Signal Recovery 7210 User manual

Model 7210

Multi-Channel

DSP Lock-in Amplifier

Instruction Manual

190480-A-MNL-F

Acknowledgement

This instrument was originally developed in conjunction with:

Dr E. Tokunaga

Masumoto Single Quantum Dot Project

Japan Science and Technology Corporation

Tsukuba Research Consortium

5-9-9 Tokodai

Tsukuba

Ibaraki 300-2635

Japan

Copyright © 2013 AMETEK ADVANCED MEASUREMENT TECHNOLOGY, INC

FCC Notice

This equipment generates, uses, and can radiate radio

used in accordance with this manual, may cause interference to radio communications. As

temporarily permitted by regulation, operation of this equipment in a residential area is likely to

cause interference, in which case the user at his own facility w

measures may be required to correct the interference.

Company Names

SIGNAL RECOVERY

is part of Advanced Measurement Technology, Inc, a division of AMETEK,

Inc. It includes the businesses formerly trading as EG&G Princeton

Instruments (Signal Recovery), EG&G Signal Recovery and PerkinElmer Instruments (Signal

Recovery)

Declaration of Conformity

This product conforms to EC Directives 89/336/EEC Electromagnetic Compatibility Directive,

amended by 92/31/

EEC and 93/68/EEC, and Low Voltage Directive 73/23/EEC amended by

93/68/EEC.

This product has been designed in conformance with the following IEC/EN standards:

EMC:

BS EN55011 (1991) Group 1, Class A (CSPIR 11:1990)

BS EN50082-

1 (1992):

IEC 801

IEC 801

IEC 801

Safety: BS EN61010-

1: 1993 (IEC 1010

Trademarks

AMETEK® and the and

logos are registered trademarks of

This equipment generates, uses, and can radiate radio

-

frequency energy and, if not installed

used in accordance with this manual, may cause interference to radio communications. As

temporarily permitted by regulation, operation of this equipment in a residential area is likely to

cause interference, in which case the user at his own facility w

ill be required to take whatever

measures may be required to correct the interference.

is part of Advanced Measurement Technology, Inc, a division of AMETEK,

Inc. It includes the businesses formerly trading as EG&G Princeton

Applied Research, EG&G

Instruments (Signal Recovery), EG&G Signal Recovery and PerkinElmer Instruments (Signal

This product conforms to EC Directives 89/336/EEC Electromagnetic Compatibility Directive,

EEC and 93/68/EEC, and Low Voltage Directive 73/23/EEC amended by

This product has been designed in conformance with the following IEC/EN standards:

BS EN55011 (1991) Group 1, Class A (CSPIR 11:1990)

1 (1992):

IEC 801

-2:1991

IEC 801

-3:1994

IEC 801

-4:1988

1: 1993 (IEC 1010

-1:1990+A1:1992)

logos are registered trademarks of

AMETEK, Inc.

frequency energy and, if not installed

and

used in accordance with this manual, may cause interference to radio communications. As

temporarily permitted by regulation, operation of this equipment in a residential area is likely to

ill be required to take whatever

is part of Advanced Measurement Technology, Inc, a division of AMETEK,

Applied Research, EG&G

Instruments (Signal Recovery), EG&G Signal Recovery and PerkinElmer Instruments (Signal

This product conforms to EC Directives 89/336/EEC Electromagnetic Compatibility Directive,

EEC and 93/68/EEC, and Low Voltage Directive 73/23/EEC amended by

This product has been designed in conformance with the following IEC/EN standards:

Table of Contents Table of Contents

i

Chapter One, Introduction

1.1 How to Use This Manual.................................................................................................................................. 1-1

1.2 What is a Lock-in Amplifier?........................................................................................................................... 1-2

1.3 Key Specifications and Benefits....................................................................................................................... 1-2

Chapter Two, Installation & Initial Checks

2.1 Installation........................................................................................................................................................ 2-1

2.1.01 Introduction ............................................................................................................................................. 2-1

2.1.02 Inspection ................................................................................................................................................ 2-1

2.1.03 Line Cord Plug......................................................................................................................................... 2-1

2.1.04 Line Voltage Selection and Line Fuses................................................................................................... 2-1

2.2 Initial Checks.................................................................................................................................................... 2-3

2.2.01 Introduction ............................................................................................................................................. 2-3

2.2.02 Procedure................................................................................................................................................. 2-3

Chapter Three, Technical Description

3.1 Introduction ...................................................................................................................................................... 3-1

