SIGRIST VisGuard 2 User manual

Document number: 14162E

Version: 2

Valid from: S/N 704010/

SW V529

INSTRUCTION MANUAL

VisGuard 2

Visibility Monitor / Dust Monitor

Copyright© SIGRIST-PHOTOMETER AG, subject to technical changes without notice 4/2018

SIGRIST-PHOTOMETER AG

Hofurlistrasse 1

CH-6373 Ennetbürgen

Switzerland

Tel. +41 41 624 54 54

Fax +41 41 624 54 55

inf o@photometer.com

w w w .photometer.com

Contents Instruction Manual VisGuard 2

14162E/2 3

Contents

1General user information........................................................................................7

1.1 Terms used in this document (glossary) ........................................................7

1.2 Purpose of the Instruction Manual ...............................................................7

1.3 Target group of the documentation .............................................................7

1.4 Additional documentation ..........................................................................7

1.5 Copyright provisions ..................................................................................7

1.6 Document storage location .........................................................................7

1.7 Order document ........................................................................................8

1.8 Proper use ................................................................................................8

1.9 Use restrictions ..........................................................................................8

1.10 User requirements .....................................................................................8

1.11 Declaration of conformity ...........................................................................8

1.12 Dangers when not used properly .................................................................9

1.13 Meaning of the safety symbols....................................................................9

1.14 Meaning of the pictograms.......................................................................10

2Instrument overview ............................................................................................11

2.1 Overview of a measuring point with SIPORT 2.............................................11

2.2 Overview of a measuring point with SICON only .........................................11

2.3 Overview of a multiple measuring point with SICON M................................12

2.4 Designation of the components.................................................................13

2.4.1 Designation of the VisGuard 2..............................................................13

2.4.2 Designation of the SICON (M/-C) ..........................................................14

2.4.3 Designation of the SIPORT 2.................................................................15

2.5 Scope of supply and accessories ................................................................16

2.5.1 Standard scope of supply for the VisGuard 2..........................................16

2.5.2 Optional scope of supply for the VisGuard 2 ..........................................17

2.6 Technical data for the VisGuard 2 ..............................................................19

3General safety points ...........................................................................................22

3.1 Dangers when properly used.....................................................................22

3.2 Residual risk............................................................................................23

3.3 Warning and danger symbols on the instrument .........................................23

3.4 Preventing undesirable online access attempts ............................................24

4Mounting ...........................................................................................................25

4.1 General information on mounting the VisGuard 2 .......................................25

4.2 Distances and corresponding cable cross-sections........................................27

4.3 Mounting the optional junction box...........................................................28

4.4 Mounting the SIPORT 2 connection box .....................................................28

4.5 Mounting the SIPORT 2 without housing....................................................28

4.6 Installing the 230 VAC sample heater on the VisGuard 2..............................29

4.7 Mounting the SICON (M)..........................................................................30

5Electrical installation ............................................................................................31

5.1 Safety pointers for the electrical connection................................................31

5.2 Installation with SIPORT 2.........................................................................32

5.2.1 Connecting the SIPORT 2.....................................................................32

5.2.2 Connecting the SIPORT 2 without housing.............................................33

5.2.3 Profibus DP: Overview and installation...................................................34

5.2.4 Profinet IO: Overview and installation....................................................35

5.2.5 Modbus RTU with repeater: Overview and installation.............................36

5.2.6 StromRel module: Overview and installation...........................................38

5.2.7 Current/Digi. input for SIPORT 2 ...........................................................39

5.2.8 Connecting an external analog sensor...................................................40

Instruction Manual VisGuard 2 Contents

4 14162E/2

5.2.9 Connecting a pressure monitor on extractive systems..............................40

5.2.10 Connecting the optional junction box ...................................................41

5.3 Connecting the SICON (M) .......................................................................43

5.3.1 Removing the cover from the SICON (M) ...............................................43

5.3.2 Overview of the opened SICON (M) control unit .....................................44

5.3.3 Installation of the SICON (M) ................................................................45

5.4 Connecting the field bus interfaces (optional) .............................................46

5.4.1 Overview of Modbus RTU and Profibus DP.............................................46

5.4.2 Terminal assignment of Modbus RTU/Profibus DP...................................47

5.4.3 Profinet IO: Overview and installation in the SICON.................................48

5.4.4 4-way current output module: Overview and Installation .........................49

5.4.5 4-way current input module: Overview and Installation ...........................50

5.4.6 Overview of HART...............................................................................51

5.4.7 Connecting to HART ...........................................................................51

5.4.8 Connecting an external analog sensor...................................................52

5.4.9 Connecting a pressure monitor on extractive systems..............................52

5.4.10 Connecting the optional 24 VDC power supply ......................................53

6Commissioning ...................................................................................................54

