SignWarehouse ENDURAPRESS CS15 User manual

www.signwarehouse.com • SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

USER MANUAL

enduraPRESS CS15

REV 04/06/2021

www.signwarehouse.com • SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

Table of Contents

Page

1

2

3

4

5

6

7

Specications

Operation Instructions Read Before Use

Control Panel Operations

Temperature display calibration

Heat Transfer Application Guidelines

Troubleshooting Tips

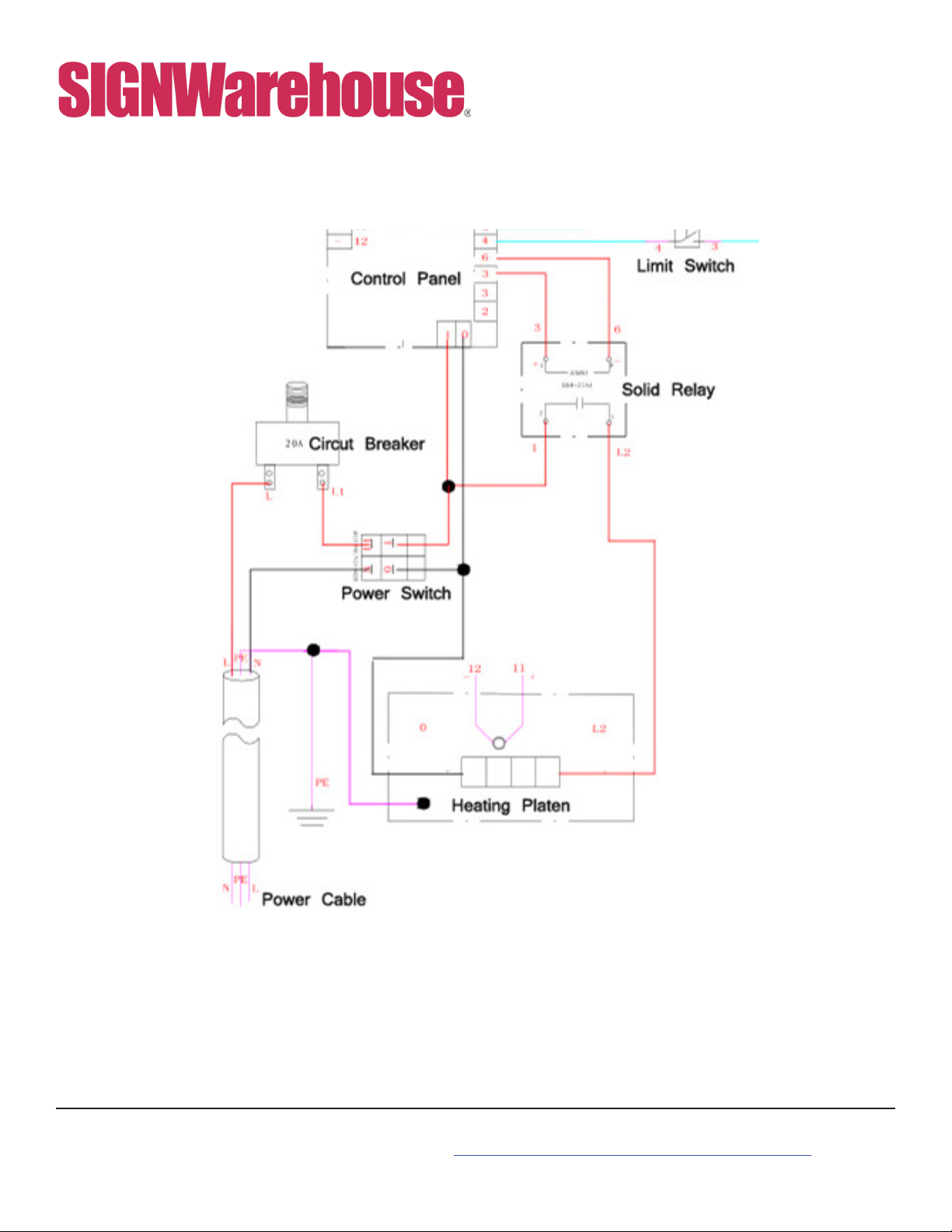

Wiring Schematic

www.signwarehouse.com • SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

Power Switch

Specications:

Model NO: ENDURAPRESS CS15

Voltage: 110V/60Hz

Power: 11.4Kw

Control Panel: LCD Control Panel

Time Range: 0~999sec.

Temp. Range: 0~480°F

Packaging: Corrugated Paper Carton

Gross Weight: 75lbs (33kg)

Operation Handle

Control

Panel

Pressure Knob

Silicone Pad

Lower Aluminum Plate

Heating Element

1

www.signwarehouse.com • SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

2

Operation Instructions

Read Before Use

1. Check the voltage before using it. The correct voltage is 110-120V/60Hz

2. Turn o the machine when not in use, and remove the power plug from

socket.

