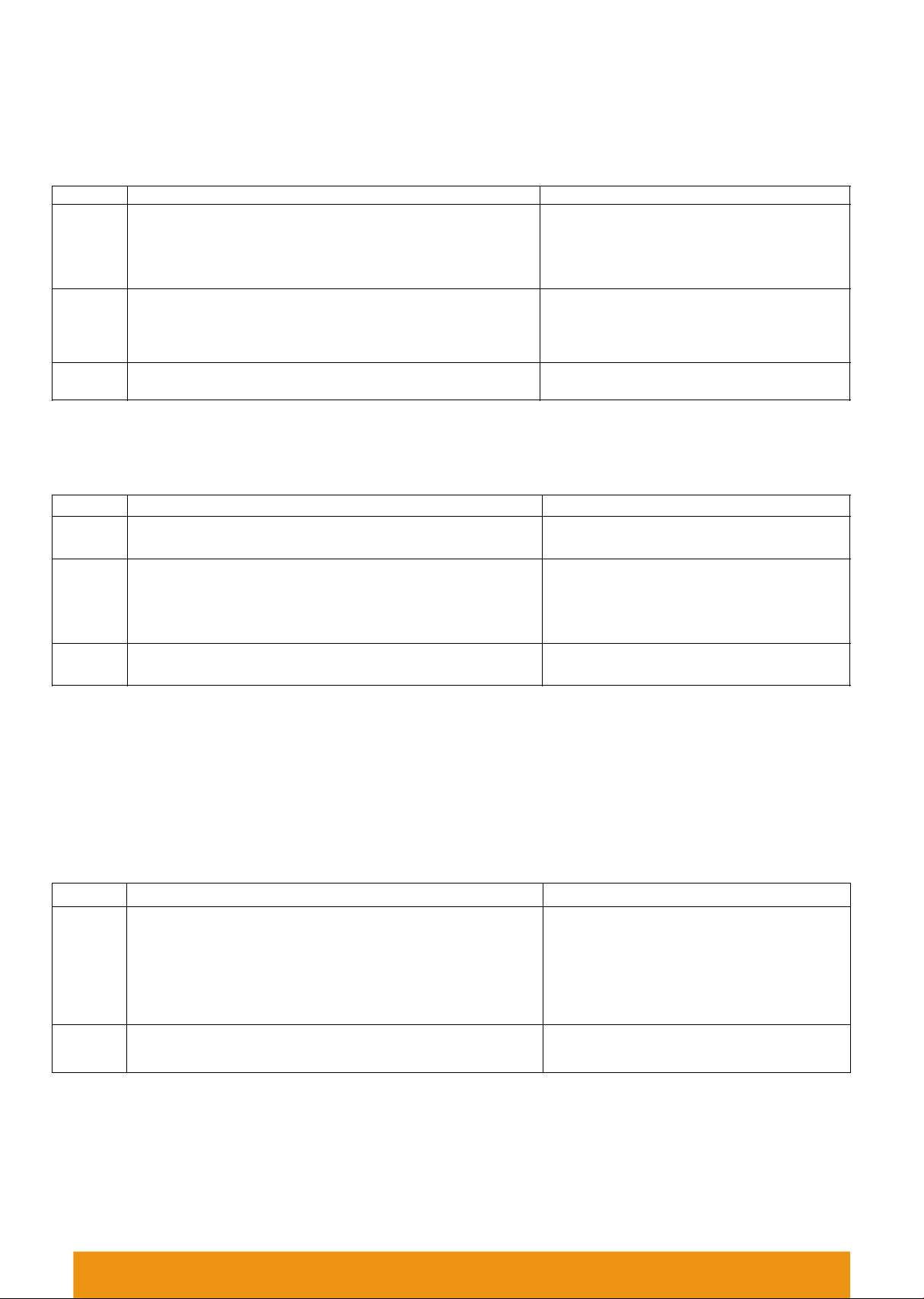

(3) Code learning operation between remote controls: Used to unify system code values or copy a new remote controls.

Since each remote controller has its own unique code at the time of delivery, when there are multiple remote controllers

in one system, one of them (for example, remote controller A) must be selected as the system code value, and the code

value of the rest remote controllers (for example, remote controller B) should be copied to the same one.

A remote control:Press and hold “ON” on the remote control

for 5 seconds, the indicator of the remote control will flash

quickly, means it enters the pairing code transmission status.

Will automatically exit code transmission

status after 60 seconds, or pressing any key

to exit.

B remote control: long press "mode key" for 5 seconds, the

remote indicator light changes from 100% light to 5% light

and flash, means entering the code value receiving state

Will automatically exit the code value

receiving state after 30 seconds, or exit after

learning the code value successfully.

see the B remote control indicator light flash 3 times

Code copying is finished and exit code value

receiving status.

(4) (4) Copying code from receiver to remote control.

A new remote control can also copy code from any one of the receivers in the whole system, after the successful

operation, the new remote control can replace the original remote (if it is lost).

Cut off the power of receiver.

Which one will be controlled by remote.

Long-press "mode key" for 5 seconds, the remote indicator

light changes from 100% light to off, means entering the

code value receiving state.

Will automatically exit the code value

receiving state after 30 seconds, or exit

after learning the code value successfully.

Power on the receiver, will see remote control indicator

light flash 3 times.

Code copying is finished and exit code

value receiving status.

* For security of the system, the distance from remote control to the one receiver should be less than 2 meters in this

operation.

*Only one time operation is requested for the whole system, no need different operation for different zones.

(5) The remote control restores the factory setting: it means that the remote control will be restored to the factory's

unique code value.

Long press "mode " for 20 seconds.

The remote indicator light dim down and

flashes continuously until the 20th second

and then back to 100% light. Means this

step is finished.

Press the "OFF" to confirm, the remote indicator light

flashes 3 times.

Restore factory settings successfully.

7.1.4 Remote control accessories installation instructions

Accessories include bracket 1pc, 3M foam sponge glue 1pc, screw 2pcs, expansion tube 2pcs.

There are 2 options for bracket installation:

1) Using screw and expansion tube make drilling installation (suitable for uneven and ash surface);

2) Using 3M foam sponge glue make free drilling installation (suitable for flat no ash surface).

P9 DIMMER AND REMOTE OPERATION