Bluff DuraSweeper series Programming manual

(800) 433-2212 •Fax (817) 293-7570

9201 South Freeway • Fort Worth, TX 76140

www.bluffmanufacturing.com

20150422

This manual has been most recently updated:

DuraSweeper®

Snow Removal System

DS-15-A-PORT

DS-15-A-PERM

DS-20-A-PORT

DS-20-A-PERM

OWNER’S MANUAL AND INSTALLATION GUIDE FOR

DuraSweeper®

Contents

Disclaimer ............................................................................................................................................. 1

Copyright............................................................................................................................................... 1

Cautions for Receiving this Product ...................................................................................................... 1

Instructions for Removal of Unit From Truck......................................................................................... 1

DuraSweeper®by Bluff.......................................................................................................................... 2

Warnings ............................................................................................................................................... 2

Safety Precautions ................................................................................................................................ 3

Pre-Operation Hazard ........................................................................................................................... 3

Modication Hazard .............................................................................................................................. 3

Exposure Hazard .................................................................................................................................. 3

Fire Hazard ........................................................................................................................................... 3

Entanglement/Severe Hazard .............................................................................................................. 3

Alcohol and Drug Hazard ..................................................................................................................... 4

Flying Object Hazard ............................................................................................................................ 4

Safety Precautions ............................................................................................................................... 4

DuraSweeper® Specications ............................................................................................................... 6

Product Specications........................................................................................................................... 6

Product Specications........................................................................................................................... 7

Ejected Material and Clear Lane .......................................................................................................... 8

Tools and Equipment............................................................................................................................. 9

Site Location Requirements - Portable Model....................................................................................... 9

Site Location Requirements - Permanent Model................................................................................. 10

Pad Suggestion for Permanent Installation..........................................................................................11

Suggested Concrete Pad Specication - Permanent Model Standard Layout.................................... 12

Suggested Concrete Pad Specication - Permanent Model Non-Standard Layout ............................ 13

Recommended Safety Barrier Equipment .......................................................................................... 14

Power Provisions................................................................................................................................. 14

Parts & Assemblies.............................................................................................................................. 15

Installation On-Site.............................................................................................................................. 16

Pre-erection Assembly......................................................................................................................... 16

Installation Tips.................................................................................................................................... 16

Recommended Tools........................................................................................................................... 17

Installation of the DuraSweeper®by Bluff............................................................................................ 18

Portable Models................................................................................................................................... 24

DuraSweeper®

Permanent Models .............................................................................................................................. 26

Main Panel Switch Locations............................................................................................................... 34

Determine Brush Motor Rotation ........................................................................................................ 34

Proximity Switch Tests......................................................................................................................... 34

Initial Testing........................................................................................................................................ 34

Upper Proximity Switch ....................................................................................................................... 35

Lower Proximity Switch ....................................................................................................................... 35

Automation Test .................................................................................................................................. 35

Standard Operation ............................................................................................................................ 37

Warnings ............................................................................................................................................. 37

Shut Down and Start Up Procedures ................................................................................................. 38

Routine Maintenance........................................................................................................................... 39

Long Term Storage.............................................................................................................................. 40

Removing from Storage....................................................................................................................... 40

Changing The Brush Wafers............................................................................................................... 41

Brush Drive.......................................................................................................................................... 42

Pulley................................................................................................................................................... 43

Hoist Drive........................................................................................................................................... 44

Brush Idler........................................................................................................................................... 45

Carriage Wheel.................................................................................................................................... 46

Electric Cable Carrier .......................................................................................................................... 47

Trouble Shooting................................................................................................................................. 48

Bluff DuraSweeper®Snow Removal System Warranty ...................................................................... 49

1

DuraSweeper®

DuraSweeper®

DISCLAIMER AND COPYRIGHT

Disclaimer

The illustrations used in this manual are intended as representative reference views only. Moreover,

because of our continuous product improvement policy, we may at any time, modify information,

illustrations and/or specications to explain and/or exemplify a product, service or maintenance

improvement. We reserve the right to make any change at any time without notice. DuraSweeper®and

DuraSweeper®, LLC. are all the same entity and are used interchangeably.

DuraSweeper® is the registered trademark of WILLIAM CANDELETTI.

Copyright

© 2015 DuraSweeper®, LLC

DuraSweeper®by Bluff Manufacturing reserves all copyright and other rights in this manual and the

manual’s content. No part of this manual may be reproduced or used in any way without the written

permission of Bluff Manufacturing, except as necessary to operate equipment of DuraSweeper®by Bluff

Manufacturing.

Cautions for Receiving this Product

Please make sure that you receive the entire number of pieces called for on the bill of lading (BOL) and

that they are in good condition before signing the receipt from the freight company. Damage claims will

not be accepted if receipt is signed.

Instructions for Removal of Unit From Truck

The brush carriage assembly should not be lifted by the brush or brush core. For more details, see

INSTALLATION INSTRUCTIONS in this manual.

The electrical enclosure should only be lifted by the lifting eye, which is located at the top of the

enclosure.

Inspect parts and assemblies for any damage from shipment and verify that the parts match the BOL.

2

DuraSweeper®

DuraSweeper®by Bluff

Warnings

This manual provides important information to familiarize you with safe operating and maintenance

procedures. Read and understand this manual before operating the DuraSweeper®by Bluff

Manufacturing and follow its instructions when operating the unit.

LOOK FOR THESE SYMBOLS WHICH POINT OUT ITEMS OF EXTREME IMPORTANCE TO THE

SAFETY OF YOU AND YOUR COWORKERS. READ AND UNDERSTAND THOROUGHLY. HEED

THE WARNING AND FOLLOW THE INSTRUCTIONS.

Keep safety labels in good condition. If safety labels become missing or damaged, replacement safety

labels are available from Bluff Manufacturing at 1-800-433-2212 (see also Safety Label Installation in

Maintenance Section).

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE

Indicates a situation which can cause damage to the equipment, personal property and/or the

environment, or cause the DuraSweeper®by Bluff to operate improperly.

NOTE: Indicates a procedure, practice, or condition that should be followed in order for the unit or

component to function in the manner intended.

