Sidamo PE 22 A User manual

User’s manual PE22A

1

USER’S MANUAL

PE 22 A

BENCH DRILLING MACHINE

Original manual

User’s manual PE22A

2

CONTENTS

1.

1.1.

1.

INTRODUCTION

INTRODUCTIONINTRODUCTION

INTRODUCTION ................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

..........................................

....................

..........3

33

3

2.

2.2.

2.

WARNING SIGNS

WARNING SIGNSWARNING SIGNS

WARNING SIGNS................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.......................................

..............

.......3

33

3

2.1.

WARNING SIGNS RELATED TO T E SAFETY OF T E MAC INE.............................................................................................................3

2.2.

WARNING SIGNS USED IN T IS MANUAL.......................................................................................................................................................3

3.

3.3.

3.

SAFETY

SAFETYSAFETY

SAFETY................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

..........................................................

....................................................

..........................4

44

4

3.1.

GENERAL SAFETY INSTRUCTIONS.......................................................................................................................................................................4

3.2.

PARTICULAR SAFETY INSTRUCTION..................................................................................................................................................................5

3.3.

PROTECTION OF T E OPERATOR......................................................................................................................................................................... 6

4.

4.4.

4.

DESCRIPTION AND OPER

DESCRIPTION AND OPERDESCRIPTION AND OPER

DESCRIPTION AND OPERATING

ATINGATING

ATING................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

............................................

........................

............6

66

6

4.1.

PURPOSE OF T E MAC INE ..................................................................................................................................................................................6

4.2.

SPECIFICATIONS.......................................................................................................................................................................................................... 6

4.3.

MAC INE OVERVIEW ................................................................................................................................................................................................7

5.

5.5.

5.

INSTALLATION

INSTALLATIONINSTALLATION

INSTALLATION ................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

............................................

........................

............8

88

8

5.1.

PACKING..................................................................................................................................................................................................... 8

5.2.

TRANSPORT AND ANDLING ...........................................................................................................................................................8

5.3.

INSTALLING T E MAC INE.................................................................................................................................................................8

5.4.

ASSEMBLING ............................................................................................................................................................................................ 9

5.5.

ELECTRICAL CONNECTION...............................................................................................................................................................12

5.6.

TEST AND INITIAL INSPECTION PRIOR TO USING T E EQUIPMENT FOR T E FIRST TIME...................................12

6.

6.6.

6.

OPERATING T E BENC

OPERATING T E BENC OPERATING T E BENC

OPERATING T E BENC DRILLING MAC INE

DRILLING MAC INEDRILLING MAC INE

DRILLING MAC INE................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

...............................................

..............................

...............13

1313

13

6.1.

CONTROL PANEL.................................................................................................................................................................................. 13

6.2.

RETURN SPRING OF T E SPINDLE...............................................................................................................................................13

6.3.

DRILLING DEPT .................................................................................................................................................................................. 13

6.4.

PROTECTIVE S IELD ...........................................................................................................................................................................14

6.5.

TABLE........................................................................................................................................................................................................ 15

6.6.

ASSEMBLING AND DISMANTLING T E TOOL.......................................................................................................................... 16

6.7.

SELECTING ROTATING SPEEDS OF T E SPINDLE................................................................................................................... 17

6.8.

LASER DEVICE........................................................................................................................................................................................ 19

6.9.

DIGITAL DISPLAY..................................................................................................................................................................................19

6.10.

DRILLING PROCEDURE ......................................................................................................................................................................20

6.11.

STORING T E MAC INE W EN IT IS NOT USED.................................................................................................................... 20

6.12.

TROUBLES OOTING............................................................................................................................................................................21

7.

7.7.

7.

MAINTENANCE

MAINTENANCEMAINTENANCE

MAINTENANCE................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

........................................

................

........23

2323

23

7.1.

DAILY MAINTENANCE........................................................................................................................................................................23

7.2.

WEEKLY MAINTENANCE .................................................................................................................................................................. 23

7.3.

MONT LY MAINTENANCE............................................................................................................................................................... 23

7.4.

6-MONT MAINTENANCE................................................................................................................................................................23

8.

8.8.

8.

EXPLODED VIEW

EXPLODED VIEWEXPLODED VIEW

EXPLODED VIEW................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.....................................

..........

.....24

2424

24

9.

9.9.

9.

ELECTRICAL CIRCUIT

ELECTRICAL CIRCUITELECTRICAL CIRCUIT

ELECTRICAL CIRCUIT ................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.............................................................

..........................................................

.............................26

2626

26

10.

10.10.

10.

NOISE LEVEL

NOISE LEVELNOISE LEVEL

NOISE LEVEL................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.............................................

..........................

.............27

2727

27

11.

11.11.

11.

VIBRATIONS LEVEL

VIBRATIONS LEVELVIBRATIONS LEVEL

VIBRATIONS LEVEL................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.................................

..

. 27

2727

27

12.

12.12.

12.

PROTECTION OF T E EN

PROTECTION OF T E ENPROTECTION OF T E EN

PROTECTION OF T E ENVIRONMENT

VIRONMENTVIRONMENT

VIRONMENT ................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

..............................................................

............................................................

..............................27

2727

27

13.

13.13.

13.

GUARANTEE

GUARANTEEGUARANTEE

GUARANTEE ................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.............................................

..........................

.............27

2727

27

14.

14.14.

14.

DECLARATION OF CONFO

DECLARATION OF CONFODECLARATION OF CONFO

DECLARATION OF CONFORMITY

RMITYRMITY

RMITY ................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.......................................

..............

.......28

2828

28

User’s manual PE22A

3

1.

1.1.

1.

INTRODUCTION

INTRODUCTIONINTRODUCTION

INTRODUCTION

For safety reasons, please careful

For safety reasons, please carefulFor safety reasons, please careful

For safety reasons, please carefully read these instructions, prior to using this machine.

ly read these instructions, prior to using this machine.ly read these instructions, prior to using this machine.

ly read these instructions, prior to using this machine.

Serious injuries to persons or damages to the machine may be caused by the non

Serious injuries to persons or damages to the machine may be caused by the nonSerious injuries to persons or damages to the machine may be caused by the non

Serious injuries to persons or damages to the machine may be caused by the non-

--

-observance of these instructions

observance of these instructionsobservance of these instructions

observance of these instructions.

..

.

This manual is intended to be used by operators, setters

and service engineers.

This manual is an important part of your equipment. It

provides rules and guidance to help you safely operating this

machine. You must read this manual and make sure of the

correct procedures and functions before operating the

machine. For your own safety, you must read these

precautions carefully and follow the instructions described

below.

These instructions must be followed anytime when

operating and servicing the machine. Serious injury and/or

failure of the machine may occur if operators fail in

observing safety guidance and instructions and operate the

machine in a wrong and different way from the one

described in this manual.

Please keep the manual with the machine or in a safe place

to make it available anytime. Make sure any person involved

in operating this machine can consult this manual. In case

this manual is damaged or lost, please contact us or your

dealer to be provided with a new manual.

Always use genuine SIDAMO parts and components.

Replacing SIDAMO parts and components by improper

parts may damage the machine and cause serious injuries

to operators.

This manual describes the safety instructions to be applied

by the operator. Both the employer and operators are

responsible, according to the article L.4122-1 of Labour

Laws, to take care of their health and safety and of the

health and safety of any other person involved by any action

or omission related to instructions given to them.

The employer is in charge of performing the assessment of

all particular risks related to the activity of his/her company.

e/she must train workers to operating the machine and

to the prevention of risks and provide with appropriate

information and instructions all workers in charge of

operating or servicing working equipments.

2.

2.2.

2.

WARNING SIGNS

WARNING SIGNSWARNING SIGNS

WARNING SIGNS

2.1.

2.1.2.1.

2.1.

WARNING SIGNS REL

WARNING SIGNS RELWARNING SIGNS REL

WARNING SIGNS RELATED TO T E SAFETY O

ATED TO T E SAFETY OATED TO T E SAFETY O

ATED TO T E SAFETY OF T E MAC INE

F T E MAC INEF T E MAC INE

F T E MAC INE

Meaning of the safety signs attached to the machine (They must remain clean. Replace them immediately in case they are peeled

off or illegible) :

Always wear protective goggles

Always wear ear protection

Carefully read the User’s Manual

Always wear protective shoes

Do not wear loose clothes, loose sleeves, jewels,

bracelets, watches, rings, …

Wear a hair covering to protect long hair

Wear protective gloves

We do not recommend wearing gloves when

machining. But we recommend wearing gloves

when cleaning, the machine being stopped, and

for any operation presenting any risk of cut, burn,

pinching … Rotation direction of the spindle

2.2.

2.2.2.2.

2.2.

WARNING SIGNS USED I

WARNING SIGNS USED IWARNING SIGNS USED I

WARNING SIGNS USED IN T IS MANUAL

N T IS MANUALN T IS MANUAL

N T IS MANUAL

Straight hazard for human persons and the

machine

The machine and its vicinity may be damaged

Technical ability level : operator, user

Minimal number of persons required to perform

some operations

Technical ability level : setter, service

Technical ability level : maintenance agent

Note

Only low voltage qualified and authorized workers should be allowed to perform interventions on the electrical

Only low voltage qualified and authorized workers should be allowed to perform interventions on the electrical Only low voltage qualified and authorized workers should be allowed to perform interventions on the electrical

Only low voltage qualified and authorized workers should be allowed to perform interventions on the electrical

circuit.

circuit.circuit.

circuit.

User’s manual PE22A

4

3.

