SICK deTec2 Core User manual

OPERATING INSTRUCTIONS

deTec2 Core HG

Safety light curtain

Described product

deTec2 Core HG

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is

only permissible within the limits of the legal determination of Copyright Law. Any modi‐

fication, abridgment or translation of this document is prohibited without the express

written permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

2O P E R A T I N G I N S T R U C T I O N S | deTec2 Core HG 8021979/1GWF/2022-11-11 | SICK

Subject to change without notice

Contents

1 About this document........................................................................ 6

1.1 Purpose of this document........................................................................ 6

1.2 Scope......................................................................................................... 6

1.3 Target groups of these operating instructions........................................ 6

1.4 Additional information.............................................................................. 6

1.5 Symbols and document conventions...................................................... 7

2 Safety information............................................................................ 8

2.1 General safety notes................................................................................ 8

2.2 Intended use............................................................................................. 8

2.3 Inappropriate use..................................................................................... 9

2.4 Requirements for the qualification of personnel.................................... 9

3 Product description........................................................................... 10

3.1 Structure and function............................................................................. 10

3.2 Product characteristics............................................................................ 11

3.2.1 Device overview....................................................................... 11

3.2.2 Hardened front screen............................................................ 11

3.2.3 Absence of blind zones........................................................... 11

3.2.4 Automatic calibration of the protective field width................ 11

3.2.5 Alignment aid........................................................................... 12

3.2.6 Status indicators...................................................................... 12

3.3 Example applications............................................................................... 13

4 Project planning................................................................................ 15

4.1 Manufacturer of the machine.................................................................. 15

4.2 Operating entity of the machine.............................................................. 15

4.3 Design........................................................................................................ 15

4.3.1 Scanning range and protective field width............................. 16

4.3.2 Minimum distance from the hazardous point....................... 17

4.3.3 Minimum distance to reflective surfaces............................... 19

4.3.4 Protection against interference from systems in close prox‐

imity to each other................................................................... 21

4.4 Integration in electrical control................................................................ 22

4.4.1 Restart interlock...................................................................... 24

4.4.2 External device monitoring (EDM).......................................... 24

4.4.3 Connection diagrams.............................................................. 25

4.5 Testing plan............................................................................................... 25

4.5.1 Test rod check.......................................................................... 26

4.5.2 Visual check of the machine and the protective device........ 29

5 Mounting............................................................................................. 30

5.1 Unpacking.................................................................................................. 30

5.2 Installation................................................................................................ 30

CONTENTS

8021979/1GWF/2022-11-11 | SICK O P E R A T I N G I N S T R U C T I O N S | deTec2 Core HG 3

Subject to change without notice

5.2.1 Mounting the QuickFix bracket............................................... 33

5.2.2 Mounting the FlexFix bracket.................................................. 35

5.2.3 Mounting the Compact FlexFix bracket.................................. 38

5.2.4 Mounting the flat mount bracket............................................ 40

5.2.5 Mounting the swivel mount bracket....................................... 41

5.2.6 Mounting the upgrade bracket............................................... 44

6 Electrical installation........................................................................ 45

6.1 Safety......................................................................................................... 45

6.2 System connection (M12, 5-pin)............................................................. 46

6.3 System connection via connection cable (M12, 5-pin to 8-pin)............ 47

7 Commissioning.................................................................................. 48

7.1 Overview.................................................................................................... 48

7.2 Switching on.............................................................................................. 48

7.3 Sender and receiver alignment................................................................ 48

7.3.1 Aligning the sender and receiver............................................ 49

7.3.2 Alignment with the QuickFix bracket...................................... 50

7.3.3 Alignment with the FlexFix bracket or with the upgrade

bracket...................................................................................... 50