6.1 Additional measuring channels for smoke measurement ..............................55

7Operation ...........................................................................................................56

7.1 Operation basics......................................................................................56

7.2 LED display on the photometer .................................................................57

7.3 Connecting SICON-C to SIPORT 2..............................................................58

7.4 Connecting the SICON-C to the SIPORT 2 without housing ..........................59

7.5 Control elements in measuring operation ...................................................60

7.6 Menu button ..........................................................................................60

7.7 Valu button.............................................................................................60

7.8 Info button .............................................................................................61

7.8.1 Info button, screen 1...........................................................................61

7.8.2 Page 2, Info button .............................................................................62

7.9 Diag button ............................................................................................63

7.10 Functions of the log screen (Log button) ....................................................64

7.11 Display in measuring operation .................................................................65

7.12 Activating and deactivating the screen lock ................................................66

7.13 Switching to service mode ........................................................................67

7.14 Control components in service mode .........................................................68

7.14.1 Input elements in service mode.............................................................68

7.14.2 Numerical entry ..................................................................................69

7.14.3 Single selection of functions .................................................................70

7.14.4 Multiple selection of functions..............................................................70

8Settings ..............................................................................................................71

8.1 Setting the operating language .................................................................71

8.2 Setting the date and time .........................................................................72

8.3 Setting the current outputs .......................................................................73

8.4 Setting the limits .....................................................................................74

8.4.1 Upper and lower threshold value of a limit.............................................75

8.4.2 Reading if limit exceeded or undershot ..................................................75

8.5 Setting the outputs ..................................................................................76

8.6 Setting the recalibration ...........................................................................77

8.7 Setting the Profibus DP parameters............................................................77

8.8 Setting the Profinet IO parameters.............................................................78

8.9 Setting the Modbus RTU parameters..........................................................79

8.10 Setting or changing the access code ..........................................................80

8.11 Backup configured data ...........................................................................81

Contents Instruction Manual VisGuard 2

14162E/2 5

9Servicing.............................................................................................................82

9.1 Servicing schedule ...................................................................................82

9.2 Cleaning the outside of the VisGuard 2 ......................................................83

9.3 Cleaning the sample inlet .........................................................................84

9.4 Replacing the filter cartridge in the VisGuard 2 In-situ ..................................85

9.5 Replacing the fan on the VisGuard 2 In-situ ................................................87

9.6 Recalibrating the VisGuard 2 .....................................................................89

9.6.1 General information on recalibrating the VisGuard 2...............................89

9.6.2 Setting checking unit number in use .....................................................89

9.6.3 Manual adjustment with a control unit ..................................................89

9.6.4 Automatically triggered adjustment ......................................................91

9.7 Changing the battery in the control unit ....................................................93

10 Troubleshooting ..................................................................................................94

10.1 Pinpointing malfunctions ..........................................................................94

10.2 Warning messages and effect on operation ................................................94

10.3 Fault messages and effect on operation .....................................................96

10.4 Prioritized fault messages and their effect on operation ...............................98

11 Customer service information ...............................................................................99

12 Decommissioning/Storage .................................................................................. 100

12.1 Decommissioning the photometer ........................................................... 100

12.2 Storing the photometer .......................................................................... 100

13 Packaging/Transport/Returning ........................................................................... 101

14 Disposal ........................................................................................................... 102

15 Spare parts list .................................................................................................. 103

16 Appendix.......................................................................................................... 104

17 Index................................................................................................................ 106

Makr o

Instruction Manual VisGuard 2 Contents

6 14162E/2

This page isintentionallyblank

Makr o

General user information Instruction Manual VisGuard 2

14162E/2 7

1General user information

1.1 Terms used in this document (glossary)

Please refer to our website for specialist terms: www.photometer.com/en/glossary/

1.2 Purpose of the Instruction Manual

This Instruction Manual provides the user with helpful information about the entire life cycle

of the VisGuard 2 and its peripheral devices. Before commissioning the ins trument, you

should be completely familiar with the Instruction Manual.

1.3 Target group of the documentation

The Instruction Manual is intended for all persons who are responsible for the operation and

maintenance of the instrument.

1.4 Additional documentation

DOC. NO.

TITLE

CONTENT

14166E

Brief Instructions

The most important functions and the servicing

schedule.

14265E

Instructions for extracti-

ve application

Information for extractive application.

14165E

Reference Handbook

More sophisticated menu functions and worksteps

for advanced users.

14289E

Data Sheet

Descriptions and technical data about the instru-

ment.