3.3.

3.

SAFETY

SAFETYSAFETY

SAFETY

3.1.

3.1.3.1.

3.1.

GENERAL SAFETY INSTR

GENERAL SAFETY INSTRGENERAL SAFETY INSTR

GENERAL SAFETY INSTRUCTIONS

UCTIONSUCTIONS

UCTIONS

Always follow the basic safety instructions to reduce risks of fire, el

Always follow the basic safety instructions to reduce risks of fire, elAlways follow the basic safety instructions to reduce risks of fire, el

Always follow the basic safety instructions to reduce risks of fire, electric shock, mechanical crash and injury for any

ectric shock, mechanical crash and injury for any ectric shock, mechanical crash and injury for any

ectric shock, mechanical crash and injury for any

person using power tools

person using power toolsperson using power tools

person using power tools.

..

.

This manual considers only reasonably predictable

behaviours.

Our machines are designed keeping first in mind the safety

of operators.

We accept no responsibility for any damage cause by the

lack of experience, any improper use of the machine and/or

the machine being damaged and/or instructions provided

by this manual not being followed.

Accidents always happen following an improper use or

because the User’s Manual was not read and understood.

We remind you that in case changes are performed on the

machine, we will be freed from our obligations.

Before starting operating the machine, always check that

guards are in place and in working condition.

Make sure moving parts run correctly, that no element is

damaged and that the machine runs correctly when it is

commissioned.

Only authorized and qualified workers should be allowed to

repair or replace faulty parts.

Keep the vicinity of the machine tidy. Put everything in order.

Make sure the operator can see the entire working area

from the working station.

Untidy working areas and benches are hazardous and can

cause serious injuries.

Never use the machine outdoor ; never expose it to rain and

damp, or to an atmosphere containing flammable fluids.

Provide good lighting conditions to the machine.

No worker under the age of eighteen is allowed to operate

the machine.

Keep children, animals and unauthorized persons away from

the working area. They are not allowed to touch either tools

or electric cables.

Never leave a running machine unattended. Always switch

the machine off. Never leave the machine until it comes to a

full stop.

Never force a tool. It will do the job better and be

safer if it used at the rate it was designed for.

Do not force small tools to perform a machining that should

be done by a larger tool.

Use the right tool and do not use tools for a job they were

not designed for.

Never damage electric cables.

Never pull the power cable to unplug the machine.

Keep the main power cable away from heat sources, greasy

parts and/or sharp edges.

Never use the power cable in wet conditions and protect it

from any damage.

Regularly check the condition of the power cable. In case it

is damaged, have it repaired by an authorized repairer. Only

an authorized company should replace faulty switches.

Never try to run the machine in case the main switch is out

of work.

Do not overestimate your strength.

Do not overreach. Never lose balance.

Always be aware. Use common sense and do not run the

machine when you are tired.

Always use both hands to run the machine.

Use only recommended accessories. Using accessories

different from the ones recommended in this manual may

be hazardous.

The user is responsible for the machine and must make

sure that :

Only qualified, authorized and trained workers can

use the drilling machine.

Safety instructions are followed.

Users have read and understood the safety

instructions.

Users have read and understood the User’s

Manual.

Responsibilities for servicing and possibly repairing

have been correctly assigned and followed.

Failures and faults have immediately been

communicated to an authorized repairer or to your

dealer.

The drilling machine is used for applications

described in this manual.

Do not use the machine for any application other

than that it was designed for. Any other use is

hazardous.

Never remove or bypass mechanical and/or

electrical protections.

Never try to modify or retrofit the machine.

SIDAMO accepts no responsibility for any damage caused to

persons, animals or objects, and resulting from the non-

observance of the safety instructions described in this

manual.

User’s manual PE22A

5

3.2.

3.2.3.2.

3.2.

PARTICULAR SAFETY IN

PARTICULAR SAFETY INPARTICULAR SAFETY IN

PARTICULAR SAFETY INSTRUCTION

STRUCTIONSTRUCTION

STRUCTION

Particular safety instructions related to bench drilling machines.

Particular safety instructions related to bench drilling machines.Particular safety instructions related to bench drilling machines.

Particular safety instructions related to bench drilling machines.

Prior to using this machine, check it has been correctly

assembled.

Do not connect to power if the drilling machine has not been

installed on a flat and stable place, showing no obstacles

and where lighting conditions are correct.

Do not use the machine if the protective guard of the belts

is not fitted.

Adjust the protective shield to prevent any access to the

non-working part of the tool.

Do not use any damaged or warped drill.

Make sure you have selected the right drill and the right

rotating speed, in relation with the material to drill.

Check whether the tension of belts is correct.

Use only adapted drilling rotating speeds. Always select a

speed when the machine has stopped.

Make sure the drill is firmly clamped into the chuck.

Do not touch the drill when it is rotating.

Always wear protective goggles.

In any case, always be concentrated on the work.

We do not recommend wearing gloves when machining.

We do not recommend wearing gloves when machining. We do not recommend wearing gloves when machining.

We do not recommend wearing gloves when machining.

Wear gloves when cleaning.

Always stop the machine and wear protective gloves when

performing hazardous tasks, presenting risks of burn, cut,

pinching, entanglement, winding, crushing, especially when

loading and unloading the tool, when handling the table, the

vice, the clamps, the workpiece.

Do not rush as it is very often a waste of time : the tool

heats, it becomes blunted and it requires grinding. The work

is not well done. There are more risks of accidents.

Always wear an ear protection.

Never hold the workpiece by hand. Always clamp the

workpiece using adapted work-holding devices, such as vices

and clamps.

Thin metal sheets are the most hazardous work pieces :

- They can cut, as they are very thin.

- The drill tends to plunge once it goes through the metal

sheet.

- Offset holes increase hazards as the workpiece, when

rotating, moves along a circle. Fingers, wrists, forearms

and event the chest are particularly exposed.

Use fixtures and clamps :

- Support fixture for flexible work pieces and work pieces

with steps.

- Guiding bush to drill small holes in a thin sleeve.

To not drill the table, adjust the table or the drilling depth.

The working table must remain clean and not populated.

Wear a breathing apparatus to reduce the risk of breathing

harmful dusts.

Prevent coolant from overflowing all around the machine, as

it is a very slippery product.

Prior to changing the workpiece or performing any

positioning or any removal of material wastes, always stop

the machine by using the Emergency Stop Slam button with

lock.

To use this Emergency Stop Slam button with lock, simply

close the cover of the control box, but do not lock it.

Prior to performing any important operation (maintenance,

servicing, …) always unplug the machine from the main

power.

Do not install additional equipments to perform tasks they

were not designed for.

Using improper tools is hazardous.

Make sure the guard of the fan is clean. Do not cover it.

Otherwise the machine could not be correctly operated.

The drill must remain perfectly clean.

Do not clean the drill when it is rotating.

The drill can become very hot during the machining. Before

replacing the drill, wait until it is cold.

When cleaning, first stop the machine and wear protective

goggles and gloves to remove chips. Collect them into tanks.

Do not use an air gun. Prefer using a vacuum cleaner, a

brush, a painting brush with long handle or a hook.

Never wash the machine using water under pressure as

water can get into electric parts.

Never use solvent or aggressive detergents.

When moving the machine, stop it and make sure all moving

parts are safely fixed.

Store the machine in a cool place, out of the reach of

children.

Accidents usually happen because :

There are no accessories used to properly hold the

workpiece.

Disorder : accessories, if present, are not set in

order, and the operator do not use them, as he

cannot find them.

azardous or inappropriate operating mode.

Insufficient training, learning and/or experience of

operators to use the machine.

Lack of protective guards during the operating of

the machine.

Loose cloths, no protective goggles when

performing some tasks.

User’s manual PE22A

6

3.3.

3.3.3.3.

3.3.

PROTECTION OF T E OP

PROTECTION OF T E OPPROTECTION OF T E OP

PROTECTION OF T E OPERATOR

ERATORERATOR

ERATOR

T

TT

To ensure operator’s safety, make sure that non

o ensure operator’s safety, make sure that nono ensure operator’s safety, make sure that non

o ensure operator’s safety, make sure that non-

--

-working parts are protected by a guard.

working parts are protected by a guard.working parts are protected by a guard.

working parts are protected by a guard.

This machine was designed to be operated by only one

operator.

The operator should wear adapted Personal Protective

Equipments, such as :

Protective goggles.

Ear protections.

Safety shoes.

Protective gloves.

The operator should wear tight clothes and should wear a

hair covering to protect long hair, if necessary.

For example, the operator should never wear :

Loose clothes or sleeves.

Bracelets, watch, ring, jewels.

Any other object subjected to be caught or

entangled by moving parts of the machine.

4.

4.4.

4.

DESCRIPTION AND OPER

DESCRIPTION AND OPERDESCRIPTION AND OPER

DESCRIPTION AND OPERATING

ATINGATING

ATING

4.1.

4.1.4.1.

4.1.

PURPOSE OF T E MAC I

PURPOSE OF T E MAC IPURPOSE OF T E MAC I

PURPOSE OF T E MAC INE

NENE

NE

The bench drilling machine PE22A is designed and

manufactured only to perform drilling, on a fixed station,

using a vertical stroke, on steel, ferrous and non-ferrous,

plastic and wooden work pieces.

When operating and maintenance are correct, the drilling

machine can provide many years of safe and consistent

work.

To do so, please thoroughly examine the different functions

of the machine.

4.2.

4.2.4.2.

4.2.