!DANGER

!WARNING

!CAUTION

3

DuraSweeper®

Safety Precautions

!CAUTION

The safety messages that follow have CAUTION level hazards.

Pre-Operation Hazard

Read and understand this Operation Manual before operating or servicing the DuraSweeper®

by Bluff to ensure that safe operating practices and maintenance procedures are followed.

• Contact Bluff Manufacturing or an authorized DuraSweeper®Dealer for additional training.

• Obtaining any and all necessary licenses to operate the unit is the responsibility of the

purchaser.

!WARNING

The safety messages that follow have WARNING level hazards.

Crush Hazard

Keep bystanders away from work area before and during operation.

Modication Hazard

Never modify the DuraSweeper®by Bluff without written consent of Bluff Manufacturing. Any

modication can affect the safe operation of the unit and may cause personal injury or death.

Modications will also nullify the warranty.

Exposure Hazard

Always wear personal protective equipment, including appropriate clothing, gloves, work

shoes, and eye protection.

• Never operate the DuraSweeper®by Bluff while wearing a headset.

Fire Hazard

Have appropriate safety equipment available. Have all re extinguishers checked periodically

for proper operation and/or readiness.

Entanglement/Severe Hazard

• Verify that all guards and covers are attached properly to the unit before starting the unit. Do

not start the unit if any guards or covers are not properly installed on the unit.

• Verify there are no people, obstacles or other equipment near the DuraSweeper®by Bluff

before starting the unit.

4

DuraSweeper®

Remove all jewelry, tie back long hair and keep hands, other body parts and clothing away

from moving/rotating parts.

Stop the unit before beginning service.

• If you must run the unit during maintenance procedures, make sure to keep bystanders clear

of the unit.

• Attach a Lockout/Tagout with “Do Not Operate” tag on the ON/OFF switch while performing

maintenance on the equipment.

Alcohol and Drug Hazard

Never operate the unit while under the inuence of alcohol or drugs, or when ill or sleepy.

Flying Object Hazard

Always wear eye protection while operating the unit or cleaning the DuraSweeper®with

compressed air or high-pressure water. Dust, ying debris, compressed air, pressurized water

or steam may injure your eyes.

!CAUTION

The safety messages that follow have CAUTION level hazards.

Poor Lighting Hazard

Ensure that the work area is adequately illuminated.

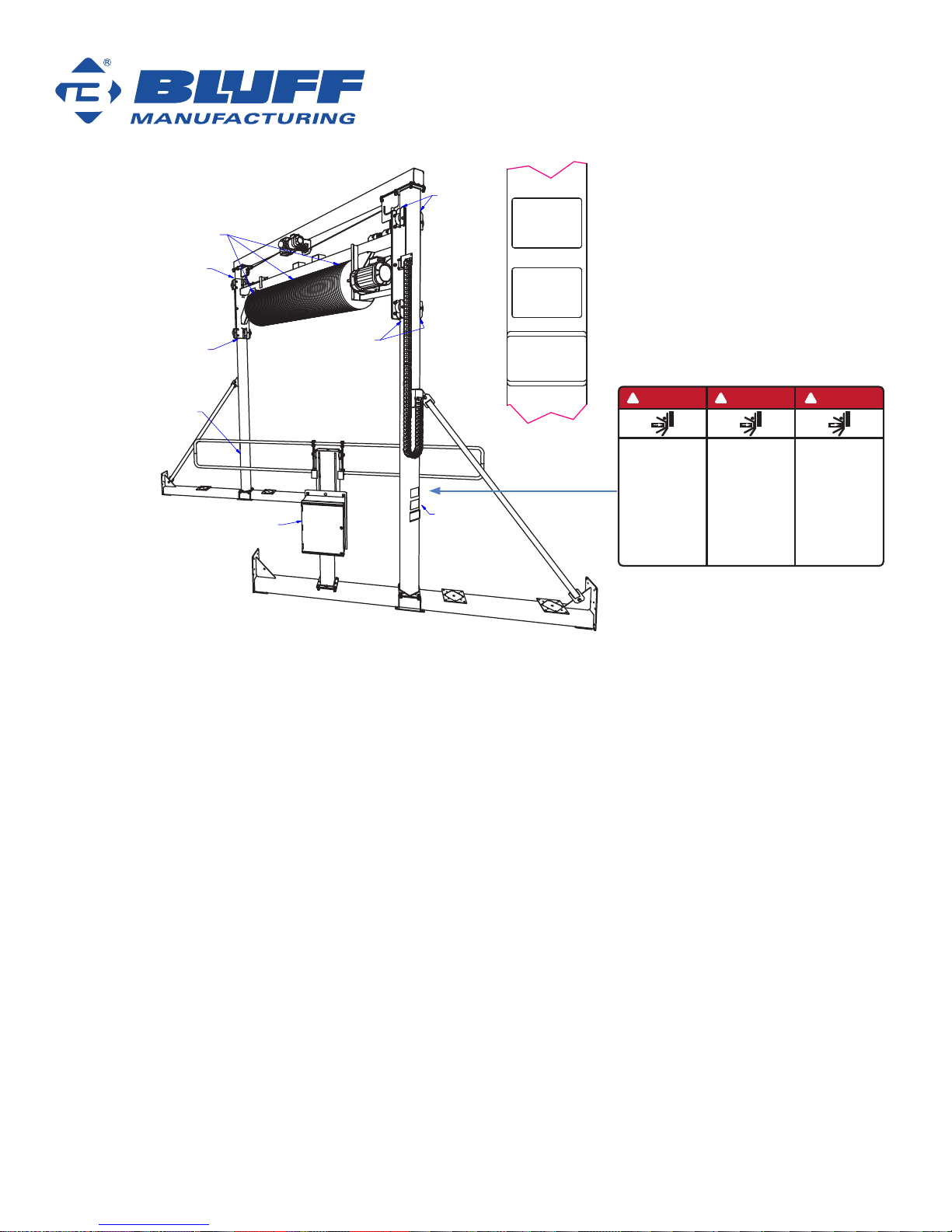

Safety Label Locations

Safety Precautions

If your unit has been renished it is extremely important that all the safety decals be replaced in their

proper locations. The illustrations below will aid you in determining the proper locations.