3.2 Operating Modes .............................................................................................................................................. 3-1

3.2.01 Introduction ............................................................................................................................................. 3-1

3.2.02 Single Reference Mode ........................................................................................................................... 3-1

3.2.03 Tandem Reference Mode......................................................................................................................... 3-1

3.3 Principles of Operation..................................................................................................................................... 3-2

3.3.01 Block Diagram......................................................................................................................................... 3-2

3.3.02 Signal Channel Inputs.............................................................................................................................. 3-3

3.3.03 AC Gain and Dynamic Reserve............................................................................................................... 3-3

3.3.04 Anti-Aliasing Filter.................................................................................................................................. 3-4

3.3.05 Main Analog-to-Digital Converter.......................................................................................................... 3-5

3.3.06 Reference Channel................................................................................................................................... 3-6

3.3.07 Phase-Shifters.......................................................................................................................................... 3-6

3.3.08 Demodulator DSP.................................................................................................................................... 3-6

3.3.09 Main Microprocessor - General............................................................................................................... 3-7

3.3.10 Main Microprocessor - Auto Functions................................................................................................... 3-7

3.3.11 Main Microprocessor - Curve Buffer...................................................................................................... 3-9

3.4 General ............................................................................................................................................................. 3-9

3.4.01 Accuracy.................................................................................................................................................. 3-9

3.4.02 Power-up Defaults................................................................................................................................... 3-9

Chapter Four, Front and Rear Panels

4.1 Front Panel........................................................................................................................................................ 4-1

4.1.01 Signal Input Connectors.......................................................................................................................... 4-1

4.1.02 REF 1 IN Connector................................................................................................................................ 4-1

4.1.03 REF 2 OUT Connector............................................................................................................................ 4-1

4.1.04 TRIG 1 and TRIG 2 Connectors.............................................................................................................. 4-2

TABLE OF CONTENTS

ii

4.1.05 Indicators................................................................................................................................................. 4-2

4.2 Rear Panel......................................................................................................................................................... 4-3

4.2.01 Line Power Switch .................................................................................................................................. 4-3

4.2.02 Line Power Input Assembly.................................................................................................................... 4-3

4.2.03 RS232 Connector .................................................................................................................................... 4-3

4.2.04 GPIB Connector...................................................................................................................................... 4-3

4.2.05 DIGITAL I/O Connector......................................................................................................................... 4-3

4.2.06 PREAMP POWER Connector ................................................................................................................ 4-4

4.2.07 LINK 1 and LINK 2 connectors.............................................................................................................. 4-4

4.2.08 GPIB Address & Master/Slave Switch.................................................................................................... 4-4

Chapter Five, Computer Operation

5.1 Introduction...................................................................................................................................................... 5-1

5.2 RS232 and GPIB Operation............................................................................................................................. 5-1

5.2.01 Introduction............................................................................................................................................. 5-1

5.2.02 RS232 Interface - General Features ........................................................................................................ 5-1

5.2.03 Choice of Baud Rate................................................................................................................................ 5-2

5.2.04 Choice of Number of Data Bits............................................................................................................... 5-2

5.2.05 Choice of Parity Check Option................................................................................................................ 5-3

5.2.06 GPIB Interface - General Features.......................................................................................................... 5-3

5.2.07 Handshaking and Echoes......................................................................................................................... 5-3

5.2.08 Terminators ............................................................................................................................................. 5-5

5.2.09 Command Format.................................................................................................................................... 5-5

5.2.10 Delimiters................................................................................................................................................ 5-6

5.2.11 Compound Commands............................................................................................................................ 5-6

5.2.12 Status Byte, Prompts and Overload Byte................................................................................................ 5-6

5.2.13 Service Requests...................................................................................................................................... 5-8

5.3 Command Descriptions.................................................................................................................................... 5-8

5.3.01 Signal Channel ........................................................................................................................................ 5-9

5.3.02 Reference Channel ................................................................................................................................ 5-12

5.3.03 Signal Channel Output Filters............................................................................................................... 5-13

5.3.04 Instrument Outputs................................................................................................................................ 5-14

5.3.05 Auxiliary Output.................................................................................................................................... 5-15

5.3.06 Output Data Curve Buffer..................................................................................................................... 5-15

5.3.07 Computer Interfaces (RS232 and GPIB)............................................................................................... 5-23

5.3.08 Instrument Identification....................................................................................................................... 5-25

5.3.09 Auto Default.......................................................................................................................................... 5-25

5.4 Programming Examples ................................................................................................................................. 5-26