SPECIFICATIONS

SPECIFICATIONSSPECIFICATIONS

SPECIFICATIONS

Digital display of the drilling depth

Protective shield of the servo chuck

Drilling position laser device

LED lighting

Belt guard fitted with a safety grip micro switch

« ON/OFF» switch fitted with an under voltage coil

Emergency Stop Slam button with lock

Transmission using dented belts pulleys

Spindle fitted with ball bearings

Ferro steel column

Square table tilting up to 45°, fitted with a coolant

collector

Rack-drive table

Comes standard with a self-clamping chuck, a

chuck shank, a taper drift, a screw vice and a set of

clamps

Max. drilling

Max. drilling Max. drilling

Max. drilling

capacity

capacitycapacity

capacity

(mm)

(mm)(mm)

(mm)

Morse

Morse Morse

Morse

taper

tapertaper

taper

Column

ColumnColumn

Column

Ø

ØØ

Ø

(mm)

(mm) (mm)

(mm)

Spindle

Spindle Spindle

Spindle

stroke

strokestroke

stroke

(mm)

(mm)(mm)

(mm)

Number

Number Number

Number

of gears

of gearsof gears

of gears

Spindle speed

Spindle speed Spindle speed

Spindle speed

range

rangerange

range

(rpm)

(rpm)(rpm)

(rpm)

Dimensions

DimensionsDimensions

Dimensions

(L x x D)

(L x x D)(L x x D)

(L x x D)

(mm)

(mm)(mm)

(mm)

Motor

Motor Motor

Motor

power

powerpower

power

(kW)

(kW)(kW)

(kW)

Power

PowerPower

Power

Weight

WeightWeight

Weight

(kg

(kg(kg

(kg)

))

)

22 MT2 72 85 16 180 – 2770 430 x 980 x 660 0,55 1-phase 230V 49

d

dd

d

(mm)

(mm)(mm)

(mm)

e

ee

e

(mm)

(mm)(mm)

(mm)

f

ff

f

(mm)

(mm)(mm)

(mm)

Table

TableTable

Table

dimensions

dimensionsdimensions

dimensions

(mm)

(mm)(mm)

(mm)

160 630 440 286 x 286

User’s manual PE22A

7

4.3.

4.3.4.3.

4.3.

MAC INE OVERVIEW

MAC INE OVERVIEW MAC INE OVERVIEW

MAC INE OVERVIEW

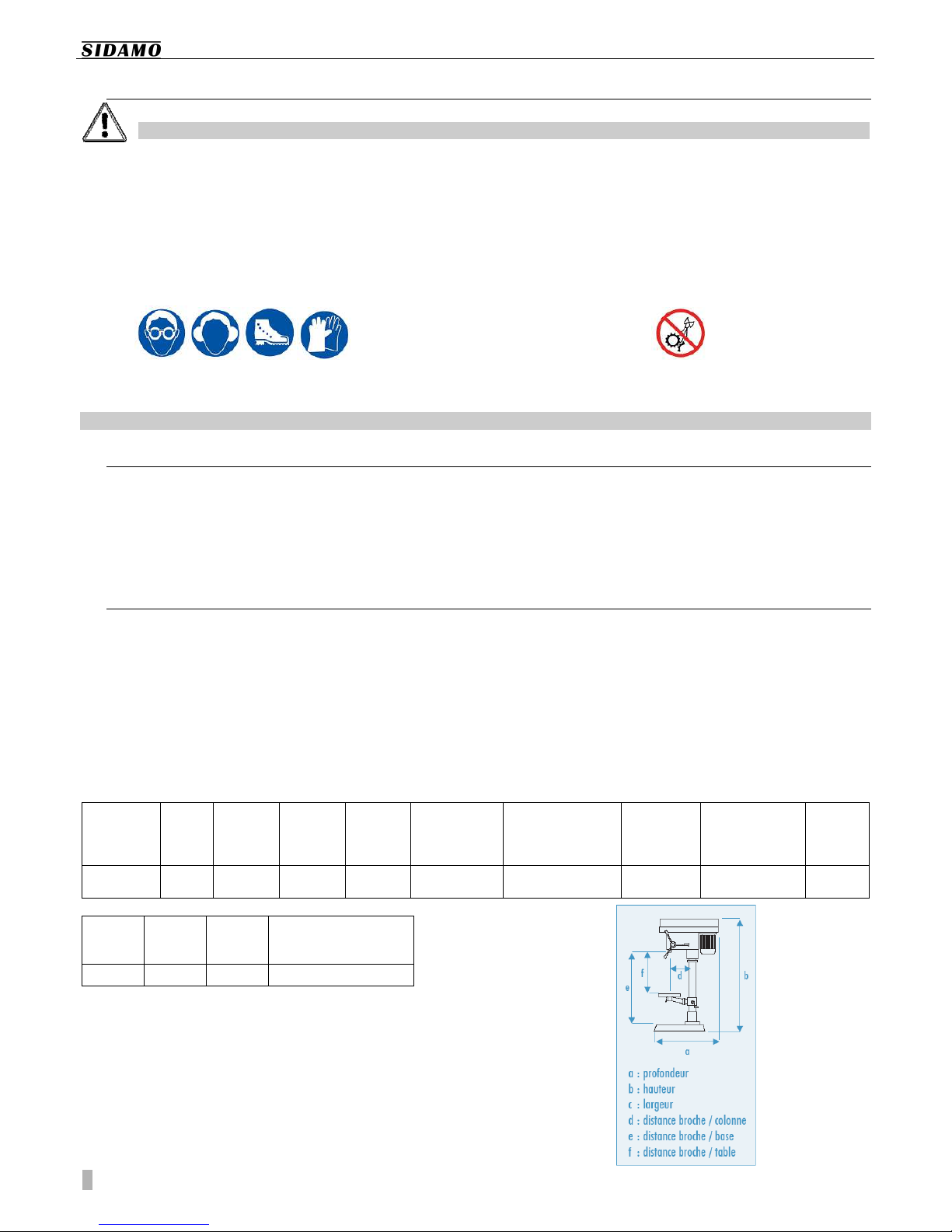

1. Belt guard

2. ead of the drilling machine

3. Electric motor

4. Laser device

5. Rack ring

6. Light

7. Column

8. Support sleeve of the scale table

9. Lock lever of the support sleeve of the scale table

10. Base

11. Lock lever of table

12. Table

13. Vice

14. Servo polycarbonate shield

15. Chuck

16. Capstan wheel

17. Spindle

18. Return spring of spindle

19. Control box

20. Digital display

1

2

3

4

7

5

12

13

8

14

16

17

Figure 1

15

10

6

11

18

9

19

20

User’s manual PE22A

8

5.

5.5.

5.

INSTALLATION

INSTALLATIONINSTALLATION

INSTALLATION

5.1.

5.1.5.1.

5.1.

PACKING

PACKING PACKING

PACKING

The packing may include a desiccant bag. Discard it and keep out of reach of children.

The packing may include a desiccant bag. Discard it and keep out of reach of children.The packing may include a desiccant bag. Discard it and keep out of reach of children.

The packing may include a desiccant bag. Discard it and keep out of reach of children.

The drilling machine comes packed in a cardboard packing.

To move the drilling machine, use a pallet truck or a forklift

truck. Several persons are required to install the machine.

Take out each component of the drilling machine. Check

their condition and then assemble the drilling machine.

Please keep the manual with the machine or in a safe place

to make it available anytime.

In case the product is not in perfect condition or if some

parts are damaged or missing, please contact your dealer.

5.2.

5.2.5.2.

5.2.

TRANSPORT AND ANDL

TRANSPORT AND ANDL TRANSPORT AND ANDL

TRANSPORT AND ANDLING

INGING

ING

Only qualified and authorized persons can perform below operations.

Only qualified and authorized persons can perform below operations.Only qualified and authorized persons can perform below operations.

Only qualified and authorized persons can perform below operations.

The mass centre of this

The mass centre of thisThe mass centre of this

The mass centre of this machine is very high. Be careful as the machine can tip over.

machine is very high. Be careful as the machine can tip over. machine is very high. Be careful as the machine can tip over.

machine is very high. Be careful as the machine can tip over.

Control the good tightening of screws that fix the head on the column.

Control the good tightening of screws that fix the head on the column.Control the good tightening of screws that fix the head on the column.

Control the good tightening of screws that fix the head on the column.

Considering the weight of the machine (49 kg),

several persons, using an adapted lifting device, are

required to install the machine.

To lift the machine, use a slinging system (ex :

polyester cable, with lifting rings and a convenient capacity).

Position the lifting device as shown on next figure.

Make sure all moving parts are securely fixed and be very

careful when lifting the drilling machine. Keep any foreign

person away.

5.3.

5.3.5.3.

5.3.

INSTALLING T E MAC

INSTALLING T E MAC INSTALLING T E MAC

INSTALLING T E MAC INE

INEINE

INE

Only qualified and authorized persons can perform below operations.

Only qualified and authorized persons can perform below operations.Only qualified and authorized persons can perform below operations.

Only qualified and authorized persons can perform below operations.

Vicinity of the equipment :

Vicinity of the equipment :Vicinity of the equipment :

Vicinity of the equipment :

Main power should comply with the specifications

of the machine.

Ambient temperature : between +5°C and +35°C.

Relative umidity : not over 90%.

Sufficient ventilation of the workshop.

Good lighting conditions in the working area : min.

300 lux.

Consider the location of the machine in the room.

Movements and movings should be easy. Respect a

distance of min. 800 mm between the back of the machine

and the wall.