7.3.4 Alignment with the Compact FlexFix bracket......................... 51

7.3.5 Alignment with the swivel mount bracket.............................. 52

7.3.6 Indication of the alignment quality......................................... 53

7.4 Check during commissioning and modifications.................................... 53

8 Operation............................................................................................ 54

8.1 Regular thorough check........................................................................... 54

9 Maintenance...................................................................................... 55

9.1 Regular cleaning....................................................................................... 55

9.2 Regular thorough check........................................................................... 56

10 Troubleshooting................................................................................. 57

10.1 Safety......................................................................................................... 57

10.2 Diagnostic LEDs........................................................................................ 57

10.2.1 Fault indicators........................................................................ 57

11 Decommissioning............................................................................. 59

11.1 Disposal..................................................................................................... 59

12 Technical data.................................................................................... 60

12.1 Data sheet................................................................................................. 60

12.2 Response time.......................................................................................... 62

12.3 Power consumption.................................................................................. 62

12.4 Length of cable......................................................................................... 63

12.5 Table of weights........................................................................................ 63

12.6 Dimensional drawings.............................................................................. 64

CONTENTS

4O P E R A T I N G I N S T R U C T I O N S | deTec2 Core HG 8021979/1GWF/2022-11-11 | SICK

Subject to change without notice

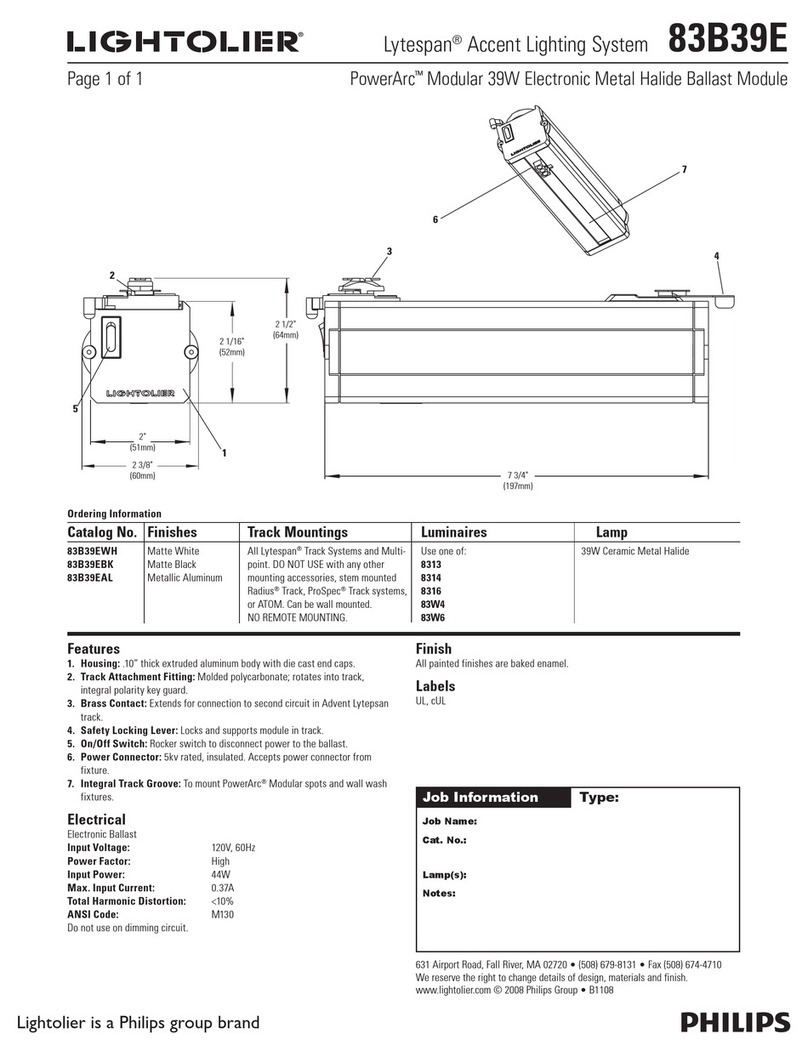

13 Ordering information........................................................................ 65

13.1 Scope of delivery....................................................................................... 65

13.2 Ordering information................................................................................. 65

14 Accessories........................................................................................ 66

14.1 Brackets.................................................................................................... 66

14.2 Mounting accessories.............................................................................. 69

14.3 Weld spark guard...................................................................................... 69

14.4 Connectors................................................................................................ 71

14.5 Alignment aid............................................................................................ 72

14.6 Deflector mirrors....................................................................................... 72

14.6.1 Function and use..................................................................... 72

14.6.2 Mounting.................................................................................. 72

14.6.3 Change in scanning range using deflector mirrors................ 73

14.6.4 Deflector mirror PNS75 - ordering information...................... 73

14.6.5 Deflector mirror PNS125 - ordering information................... 73

14.7 Mirror columns.......................................................................................... 74

14.8 Device columns......................................................................................... 74

14.9 Cleaning agent.......................................................................................... 74

14.10 Test rods.................................................................................................... 75

15 Annex.................................................................................................. 76

15.1 Conformities and certificates................................................................... 76

15.1.1 EU declaration of conformity................................................... 76

15.1.2 UK declaration of conformity.................................................. 76

15.2 Note on standards.................................................................................... 76

15.3 Checklist for initial commissioning and commissioning........................ 78

16 List of figures..................................................................................... 79

17 List of tables....................................................................................... 80

CONTENTS

8021979/1GWF/2022-11-11 | SICK O P E R A T I N G I N S T R U C T I O N S | deTec2 Core HG 5

Subject to change without notice

1 About this document

1.1 Purpose of this document

These operating instructions contain information required during the life cycle of the

safety light curtain.

These operating instructions are available to all those who work with the safety light

curtain.

Please read these operating instructions carefully and make sure that you understand

the content fully before working with the safety light curtain.