5.4.01 Introduction........................................................................................................................................... 5-26

5.4.02 Basic Signal Recovery - Single Reference Mode.................................................................................. 5-26

5.4.03 Basic Signal Recovery - Tandem Reference Mode............................................................................... 5-26

5.4.04 Tandem Reference Mode with Output Data Sampling Correlation ...................................................... 5-27

Appendix A, Specifications

TABLE OF CONTENTS

iii

Appendix B, Pinouts

B1 RS232 Connector Pinout ..................................................................................................................................B-1

B2 Digital Output Port Connector..........................................................................................................................B-1

B3 Preamplifier Power Connector Pinout..............................................................................................................B-1

Appendix C, Demonstration Programs

C1 Simple Terminal Emulator................................................................................................................................C-1

C2 RS232 Control Program with Handshakes .......................................................................................................C-1

C3 GPIB User Interface Program...........................................................................................................................C-3

Appendix D, Cable Diagrams

D1 RS232 Cable Diagrams......................................................................................................................................D1

Appendix E, Alphabetical Listing of Commands

Index

Warranty

...................................................................................................................................... End of Manual

Introduction Chapter

1

1-1

1.1 How to Use This Manual

This manual gives detailed instructions for setting up and operating the

SIGNAL RECOVERY Model 7210 Multi-Channel Digital Signal Processing (DSP)

dual phase lock-in amplifier. It is split into the following chapters:-

Chapter 1 - Introduction

Provides an introduction to the manual, briefly describes what a lock-in amplifier is

and the types of measurements it may be used for, and lists the major specifications

of the model 7210.

Chapter 2 - Installation and Initial Checks

Describes how to install the instrument and gives a simple test procedure which may

be used to check that the unit has arrived in full working order.

Chapter 3 - Technical Description

Provides an outline description of the design of the instrument and discusses the

effect of the various controls. A good understanding of the design will enable the user

to get the best possible performance from the unit.

Chapter 4 - Front and Rear Panels

Describes the connectors, controls and indicators which are found on the unit and

which are referred to in the subsequent chapters.

Chapter 5 - Computer Operation

This chapter provides detailed information on operating the instrument from a

computer over the GPIB (IEEE-488) or RS232 interfaces. It includes information on

how to establish communications, the functions available, the command syntax and a

detailed command listing.

Appendix A

Gives the detailed specifications of the model 7210.

Appendix B

Details the pinouts of the multi-way connectors on the rear panel.

Appendix C

Lists three simple terminal programs which may be used as the basis for more

complex user-written programs.

Appendix D

Shows the connection diagrams for suitable RS232 null-modem cables to couple the

unit to an IBM-PC or 100% compatible computer.

Chapter 1, INTRODUCTION

1-2

Appendix E

Gives an alphabetical listing of the computer commands for easy reference.

New users are recommended to unpack the instrument and carry out the procedure in

chapter 2 to check that it is working satisfactorily. They should then make themselves

familiar with the information in chapters 3 and 4 before turning to chapter 5 for

information on how to operate the instrument. Once the structure of the computer

commands is familiar, appendix E will prove convenient as it provides a complete

alphabetical listing of these commands in a single easy-to-use section.

1.2 What is a Lock-in Amplifier?

In its most basic form the single-channel lock-in amplifier is an instrument with dual

capability. It can recover signals in the presence of an overwhelming noise

background or alternatively it can provide high resolution measurements of relatively

clean signals over several orders of magnitude and frequency.

The model 7210 extends this capability to experiments requiring several detection

channels, where previously the only way of implementing them has been with

multiple single-channel instruments. It therefore offers a cost-effective and physically

much more compact solution to such requirements.

The model 7210 lock-in amplifier can function as a:-

AC Signal Recovery Instrument Vector Voltmeter

Phase Meter Frequency Meter

These characteristics, all available in a single compact unit, make it an invaluable

addition to any laboratory.

1.3 Key Specifications and Benefits

The SIGNAL RECOVERY Model 7210 represents a significant advance in the

application of DSP technology in the design of a lock-in amplifier. Until now, units

have been restricted to a single signal channel, allowing only one, or at most two,

signals to be measured at any one time. The model 7210, with its use of the latest

technology, allows up to 32 signals to be measured simultaneously. What is more,

units can be linked together to give more detection channels. For example, four units

would give 128 channels, while sixteen would give 512 channels.