14168E

Service Manual

Repair and conversion instructions for service engi-

neers.

14288DEF

Declaration of Confor-

mity

Compliance with the underlying directives and

standards.

1.5 Copyright provisions

This document has been written by SIGRIST-PHOTOMETER AG. Copying or modifying the

content or giving this document to third parties is permitted only with the express consent of

SIGRIST-PHOTOMETER AG.

1.6 Document storage location

This document is part of the product. It should be stored in a safe place and always be close

at hand for the user.

Instruction Manual VisGuard 2 General user information

8 14162E/2

1.7 Order document

The most recent version of this document can be downloaded at www.photometer.com

(first time registration required).

It can also be ordered from a SIGRIST representative in your country (Instruction Manual

“Customer service information”).

1.8 Proper use

The photometer and its peripherals are designed for measuring visibility and dust in non-

explosive atmospheres at ambient temperatures of between -30 °C (minimum) and 55 °C

(maximum).

1.9 Use restrictions

EXPLOSION

HAZARD!

Operation in an inappropriate environment.

Use in explosive areas can cause explosions, which can lead to the death of persons in the

vicinity.

It is not permitted to operate the instrument in explosion hazardous areas or rooms.

It is not permitted to use the instrument with explosive sample substances.

1.10 User requirements

The instrument may be operated only by trained technical personnel who have read and un-

derstood the content of the Instruction Manual.

1.11 Declaration of conformity

Current technological principles were followed in designing and manufacturing the instru-

ment. They comply with the applicable guidelines concerning safety and duty to take due

care.

EU: The measuring instrument meets all applicable requirements within the European Union

(EU) for carrying the CE mark.

Please refer to the separate declaration of conformity for details. Section 1.4

General user information Instruction Manual VisGuard 2

14162E/2 9

1.12 Dangers when not used properly

DANGER!

Operation when not used properly.

Improper use of the instrument can cause injuries to persons, process-related consequential

damage and damage to the instrument and its peripherals.

In the following cases the manufacturer cannot guarantee the protection of persons and the

instrument and therefore assumes no legal responsibility:

The instrument is used in a way not included in the described area of application.

The instrument is not properly mounted or set up.

The instrument is not installed and operated in accordance with the Instruction Manual.

The instrument has been operated with accessory parts which SIGRIST-PHOTOMETER

AG has not expressly recommended.

Improper changes to the instrument have been performed.

The instrument has not been operated within the specifications, in particular concerning

pressure and temperature.

1.13 Meaning of the safety symbols

All danger symbols used in this document are explained below:

DANGER!

Danger due to electrical shock that may result in serious bodily injury or death.

Non-observance of this notice may lead to electrical shocks and death.

EXPLOSION

HAZARD!

Danger due to explosion that may result in serious bodily injury or death.

Non-observance of this notice may cause explosions resulting in serious property damage

and death.

WARNING!

Warning about bodily injury or hazards to health with long-term effects.

Non-observance of this warning may lead to injuries with possible long-term effects.

CAUTION!

Notice about possible material damage.

Non-observance of this notice may cause material damage to the instrument and its

peripherals.

Instruction Manual VisGuard 2 General user information

10 14162E/2

1.14 Meaning of the pictograms

All pictograms used in this document are explained below:

Additional information about the current topic.

Practical procedures when working with the VisGuard 2.

Manipulations on the touchscreen.

The screenshot is an example and may differ from current device.