Several persons are required to install the machine.

Position the machine on a flat and horizontal

surface, so that it is level and as stable as possible.

Use a strong enough support base for the machine.

Drill the fixing holes in the support. They must match base

holes. Fix the machine.

Prior to tightening bolt, make sure the machine is level. To

adjust level, use adapted metal sheets (reference shims)

between the surface of the support and the feet.

To perform machining while respecting ergonomic criteria,

the vice plane should be ideally positioned at about 90/95

cm from the floor.

12

User’s manual PE22A

9

Cleaning a new machine :

Cleaning a new machine :Cleaning a new machine :

Cleaning a new machine :

All our machines are supplied with rustproof oil on

ground surfaces. Before using the machine, first

remove this oil, using a thinner. This is very

important. Please use extreme care when

performing this cleaning : jammings can occur if

this oil is not totally removed.

There should be no chips and no oil residues on the

surface of the clamping table.

Once the machine has been cleaned, apply a thin

film of oil onto all non-painted surfaces, using

medium-viscosity oil.

Clean the inner part of both spindle and chuck,

using a dry cloth and firmly insert the Morse taper

into the spindle. Then, insert firmly the chuck into

the shank of the Morse taper.

5.4.

5.4.5.4.

5.4.

ASSEMBLING

ASSEMBLING ASSEMBLING

ASSEMBLING

Only qualified and authorized persons can perform below operations.

Only qualified and authorized persons can perform below operations.Only qualified and authorized persons can perform below operations.

Only qualified and authorized persons can perform below operations.

Several persons are required to assemble

Several persons are required to assemble Several persons are required to assemble

Several persons are required to assemble the machine.

the machine.the machine.

the machine.

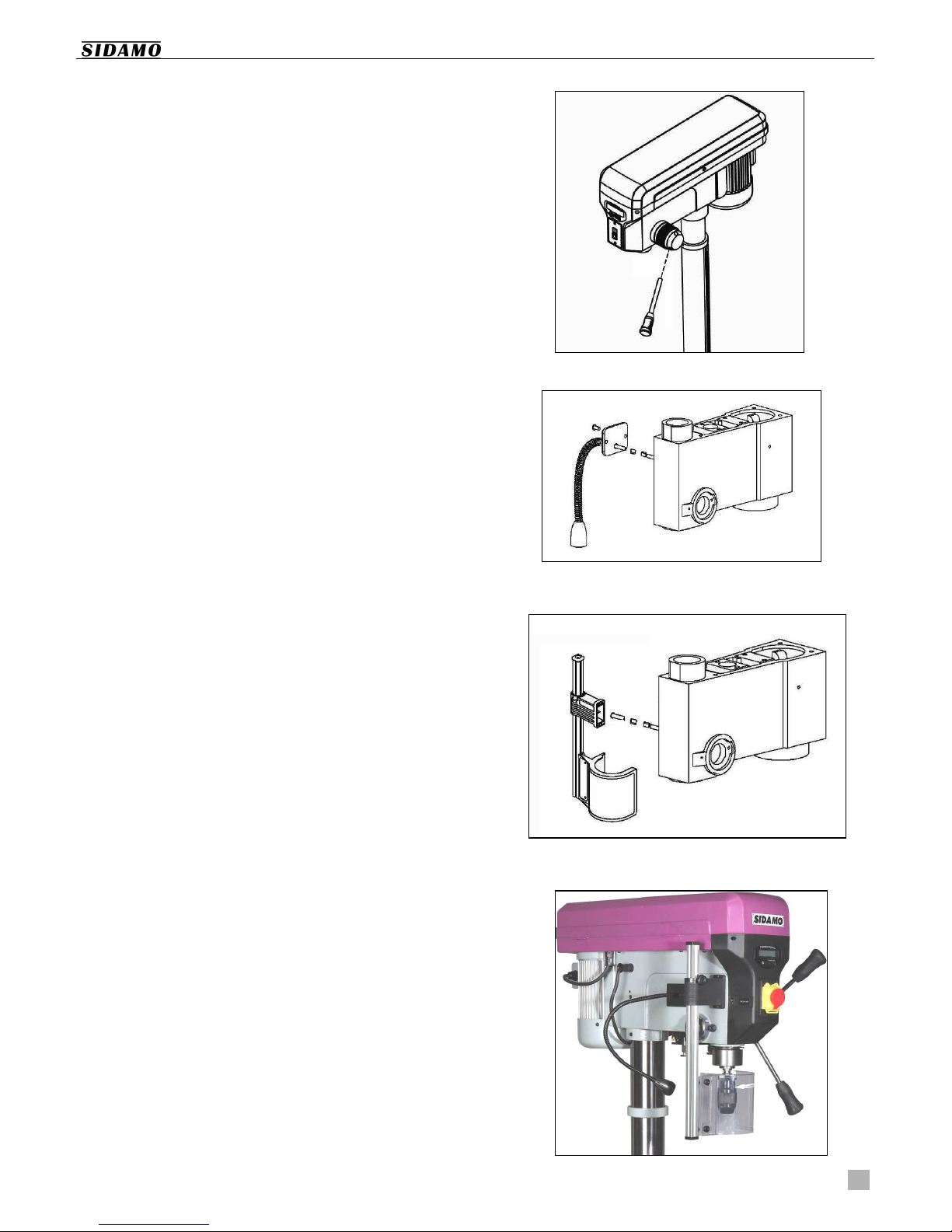

Figure 2

1. Install the base (9 fig.2) on a solid and flat surface.

2. Assemble the column (14 fig.2) to the base and fix

it using bolts (8 fig.2).

User’s manual PE22A

10

3. Insert the rack, in the right direction (6 fig.2), into

the support sleeve of the table (12 fig.2).

4. old the rack (teeth towards the inner right side of

the support sleeve of the table) and slide the

assembly into the column (14 fig.2).

5. Slide the rack ring (15 fig.2) on the column, the

chamfer being oriented downwards, to make sure

the top side of the rack is locked (value of the

clearance with the rack : 1 mm).

6. Tighten the screw of the ring.

7. Fit the table (10 fig.2) on its support (12 fig.2).

8. Fit the handle (13 fig.2) on the shaft of the support

sleeve of the table and tighten the screw.

9. Check whether you can move the table up and

down.

The ideal height between the table and the floor is

about 90/95 cm.

10. Fit the head (1 fig.2) on the column (at least two

persons are required).

11. Check whether the assembly of the head is correct.

12. To balance correctly the assembly, align the head

with the centreline of the base.

13. Tighten the screws to firmly hold the head in place.

User’s manual PE22A

11

14. Screw the three handles (2 fig.2) on the capstan

wheel, used to move the head down.

15. Connect the lamp to the terminals.

16. Fix it using convenient screws.

17. Connect the body of the protector to the terminals.

18. Fit the protective shield on the shield support, using

two screws.

19. Fit the assembly in the body of the protector.

20. Position the shaft and tighten the screw.

21. Clean the inner side of the chuck (5 fig.2).

22. Fit the chuck on the shank of the chuck (4 fig.2).

23. Clean the inner side of the spindle and the shank of

the chuck.

24. Fit the assembly shank of chuck + chuck into the

spindle.

User’s manual PE22A

12

5.5.

5.5.5.5.

5.5.

ELECTRICAL CONNECTIO

ELECTRICAL CONNECTIOELECTRICAL CONNECTIO

ELECTRICAL CONNECTION

NN

N

Only low voltage trained and authorized technicians should be allowed to perform interventions on the electric circuit

Only low voltage trained and authorized technicians should be allowed to perform interventions on the electric circuitOnly low voltage trained and authorized technicians should be allowed to perform interventions on the electric circuit

Only low voltage trained and authorized technicians should be allowed to perform interventions on the electric circuit.

..

.

POWER

POWERPOWER

POWER

Make sure the voltage of the motor matches the voltage of

the main power.

Perform the connection, using the power cable.

The power socket must match the plug of the machine.

The machine is connected to a power system. This system

must be connected to earth, according to in-force safety

regulations.

We remind the user that a magneto thermal breaker must

be installed before the electrical circuit to protect all

conductive devices against short-circuits and overloads.

This protection should always be selected according to the

electrical specifications of the machine, as stated on the

rate plate :

Voltage : one-phase 230 V

Frequency : 50 z

Rating : 2,6 A

Motor power : 0,55 kW

Power connections and extensions must be protected

against splashes and should be fitted onto dry surfaces.

Regularly inspect condition of the power cable, of the switch

and of the cable ducting.

Operating the machine, using a damaged power cable, is strictly prohibited.

Operating the machine, using a damaged power cable, is strictly prohibited.Operating the machine, using a damaged power cable, is strictly prohibited.

Operating the machine, using a damaged power cable, is strictly prohibited.

Always use a cable winder with both section and length adapted to the power

Always use a cable winder with both section and length adapted to the powerAlways use a cable winder with both section and length adapted to the power

Always use a cable winder with both section and length adapted to the power of the machine. Unwind completely the

of the machine. Unwind completely the of the machine. Unwind completely the

of the machine. Unwind completely the

cable.

cable.cable.

cable.

Never pull the cable to unplug the grinder. Always use the plug.

Never pull the cable to unplug the grinder. Always use the plug.Never pull the cable to unplug the grinder. Always use the plug.

Never pull the cable to unplug the grinder. Always use the plug.

Please check the spindle rotates clockwise, as shown on sign fixed on the front of the protective shield.