The unit can effectively operate as 32 parallel dual-phase lock-in amplifiers, running

at the same external reference frequency, measuring 32 signals and generating 32

pairs of X and Y outputs. It can also operate in a tandem mode in which it generates a

second reference signal which is an integer division of the external reference. This

second reference is applied to the external experiment in such a way as to induce an

amplitude modulation on the signal at the first reference frequency.

The amplitude modulation is detected by the first set of demodulators, which run at

the external frequency, and then further demodulated by a second set of demodulators

running at the generated reference frequency, to give a second set of X and Y outputs

Chapter 1, INTRODUCTION

1-3

per channel. This detection method would previously have required two lock-in

amplifiers connected in series, so in this mode the 32-channels of the 7210 are

equivalent to 64 dual phase lock-in amplifiers. To date, no other commercially

available instrument matches this capability.

Key specifications include:

32 Dual-Phase Detection Channels

Up to sixteen instruments can be interconnected to give 512 detection channels

External Frequency range: 20 Hz to 50.5 kHz

Voltage, Wide Bandwidth Current or Low Noise Current input modes, depending

on input signal board configuration

Dual phase demodulators with 5-digit readings of X and Y outputs

Very low phase noise of < 0.0001

°

rms

Output time constant: 2 ms to 1 ks

Tandem Reference Mode - Unit generates a second reference frequency by

integer division of the first reference frequency. This second frequency is used in

the experiment to amplitude modulate the signal at the first frequency. The

instrument then uses a second stage of demodulation to detect the resulting

modulation at the X output of the first stage demodulation

8-bit programmable digital output port for control of peripheral devices

Full range of auto-modes

Internal data buffer capable of storing up to 4000 sets of 32-output readings at

intervals of down to 2 ms per set

Data buffer can be used in first-in, first out (FIFO) mode for continuous data

acquisition

Installation &

Initial Checks Chapter

2

2-1

2.1 Installation

2.1.01 Introduction

Installation of the model 7210 in the laboratory or on the production line is very

simple. It can be operated on almost any laboratory bench or be rack mounted using

the integral flanges at the user's convenience. With an ambient operating temperature

range of 0 °C to 30 °C, it is highly tolerant to environmental variables, needing only

to be protected from exposure to dust, corrosive agents and liquids.

The instrument uses forced-air ventilation and as such should be located so that the

ventilation holes on the bottom and/or top cover and rear panels are not obstructed.

This condition is best satisfied by leaving a space of at least 2" (5 cm) between the

top/bottom covers and rear panels and any adjacent surface

2.1.02 Inspection

Upon receipt the model 7210 Lock-in Amplifier should be inspected for shipping

damage. If any is noted, SIGNAL RECOVERY should be notified immediately and

a claim filed with the carrier. The shipping container should be saved for inspection

by the carrier.

2.1.03 Line Cord Plug

A standard IEC 320 socket is mounted on the rear panel of the instrument and a

suitable line cord is supplied.

2.1.04 Line Voltage Selection and Line Fuses

Before plugging in the line cord, ensure that the model 7210 is set to the voltage of

the AC power supply to be used.

A detailed discussion of how to check and, if necessary, change the line voltage

setting follows.

CAUTION: The model 7210 may be damaged if the line voltage is set for 110 V AC

operation and it is turned on with 220 V AC applied to the power input connector.

The model 7210 can operate from any one of four different line voltage ranges,

90-110 V, 110-130 V, 200-240 V, and 220-260 V, at 50-60 Hz. The change from one

range to another is made by repositioning a plug-in barrel selector internal to the Line

Input Assembly on the rear panel of the unit. Instruments are normally shipped from

the factory with the line voltage selector set to 110-130 V AC, unless they are

destined for an area known to use a line voltage in the 220-260 V range, in which

case, they are shipped configured for operation from the higher range.

The line voltage setting can be seen through a small rectangular window in the line

input assembly on the rear panel of the instrument (figure 2-1). If the number

Chapter 2, INSTALLATION & INITIAL CHECKS

2-2

showing is incorrect for the prevailing line voltage (refer to table 2-1), then the barrel

selector will need to be repositioned as follows.

Observing the instrument from the rear, note the plastic door immediately adjacent to

the line cord connector (figure 2-1) on the right-hand side of the instrument. When

the line cord is removed from the rear-panel connector, the plastic door can be

opened outwards by placing a small, flat-bladed screwdriver in the slot on the topside

and levering gently. This gives access to the fuse and to the voltage barrel selector,

which is located at the right-hand edge of the fuse compartment. Remove the barrel

selector with the aid of a small screwdriver or similar tool. With the barrel selector

removed, four numbers become visible on it: 100, 120, 220, and 240, only one of

which is visible when the door is closed. Table 2-1 indicates the actual line voltage

range represented by each number. Position the barrel selector such that the required

number (see table 2-1) will be visible when the barrel selector is inserted and the door

closed.