3. Grasp the handle rmly when opening.

4. Keep children away from the machine.

5. Do not touch the heating platen and platen cover after pressing whilst in

operation

6. Do not attempt to press products that are not intended for normal heat

transfer

7. Do not set the temperature any higher than 480F as it may cause over heat

and stop working.

8. The heat press carries a ground line by default, please make sure the

socket gets a ground line protector.

9. Do not set the pressure too high. Reduce the pressure when pressing

thicker items. Setting the pressure excessively high can damage the press.

10. The heat press carries a ground line by default, please make sure the

socket gets a ground line protector.

www.signwarehouse.com • SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

3

Control Panel Operations

Control Panel Display P-1: Temperature Setting

Mode

Hit SET & use the up and down

arrows to set temperature

P-3: ºC or ºF Read Out

Hit SET three times & use the up

and down arrows to select Celsius

or Fahrenheit

Auto Shut O Mode

The screen will read OFF and

start to cool down if heat press is

inactive

To reheat the press, hit any button

P-3: ºC or ºF Read Out

Hit SET three times & use the up

and down arrows to select Celsius

or Fahrenheit

P-2: Time Setting Mode

Hit SET twice & use the up and

down arrows to set amount of time

for pressing

P-4: Auto Shut O Mode

Hit SET four times & use the up and

down arrows to set auto shut o

when inactive 0-120 minutes range

Clear Counter Number

Long hold the CLEAR button to clear

your counter on the panel.

Other Functions

If you need to calibrate your press,

hold the up and down arrow

together for a few seconds.

If you need to clear your counter,

hold your clear button for a few

seconds.

www.signwarehouse.com • SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

4

Temperature display calibration

Touch the up and down arrow for a

few seconds together.

Touch the SET key till you nd a

window like the picture above.

Gauge enters into a window like

above picture

Touch the up and down arrow to

determine the temperature will

be modied. Say -30 (i.e. heating

platen 30°F cooler than the gauge

read-out)

Touch the up and down arrow to

determine the temperature will be

modied. Say 30 (i.e. heating platen

30°F hotter than the gauge read-

out)

Touch the up arrow till you hit 88.

Touch the SET key back to the

temperature, and it will read out

200°F, and the press will continue to

heat up to 230°F.

Touch the SET key back to the

temperature, and it will read out

260°F, and the press will cool down

to 230°F.