Please check the spindle rotates clockwise, as shown on sign fixed on the front of the protective shield.Please check the spindle rotates clockwise, as shown on sign fixed on the front of the protective shield.

Please check the spindle rotates clockwise, as shown on sign fixed on the front of the protective shield.

The guarantee does not cover dam

The guarantee does not cover damThe guarantee does not cover dam

The guarantee does not cover damages resulting from a poor connection

ages resulting from a poor connectionages resulting from a poor connection

ages resulting from a poor connection.

..

.

5.6.

5.6.5.6.

5.6.

TEST AND INITIAL INS

TEST AND INITIAL INSTEST AND INITIAL INS

TEST AND INITIAL INSPECTION PRIOR TO USI

PECTION PRIOR TO USIPECTION PRIOR TO USI

PECTION PRIOR TO USING T E EQUIPMENT FOR

NG T E EQUIPMENT FORNG T E EQUIPMENT FOR

NG T E EQUIPMENT FOR T E FIRST TIME

T E FIRST TIME T E FIRST TIME

T E FIRST TIME

Make sure all protections are in place and in

working condition.

Make sure moving parts correctly run and that no

part is damaged.

Check condition of the drill.

Make sure the head and the table are firmly fixed to

the column.

Make sure the bench drilling machine is located on

a flat and solid surface.

Perform a dry test : the machine should run

correctly.

Make sure the spindle goes down, the protective

shield can be adjusted and the table can go up and

down.

User’s manual PE22A

13

6.

6.6.

6.

OPERATING T E BENC

OPERATING T E BENC OPERATING T E BENC

OPERATING T E BENC DRILLING MAC INE

DRILLING MAC INEDRILLING MAC INE

DRILLING MAC INE

Prior to starting the drilling machine, make sure you are familiar with control devices

Prior to starting the drilling machine, make sure you are familiar with control devicesPrior to starting the drilling machine, make sure you are familiar with control devices

Prior to starting the drilling machine, make sure you are familiar with control devices.

..

.

Prior to any servicing or maintenance

Prior to any servicing or maintenancePrior to any servicing or maintenance

Prior to any servicing or maintenance, always unplug the machine.

, always unplug the machine., always unplug the machine.

, always unplug the machine.

6.1.

6.1.6.1.

6.1.

CONTROL PANEL

CONTROL PANEL CONTROL PANEL

CONTROL PANEL

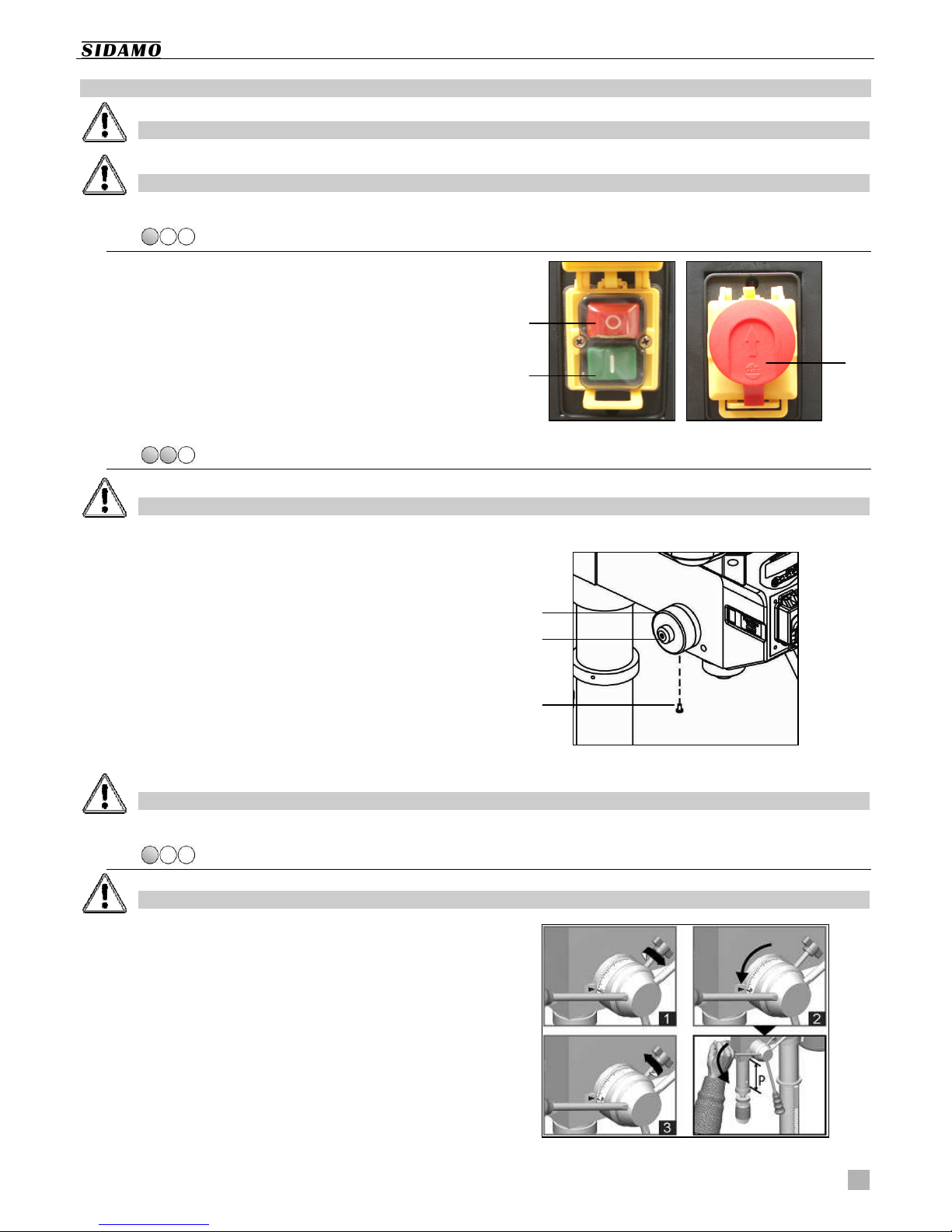

Control box :

Control box :Control box :

Control box :

A. Red Stop button « 0 »

B. Green Run button « I »

C. Emergency Stop slam button with lock

6.2.

6.2.6.2.

6.2.

RETURN SPRING OF T

RETURN SPRING OF T RETURN SPRING OF T

RETURN SPRING OF T E SPINDLE

E SPINDLEE SPINDLE

E SPINDLE

First switch off the machine prior to performing this operat

First switch off the machine prior to performing this operatFirst switch off the machine prior to performing this operat

First switch off the machine prior to performing this operation.

ion.ion.

ion.

The drilling machine is supplied with the spindle

counterbalanced by a spiral spring.

When the spindle cannot go up to its higher position,

adjusting the return spring of the spindle is possible :

1. Stop the machine.

2. Untighten the screw (A).

3. Untighten the screw (B).

4. Carefully rotate the casing (C) in the right direction

to tension, more or less, the spring (to tighten :

rotate anticlockwise). Be careful as the spring can

suddenly get out of the casing.

5. Tighten the screws.

6. Test whether the spindle can go up.

Do not move the spindle back too fast as it could be hazardous and could then threaten the lifespan of the spring.

Do not move the spindle back too fast as it could be hazardous and could then threaten the lifespan of the spring. Do not move the spindle back too fast as it could be hazardous and could then threaten the lifespan of the spring.

Do not move the spindle back too fast as it could be hazardous and could then threaten the lifespan of the spring.

6.3.

6.3.6.3.

6.3.

DRILLING DEPT

DRILLING DEPTDRILLING DEPT

DRILLING DEPT

First switch off the machine prior to performing this operation.

First switch off the machine prior to performing this operation.First switch off the machine prior to performing this operation.

First switch off the machine prior to performing this operation.

Using the drilling depth

Using the drilling depthUsing the drilling depth

Using the drilling depth stop

stop stop

stop

To stop drilling at the depth required :

1. Make sure the spindle is on its up position and the

depth stop is untightened.

2. Rotate the graduations until matching the drilling

depth required.

3. Tighten the depth stop.

4. Move the spindle down, using the capstan wheel, in

order to check the drilling height.

P = drilling depth

B

A

C

C

A

B

User’s manual PE22A

14

6.4.

6.4.6.4.

6.4.