1.2 Scope

This document applies to the following products:

•Product code: deTec2 Core HG

•“Operating instructions” type label entry: 8021977

Document identification

Document part number:

•This document: 8021979

•Available language versions of this document: 8021977

You can find the current version of all documents at www.sick.com.

1.3 Target groups of these operating instructions

Some sections of these operating instructions are intended for certain target groups.

However, the entire operating instructions are relevant for intended use of the product.

Table 1: Target groups and selected sections of these operating instructions

Target group Sections of these operating instructions

Project developers (planners, developers,

designers)

"Project planning", page 15

"Technical data", page 60

"Accessories", page 66

Installers "Mounting", page 30

Electricians "Electrical installation", page 45

Safety experts (such as CE authorized repre‐

sentatives, compliance officers, people who

test and approve the application)

"Project planning", page 15

"Commissioning", page 48

"Technical data", page 60

"Checklist for initial commissioning and com‐

missioning", page 78

Operators "Operation", page 54

"Troubleshooting", page 57

Maintenance personnel "Maintenance", page 55

"Troubleshooting", page 57

1.4 Additional information

www.sick.com

The following information is available on the Internet:

•Data sheets and application examples

•CAD data and dimensional drawings

1 ABOUT THIS DOCUMENT

6O P E R A T I N G I N S T R U C T I O N S | deTec2 Core HG 8021979/1GWF/2022-11-11 | SICK

Subject to change without notice

•Certificates (e.g. EU declaration of conformity)

•Guide for Safe Machinery Six steps to a safe machine

1.5 Symbols and document conventions

The following symbols and conventions are used in this document:

Safety notes and other notes

DANGER

Indicates a situation presenting imminent danger, which will lead to death or serious

injuries if not prevented.

WARNING

Indicates a situation presenting possible danger, which may lead to death or serious

injuries if not prevented.

CAUTION

Indicates a situation presenting possible danger, which may lead to moderate or minor

injuries if not prevented.

NOTICE

Indicates a situation presenting possible danger, which may lead to property damage if

not prevented.

NOTE

Indicates useful tips and recommendations.

Instructions to action

bThe arrow denotes instructions to action.

1. The sequence of instructions for action is numbered.

2. Follow the order in which the numbered instructions are given.

✓The check mark denotes the result of an instruction.

LED symbols

These symbols indicate the status of an LED:

oThe LED is off.

ÖThe LED is flashing.

OThe LED is illuminated continuously.

Sender and receiver

These symbols indicate the sender and receiver of the device:

sThe symbol indicates the sender.

rThe symbol indicates the receiver.

ABOUT THIS DOCUMENT 1

8021979/1GWF/2022-11-11 | SICK O P E R A T I N G I N S T R U C T I O N S | deTec2 Core HG 7

Subject to change without notice

2 Safety information

2.1 General safety notes

DANGER

The product can not offer the expected protection if it is integrated incorrectly.

bPlan the integration of the product in accordance with the machine requirements

(project planning).

bImplement the integration of the product in accordance with the project planning.

DANGER

Death or severe injury due to electrical voltage and/or an unexpected startup of the

machine

bMake sure that the machine is (and remains) disconnected from the voltage

supply during mounting and electrical installation.

bMake sure that the dangerous state of the machine is and remains switched off.

DANGER

Improper work on the product

A modified product may not offer the expected protection if it is integrated incorrectly.

bApart from the procedures described in this document, do not repair, open, manip‐

ulate or otherwise modify the product.

DANGER

Risk of injury due to damage to the front screen

The front screen is made of glass. Glass splinters or damage can change the optical

characteristics or lead to injury.

bReplace the device if the front screen is scratched or damaged.

2.2 Intended use

The deTec2 Core HG safety light curtain is an electro-sensitive protective device (ESPE)

and is suitable for the following applications:

•Hazardous point protection

•Access protection

•Hazardous area protection

The product may be used in safety functions.

The deTec2 Core HG safety light curtain must only be used within the limits of the

prescribed and specified technical data and operating conditions at all times.

Any instance of improper use, incorrect modification, or manipulation of the deTec2

Core HG safety light curtain shall void any warranty provided by SICK AG; furthermore,

SICK AG shall not accept any responsibility or liability for any resulting damage and

consequential damage.

2 SAFETY INFORMATION

8O P E R A T I N G I N S T R U C T I O N S | deTec2 Core HG 8021979/1GWF/2022-11-11 | SICK

Subject to change without notice

2.3 Inappropriate use

The safety light curtain works as an indirect protective measure and cannot provide

protection from parts thrown out nor from emitted radiation. Transparent objects are

not detected.

Among others, the deTec2 Core HG safety light curtain is not suitable for the following

applications:

•Outdoors

•Underwater

•In explosion-hazardous areas

•At altitudes over 3,000m above sea level

•In environments with increased levels of ionizing radiation

•In environments where glass splinters pose a risk

2.4 Requirements for the qualification of personnel

The safety light curtain must only be configured, installed, connected, commissioned

and serviced by qualified safety personnel.