www.signwarehouse.com • SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

5

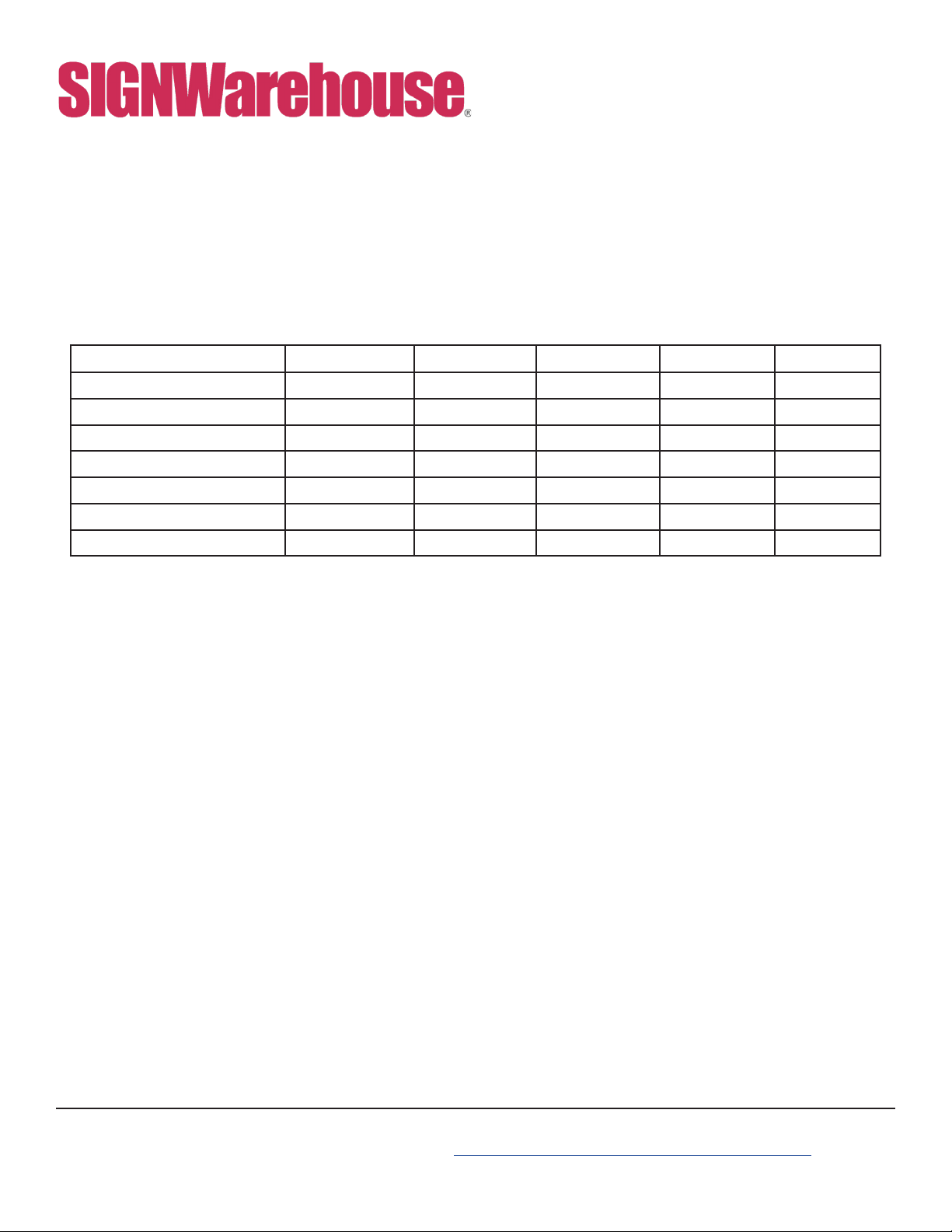

Heat Transfer Application Guidelines

These are general guidelines. For specic time and temperature settings for specic lms

and/or transfer papers, please refer to the instructions for that particular product.

** The EnduraPRESS CS15, CS15-AR, CS16, and CS16-AR are not recommended for use

with two-step laser transfer papers. For these demanding applications, we recommend the

EnduraPRESS SA12 or SD20.

TRANSFERS Device Fabric TEMP. TIME PRESSURE

Sublimation Paper Ricoh, Epson Polyester 400°F 25~30sec. 30Psi

Ink Tran. Paper Inkjet Printer Light Color 365°F 15sec. 30Psi

Dark Color 330°F 25sec. 30Psi

Laser Transfer Paper** Laser Printer Light Color 345°F 30sec. 30Psi

Laser Printer Dark Color 260 - 320°F 35 - 120 sec. 25Psi

Transfer Vinyls Cutting Plotter / 300~320°F 8~10sec. 30Psi

Plastisol Transfer / / 335°F 12sec. 50Psi

www.signwarehouse.com • SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

6

Troubleshooting Tips

Q. Why isn’t my heat transfer vinyl sticking to the fabric?

A. This can be caused by three things. Insucient pressure, or temperature, or time.

Time: Some heat transfer lms need a few seconds to cool before you remove the liner. Try a

warm or cold peel rst.

Temperature: If that doesn’t work, check to make sure you are using the recommended time and

temperature settings. If you are, your press may not be putting out the correct amount of heat.

Use a Geo Knight IR thermometer to check the actual temperature of the platen. If it is more

than 5° dierent from the LCD display (PV), adjust it using step four in the control panel (see

page 4).

Pressure: If the temperature is correct, adjust the pressure. Some lms require more pressure to

bond the adhesive to the fabric. There should be some resistance when you close the press.

If you have veried all of these and the lm doesn’t stick, contact SIGNWarehouse customer

service or Technical Support for further assistance.

Q. Why does my sublimated transfer look washed out?

A. This is usually caused by insucient temperature. Sublimation works best at or near 400°F.

If your transfer is faded, check the output of the heat platen with a contact thermometer and

make sure the output matches the displayed temperature. If not, adjust as directed above.

Then repress at 390 - 400°F.

Q. Why are my transfers are sticking to the heating element of the upper platen?

A. If T-shirt vinyl is sticking to the heating element, you have it upside down. Remove any

adhesive residue, ip it over and try again. If an inkjet or laser transfer is sticking to the heating

element, it’s because the heat is aecting the ink. Cover it with a Teon sheet or sheet of

silicone Kraft paper to prevent this. Using a Teon sheet or Kraft paper is recommended for

almost all heat transfer applications.

Q. Why is it so hard to peel the liner when I’m done pressing the paper?

A. A hot or warm peel lm may become hard to peel if allowed to cool. Always peel the lm or

transfer paper in accordance with the product’s recommendations.

www.signwarehouse.com • SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

7

Wiring Schematic

WARRANTY

Thank you for choosing our products, you are entitled to one year free warranty service

for our products. All exceeds warranty period we will still provide technical supports and

maintenance guidance.

Table of contents

Other SignWarehouse Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Festo

Festo DMSP Series operating instructions

Baileigh Industrial

Baileigh Industrial BR-16E-36 Operator's manual

SCHUNK

SCHUNK MPG-plus Assembly and operating manual

SUHNER

SUHNER LSB 70-TOP Technical document

Mayr

Mayr EAS-smartic 484.XX5 Series Installation and operational instructions

M-system

M-system M8BS-16K2 instruction manual

Panasonic

Panasonic EXC28CG quick start guide

Phoenix Contact

Phoenix Contact Axioline E EtherCAT Firmware update

Southern States

Southern States RDA Installation instructions manual

Mace

Mace Screena Operator's manual

Danfoss

Danfoss VLT OneGearDrive instruction manual

FLENDER

FLENDER H SH Series Assembly instructions