PROTECTIVE S IELD

PROTECTIVE S IELD PROTECTIVE S IELD

PROTECTIVE S IELD

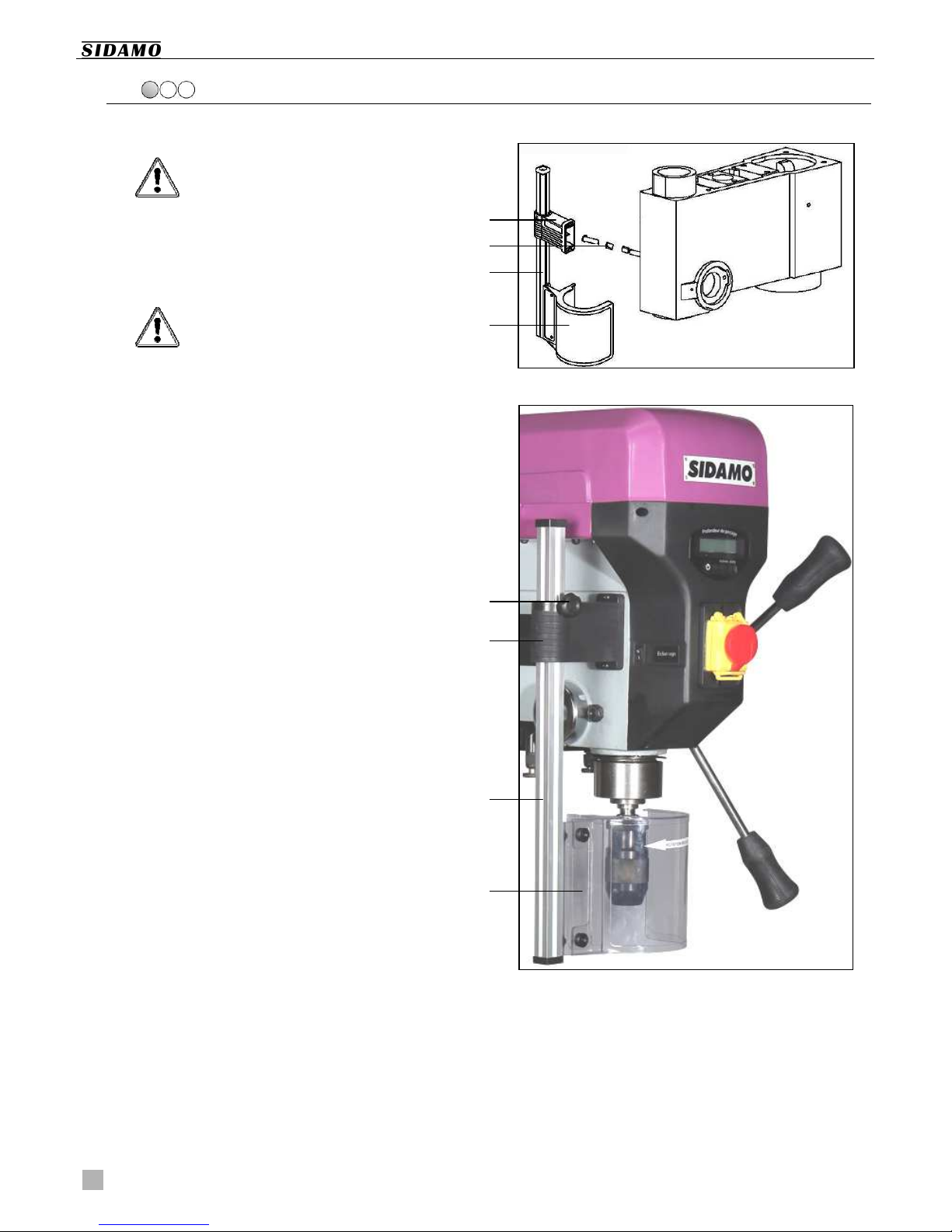

Before starting using the drilling machine, fit the servo

polycarbonate protective shield and adjust it correctly :

1. Check the good tightening of the electrical

connections of the protective shield (A) and of the

electrical connections coming out of the head of the

drilling machine (B).

2. Connect the support of the protective shield (A) to

electrical terminals (B) located on the head of the

drilling machine.

3. Set the tightening knob (C), located on the

support of the protective shield (A) by turning it

upwards (see fig.3).

4. Fit the protective shield (D) on the shaft of the shield

support (E) using two screws.

5. Fit the assembly into the support of the protective

shield (A).

6. Position the shaft (E) and tighten the knob (C).

7. To operate the drilling machine, adjust precisely the

protective shield of the chuck, the shaft being in its

closed position (a safety micro switch ensures the

closing) and tighten the knob (C).

To move the protective shield up and down :

1. Untighten the knob (C).

2. Set the protective shield (D) to the height

required, using the shaft (E).

3. Tighten the knob (C).

To fix the protective shield :

1. Tighten the knob (C).

A

B

C

Figure 3

A

D

D

E

E

User’s manual PE22A

15

6.5.

6.5.6.5.

6.5.

TABLE

TABLE TABLE

TABLE

Stop the machine before moving the table and the workpiece.

Stop the machine before moving the table and the workpiece.Stop the machine before moving the table and the workpiece.

Stop the machine before moving the table and the workpiece.

Never hold the workpiece with your hands. Always clamp it using a vice or clamps.

Never hold the workpiece with your hands. Always clamp it using a vice or clamps.Never hold the workpiece with your hands. Always clamp it using a vice or clamps.

Never hold the workpiece with your hands. Always clamp it using a vice or clamps.

Remove all objects from the table and remove the tool f

Remove all objects from the table and remove the tool fRemove all objects from the table and remove the tool f

Remove all objects from the table and remove the tool from the chuck, prior to any operation.

rom the chuck, prior to any operation.rom the chuck, prior to any operation.

rom the chuck, prior to any operation.

Mind the risk of pinching and crushing.

Mind the risk of pinching and crushing.Mind the risk of pinching and crushing.

Mind the risk of pinching and crushing.

Fix the vice of the workpiece to the table, using a set of clamps.

Fix the vice of the workpiece to the table, using a set of clamps.Fix the vice of the workpiece to the table, using a set of clamps.

Fix the vice of the workpiece to the table, using a set of clamps.

A.

A.A.

A.

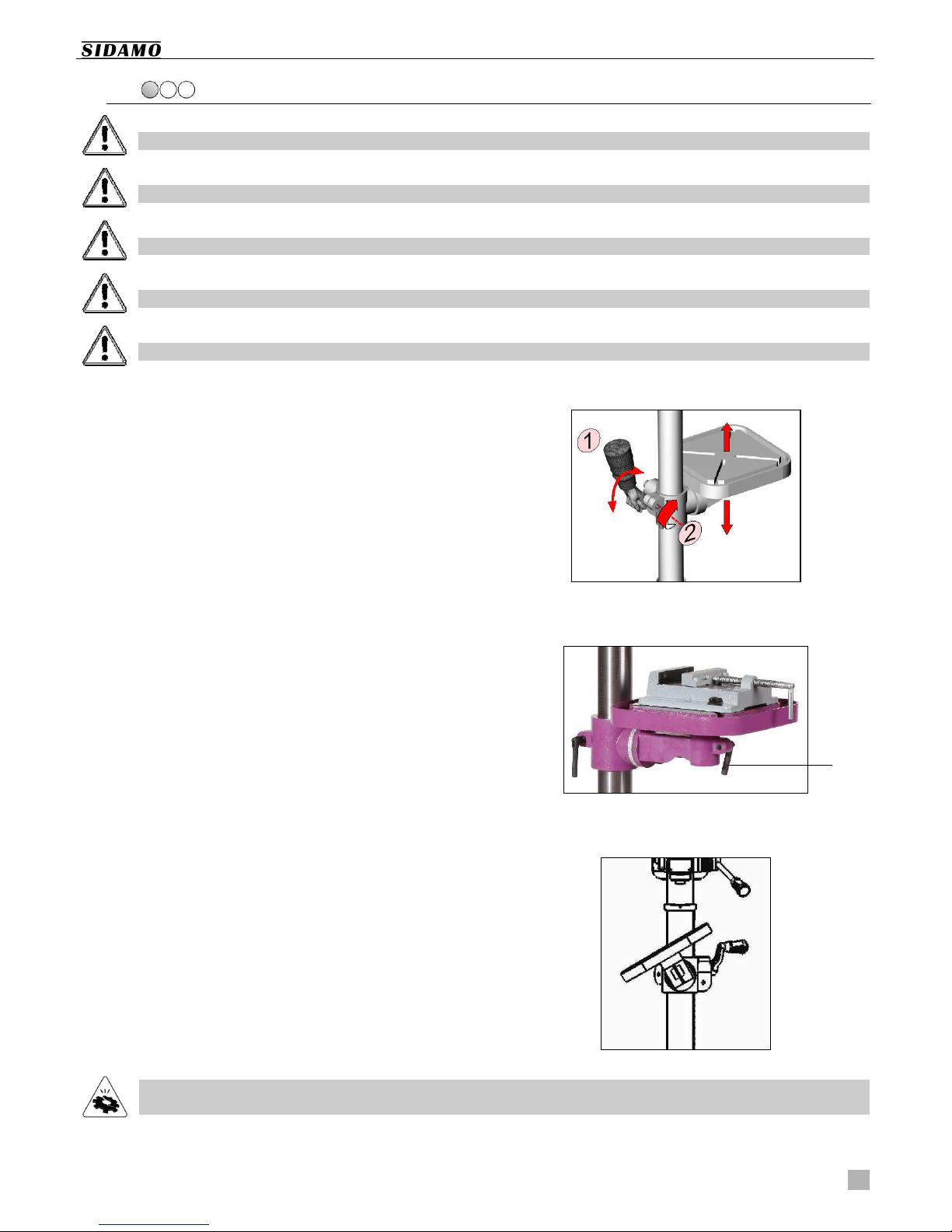

To move the table up and down :

To move the table up and down :To move the table up and down :

To move the table up and down :

1. Untighten the locking handle of the support

sleeve of the table (2).

2. Rotate the handle to move the table (1) up or

down.

3. Tighten the locking handle of the support

sleeve of the table (2).

B.

B.B.

B.

To tilt the table :

To tilt the table :To tilt the table :

To tilt the table :

1. Untighten the locking handle of the table (3).

2. Tilt the table.

3. Tighten the locking handle of the table (3).

C.

C.C.

C.

To give an angle to the

To give an angle to theTo give an angle to the

To give an angle to the table :

table : table :

table :

1. Untighten the pivot bolt located under the

table.

2. Set the table to the angle required, using the

marking.