A description of location is provided for each safety label. For additional instructions, contact your

dealer (see also Safety Label Installation in Maintenance Section).

5

DuraSweeper®

Warning Labels

on Both Columns

A

Warning Label

Location

Warning Label

Location

Illustration for Warning Label Page

file locations:

model - C:\Users\stevebales\Desktop\DuraSweeperManual\Inventor Model 5\DS-PortableStandard.iam

drawing - C:\Users\stevebales\Desktop\DuraSweeperManual\Inventor Model 5\InstallationManualPrints\DS-PortableStandard-SafetyLabels.idw

PDF - C:\Users\stevebales\Desktop\DuraSweeperManual\Inventor Model 5\InstallationManualPrints\DS-PortableStandard-SafetyLabels.pdf

2. Entanglement

Hazard

1. Pinch Hazard

1. Pinch Hazard

1. Pinch

Hazard

1. Pinch Hazard

3. Electricution

Hazard

WARNING

1. PINCH HAZARD! Stay clear of the columns. Failure to comply can result in death or serious injury.

2. ENTANGLEMENT HAZARD! Rotating brush. Keep hands, feet and clothing away. Failure to comply

could result in death or serious injury.

3. ELECTROCUTION HAZARD! Read owner manual before operating equipment.

ADVERTENCIA

1. ¡RIESGO DE SER ESTRUJADO! Mantengase alejado de las columnas. Si no se cumple con esta

disposición, podria causar muerte o lesions graves..

2. ¡RIESGO DE SER ESTRUJADO! Mantenerse alejado de esta zona. Si no se cumple con esta

disposición, se causará la muerte o lesiones graves.

3. ATTENTION! Lire manuel du propriétaire avant utilisation.

AVERTISSEMENT

1. DANGER DE PINCEMENT ! Ne pas s’approcher des colonnes. Le non-respect de cette régle peut

entraîner la mort ou des blessures graves.

2. RISQUE D'ENCHEVÊTREMENT! Brosse rotative. Ne pas approcher les mains, les pieds ni les

vêtements. Le non-respect de cette règle risque d’entraîner des blessures graves, voire mortelles.

3. ¡CUIDADO! Lea el manual del propietario antes de operar el equipo.

PINCH

HAZARD!

Stay clear of

the columns.

Failure to comply

can result in death or

serious injury.

¡RIESGO DE SER

ESTRUJADO!

Mantengase

alejado de las

columnas.

Si no se cumple con

esta disposición,

podria causar

muerte o lesions

graves.

DANGER DE

PINCEMENT!

Ne pas s’approcher

des colonnes.

Le non-respect de

cette régle peut

entraîner la mort

ou des blessures

graves.

DANGER

!PELIGRO

!DANGER

!

DS Label 2 2015-02

6

DuraSweeper®

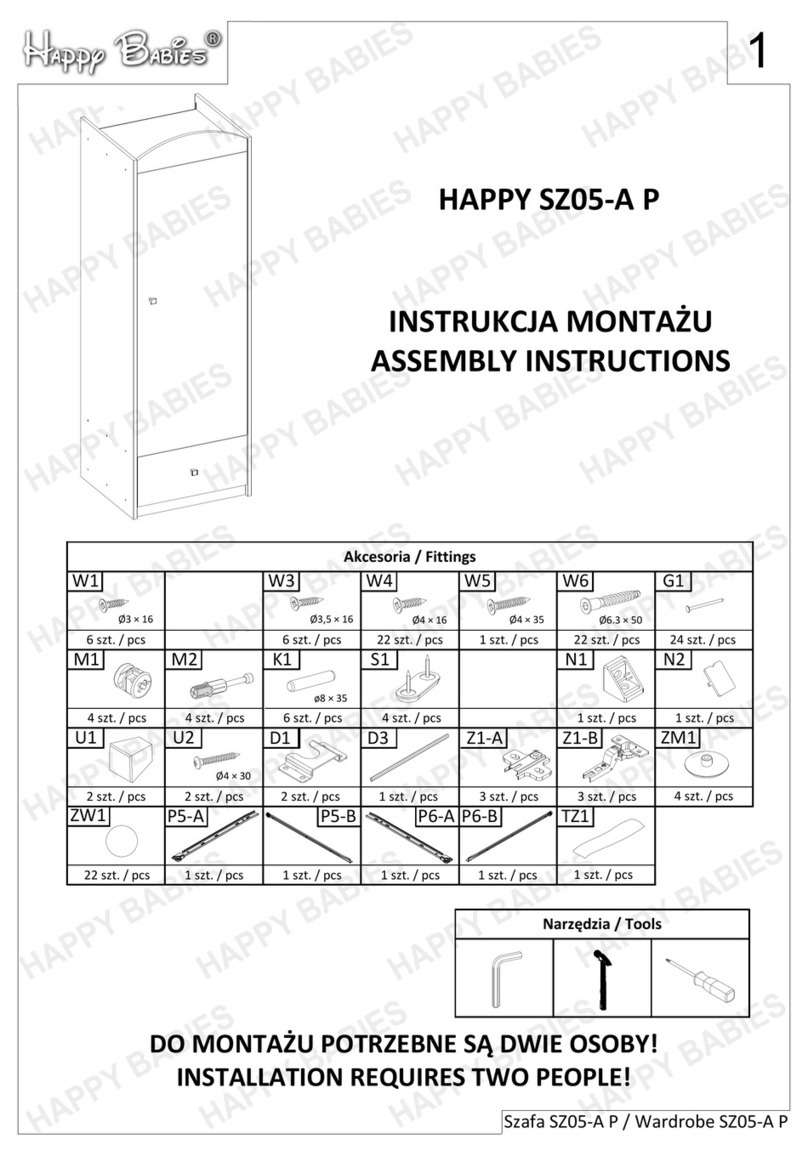

Product Specications

Having the site ready for unit installation prior to unit arrival is critical to the timely and proper

installation of the DuraSweeper® by Bluff. The following pages detail unit specication, site

preparation, tools, equipment, and training.