Project planning

You need safety expertise to implement safety functions and select suitable products

for that purpose. You need expert knowledge of the applicable standards and regula‐

tions.

Mounting, electrical installation and commissioning

You need suitable expertise and experience. You must be able to assess if the machine

is operating safely.

Operation and maintenance

You need suitable expertise and experience. You must be instructed in machine oper‐

ation by the machine operator. For maintenance, you must be able to assess if the

machine is operating safely.

SAFETY INFORMATION 2

8021979/1GWF/2022-11-11 | SICK O P E R A T I N G I N S T R U C T I O N S | deTec2 Core HG 9

Subject to change without notice

3 Product description

3.1 Structure and function

Overview

The deTec2 Core HG safety light curtain is an electro-sensitive protective device (ESPE)

consisting of a sender and receiver.

A series of parallel infrared light beams forms a protective field between sender and

receiver that protects the hazardous area (hazardous point, access, and hazardous

area protection). When one or more beams are completely interrupted, the safety light

curtain reports the interruption in the light path to the secure output signal switching

devices (OSSDs) by a signal change. The machine or its control must safely analyze the

signals (for example using a safe control or safety relays) and stop the dangerous state.

Sender and receiver automatically synchronize themselves optically. An electrical con‐

nection between both components is not required.

r

s

Figure 1: Sender and receiver

Protective field height

The protective field height indicates the range within which the test rod belonging to the

safety light curtain is reliably detected.

Protective field width

The protective field width is the dimension of the light path between sender and

receiver. The maximum protective field width is limited by the scanning range.

Resolution

The resolution describes the size of the smallest object detected by the safety light

curtain in the protective field. The resolution corresponds to the diameter of the test rod

belonging to the safety light curtain.

The safety light curtain has a resolution of 14 mm. This resolution provides finger

protection.

The safety light curtain has a resolution of 30mm. This resolution provides hand

protection.

3 PRODUCT DESCRIPTION

10 O P E R A T I N G I N S T R U C T I O N S | deTec2 Core HG 8021979/1GWF/2022-11-11 | SICK

Subject to change without notice

Scanning range

The scanning range is the maximum protective field width.

The scanning range is reduced by using deflector mirrors.

The scanning range is reduced by using a weld spark guard.

Further topics

•"Data sheet", page 60

•"Deflector mirrors", page 72

•"Weld spark guard", page 69

3.2 Product characteristics

3.2.1 Device overview

1

2

Figure 2: Device overview

1Sender or receiver

2System connection

3.2.2 Hardened front screen

The front screen of the safety light curtain deTec2 Core HG (hardened glass) has a

high resistance to chemicals and is suitable for environments in which coolants and

lubricants or cleaning agents are used.

A list of all substances that have been tested for compatibility with the device materials

is available from SICK on request.

3.2.3 Absence of blind zones

The design and construction of the safety light curtain extends the protective function

of a device to the end of the housing without any blind spots. The absence of blind

zones reduces the space requirement when integrated in the machine.

3.2.4 Automatic calibration of the protective field width

When switched on, the safety light curtain automatically calibrates to the protective

field width.

PRODUCT DESCRIPTION 3

8021979/1GWF/2022-11-11 | SICK O P E R A T I N G I N S T R U C T I O N S | deTec2 Core HG 11

Subject to change without notice

3.2.5 Alignment aid

Alignment quality LEDs are installed in the receiver of the safety light curtain. To

perform a simple alignment of the receiver, the alignment quality LEDs indicate the

alignment quality once the safety light curtain has been switched on.