Instrument overview Instruction Manual VisGuard 2

14162E/2 11

2Instrument overview

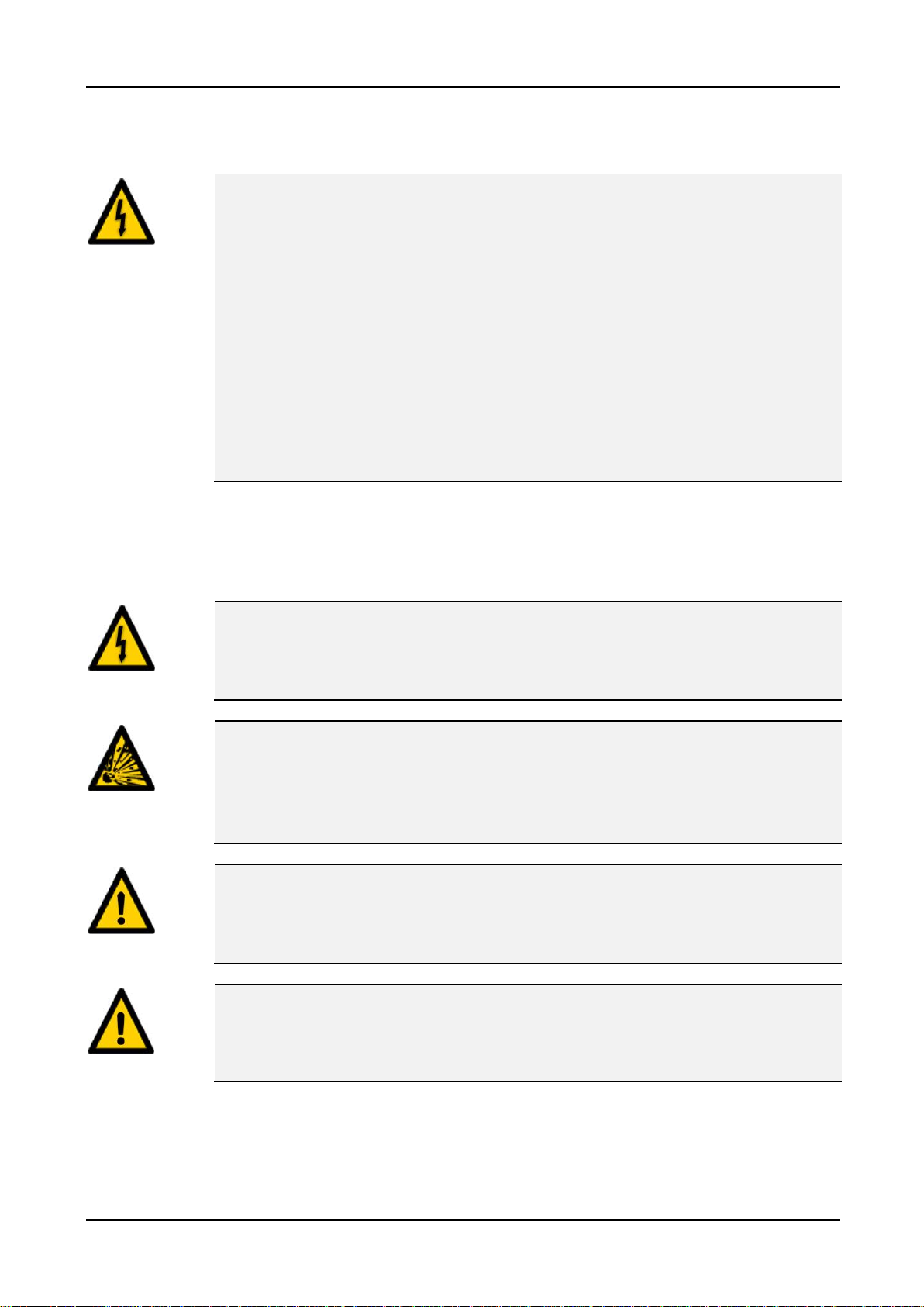

2.1 Overview of a measuring point with SIPORT 2

Figure 1: Overview of a measuring point with VisGuard 2 In-situ

VisGuard 2 In-situ

Connection box (optional)

SIPORT 2 connection box

SICON-C portable control unit, can be

connected to the SIPORT 2 or connec-

tion box via cable

2.2 Overview of a measuring point with SICON only

Figure 2: Overview of a measuring point with VisGuard 2 In-situ connected to the SICON