DuraSweeper® Specications

Specication Details Notes

Max Truck/Trailer Height 15'

Energy Source Required 460 VAC, 60 Hz, 3 Phase, 60 Amp If the power source available does not

match panel specications, a transformer

is required.

Rate of Snow Removal Needs to be dened by conditions, such

as snow density, truck width, drive HP

rating, truck speed, etc.

Temperature Rating (-13°F) for operation by activation bar

(-40°F) for operation by manual control

The DuraSweeper®is purchased by selecting 4 components. The portable package requires

concrete Ecoblocks to stabilize the unit . Below is a brief description of the components, and

specifications can be found on the next page.

1 BASE DS-BS-MOD Base Module

2 DRIVE DS-D15 Drive, 15 HP Package

DS-D20 Drive, 20 HP Package

3 PANEL DS-E20 Electrical Panel, 15/20 HP Package

4 ANCHOR DS-PORT Portable Package

DS-PERM Permanent Package

7

DuraSweeper®

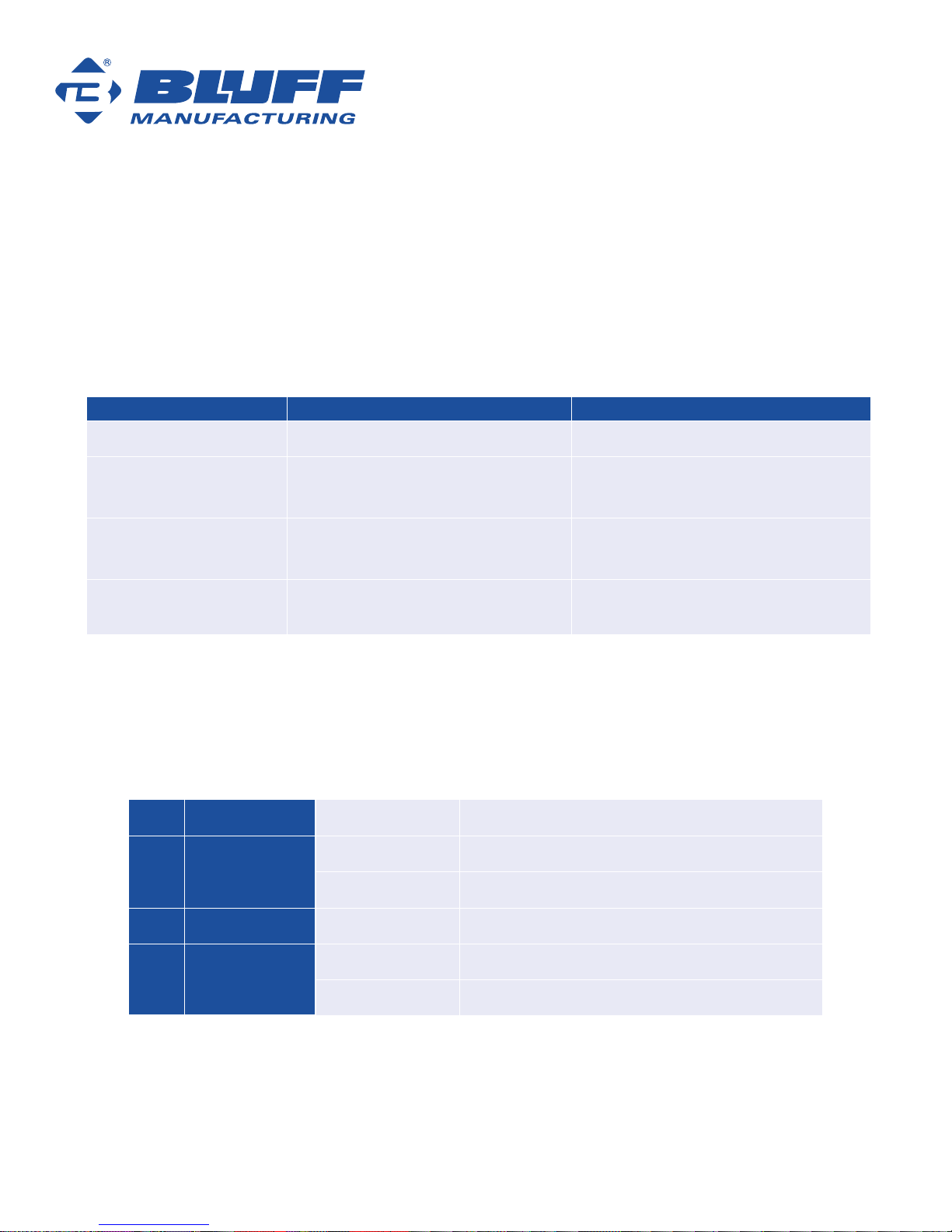

Product Specications

Package Part # Description Unit Weight

(Lb) Notes Size Image

BASE

DS-BS-MOD DuraSweeper

Base Module 4300 Size dimensions do not include

Anchor Package.

Height: (21’ 3”)

Width: (14’ 6”)

Length: (27’ 7”)

DS-D15 DuraSweeper,

Drive, 15 HP

Package 345 Actual color of drive may vary from

that shown herein. Power required

460 VAC, 3 Phase, 60 HZ

H e i g h t : N / A

W i d t h : N / A

Length: N/A

DS-D20 DuraSweeper,

Drive, 20 HP

Package 550 Actual color of drive may vary from

that shown herein. Power required

460 VAC, 3 Phase, 60 HZ

H e i g h t : N / A

W i d t h : N / A

Length: N/A

DS-E20

DuraSweeper,

Electrical Panel,

15/20 HP

Package

300

Automated control activation bar.

Manual controls on panel for

maintenance. Both extension bars

provided. However, as an option,

only one needs to be installed.

Height dimension is at the tallest

position.

H e i g h t : ( 7 ’ 5 ” )

W i d t h : ( 2 ’ 5 ” )

Length: (15’ 2”)

ANCHOR

DS-PORT DuraSweeper,

Portable

Package 584 Does not include ecology blocks.

Requires 2 each (DS-ECO-226).

