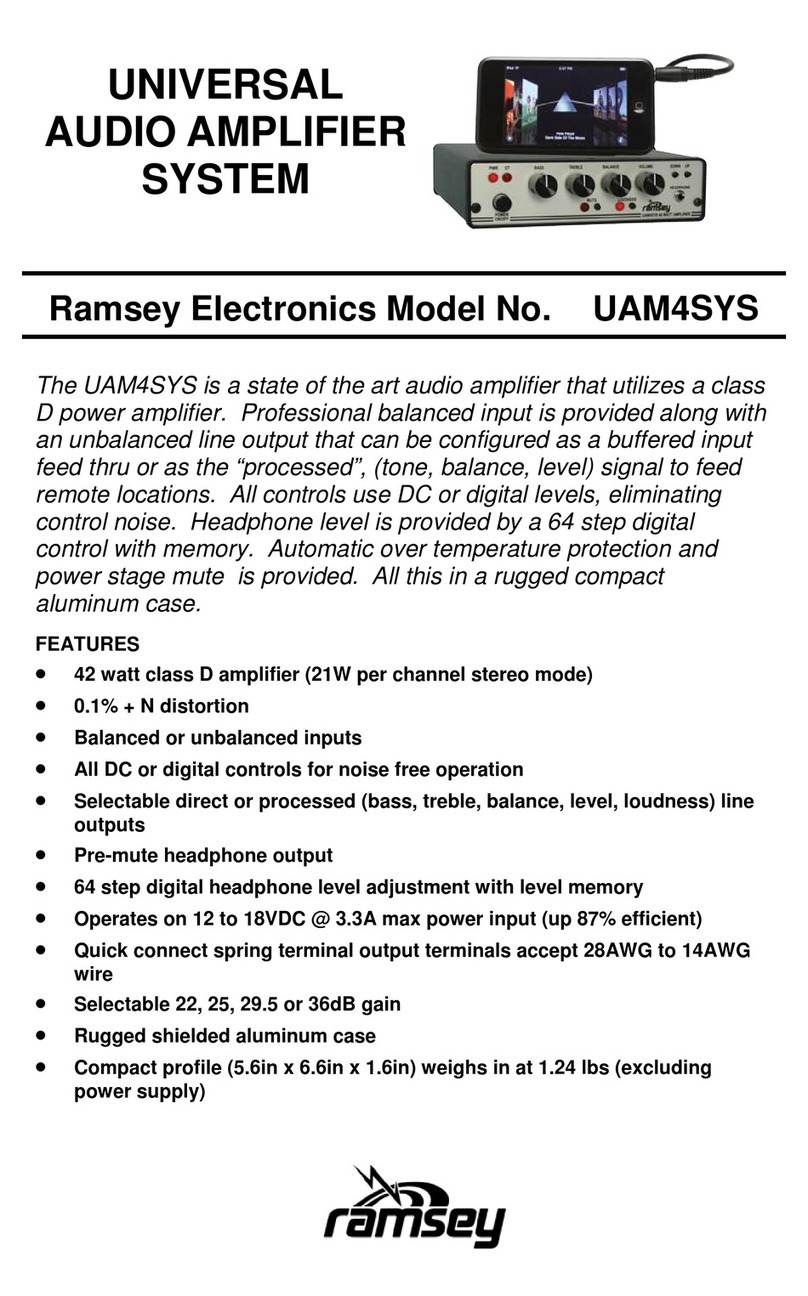

3.4 Status indicators

The UE403 has a status LED for the input and output (I/O) on each M12 connection. Other

indications during operation are also indicated on the 7>segment display on the M4000

receiver.

Status LED

COM connection

Display Meaning

Yellow LED off: No supply voltage

Yellow LED illuminated: Device ready for operation

Yellow LED flashing: Error

(See chapter 9.3 “Error displays of the LEDs” on page 30ff.)

Connections RES/OVR, A1, A2, B1, B2,

Display Meaning

Yellow LED off: No signal (0 V LOW)

Yellow LED illuminated: Signal is present (24 V HIGH)

•The combined RES/OVR connection can process several signals. However, the status

LED only indicates whether a signal is present or not. A decision as to which signal is

present is not made.

•The electrical connection is described in chapter 5.4 “Reset/override/additional signal

C1/belt stop connection M12×5” on page 21.

Fig. 3: Status LED of the

UE403

Tab.

2

:

Meaning of the status

LEDs of the UE403

Notes

Status LED

RES/OVR:

Reset/override/C1/belt stop

A2:

Muting sensor

B2:

Muting sensor

COM:

EFI connection

A1:

Muting

sensor

B1:

Muting

sensor

:

External muting lamp

Configuration connection (

under

protective cover)

Table of contents

Other SICK Amplifier manuals