Figure 2-1, Line Input Assembly

VISIBLE # VOLTAGE RANGE

100 90 - 110 V

120 110 - 130 V

220 200 - 240 V

240 220 - 260 V

Table 2-1, Range vs. Barrel Position

Next check the fuse rating. For operation from a nominal line voltage of 100 V or

120 V, use a 20 mm slow-blow fuse rated at 2.0 A, 250 V. For operation from a

Chapter 2, INSTALLATION & INITIAL CHECKS

2-3

nominal line voltage of 220 V or 240 V, use a 20 mm slow-blow fuse rated at 1.0 A,

250 V.

To change the fuse, first remove the fuse holder by pulling the plastic tab marked

with an arrow. Remove the fuse and replace with a slow-blow fuse of the correct

voltage and current rating. Install the fuse holder by sliding it into place, making sure

the arrow on the plastic tab is pointing downwards. When the proper fuse has been

installed, close the plastic door firmly. The correct selected voltage setting should

now be showing through the rectangular window. Ensure that only fuses with the

required current and voltage ratings and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuse holders is

prohibited and potentially dangerous.

2.2 Initial Checks

2.2.01 Introduction

The following procedure checks the performance of a single model 7210. In general,

this procedure should be carried out after inspecting the instrument for obvious

shipping damage. If several instruments have been supplied already interconnected as

a system, then separate instructions apply, but the given procedure is still valid for

checking a single unit.

NOTE: Any damage must be reported to the carrier and to SIGNAL RECOVERY

immediately. In addition the shipping container must be retained for inspection by

the carrier.

Note that this procedure is intended to demonstrate that the instrument has arrived in

good working order, not that it meets specifications. Each instrument receives a

careful and thorough checkout before leaving the factory, and normally, if no

shipping damage has occurred, will perform within the limits of the quoted

specifications. If any problems are encountered in carrying out these checks, contact

SIGNAL RECOVERY or the nearest authorized representative for assistance.

2.2.02 Procedure

1) Ensure that the model 7210 is set to the line voltage of the power source to be

used, as described in section 2.1.05.

Figure 2-2, Model 7210 GPIB Address and

Master/Slave Switch

2) Locate the GPIB Address and Master/Slave switch on the lower left-hand side of

the rear-panel, as shown in figure 2-2

3) Confirm that the switches are set as shown in figure 2-2. This configures the

Chapter 2, INSTALLATION & INITIAL CHECKS

2-4

instrument as a Master unit and the GPIB address as 12.

Note:- If several units have been supplied as a system then the switches may be

set to different positions. Record the existing settings before changing them to

match the above so that you can restore them on completion of this procedure.

4) Connect an RS232 null modem cable, SIGNAL RECOVERY part number

C01003, between the RS232 connector on the rear-panel of the instrument and a

serial port on a PC compatible computer running Windows 95 or 98.

5) Start Windows HyperTerminal or other RS232 terminal emulator software. Set

the communications port properties in the software, for the port to which the

instrument is cabled, to 9600 baud, 7 data bits, 1 stop bit, even parity and no flow

control.

6) With the rear-panel mounted power switch (located above the line power input

connector) set to 0(off), plug in the line cord to an appropriate line source.

7) Turn the model 7210's power switch to the I (on) position.

8) The instrument's front panel PWR, UNLK, and MSTR LEDs should light and

"Model 7210" will appear on the computer monitor.

9) Type "ID" and press the return key to send the ID command to the instrument.

The response should be "7210", a newline, carriage return and a "?" character.

10) Use a signal generator capable of generating a 1 kHz output sinewave in the

range 0.1 V to 1.0 V rms and fitted with a TTL sync output. Connect the sync

output to the front panel REF 1 IN connector. The UNLK LED should

extinguish.

11) Type "FRQ1" and press the return key to send the FRQ1 command to the

instrument. The response should be "1000", a newline, carriage return and a "*"

character., indicating a detected reference frequency on 1.000 kHz

12) If the unit is fitted with voltage mode input signal boards (7210/99), set the signal

generator output amplitude to 1 V rms and apply this to the front panel signal

input connector marked "1".