H e i g h t : N / A

W i d t h : N / A

Length: N/A

DS-PERM DuraSweeper,

Permanent

Package 248 H e i g h t : N / A

W i d t h : N / A

Length: N/A

8

DuraSweeper®

Ejected Material and Clear Lane

The volume of material to be removed can be signicant. There are two critical factors to successful

placement of the DuraSweeper® at your location:

1. Having adequate space and means to remove the snow from the clear lane.

2. Working WITH the prevailing wind for storms in your area. Make sure when placing the

DuraSweeper®that the blowing wind will work WITH the action of the brush to blow the snow

away from the truck, the clear lane and the electrical panel.

Ejected material must not be allowed to accumulate in the vehicle lane beyond 4" of packed snow or

trucks will not pass. Prevailing wind conditions during snow season should be considered to maximize

the distance with which the material can be ejected. We recommend allowing 30’ minimum distance to

the side where the ejected snow accumulates in order to keep the drive lane clear.

The clear lane is dened as a straight and centered lane that the vehicle may approach, engage, and

leave the equipment on a straight and centered path. The material of the clear lane is not critical to the

installation and operation of the equipment. We recommend 74’ clear lane both before and after the

placement of the DuraSweeper®to allow for a standard tractor trailer entering the DuraSweeper®station

in a straight line. If you have longer trailers or double trailers, please allow additional space.

NOTICE

Material accumulation in the clear lane can cause damage to the equipment or create fault

conditions where vehicles cannot pass under brush with proper clearance and remain level.

Vehicle Travel

STANDARD PORTABLE MODEL

(shown)

Ejected

Material

Keep approx

30' clear for

ejected

snow pile

accumulation Electric

Panel

Ecology

Block

this drawing is for

Ejected Material and Clear Lane - Portable Model Shown

model for this drawing: DS-PortableStandard

CROP TO ELIMINATE TOP AND BOTTOM EXTENSION LINES

31 ft

74 ft

74 ft

9

DuraSweeper®

Tools and Equipment

The proper tools and equipment for installation and maintenance include, but are not limited to,

the following items:

• Large wrench or socket set

• Hammer drill

• Concrete bit (wedge anchor required diameter and length)

• Rubber mallet

• Lifting straps

• Crane/fork truck, or Skyboom with 8,000 lb. capacity

• Small wrench or socket set

• Small hex wrench set

Bluff provides wiring from the panel to the drives in accordance with National Electrical Code. Local or

state code may vary. Please consult a licensed electrician and the regulations in your area to determine

and source appropriate wiring, conduit, insulation and/or process required for your area.

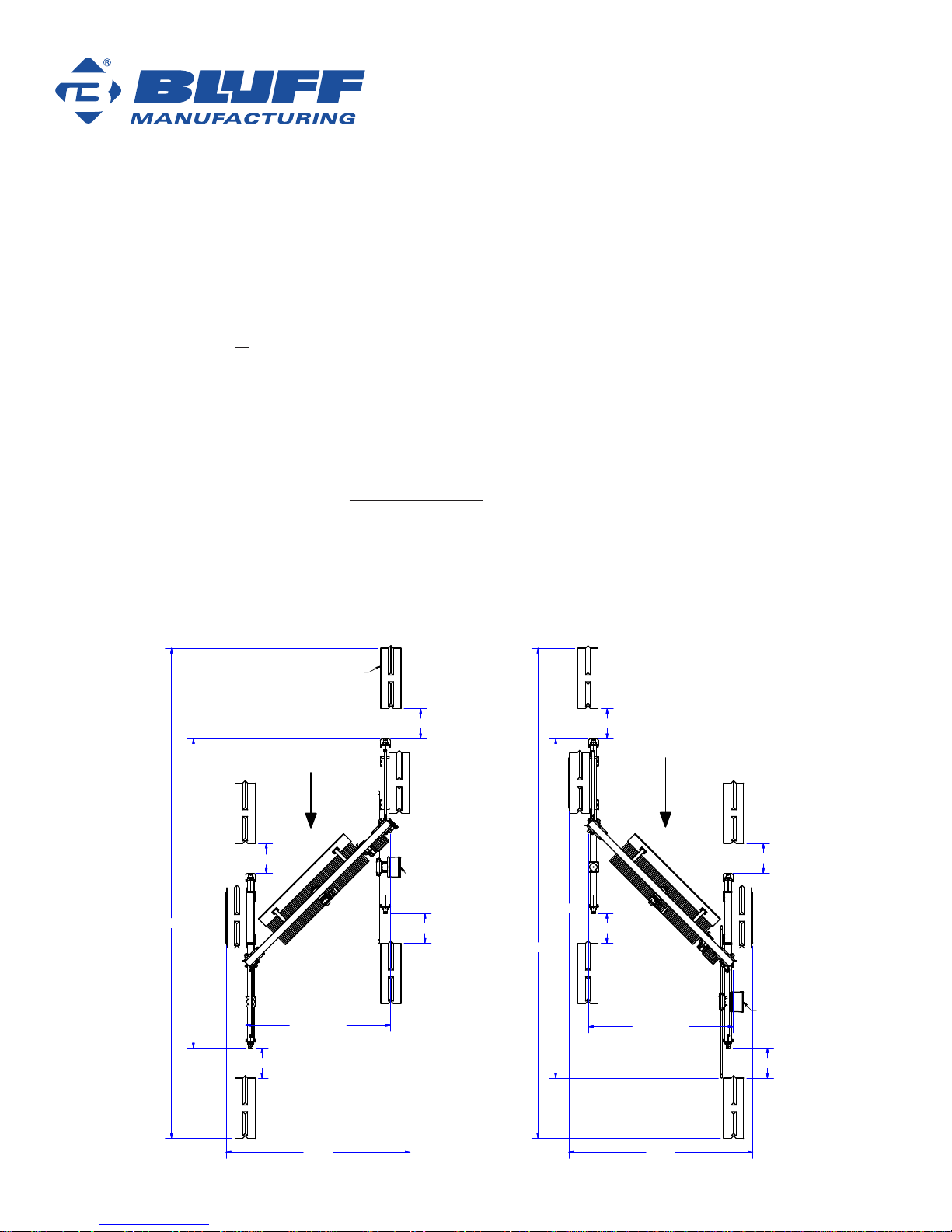

Site Location Requirements - Portable Model

Please read entire pre-installation manual before proceeding.

