SIGRIST DESIGN DA-M Series User manual

QUICK START

GUIDE

Sigrist Design is an Australian

owned and operated company,

specialising in the design and

manufacture of industrial and

commercial fans, ventilation and

dust collection solutions. With

over 30 years of experience, our

HVAC expertise has been earned by

delivering over 25,000 engineered

projects.

Our products are designed and

manufactured in our state-of-the-art

facilities in Queensland for industrial,

commercial, building and construction

markets.

2SIGRIST CASE STUDIES

The information presented in this guide is accurate at the time of publishing.

Sigrist Design Pty Ltd reserves the right to make changes to products or information at any time

without notice as part of our continuous improvement process.

Information provided by Sigrist Design Pty Ltd is believed to be accurate and reliable. However, no

responsibility is assumed by Sigrist Design Pty Ltd for its use, nor for any infringements of patents or

other rights of third parties which may result from its use.

This Quick Start Guide v0.5.9 was published in December 2020 by Sigrist Design Pty Ltd in Brisbane,

Australia.

Copyright 2020 © Sigrist Design. All rights reserved.

TABLE OF CONTENTS

QUICK START GUIDE 4

Delivery 4

Storage 4

Safety 4

Start Up 4

Maintenance 4

Sound Levels 4

Terms and Conditions of Trade 4

Warranty 4

INSTALLATION 5

Mounting 5

Roof Mounted Fans 5

Inline Fans 6

WIRING 7

SDD1 7

SDD2 8

SDD3 8

SDD4 9

SDD5 9

SDD6 9

SDD7 10

SDD8 10

3SIGRIST CASE STUDIES

DELIVERY

Fans should be inspected on delivery to ensure no damage was sustained

during transit and that the quantity and type of parts are correct. If any

discrepancies are apparent or goods are found to be damaged, contact your

Sigrist Design sales representative immediately.

STORAGE

If a fan or other products are not installed immediately after delivery, the

goods must be stored in a clean and dry environment. Failing to meet these

conditions may void the product’s warranty.

SAFETY

Rotating fans are dangerous and pose a serious risk to safety if precautions

are not undertaken. It is the responsibility of those undertaking work

to ensure the safety of those involved. The following safety tips are

recommended as a starting guide to staying safe when maintaining or

inspecting fans.

1. The fan should be electrically isolated before maintenance work

is started.

2. Ensure the blades of the fan are not rotating.

3. Install each fan in an easy access location so that there is minimal

obstruction to remove or open the fan.

4. Ensure workers are fully qualied to undertake inspection and/or

maintenance work.

5. All fasteners should be regularly checked to ensure tightness.

START UP

Before starting up the fan, ensure the blades are clean and free from

debris and all fasteners are tight. Once the fan is started, the impeller

should rotate in the direction of the arrows on the side of the fan casing (if

applicable). If the blades are rotating in the opposite direction, the fan may

have been wired incorrectly. If so, refer to the fan’s wiring diagram on page

6.

Air should be moving in the direction of the arrow on the side of the fan

casing (if applicable). If the air is moving in the opposite direction, the fan

may have been wired incorrectly. If so, refer to the fan’s wiring diagram on

page 6.

If a fan which contains a backwards curved centrifugal impeller sounds

excessively loud on start up with the air moving in the correct direction,

the rotor would be running backwards. In such case, refer to the respective

wiring diagram on page 6.

MAINTENANCE

After installation, each fan should be inspected after three months to

ensure all fasteners are tight and the blades are clean. Following this, fans

are to be inspected at regular intervals no longer than six months apart. It

may be required to undertake inspection at shorter intervals depending on

the environment or air ow conditions.

Belt driven fans should have the pulley alignment and belt tension

inspected before start-up. These should be inspected again, and the belt

tightened within the rst month of operation.

SOUND LEVELS

Technical data provided for each fan lists the sound levels in hypothetical

free eld conditions. This is where the fan is not surrounded by any walls or

obstructions and sound propagates spherically outwards.