3. Tighten the pivot bolt.

To ensure a maximal safety when working, always firmly clam

To ensure a maximal safety when working, always firmly clamTo ensure a maximal safety when working, always firmly clam

To ensure a maximal safety when working, always firmly clamp the workpiece using a convenient clamping tool fixed to

p the workpiece using a convenient clamping tool fixed to p the workpiece using a convenient clamping tool fixed to

p the workpiece using a convenient clamping tool fixed to

the T slots of the table or into the vice.

the T slots of the table or into the vice.the T slots of the table or into the vice.

the T slots of the table or into the vice.

3

User’s manual PE22A

16

6.6.

6.6.6.6.

6.6.

ASSEMBLING AND DISM

ASSEMBLING AND DISM ASSEMBLING AND DISM

ASSEMBLING AND DISMANTLING T E TOOL

ANTLING T E TOOLANTLING T E TOOL

ANTLING T E TOOL

Stop the machine before any tool change.

Stop the machine before any tool change.Stop the machine before any tool change.

Stop the machine before any tool change.

Remove all objects from the table prior to any operation.

Remove all objects from the table prior to any operation.Remove all objects from the table prior to any operation.

Remove all objects from the table prior to any operation.

Mind t

Mind tMind t

Mind the risk of punching, pinching, prick, and crushing.

he risk of punching, pinching, prick, and crushing.he risk of punching, pinching, prick, and crushing.

he risk of punching, pinching, prick, and crushing.

Wear protective gloves.

Wear protective gloves.Wear protective gloves.

Wear protective gloves.

Use following tools :

CM2 - B18 shank of chuck with a self-clamping

chuck 1 to 16 mm - B18.

taper shank CM2.

I.

I.I.

I.

Assembling the tool :

Assembling the tool :Assembling the tool :

Assembling the tool :

1. Stop the machine.

2. Degrease the spindle and the shank of the chuck or

the taper part of the tool.

A. 1. Fit the shank of the chuck into the chuck.

2. Fit the assembly into the spindle.

3. Fit the cylindrical-shank tool Ø1 mm to Ø16

mm into the chuck.

B. 1. Directly fit the taper-shank tool into the

spindle (if necessary, adapt the size of the

morse taper, using a convenient adaptor).

II.

II.II.

II.

Dismantling the tool :

Dismantling the tool :Dismantling the tool :

Dismantling the tool :

1. Stop the machine.

2. Move the table up so it is 250 mm under the

accessory.

3. Move the spindle down, using the capstan wheel, on

about 100 mm.

4. Stop the spindle, so that it cannot move up, using

the drilling depth stop.

5. Rotate the spindle by hand until you can see the

shank of the chuck.

6. Fit a taper drift (A) into the port of the spindle (B).

7. Gently tap on the end on the taper drift, using a

mallet, to take the shank of the chuck or the taper

part of the tool out.

A

B

User’s manual PE22A

17

6.7.

6.7.6.7.

6.7.

SELECTING ROTATING S

SELECTING ROTATING SSELECTING ROTATING S

SELECTING ROTATING SPEEDS OF T E SPINDLE

PEEDS OF T E SPINDLEPEEDS OF T E SPINDLE

PEEDS OF T E SPINDLE

Stop the machine before selecting a gear.

Stop the machine before selecting a gear.Stop the machine before selecting a gear.

Stop the machine before selecting a gear.

Mind the risk of entanglement or winding.

Mind the risk of entanglement or winding.Mind the risk of entanglement or winding.

Mind the risk of entanglement or winding.

A safety grip micro switch prevents the machine from

starting in case the belt cover is opened.

To select a rotating speed for the spindle :

1. Stop the machine.

2. Remove the screw of the belt cover to open it.

3. Unlock the motor by untightening the three

tensioning nuts of the motor (A).

4. Rotate the tension knob of belts (B) to release the

belts and change the position of belts, according to

following table (see next page), to get the speed

required.

5. Tension the belts and lock the motor in this

position, using the three tensioning screws of the

motor.

6. To make sure the tension of the belt is correct, the

deflection must be about 13 mm when a 5 kg

pressure is applied.

7. Close the belt cover.

Perform the change of spindle speed, when

Perform the change of spindle speed, whenPerform the change of spindle speed, when

Perform the change of spindle speed, when the spindle is on its higher position.

the spindle is on its higher position. the spindle is on its higher position.

the spindle is on its higher position.

A

B

User’s manual PE22A

18

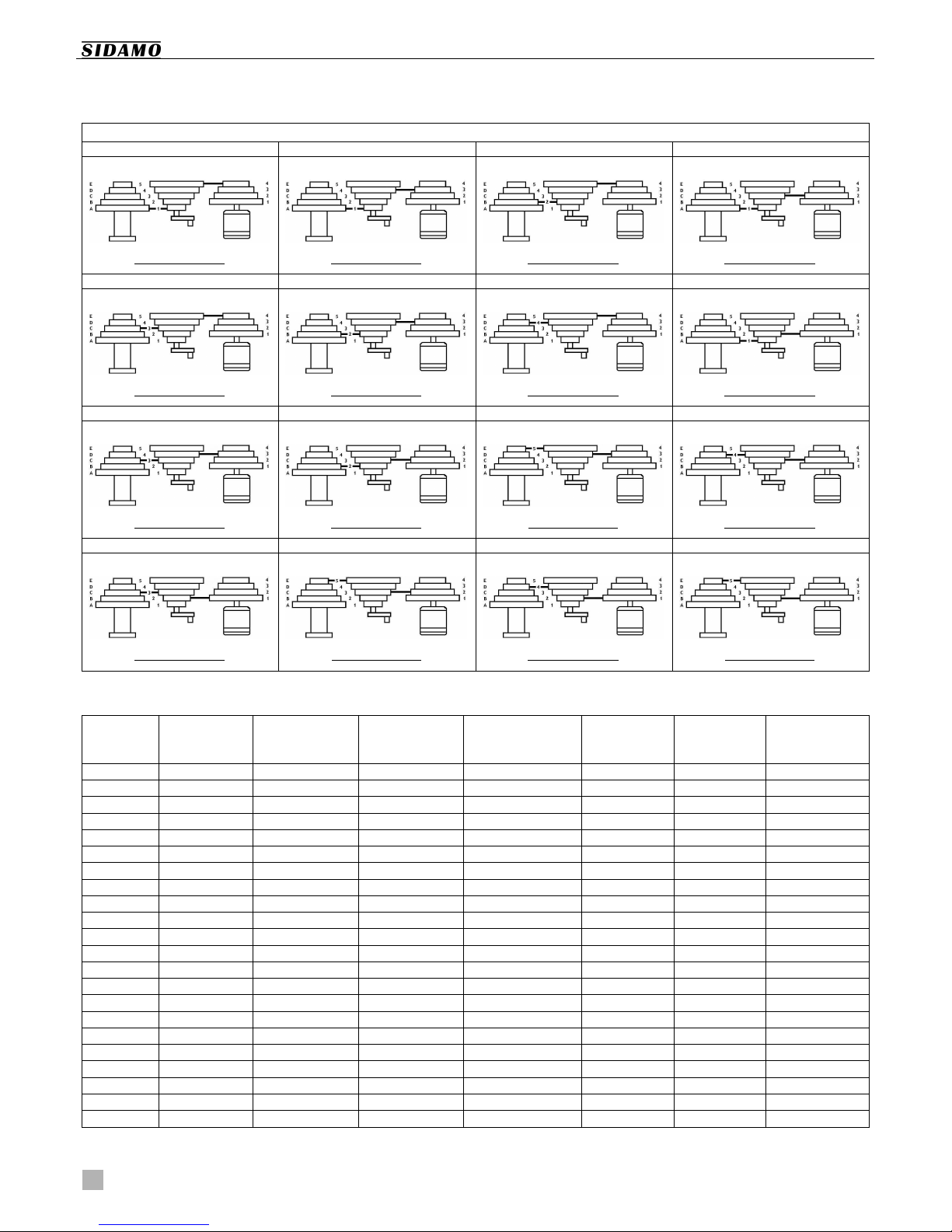

To the rotating speed, change the position of the belts on

the driving pulleys.

Please refer to the speed table fixed into the belt cover.