If it is fitted with wide bandwidth current mode input signal boards (7210/98), set

the signal generator output amplitude to 1 V rms and apply this via series resistor

of 1 MΩ(1% accuracy) to the front panel signal input connector marked "1".

This resistor generates a nominal current of 1 µA rms.

If it is fitted with low noise current mode input signal boards (7210/97) ), set the

signal generator output amplitude to 0.1 V rms and apply this via a series resistor

of 1 MΩ(1% accuracy) to the front panel signal input connector marked "1".

This resistor generates a nominal current of 1 µA rms.

13) Type "SEN1 1 9" and press the return key to set the channel 1 full-scale

sensitivity to the least sensitive range (1 V for voltage mode inputs, 1 µA for

wide bandwidth current mode inputs and 100 nA for low noise current mode

Chapter 2, INSTALLATION & INITIAL CHECKS

2-5

inputs) and wait a second or so to allow the channel to settle. Then type "AQN1

1; X1 1" and press the return key to perform an autophase and read the X1

output. The response should be "10000", a newline and carriage return and a "*"

character, although the actual number received may differ by up to ±500 counts,

depending on the real level of applied signal.

14) Turn off the model 7210 and, if the DIP switch settings were changed at step 2,

restore them to their initial values.

This completes the initial checks. Even though the procedure leaves many functions

untested, if the indicated results were obtained then the user can be reasonably sure

that the unit incurred no hidden damage in shipment and is in good working order.

Technical Description Chapter

3

3-1

3.1 Introduction

The model 7210 is a very sophisticated instrument and its tandem demodulation

mode means that its operation is more complex than conventional lock-in amplifiers.

This chapter discusses the operating modes it offers and describes how these are

implemented by considering the instrument as a series of functional blocks. A good

understanding of the design will allow the user to make best use of the instrument’s

versatility.

3.2 Operating Modes

3.2.01 Introduction

Throughout this manual, reference is made to the two different operating modes

within the instrument, so in order to aid the reader’s understanding they are defined

here.

3.2.02 Single Reference Mode

This is the conventional mode of operation common to all lock-in amplifiers. The

instrument measures the amplitude of the two components of the signal at its inputs

that are in-phase and in quadrature (i.e. 90° out of phase) with an internally generated

sinusoidal demodulator signal. This demodulator signal is in turn phase locked to the

applied external reference signal.

The two measured components per signal channel are conventionally known as the X

and Y channel outputs. All 32 signal channels are measured with respect to the same

external reference signal, so the instrument generates 64 output values.

3.2.03 Tandem Reference Mode

If an amplitude-modulated sinusoidal carrier signal is applied to a conventional lock-

in amplifier which is operated at the carrier frequency and reference phase adjusted to

yield zero Y channel output, then the X output signal will be the modulating signal.

This only applies if the output time constant of the first lock-in is sufficiently short to

allow the modulation to pass.

If this X output signal is then applied to a second lock-in amplifier, but this time

running at the modulating frequency, then this second lock-in can directly measure

the amplitude of the modulation.

In the past this type of experiment would have required two lock-in amplifier, with a

physical cable coupling the X output of one to the input of the second. However, the

7210 includes this capability as a standard feature, subject to only a few limitations.

In order to allow the second demodulator to run synchronously with the first, it is

desirable for its reference frequency to be the result of an integer division of the first

reference frequency. This condition is best satisfied by ensuring that the second

reference frequency be internally generated by the instrument and made available via

Chapter 3, TECHNICAL DESCRIPTION

3-2

a connector so that it can be used as the source of modulation for the signal.

Consequently the 7210 is fitted with two reference connectors; REF 1 IN is used to

apply the external reference frequency at which the first demodulation stage operates,

and the second. REF 2 OUT outputs a TTL reference waveform at the frequency of

the second stage. The user can specify the divisor used to generate the second

reference from the first.

It will be appreciated that in tandem mode there are four outputs per signal channel,

an X and Y pair from the first stage and an X and Y pair from the second. To avoid

confusion, the outputs from the first stage, even when the unit is operating in single

reference mode, are referred to as X1 and Y1 and those from the second as X2 and

Y2.

It will also be seen that in Tandem mode the instrument generates 128 output values.