It is important to note that the perceived sound level on site will be louder

than that specied in the technical data. This is because the surrounding

environment to the fan signicantly aects the way the sound is

propagated. Factors that aect sound levels may include the fan’s proximity

to a wall, corner, obstruction or another fan, the reectivity of the material

of the walls nearby, the distance between the observer and the fan as well

as the angle between the fan’s direction and the observer.

The operating point of the fan can also cause higher than expected sound

levels or tonality. Ideally each fan should be performing as close to the point

of maximum eciency for most of its operation. Performing to the left

side of the fan performance curve increases the low frequency spectrum of

sound giving a perceived “rumble”. Operating to the right side of the fan

curve increases mid to high frequency noise.

TERMS AND CONDITIONS OF TRADE

For a full list of terms and conditions of trade, click here

WARRANTY DETAILS

TERMS AND CONDITIONS

WARRANTY

For full warranty details, click here:

QUICK START GUIDE

4SIGRIST CASE STUDIES

MOUNTING

Always lift the fan using lifting lugs if available. Alternatively, lift the fan via the base or motor support plate.

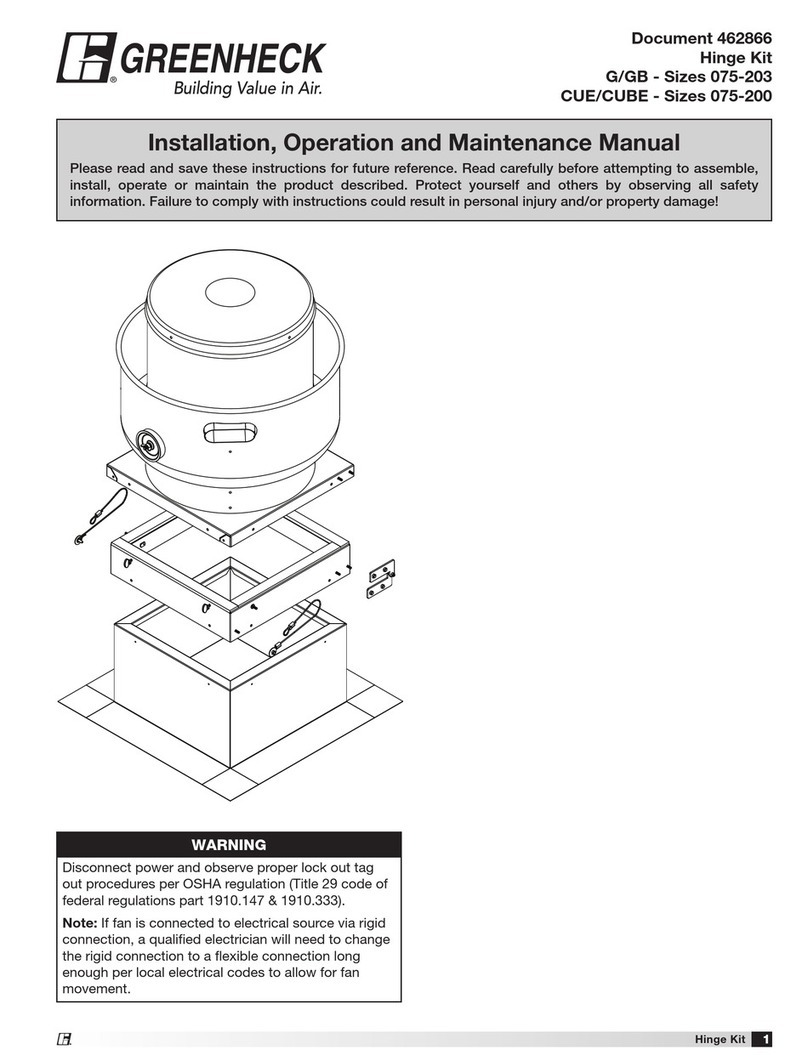

ROOF MOUNTED FANS

1. Maximise the upstand area to allow for the

most air into the fan.

2. Ductwork should run perpendicular to the

ground such that the base of the fan is level.

