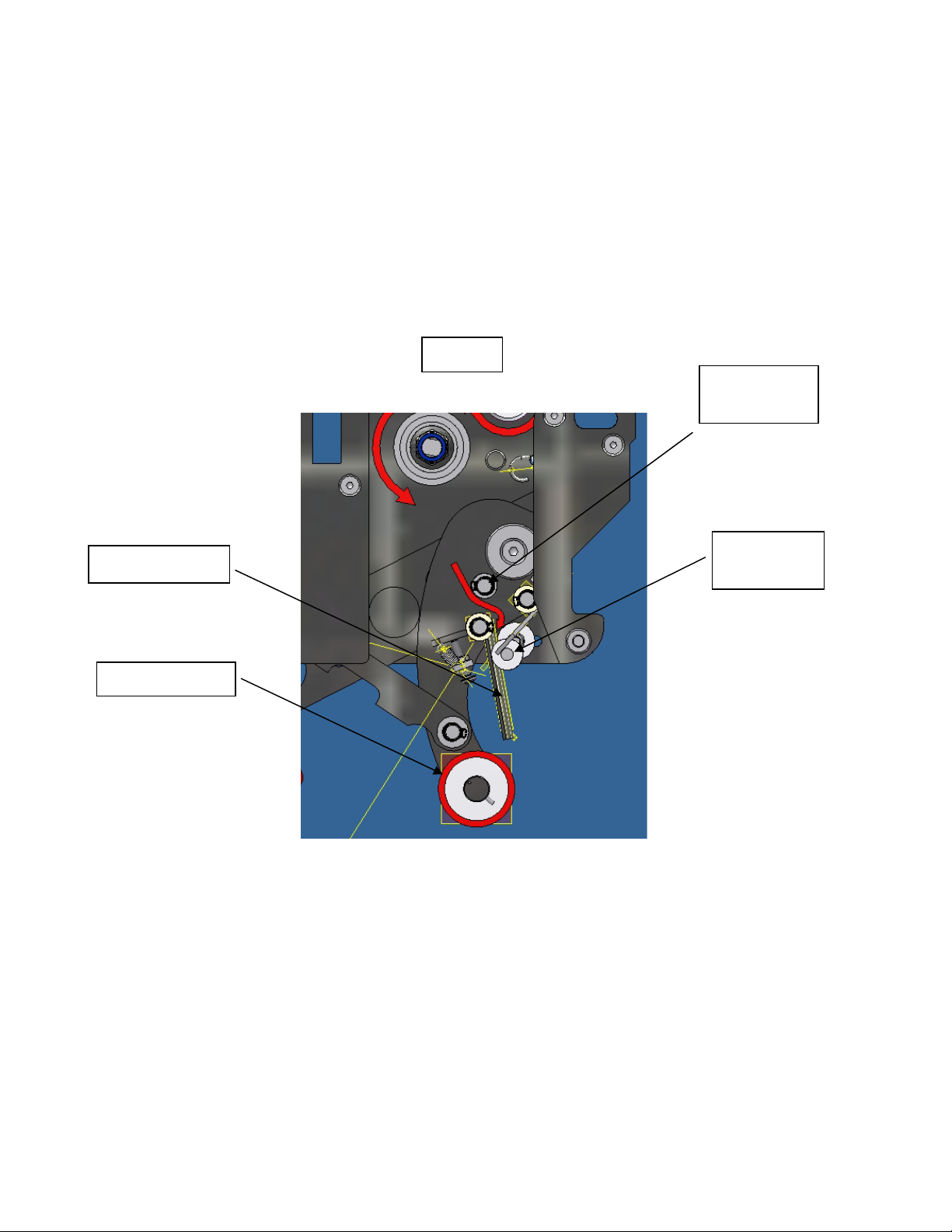

Theory of Operation: (Pneumatic Cartridge)

Pressure sensitive tape is applied to the corrugated box as it passes by the

cartridge. The box will contact the front arm roller which has pressure sensitive

tape adhesive side facing outward towards the oncoming box. The front leading

side of the box will contact the front roller arm and the tape will adhere to the

box. As the box continues to move forward the front roller arm and knife arm will

be rotated into the frame of the cartridge. At this box position the leading edge

of the box will trigger a photo eye. The photo eye will energize a solenoid valve

which will switch air pressure to the two cylinders in the tape cartridge. One

cylinder acts against or balance out the knife arm spring the other acts against

or balances out the main spring that biases the front roller arms. The amount of

force the biased arms place on top of the box can be adjust with and air

regulator. The front arm initial application force can be set to accommodate the

strength of the box as well as the sturdiness of the contents in the box.

As the front arm application roller transitions from the leading panel of the box

to the top major flaps a separate wipe down spring is engaged. The sole

purpose of this spring is to add speed to the rear wipe roller actuation to insure

the rear tape tab is completely wiped to the rear trailing panel of the box. At this

time the knife arm is retracted into the cartridge and the knife blade guard is

fully retracted uncovering the blade. As the knife arm rotated into the cartridge

the knife activation spring extends, generating cut force.

As the box proceeds pass the cartridge the front arm roller will no longer

contact the major flaps of the box, but the rear wipe roller will still contact the

major flaps. At this point the box will move past the photo eye the engaged the

pneumatic balance. The solenoid valve will de-energize and all of the air

pressure will be evacuated and the normal spring biasing will apply pressure to

the box. Eventually as the box travels the knife arm will completely stop

contacting the major flaps of the box. This will allow the knife arm to travel back

towards its home position allowing the knife blade to puncture and cut through

the tape. As the box continues to move the rear wipe arm roller will no longer

contact the major flaps of the box. This will allow the wipe arm roller to spring

out of the cartridge and contact the rear tab length of tape and press against the

trailing panel of the box. The rear wipe arm roller booster spring starts the wipe

and the main cartridge spring finishes the wipe sequence.

The box travelling pass the cartridge is the vehicle which pulls the tape through

the cartridge. The cartridge is design to run most pressure sensitive tapes with