3.3 Principles of Operation

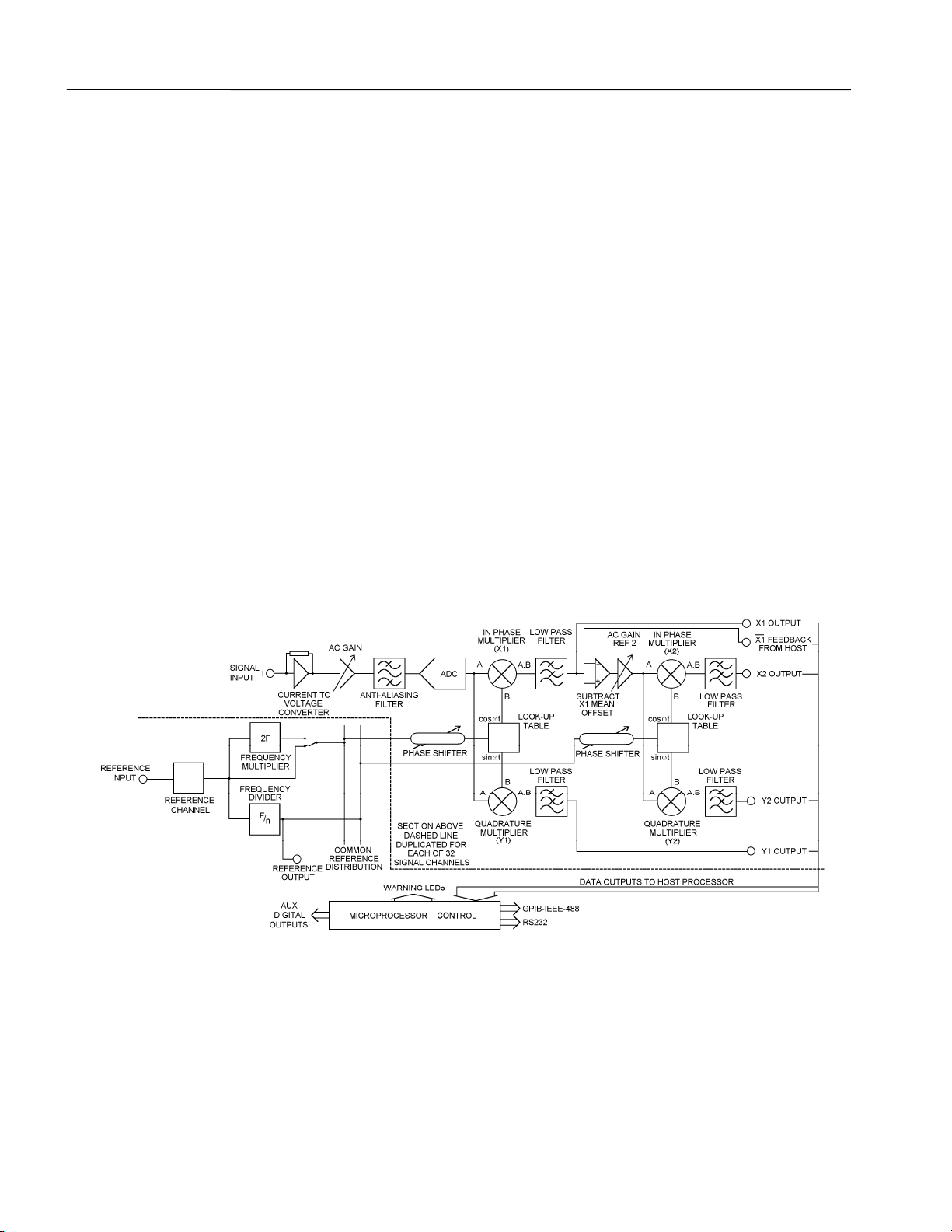

3.3.01 Block Diagram

The model 7210 uses 32 ADC's and digital signal processors (DSP's), a

microprocessor and very low-noise analog circuitry to achieve its specifications. A

block diagram of the instrument is shown in figure 3-1. The sections that follow

describe how each functional block operates and the effect it has on the instrument's

performance.

Figure 3-1, Model 7210 - Block Diagram

Chapter 3, TECHNICAL DESCRIPTION

3-3

3.3.02 Signal Channel Inputs

The signal input amplifier depends on the type of input signal boards fitted:

7210/99 Signal Board - Voltage Mode Inputs

In this case the input amplifier is a buffer stage with an input impedance of 10 MΩ.