3. The fan’s position should be such as to avoid

exposure to cross winds. A fan below the

roof peak will experience less cross wind and

consequent back-pressure eects.

4. A foam sealant strip should be used between

the curbs and fan base to seal the airow.

Failing to do so can cause air recirculation, air

recirculation will cause the fan to be less

ecient at exhausting air. Note: The fan

mounting to the duct/upstand must be

squarely tted, without deformation or

warping of either the fan housing or

duct/upstand.

INSTALLATION

5SIGRIST CASE STUDIES

2. A minimum of a one diameter spacing

between the fan inlet/outlet and the wall or

obstruction should be used to maintain good

airow in/out of the inline fan.

3. Square-to-round transitions and turning

vanes in elbows assists uniform airow; this is

a compromise only and by no means ideal.

INLINE FANS

1. Cones should be tted to inline fans that have

a free inlet to improve the fan’s eciency.

6SIGRIST CASE STUDIES

SDD1

Single phase, single speed motor.

The following table shows a list of wiring diagrams for each product series. Check the wiring diagram

supplied with the motor.

*Table above contains the most popular Product Series, refer to sigristdesign.com.au for full fan

ranges and product datasheets.

PRODUCT SERIES WIRING DIAGRAM/S

DA-M Roof Axial Exhaust SDD3/4

DC-FT-146 Roof Centrifugal Exhaust/Supply SDD5

DC-R Roof Centrifugal Exhaust SDD1/2/7/8

FASU Wall Centrifugal Supply SDD5

IA-Q Inline Axial SDD6

IC-R Inline Centrifugal SDD1/2/7/8

PA-EQ Plate Axial SDD1

RC-R Inline Centrifugal SDD1/2/7/8

SA-M Roof Axial Supply SDD3/4

SC-R Roof Centrifugal Supply SDD1/2/7/8

TA-M Inline Axial SDD3/4

VC-R Roof Centrifugal Exhaust SDD1/2/7/8

Single phase A.C. motor with operating

capacitor and thermostatic switch.

Thermostatic switch wired in series with

windings if RE controllers are used. Insert

bridge (x) and wiring connections shown as

dash-line on the drawing

U1: Brown

V1: Blue

Z1: Black

Z2: Orange

TB: White

PE: Yellow - Green

WIRING

7SIGRIST CASE STUDIES

SDD3

Single phase, single speed motor.

SDD2

Three phase, two speed motor.

Three phase motor with 2 speeds and

thermostatic switch (TB). Speed changing by

Y switching. Changing of rotation direction

by interchanging of 2 phases. If MSD 2 2-step

switching units are used do not insert bridge and

connect dotted lines in the wiring diagram to the

switching unit.

U1: Brown

V1: Blue

W1: Black

U2: Red

V2: Grey

W2: Orange

TB: White

PE: Yellow - Green

x: Bridge for high speed

y: Bridge for low speed

8SIGRIST CASE STUDIES

SDD4

Three phase, single speed motor.

SDD5

Single phase, three speed motor.

SDD6

Single phase, single speed motor.

9SIGRIST CASE STUDIES

SDD7

Single phase, EC motor.

SDD8

Three phase, EC motor.

X2: Control cable

5: Brown

6: Black

7: Yellow

8: Blue

9: Green

10: Violet

11: Red

12: Orange

Operation mode

a: Open loop control

Operation mode

b: Closed loop control

Operation mode

a: Open loop control

Operation mode

a: Closed loop control

10 SIGRIST CASE STUDIES

This manual suits for next models

19

Table of contents

Popular Fan manuals by other brands

Ebmpapst

Ebmpapst R2E250-AS47-09 operating instructions

Ebmpapst

Ebmpapst D4E200-CA08-41 operating instructions

Ebmpapst

Ebmpapst D4E225-CC07-37 operating instructions

Silvercrest

Silvercrest STV 45 C2 operating instructions

minkaAire

minkaAire DREAM STAR F788L Instruction manual warranty certificate

Concept2

Concept2 VS 5020 manual