The rst step in the pre planning process is to determine the best orientation of the unit for your site.

The orientation of the unit determines the material ejection direction. Unit orientations are dened in

the gures below. The standard orientation ejects material away from the operator. The non-standard

orientation, while not ideal, can be used. For portable units Bluff recommends placing four additional

ecology blocks at the entrance and exit (for a total of six blocks) to prevent damage from vehicles.

Vehicle Travel

Vehicle Travel

Standard

Configuration

Non-Standard

Configuration

Electric

Panel

Electric

Panel

36 in approx

Ecology Block

36 in

36 in

36 in

36 in

36 in

36 in

36 in

220 in

370 in

586 in

586 in

406 in

this drawing is for

Site Location Requirements - Portable Model

173 in

base to base

173 in

base to base

model for this drawing:

DS-PortableStandard

model for this drawing:

DS-PortableNonStandard

220 in

approx

10

DuraSweeper®

Site Location Requirements - Permanent Model

Please read entire pre-installation manual before proceeding

The rst step in the pre planning process is to determine the best orientation of the unit for your site.

The orientation of the unit determines the material ejection direction. Unit orientations are dened in

the gures below. The standard orientation ejects material away from the operator. The non-standard

orientation, while not ideal, can be used. For permanent units Bluff recommends installing four Bluff

bollards at the entrance and exit to prevent damage from vehicles. We also recommend two additional

bollards to protect the electrical panel.

NOTICE

On a permanent model, orientation cannot be changed without a full reinstall. Please contact

your Bluff Manufacturing dealer or Bluff directly concerning switching unit orientation.

Vehicle Travel Vehicle Travel

Standard

Configuration

Non-Standard

Configuration

185 in

412 in

this drawing is for

Site Location Requirements - Permanent Model

173 in

base to base

173 in

base to base

model for this drawing:

DS-PermanentStandard

model for this drawing:

DS-PermanentNonStandard

445 in

12 in

approx

12 in

36 in

36 in

12 in

Electric

Panel

Electric

Panel

36 in

12 in

approx

12 in

12 in

381 in

421 in

185 in

36 in

Bluff Bollard SRB42

Bluff Bollard

SRB42

Bluff Bollard

SRB42

Bluff Bollard

SRB42

Bluff Bollard

SRB42

Blu

ff Bollard

SRB42

Bluff Bollard SRB42

Bluff Bollard

SRB42

Bluff Bollard

SRB42 Bluff Bollard

SRB42

Bluff Bollard

SRB42

Bluff Bollard SRB42

11

DuraSweeper®

Pad Suggestion for Permanent Installation

The concrete foundation pad for the structure is the most important structural preparation for the Bluff

DuraSweeper®. The suggested pads detailed in the following gures may not be sufcient for all site

locations, so check with your concrete engineer for proper depth, structure, and grade for your site

location.

Concrete pad should be poured by qualied personnel under the direction of properly trained

and qualied supervision. Failure to do so could result in pad failure that could cause serious

injury, death, and catastrophic damage to the equipment.

The pads for each permanently installed column are expected to be level and on-plane to each other.

Some variations may be overcome with shims under the column bases.

Concrete should meet all recommendations of the latest ACI 318 code, particularly with regard to cold-

weather pouring of concrete.

Note: Concrete piers can be used in place of concrete pads. Contact Bluff for additional information.

!DANGER

12

DuraSweeper®

Suggested Concrete Pad Specication - Permanent Model Standard Layout

Concrete pads should be at a minimum 6 inch depth and have a minimum compressive strength of

3,000 lb. Wedge anchors require a minimum embedment depth of 3.375 inches. The minimum pad foot

prints are shown in the Standard Concrete Layout and Non-Standard Concrete Layout. Edge of bollard

base plate should be recessed from all pad edges by at least 6".

Note: Concrete piers can be used in place of concrete pads. Contact Bluff for additional information.

Vehicle Travel

PERMANENT MODEL

Standard Concrete Layout

this drawing is for

Suggested Concrete Pad Specification - Permanent Standard Layout

model for this drawing: DS-PermanentStandardConcrete

25 ft

7 ft

24 ft

3 ft

11 ft

13 ft

12 ft

Bluff Bollard

SRB42

Bluff Bollard

SRB42

Bluff Bollard

SRB42

Bluff Bollard

SRB42

Bluff Bollard

SRB42

Bluff Bollard

SRB42

13

DuraSweeper®

Suggested Concrete Pad Specication - Permanent Model Non-Standard Layout

Concrete pads should be at a minimum 6 inch depth and have a minimum compressive strength of

3,000 lb. Wedge anchors require a minimum embedment depth of 3.375 inches. The minimum pad foot

prints are shown in the Standard Concrete Layout and Non-Standard Concrete Layout. Edge of bollard

base plate should be recessed from all pad edges by at least 6".

Note: Concrete piers can be used in place of concrete pads. Contact Bluff for additional information.

Vehicle Travel

PERMANENT MODEL

Non-Standard Layout

this drawing is for

Suggested Concrete Pad Specification - Permanent Model Non-Standard Layout

model for this drawing: DS-PermanentNonStandardConcrete

25 ft

7 ft

3 ft

24 ft

15 ft

14 ft

Bluff Bollard

SRB42

Bluff Bollard

SRB42

Bluff Bollard

SRB42

Bluff Bollard

SRB42

Bluff Bollard

SRB42

Bluff Bollard

SRB42

Electric

Panel

14

DuraSweeper®

Recommended Safety Barrier Equipment

Bluff Manufacturing recommends you protect your investment in the DuraSweeper®with bollards

or similar safety barrier equipment to prevent possible damage to all the components of the

DuraSweeper®, as well as the electrical panel. Below is a view of our suggestion for that protection. If

you need assistance to obtain the bollards, please contact your Bluff dealer for a quote.