3.2.6 Status indicators

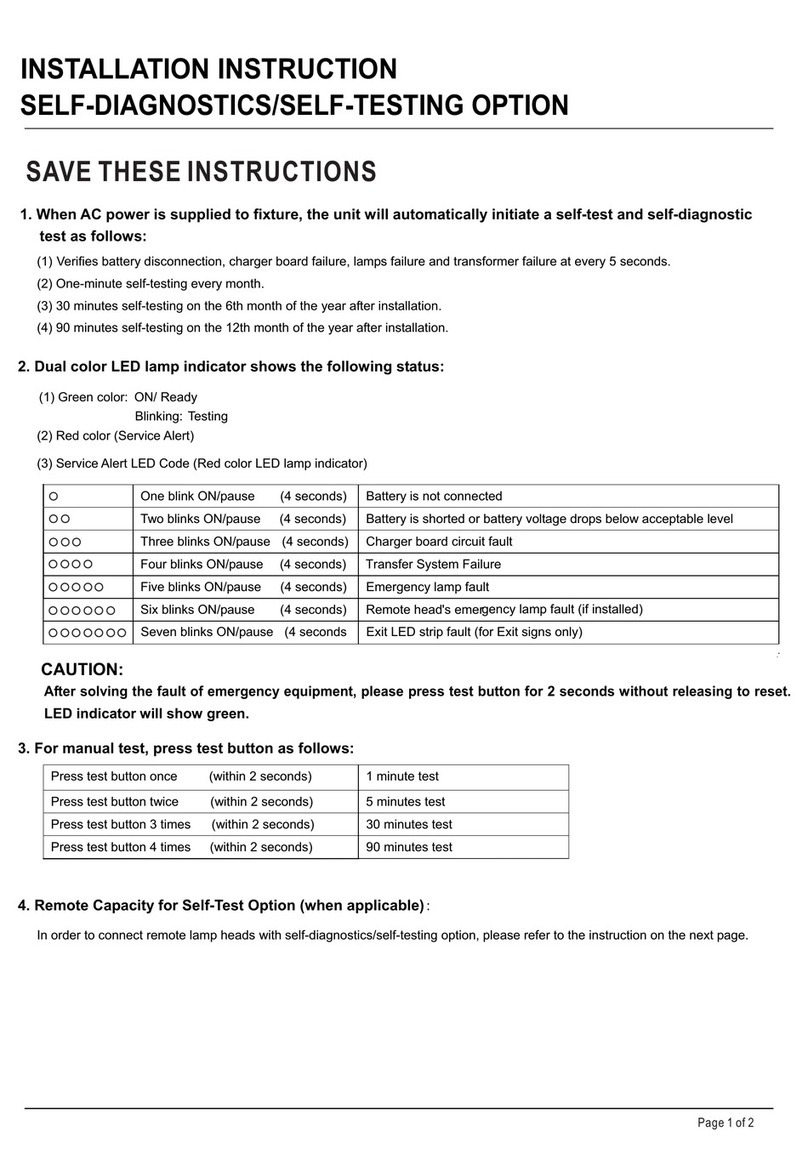

Overview

The sender and receiver LEDs indicate the operational status of the safety light curtain.

Sender displays

1PWR

2ERR

Figure 3: Sender displays

2 LEDs on the sender indicate the operational status:

Position LED color Display Labeling

1Yellow Status indicator PWR

2Red Fault indicator ERR

Receiver displays

1OSSD

2ERR

3

1234

Figure 4: Receiver displays

6 LEDs on the receiver indicate the operational status:

3 PRODUCT DESCRIPTION

12 O P E R A T I N G I N S T R U C T I O N S | deTec2 Core HG 8021979/1GWF/2022-11-11 | SICK

Subject to change without notice

Position LED color Display Labeling

1Red/green OSSD status OSSD

2Red Fault indication ERR

3Blue Alignment quality 1, 2, 3, 4

The blue alignment quality light emitting diodes in combination with the red flashing

ERR LED also denote faults.

Further topics

•"Diagnostic LEDs", page 57

3.3 Example applications

Figure 5: Hazardous point protection

Figure 6: Access protection

PRODUCT DESCRIPTION 3

8021979/1GWF/2022-11-11 | SICK O P E R A T I N G I N S T R U C T I O N S | deTec2 Core HG 13

Subject to change without notice

Figure 7: Hazardous area protection

3 PRODUCT DESCRIPTION

14 O P E R A T I N G I N S T R U C T I O N S | deTec2 Core HG 8021979/1GWF/2022-11-11 | SICK

Subject to change without notice

4 Project planning

4.1 Manufacturer of the machine

The manufacturer of the machinery must carry out a risk assessment and apply appro‐

priate protective measures. Further protective measures may be required in addition to

the product.

The product must not be tampered with or changed, except for the procedures descri‐

bed in this document.

The product must only be repaired by the manufacturer of the product or by someone

authorized by the manufacturer. Improper repair can result in the product not providing

the expected protection.

4.2 Operating entity of the machine

Changes to the electrical integration of the product in the machine controller and

changes to the mechanical mounting of the product necessitate a new risk assess‐

ment. The results of this risk assessment may require the entity operating the machine

to meet the obligations of a manufacturer.

The product must not be tampered with or changed, except for the procedures descri‐

bed in this document.

The product must only be repaired by the manufacturer of the product or by someone

authorized by the manufacturer. Improper repair can result in the product not providing

the expected protection.

4.3 Design

Overview

This chapter contains important information about the design.

Important information

DANGER

Hazard due to lack of effectiveness of the protective device

Persons and parts of the body to be protected may not be recognized in case of

non-observance.

bMake sure that the following construction requirements are met so that the safety

light curtain can fulfill its protective function.

°Sender and receiver must be arranged such that persons or parts of the body

are reliably detected when they enter the hazardous area.

°Reaching under, over, and around as well as moving the safety light curtain

must be prevented.