SPEEDS IN RPM ACCORDING TO T E TRANSMISSION RATIO

SPEEDS IN RPM ACCORDING TO T E TRANSMISSION RATIOSPEEDS IN RPM ACCORDING TO T E TRANSMISSION RATIO

SPEEDS IN RPM ACCORDING TO T E TRANSMISSION RATIO

1

11

1

2

22

2

3

33

3

4

44

4

180 rpm

180 rpm180 rpm

180 rpm

270 rpm

270 rpm270 rpm

270 rpm

310 rpm

310 rpm310 rpm

310 rpm

420 rpm

420 rpm420 rpm

420 rpm

BELTS : A–1 . 5–4

BELTS : A–1 . 4–3 BELTS : B–2 . 5–4 BELTS : A–1 . 3–2

5

55

5

6

66

6

7

77

7

8

88

8

430 rpm

430 rpm430 rpm

430 rpm

470 rpm

470 rpm470 rpm

470 rpm

580 rpm

580 rpm580 rpm

580 rpm

630 rpm

630 rpm630 rpm

630 rpm

BELTS : C–3 . 5–4

BELTS : B–2 . 4–3 BELTS : D–4 . 5–4 BELTS : A–1 . 2–1

9

99

9

10

1010

10

11

1111

11

12

1212

12

650 rpm

650 rpm650 rpm

650 rpm

720 rpm

720 rpm720 rpm

720 rpm

1230 rpm

1230 rpm1230 rpm

1230 rpm

1320 rpm

1320 rpm1320 rpm

1320 rpm

BELTS : C–3 . 4–3

BELTS : B–2 . 3–2 BELTS : E–5 . 4–3 BELTS : D–4 . 3–2

13

1313

13

14

1414

14

15

1515

15

16

1616

16

1460 rpm

1460 rpm1460 rpm

1460 rpm

1880 rpm

1880 rpm1880 rpm

1880 rpm

1950 rpm

1950 rpm1950 rpm

1950 rpm

2770 rpm

2770 rpm2770 rpm

2770 rpm

BELTS : C–3 . 2–1

BELTS : E–5 . 3–2 BELTS : D–4 . 2–1 BELTS : E–5 . 2–1

TABLE OF RECOMMENDED SPEEDS, IN RELATION WIT MATERIALS AND DRILL DIAMETERS

Diameter

DiameterDiameter

Diameter

Steel

SteelSteel

Steel

30 to 40

30 to 4030 to 40

30 to 40

kg/mm²

kg/mm²kg/mm²

kg/mm²

Steel

SteelSteel

Steel

50 to 70

50 to 7050 to 70

50 to 70

kg/mm²

kg/mm²kg/mm²

kg/mm²

Steel

SteelSteel

Steel

80 to 90

80 to 9080 to 90

80 to 90

kg/mm²

kg/mm²kg/mm²

kg/mm²

Allied steel

Allied steelAllied steel

Allied steel

140 to 180

140 to 180140 to 180

140 to 180

kg/mm²

kg/mm²kg/mm²

kg/mm²

Cast iron

Cast ironCast iron

Cast iron

Brass

BrassBrass

Brass

Al

AlAl

Aluminium

uminiumuminium

uminium

35

3535

35

248 181 105 76 171 457 1 190

34

3434

34

255 186 108 78 176 471 1 225

32

3232

32

271 198 115 83 188 500 1 302

30

3030

30

289 211 122 89 200 533 1 389

28

2828

28

310 226 131 95 214 571 1 488

25

2525

25

347 253 147 107 240 640 1 667

22

2222

22

394 288 167 121 273 727 1 894

20

2020

20

433 317 183 133 300 800 2 083

18

1818

18

481 352 204 148 333 889 2 315

16

1616

16

542 396 229 167 375 1 000 2 604

14

1414

14

619 452 262 190 429 1 143 2 976

13

1313

13

667 487 282 205 462 1 231 3 205

12

1212

12

722 528 306 222 500 1 333 3 472

11

1111

11

788 576 333 242 545 1 455 3 788

10

1010

10

867 633 367 267 600 1 600 4 167

9

99

9

963 704 407 296 667 1 778 4 630

8

88

8

1 083 792 458 333 750 2 000 5 208

7

77

7

1 238 905 524 381 857 2 286 5 952

6

66

6

1 444 1 056 611 444 1 000 2 667 6 944

5

55

5

1 733 1 267 733 533 1 200 3 200 8 333

4

44

4

2 167 1 583 917 667 1 500 4 000 10 417

3

33

3

2 889 2 111 1 222 889 2 000 5 333 13 889

User’s manual PE22A

19

6.8.

6.8.6.8.

6.8.

LASER DEVICE

LASER DEVICE LASER DEVICE

LASER DEVICE

Switch off the machine prior to opening the battery housing.

Switch off the machine prior to opening the battery housing.Switch off the machine prior to opening the battery housing.

Switch off the machine prior to opening the battery housing.

Do not open the battery housing when the machine is running.

Do not open the battery housing when the machine is running.Do not open the battery housing when the machine is running.

Do not open the battery housing when the machine is running.

The drilling machine PE22A is equipped with a Class 2 laser

device, to position the drilling :

1. Insert two batteries (type AAA R03 1.5V) into the

housing located opposite to the switch. Respect

polarities.

2. Press the « I » position of the switch (A) to start the

laser device.

3. Adjust the laser device, using both knobs (B) to

correctly position the drilling, the table and the

workpiece.

4. Do not move the table to not change the

position of the drilling.

Use only AAA R03 1.5V type batteries.

Use only AAA R03 1.5V type batteries.Use only AAA R03 1.5V type batteries.

Use only AAA R03 1.5V type batteries.

Do not attempt to charge the batteries supplied with the machine.

Do not attempt to charge the batteries supplied with the machine.Do not attempt to charge the batteries supplied with the machine.

Do not attempt to charge the batteries supplied with the machine.

Remove batteries from the housing in case they are not used for a long period of time.

Remove batteries from the housing in case they are not used for a long period of time.Remove batteries from the housing in case they are not used for a long period of time.

Remove batteries from the housing in case they are not used for a long period of time.

Replace all batteries at the same time.

Replace all batteries at the same time.Replace all batteries at the same time.

Replace all batteries at the same time.

In case batteries are damaged or in case of improper use of batteries, some corrosive liquid can be expelled and some

In case batteries are damaged or in case of improper use of batteries, some corrosive liquid can be expelled and some In case batteries are damaged or in case of improper use of batteries, some corrosive liquid can be expelled and some

In case batteries are damaged or in case of improper use of batteries, some corrosive liquid can be expelled and some

fumes

fumesfumes

fumes can come out : avoid any contact with the hands, the skin and the eyes (this liquid can cause

can come out : avoid any contact with the hands, the skin and the eyes (this liquid can cause can come out : avoid any contact with the hands, the skin and the eyes (this liquid can cause

can come out : avoid any contact with the hands, the skin and the eyes (this liquid can cause irritations or burns

irritations or burns irritations or burns

irritations or burns

and is poisonous when ingested) and ventilate the working place (the fumes can cause

and is poisonous when ingested) and ventilate the working place (the fumes can cause and is poisonous when ingested) and ventilate the working place (the fumes can cause

and is poisonous when ingested) and ventilate the working place (the fumes can cause irritations of airways). In case of

irritations of airways). In case of irritations of airways). In case of

irritations of airways). In case of

accidental contact,

accidental contact,accidental contact,

accidental contact, wash using water and/or in case of unease, contact a doctor.

wash using water and/or in case of unease, contact a doctor. wash using water and/or in case of unease, contact a doctor.

wash using water and/or in case of unease, contact a doctor.

Do not dispose of batteries in a fire (risk of explosion) or in a dustbin.

Do not dispose of batteries in a fire (risk of explosion) or in a dustbin.Do not dispose of batteries in a fire (risk of explosion) or in a dustbin.

Do not dispose of batteries in a fire (risk of explosion) or in a dustbin.

According to the European Directive 2006/66/CE, used or defective batteries must be put apart and recycled,

According to the European Directive 2006/66/CE, used or defective batteries must be put apart and recycled, According to the European Directive 2006/66/CE, used or defective batteries must be put apart and recycled,

According to the European Directive 2006/66/CE, used or defective batteries must be put apart and recycled,

following

followingfollowing

following a convenient process.

a convenient process. a convenient process.

a convenient process.

6.9.

6.9.6.9.

6.9.

DIGITAL DISPLAY

DIGITAL DISPLAY DIGITAL DISPLAY

DIGITAL DISPLAY

The drilling machine PE22A is equipped with a digital display

for the drilling depth, with a tolerance of +/- 5 mm :

There are three keys to operate the display :

A. Switching on the digital display.

B. Selection of the unit, for distances : « inch » and

« mm » (millimetre).

C. Stetting the spindle stroke to zero.

A

B

C

A

B

User’s manual PE22A

20

6.10.

6.10.6.10.

6.10.

DRILLING PROCEDURE

DRILLING PROCEDURE DRILLING PROCEDURE

DRILLING PROCEDURE

Always wear adapted personal protective equipments.

Always wear adapted personal protective equipments.Always wear adapted personal protective equipments.

Always wear adapted personal protective equipments.

All operations relating to drilling must be performed when the s

All operations relating to drilling must be performed when the sAll operations relating to drilling must be performed when the s

All operations relating to drilling must be performed when the spindle is on its up position. The drill must show no

pindle is on its up position. The drill must show no pindle is on its up position. The drill must show no

pindle is on its up position. The drill must show no

evidence of rotation.

evidence of rotation.evidence of rotation.

evidence of rotation.

Always keep your hands away from the drilling area when the machine is operated.

Always keep your hands away from the drilling area when the machine is operated.Always keep your hands away from the drilling area when the machine is operated.

Always keep your hands away from the drilling area when the machine is operated.

Always switch off the machine prior to performing any positioning of a workpiece or removal of chi

Always switch off the machine prior to performing any positioning of a workpiece or removal of chiAlways switch off the machine prior to performing any positioning of a workpiece or removal of chi

Always switch off the machine prior to performing any positioning of a workpiece or removal of chips.

ps.ps.

ps.

Never hold work pieces with your hands. Carefully clamp them using convenient a tooling, such as a vice or clamps.

Never hold work pieces with your hands. Carefully clamp them using convenient a tooling, such as a vice or clamps.Never hold work pieces with your hands. Carefully clamp them using convenient a tooling, such as a vice or clamps.

Never hold work pieces with your hands. Carefully clamp them using convenient a tooling, such as a vice or clamps.

Operating cycle

Operating cycleOperating cycle

Operating cycle

Drilling instructions :

1. The drill should be perfectly sharpened and

clamped. The workpiece should be firmly clamped

on the table or in the vice.

2. Adjust the height of the working table.

3. Properly adjust the protective shield of the chuck,

by positioning the pin (a safety micro switch is used

to closing) and tighten the screw.