The electrical panel should be secured and cables should be protected from vehicle damage. Power

to the electrical panel should be protected from foot, vehicular, and environmental wear in the best

manner the prevailing conditions on the site allow. While the electrical panel is rated for the cold and

weather, any additional protection provided should increase the working life of the equipment.

Vehicle

Travel

this drawing is for

Recommended Safety Barrier Equipment

model for this drawing: DS-PermanentStandard

Bluff Bollard

SRB42

Bluff Bollard

SRB42

Bluff Bollard

SRB42

Electric

Panel

Bluff Bollard

SRB42

Bluff Bollard

SRB42

Bluff Bollard

SRB42

Power Provisions

Power must be supplied to the unit at the rated voltage and phase required by the model purchased.

Refer to the product specications section of the manual for specic power requirements for your unit.

This power must be provided to the electrical control panel per all regulatory codes that apply to the

location. See electrical schematic in the interior pocket of the electrical enclosure for power connection

points.

!DANGER

Only licensed electricians are allowed to install or work with high voltage connections. Use

proper personal protective equipment as required. Serious injury or death to personnel, or

severe damage to equipment could result from non-compliance.

15

DuraSweeper®

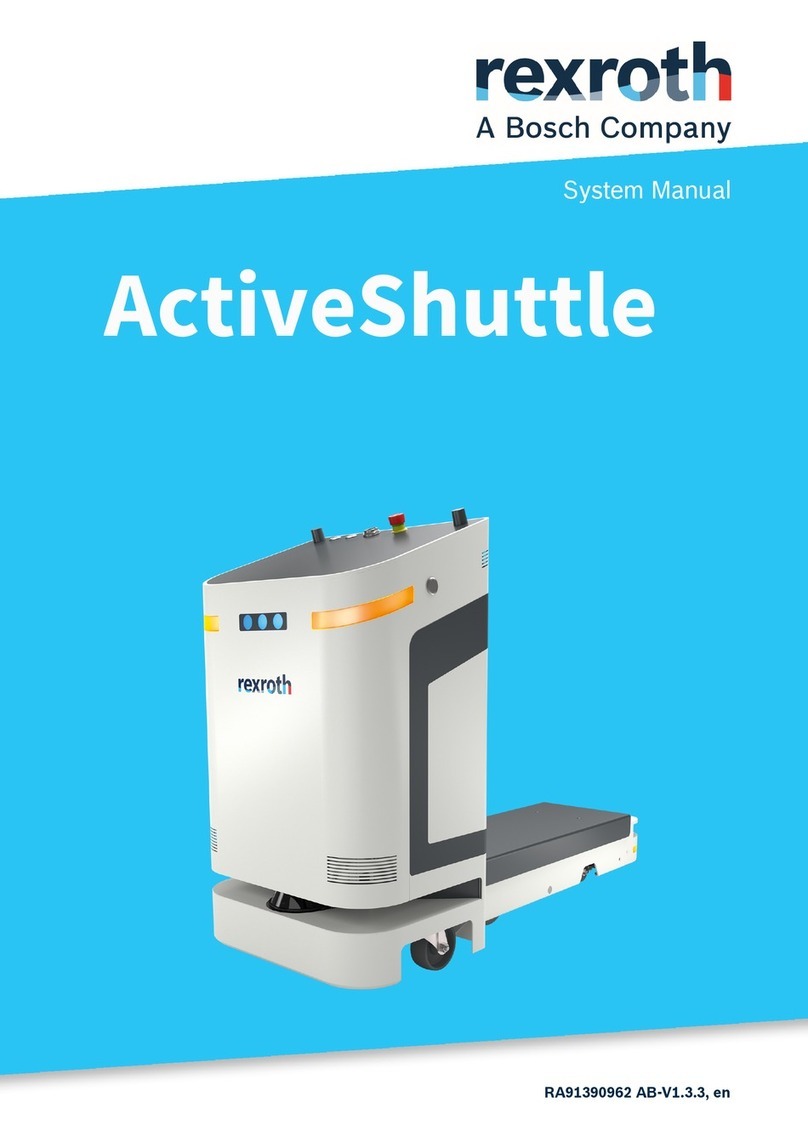

Parts & Assemblies

The following illustrations and diagrams detail the parts and assemblies of the DuraSweeper®by Bluff.

Some pieces are welded together and are considered a single part. Weldments are not considered

wear parts, so damage to any weldment should be reported to Bluff Manufacturing or a Bluff Distributor

immediately. Repairs to weldments will be subject to the judgment of the Bluff engineering team,

and not all weldments can or should be repaired due to safety concerns or feasibility. In such cases,

complete replacement of the weldment will be necessary.