°Check whether additional safety measures (e.g. restart interlocking) are nec‐

essary when it is possible for people to be located between the protection

system and the danger point without being detected.

PROJECT PLANNING 4

8021979/1GWF/2022-11-11 | SICK O P E R A T I N G I N S T R U C T I O N S | deTec2 Core HG 15

Subject to change without notice

DANGER

Hazard due to lack of effectiveness of the protective device

Persons and parts of the body to be protected may not be recognized in case of

non-observance.

bMake sure that the optical properties of the front screens of the sender and

receiver are not changed, e.g., by:

°beading water, mist, frost, or ice formation. If applicable, remove films or

other types of contamination, disconnect the voltage supply of the receiver

and then switch it back on.

°Scratches or damage. Replace the device whose front screen is scratched or

damaged.

bMake sure that all reflective surfaces and objects maintain a minimum distance

from the protective field.

bMake sure that no dispersive media (e.g., dust, fog, or smoke) are within the

calculated minimum distance from the protective field.

Further topics

•"Mounting", page 30

4.3.1 Scanning range and protective field width

Important information

DANGER

Hazard due to lack of effectiveness of the protective device

Persons and parts of the body to be protected may not be recognized in case of

non-observance.

bThe safety light curtain can only be mounted to machines on which the protective

field width does not change when the safety light curtain is switched on.

Protective field width

The protective field width is the dimension of the light path between sender and

receiver. The maximum protective field width is limited by the scanning range.

The protective field width is automatically calibrated when the safety light curtain is

switched on during initialization and must not be changed during operation.

Scanning range

The scanning range limits the maximum protective field width. The protective field width

cannot change during operation.

The scanning range is reduced by using deflector mirrors.

The scanning range is reduced by using a weld spark guard.

Further topics

•"Minimum distance to reflective surfaces", page 19

•"Technical data", page 60

•"Deflector mirrors", page 72

•"Weld spark guard", page 69

4 PROJECT PLANNING

16 O P E R A T I N G I N S T R U C T I O N S | deTec2 Core HG 8021979/1GWF/2022-11-11 | SICK

Subject to change without notice

4.3.2 Minimum distance from the hazardous point

Overview

A minimum distance must be maintained between the safety light curtain and the

hazardous point. This distance is required to prevent a person or part of their body from

reaching the hazardous point before the end of the machine’s dangerous state.

Calculation of the minimum distance according to ISO13855

The calculation of the minimum distance is based on international or national stand‐

ards and statutory requirements applicable at the place of installation of the machine.

If the minimum distance is calculated according to ISO13855, then it depends on the

following points:

•Machine stopping time (time interval between triggering the sensor function and

the end of the machine’s dangerous state)

•Response time of the protective device

•Reach or approach speed of the person

•Resolution (detection capability) of the safety light curtain

•Type of approach: orthogonal (at right angles) or parallel

•Parameters specified based on the application

For the USA (scope of OSHA and ANSI), different regulations may apply, e.g.:

a) Laws: Code of Federal Regulations, Title 29 (CFR 29), Part 1910.217

b) Standards: ANSIB11.19

Complementary information

More information is available in the ISO13855 standard and in the Guide for Safe

Machinery.

SICK offers a stopping/run-down time measurement service in many countries.

Further topics

•"Response time", page 62

4.3.2.1 Calculating minimum distance from the hazardous point

Important information

DANGER

Minimum distance from the hazardous point is too small

The dangerous state of the machine may not be stopped or not be stopped in a timely

manner due to a minimum distance that is too small.

bCalculate the minimum distances for the machine in which the safety light curtain

is integrated.

bWhen mounting the safety light curtain, observe the minimum distance.

Approach

The example shows the calculation of the minimum distance in accordance with ISO

13855 for an orthogonal (right-angled) approach to the protective field. A different

calculation may be required depending on the application and the ambient conditions

(e.g., for a protective field parallel to or at any angle to the direction of approach or an

indirect approach).

1. First, calculate S using the following formula:

S = (K × T) + 8 × (d – 14mm)

PROJECT PLANNING 4

8021979/1GWF/2022-11-11 | SICK O P E R A T I N G I N S T R U C T I O N S | deTec2 Core HG 17

Subject to change without notice

Where:

°S =minimum distance in millimeters (mm)

°K = approach speed (stepping and/or gripping speed) of a person or a body

part (mm/s), e.g. 2,000mm/s

°T = machine stopping time + response time of the protective device after

interruption in the light path in seconds (s)

°d = resolution of the safety light curtain in millimeters (mm)

2. If the result S is ≤500mm, then use the determined value as the minimum

distance.

3. If the result S is >500mm, then recalculate S with an approach speed of 1,600

mm/s as follows:

S=1,600mm/s×T+8× (d–14mm)

4. If the new value S is >500mm, then use the newly determined value as the

minimum distance.

5. If the new value S is ≤500mm, then use 500mm.

!