The frequency response (-3 dB) extends from 20 Hz to 50.5 kHz

7210/98 Signal Board - Wide Bandwidth Current Mode Inputs

In this case the input amplifier is a single-ended current mode device with a fixed

transimpedance setting of 10E6 V/A. Hence an applied current of 1 µA will give a

1 V signal into the next stage. The frequency response (-3 dB) extends from 20 Hz to

50.5 kHz

7210/97 Signal Board - Low Noise Current Mode Inputs

In this case the input amplifier is a single-ended current mode device with a fixed

transimpedance setting of 10E7 V/A. Hence an applied current of 100 nA will give a

1 V signal into the next stage. The frequency response (-3 dB) extends from 20 Hz to

5.0 kHz.

3.3.03 AC Gain and Dynamic Reserve

The signal channel contains a number of analog filters and amplifiers whose overall

gain is defined by the AC Gain parameter, which is specified in terms of decibels

(dB). For each value of AC Gain there is a corresponding value of the INPUT LIMIT

parameter, which is the maximum instantaneous (peak) voltage or current that can be

applied to the input without causing input overload, as shown in table 3-1 below.

AC Gain (dB) INPUT LIMIT (V) INPUT LIMIT (nA) INPUT LIMIT (nA)

Voltage Mode Wide Bandwidth Low Noise

Current Mode Current Mode

0 3.1 3100 310

10 1.5 150 15

20 0.31 31 3.1

30 0.15 15 1.5

40 0.031 3.1 0.31

50 0.015 1.5 0.15

60 0.0031 0.31 0.031

Table 3-1, Input Limit vs AC Gain

It is a basic property of the digital signal processing (DSP) lock-in amplifier that the

best demodulator performance is obtained by presenting as large a signal as possible

to the main analog-to-digital converter (ADC). Therefore, in principle, the AC Gain

value should be made as large as possible without causing the signal channel

amplifier or converter to overload. This constraint is not too critical however and the

use of a value 10 or 20 dB below the optimum value makes little difference. Note that

as the AC Gain value is changed, the demodulator gain (described later in section

3.3.08) is also adjusted in order to maintain the selected full-scale sensitivity.

The full-scale sensitivity is set by a combination of AC Gain and demodulator gain.

Since the demodulator gain is entirely digital, changes in full-scale sensitivity which

Chapter 3, TECHNICAL DESCRIPTION

3-4

do not change the AC Gain do not cause any of the errors which might arise from a

change in the AC Gain.

The user is prevented from setting an illegal AC Gain value, i.e. one that would result

in overload on a full-scale input signal. Similarly, if the user selects a full-scale

sensitivity which causes the present AC Gain value to be illegal, the AC Gain will

change to the nearest legal value.

In practice, this system is very easy to operate. However, the user may prefer to make

use of the AUTOMATIC AC Gain feature which gives very good results in most

cases. When this is active the AC Gain is automatically controlled by the instrument,

which determines the optimum setting based on the full-scale sensitivity currently

being used.

At any given setting, the ratio

ySensitivitScale-Full LimitInput

0.7DR ×=

represents the factor by which the largest acceptable sinusoidal interference input

exceeds the full-scale sensitivity and is called the Dynamic Reserve of the lock-in

amplifier at that setting. (The factor 0.7 is a peak-to-rms conversion). The dynamic

reserve is often expressed in decibels, for which

))ratioalog(DR(as20dB)DR(in

×

=

Applying this formula to the model 7210 at the maximum value of INPUT LIMIT

and the smallest available value of FULL-SCALE SENSITIVITY, gives a maximum

available dynamic reserve of better than 80 dB.

3.3.04 Anti-Aliasing Filter

Prior to the main analog-to-digital converter (ADC) the signal passes through an anti-

aliasing filter to remove unwanted frequencies which would cause a spurious output

from the ADC due to the sampling process.

Consider the situation when the lock-in amplifier is measuring a sinusoidal signal of

frequency

f

signal

Hz, which is sampled by the main ADC at a sampling frequency

f

sampling

Hz. In order to ensure correct operation of the instrument the output values

representing the

f

signal

frequency must be uniquely generated by the signal to be

measured, and not by any other process.

However, if the input to the ADC has, in addition, an unwanted sinusoidal signal with

frequency

f

1

Hz, where

f

1

is greater than half the sampling frequency, then this will

appear in the output as a sampled-data sinusoid with frequency less than half the

sampling frequency,

f

alias

= |

f

1

- nf

sampling

|, where

n

is an integer. This alias signal is

indistinguishable from the output generated when a genuine signal at frequency

f

alias

is sampled. Hence if the frequency of the unwanted signal were such that the alias

signal frequency produced from it was close to, or equal to, that of the wanted signal

then it is clear that a spurious output would result.

Table of contents

Other Signal Recovery Amplifier manuals