PARTS LIST

TITLEPART NUMBER

QTY

ITEM Assy - Base Module

DS-BS-MOD

11 Horizontal Beam/Hoist AssemblyDS180-003

11.1 Weld - Beam

DS180-00211.1.1 BeamDS180-002-00111.1.1.1 Bracket

DS180-002-002

1

1.1.1.2 End PlateDS180-002-00421.1.1.3 Plate, Cross Brace

DS180-002-00621.1.1.4 Plate, Cable Support

DS180-004-001-01521.1.1.5 Weld - SpoolDS180-003-001

1

1.1.2 Shaft WasherDS180-003-001-00321.1.2.1 Spool Pipe

DS180-003-001-00481.1.2.2Hoist, Drive Shaft

DS180-003-001-00511.1.2.3 Bolt StackupDS180-BS-4

4

1.1.3 Hoist Shaft SpacerDS180-003-002

11.1.4 Bolt Stackup

DS180-BS-1841.1.5 Hoist Package, Key

DS180-003-004

1

1.1.6 Gearbox DriveDS180-003-005

11.1.7 Shaft Collar

SHAFTCOL2002

1.1.8 BearingBRINGMNT4B20011.1.9 Hoist Shaft Spacer

DS180-003-006

1

1.1.10 Base Beam Assy

DS180-00721.2 Brush Carriage Assy

DS180-00411.3 Column Brace

DS180-00821.4 Cable

DS180-009-001

11.5 Assy - Cable, Take-upDS180-BS-7

1

1.6 Column Assy

DS180-01621.7 Bracket

DS180-004-001-02511.8 Assy - Carriage Guide Bracket

DS180-004-00721.9 Bolt StackupDS180-BS-4

4

1.10 Bolt Stackup

DS180-BS-1441.11 Bolt Stackup

DS180-BS-1341.12 Assy - Cable, Static

DS180-BS-8

1

1.13 Prox Switch BracketDS180-030-001

11.14

Rep - Energy Chain Loop

2

11.15

Rep - Wire Rope 2

1

1.16 Prox Switch - Cable SetPROXSWTCHCS15

11.17 Proximity Switch

PROXSWTCH4011.18 Energy Chain, Mounting Bracket, Female

NRGYCHN13MB11.19 Energy Chain, Mounting Bracket, MaleRep - Energy Chain,

4556T66, Male

1

1.20

Energy Chain

NRGYCHN13LNK641.21 Assy - Anchor Package: Permanent

DS180-PERM

1

2Base Anchor Bracket AssyDS180-017

4

2.1 Bolt StackupDS180-BS-1

162.2 Wedge Anchor Kit

F34512WA242.3 Shim

DS-PERM-00182.4 Assy - Control PackageDS-E10

1

3Assy - Drive Package

DS-D1014 Assy - Drive Package

DS-D1515 Assy - Drive Package

DS-D20

1

6Electrical PanelDS-E20

17 Utility vehicle 14.8 m3 color Whiteutility_white

18 Assy - Anchor Package: Portable

DS-PORT19 Jack Assy

DS180-022

4

9.1 Ecology Block PlatformDS180-01329.2 Bolt Stackup

DS180-BS-1369.3 Jack Caster Shoe

DS180-027-00129.4

Ecology Block610 Prox Switch Bracket, LowerDS180-036-0012

11

Illustration for Parts and Assemblies Page

file locations:

model - C:\Users\stevebales\Desktop\DuraSweeperManual\Inventor Model 5\Layout.iam

persentation file - C:\Users\stevebales\Desktop\DuraSweeperManual\Inventor Model 5\DS-MainExplodedView-10HP.ipn

drawing - C:\Users\stevebales\Desktop\DuraSweeperManual\Inventor Model 5\DS-MainExplodedView-10HP.idw

PDF - C:\Users\stevebales\Desktop\DuraSweeperManual\Inventor Model 5\DS-MainExplodedView-10HP.pdf

DS180-003

Horizontal Beam/Hoist Assembly

Ecology Block

*not included

Energy Chain

DS180-022

Jack Assy

4 reqd.

DS180-027-001

Jack Caster Shoe

2 reqd.

Ecology Block

*not included

DS180-013

Ecology Block Platform

2 reqd.

DS180-017

Base Anchor Bracket

4 reqd.

DS-PERM-001

Base Shims

8 reqd.

Notes:

Lifting Cable not shown

Fasteners are not shown. See assembly fasteners list.

Base Package consists of items labeled in BLUE text.

Portable Anchor Package consists of items labeled in RED text.

Permanent Anchor Package consists of items labeled in GREEN text.

DS180-007

Base Beam Assy

2 reqd.

DS180-008

Column Brace

2 reqd.

DS180-016

Column Assy

2 reqd.

DS180-004

Brush Carriage Assy

motor not included

DS-D15 Drive Motor

DS-D20 Drive Motor

DS180-036-001

Prox Switch Bracket

1 upper, 1 lower

(both are identical)

DS180-036-001

Prox Switch Bracket

1 upper, 1 lower

(both are identical)

DS-E10

Electrical Panel

Figure 10

16

DuraSweeper®

NOTE: The Electrical Enclosure is designed and rated for the operation of the DuraSweeper®by Bluff.

It is not intended to supply power to additional add-ons (lights, for example). Nothing additional should

be wired from the electrical enclosure. See product specications for power requirements. The wiring

from the panel to the hoist and brush drive motors is supplied. The customer should comply with all

local electrical codes and regulations. All electrical installation should be performed by a licensed

electrician.

Pre-erection Assembly

The DuraSweeper®by Bluff ships as several pre-assembled components. Before attempting to

install any components, remove packaging and inspect components for any defects or damage.

Closely inspect wire rope and pulleys for defects or damage that might cause premature wear to the

components. Replace wire rope if any damage, kinks, crimps, fraying, loose strands, or broken strands

are found.

Installation Tips

• Installation site should be clear of debris and clutter - clear snow to surface.

• Make sure to plan the area so that there is plenty of room to maneuver the trucks through the unit

and plenty of space for the ejected snow.

Prevailing wind direction during snow season should be considered to maximize the distance

and direction the snow will be ejected.

• Carefully read and understand all sections of this manual before attempting the installation. The

pages listed below are also in the Pre-Installation Guide For Bluff DuraSweeper®:

- Ejected Material and Clear Lane

- Site Location Requirements – Portable Model

- Site Location Requirements – Permanent Model

- Pad Suggestion for Permanent Installation

- Suggested Concrete Pad Specication – Permanent Model Standard Layout

- Suggested Concrete Pad Specication – Permanent Model Non-standard Layout

- Recommended Safety Barrier Equipment

• These installation instructions describe a typical installation for a portable or a permanently installed

unit. There may be installations that require special requirements not covered in this manual. Contact

Bluff Manufacturing in those cases.

• When assemblies involve an array of bolts, it is always good practice to install and snug all the bolts

before fully tightening any of them. Tightening each bolt as it is installed will result in difculties

during the installation.

Installation On-Site

17

DuraSweeper®

Recommended Tools

The following are recommended for this installation:

• Boom Lift with a man basket with minimum 30’ lifting height and a minimum 8,000 lb. lifting capacity.

• Two lifting slings are recommended when lifting the main structure. Slings need to have a minimum

capacity of 2000 lbs. each (when used in a choker conguration).

• Heavy duty saw horses or equivalent to support the structure during the initial structure assembly.

• A spud wrench is strongly recommended to align bolt holes, etc.

• Assorted wrenches, ratchets, etc.

This manual suits for next models

4

Table of contents

Other Bluff Industrial Equipment manuals