"

§

S

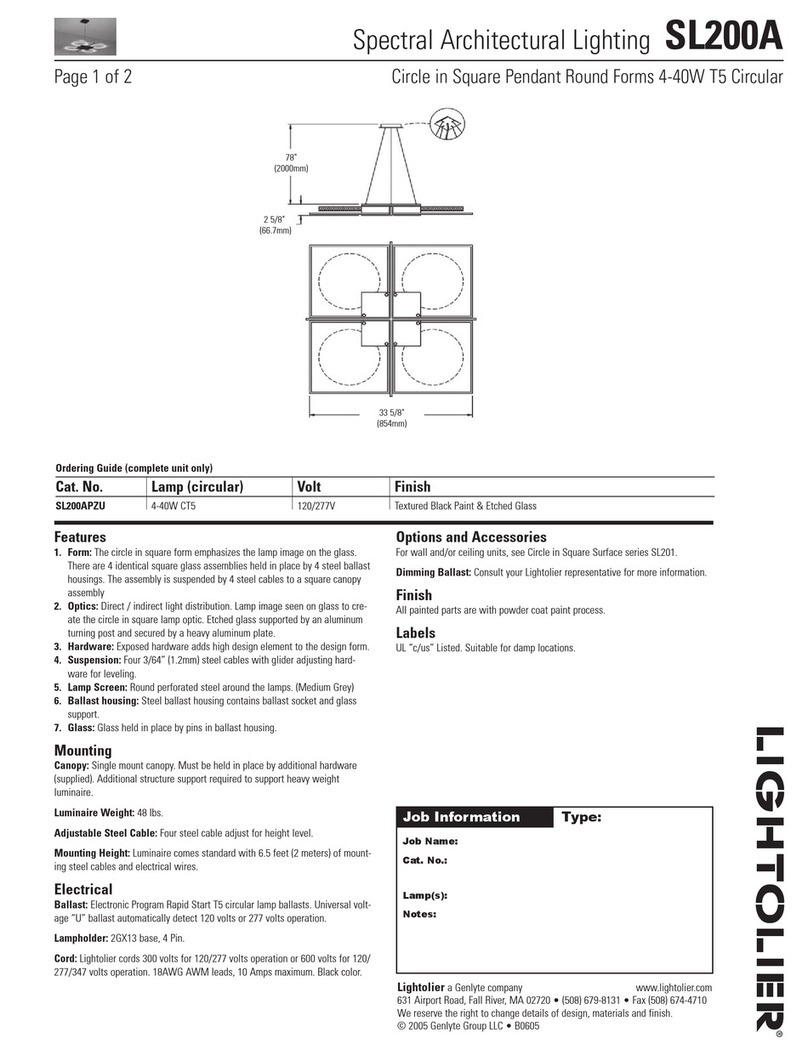

Figure 8: Minimum distance to the hazardous point for orthogonal (rectangular) approach to the

protective field

1Protective field height

2Hazardous point

3Depending on the application and distance, persons must be prevented from standing

behind the protective device.

Example calculation

Machine stopping time = 290ms

Response time after interruption of the light path = 30ms

Resolution of the safety light curtain = 14mm

T = 290ms + 30ms = 320ms = 0.32s

S = 2,000mm/s × 0.32s + 8 × (14mm – 14mm) = 640mm

S >500mm, therefore:

S = 1,600mm/s × 0.32s + 8 × (14mm – 14mm) = 512mm

4 PROJECT PLANNING

18 O P E R A T I N G I N S T R U C T I O N S | deTec2 Core HG 8021979/1GWF/2022-11-11 | SICK

Subject to change without notice

4.3.2.2 Taking reach over into account

In accordance with ISO 13855, it must not be possible to defeat the ESPE. If access to

the hazardous area by reaching over a protective field cannot be prevented, the height

of the protective field and minimum distance of the ESPE must be determined. This is

done by comparing the calculated values based on the possible detection of limbs or

body parts with the values resulting from reaching over the protective field. The greater

value resulting from this comparison must be used.

Figure 9: Representation of the accessibility of ESPE by reaching over. Left: Protective field that

cannot be reached over. Right: Protective field that can be reached over.

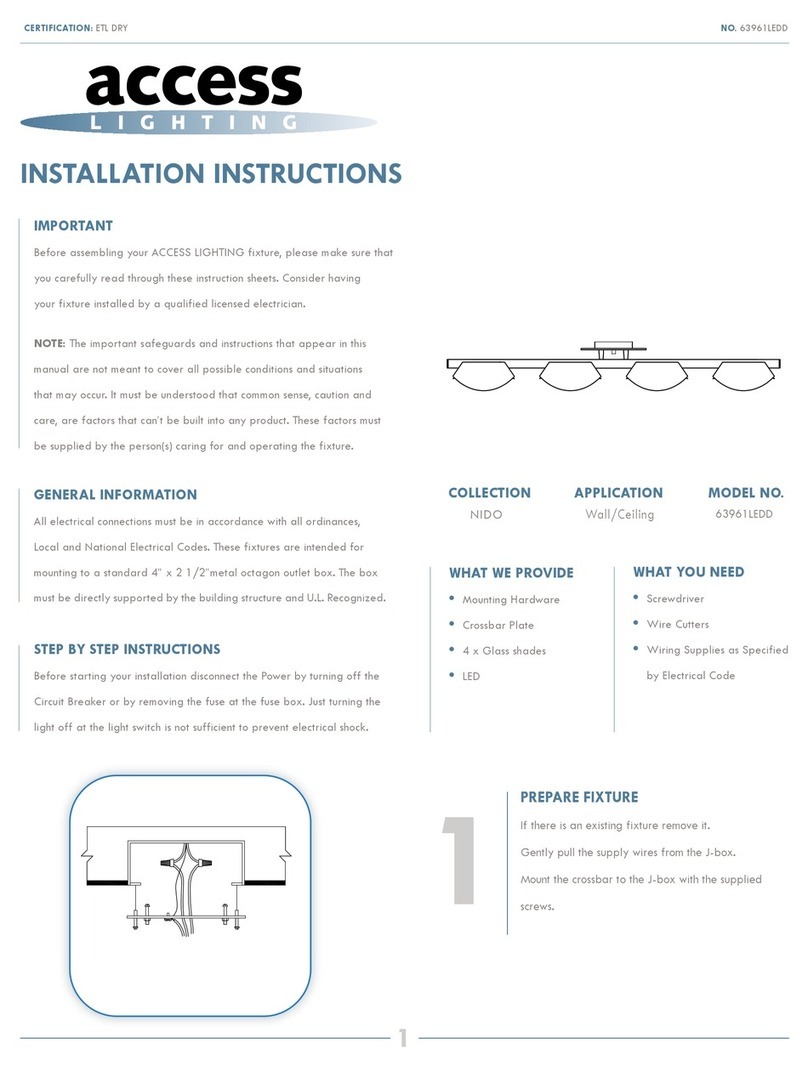

4.3.3 Minimum distance to reflective surfaces

Overview

The light beams from the sender may be deflected by reflective surfaces and dispersive

media. This may prevent an object from being detected.

Therefore, all reflective surfaces and objects (e.g. material bins, machine table, etc.)

must maintain a minimum distance (a) from the protective field. This minimum dis‐

tance (a) must be maintained on all sides of the protective field. This applies in

horizontal, vertical and diagonal directions as well as at the end of the safety light

curtain. The same area must be free of dispersive media (e.g., dust, fog, or smoke).

The minimum distance (a) depends on the distance (D) between sender and receiver

(protective field width).

The weld spark guard can influence the optical properties of the safety light curtain,

meaning that reflective surfaces have to observe a larger minimum distance.

rs

D

a

Figure 10: Minimum distance from reflective surfaces

PROJECT PLANNING 4

8021979/1GWF/2022-11-11 | SICK O P E R A T I N G I N S T R U C T I O N S | deTec2 Core HG 19

Subject to change without notice

Important information

DANGER

Hazard due to lack of effectiveness of the protective device

Reflective surfaces and dispersive media can prevent persons or parts of the body to

be protected from being properly reflected and, therefore, remain undetected.

bMake sure that all reflective surfaces and objects maintain a minimum distance

from the protective field.

bMake sure that no dispersive media (e.g., dust, fog, or smoke) are within the

calculated minimum distance from the protective field.

Determining minimum distance from reflective surfaces with automated calibration of

the protective field width

The minimum distance can be determined as follows:

bDetermine the distance between sender and receiver D in meters (m).

bRead the minimum distance a in millimeters (mm) in the graph or calculate using

the respective formula to determine the minimum distance to reflective surfaces:

a [mm]

1100

1000

900

800

700

600

500

400

300

200

100

0,5 1 1,5 2 2,5 3 3,5 4 4,5 5 5,5 6 6,5 7 7,5 8 8,5 9 9,5 10 11 12 D [m]

Figure 11: Graph of minimum distance from reflective surfaces

Table 2: Formula for calculating the minimum distance to reflective surfaces

Distance between sender and

receiver D in m

Calculating the minimum distance to reflective surfaces

a in mm

D ≤3m a = 262mm

D >3m a = tan (5°) × 1,000mm/m × D = 87.49 × 1mm/m × D

Further topics

•"Weld spark guard", page 69

4 PROJECT PLANNING

20 O P E R A T I N G I N S T R U C T I O N S | deTec2 Core HG 8021979/1GWF/2022-11-11 | SICK

Subject to change without notice

Other manuals for deTec2 Core

12

Table of contents