VisGuard 2 In-situ

SICON (M) control unit

Instruction Manual VisGuard 2 Instrument overview

12 14162E/2

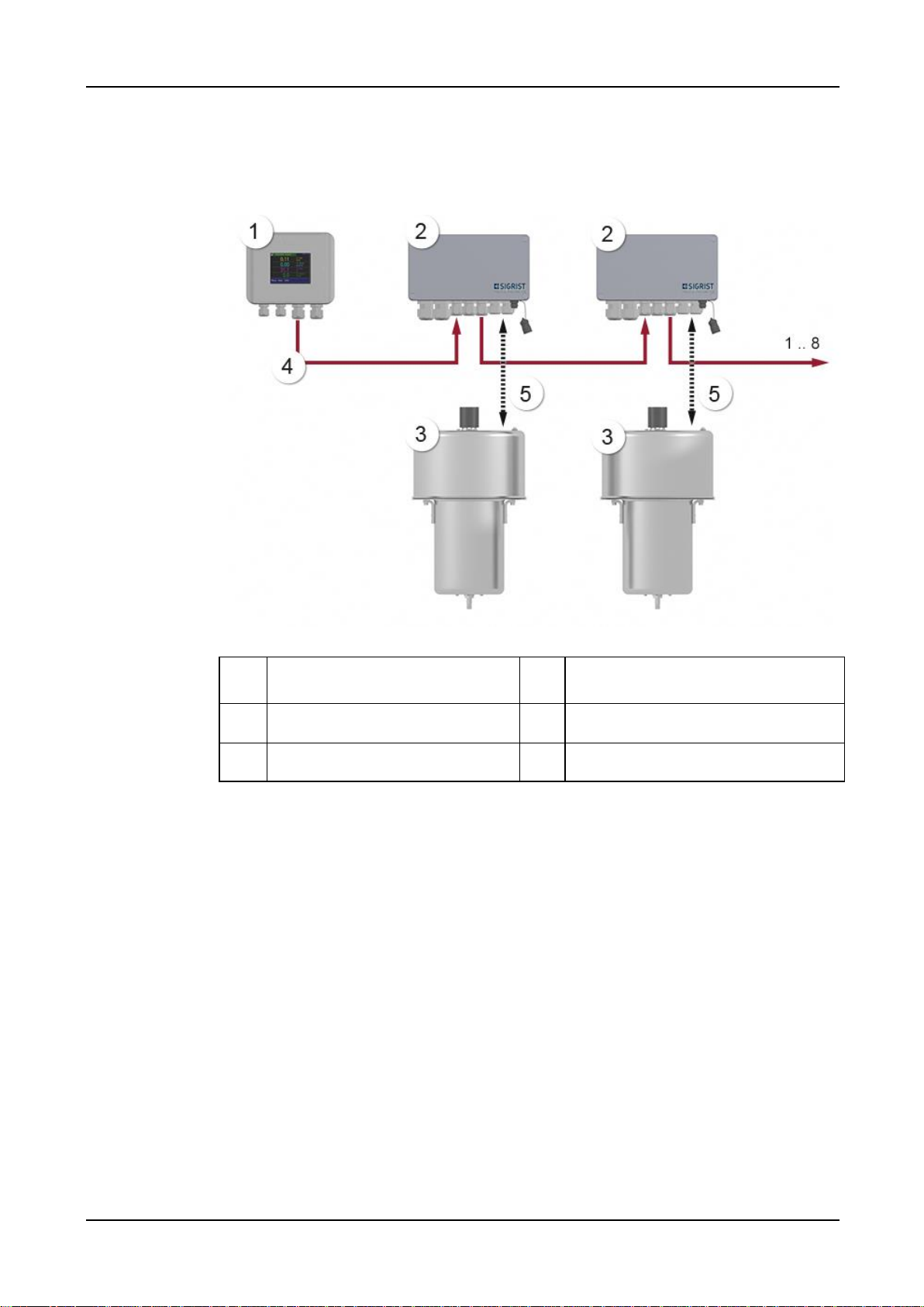

2.3 Overview of a multiple measuring point with SICON M

Up to eight VisGuard 2 instruments can be connected and operated on the SICON M.

Figure 3: Overview of a multiple measuring point with VisGuard 2

SICON M multi-channel control

unit

SIPORT 2 connection box with in-

tegrated Modbus RTU with repeater

VisGuard 2 In-situ (1 .. 8)

RS-485 bus connection

Connection cable to VisGuard 2

Instrument overview Instruction Manual VisGuard 2

14162E/2 13

2.4 Designation of the components

2.4.1 Designationof the VisGuard 2

The VisGuard 2 is fitted with the following rating plate:

Figure 4: Designation of the VisGuard 2

Manufacturer

Country of origin

Product name

Serial number

Date of manufacture

Service voltage

Frequency range

Power

Observe the Instruction Manual

Observe the disposal information

A red sticker is attached to the VisGuard 2 (arrow). This dis-

tinguishes it from instruments with a similar appearance.

Figure 5: Red sticker for identifying the VisGuard 2

Instruction Manual VisGuard 2 Instrument overview

14 14162E/2

2.4.2 Designationof the SICON(M/-C)

The SICON (M/-C) control unit is fitted with the following rating plate:

Figure 6: Designation of the SICON-C

Manufacturer

Country of origin

Product name

Serial number

Date of manufacture

Service voltage

Frequency range

Power

Observe the Instruction Manual

Observe the disposal information

Instrument overview Instruction Manual VisGuard 2

14162E/2 15

2.4.3 Designationof the SIPORT 2

The SIPORT 2 connection box is fitted with the following rating plate:

Figure 7: Rating plate on SIPORT 2

Manufacturer

Country of origin

Product name

Serial number

Date of manufacture

Service voltage

Frequency range

Power

Observe the Instruction Manual

Observe the disposal information

Instruction Manual VisGuard 2 Instrument overview

16 14162E/2

2.5 Scope of supply and accessories

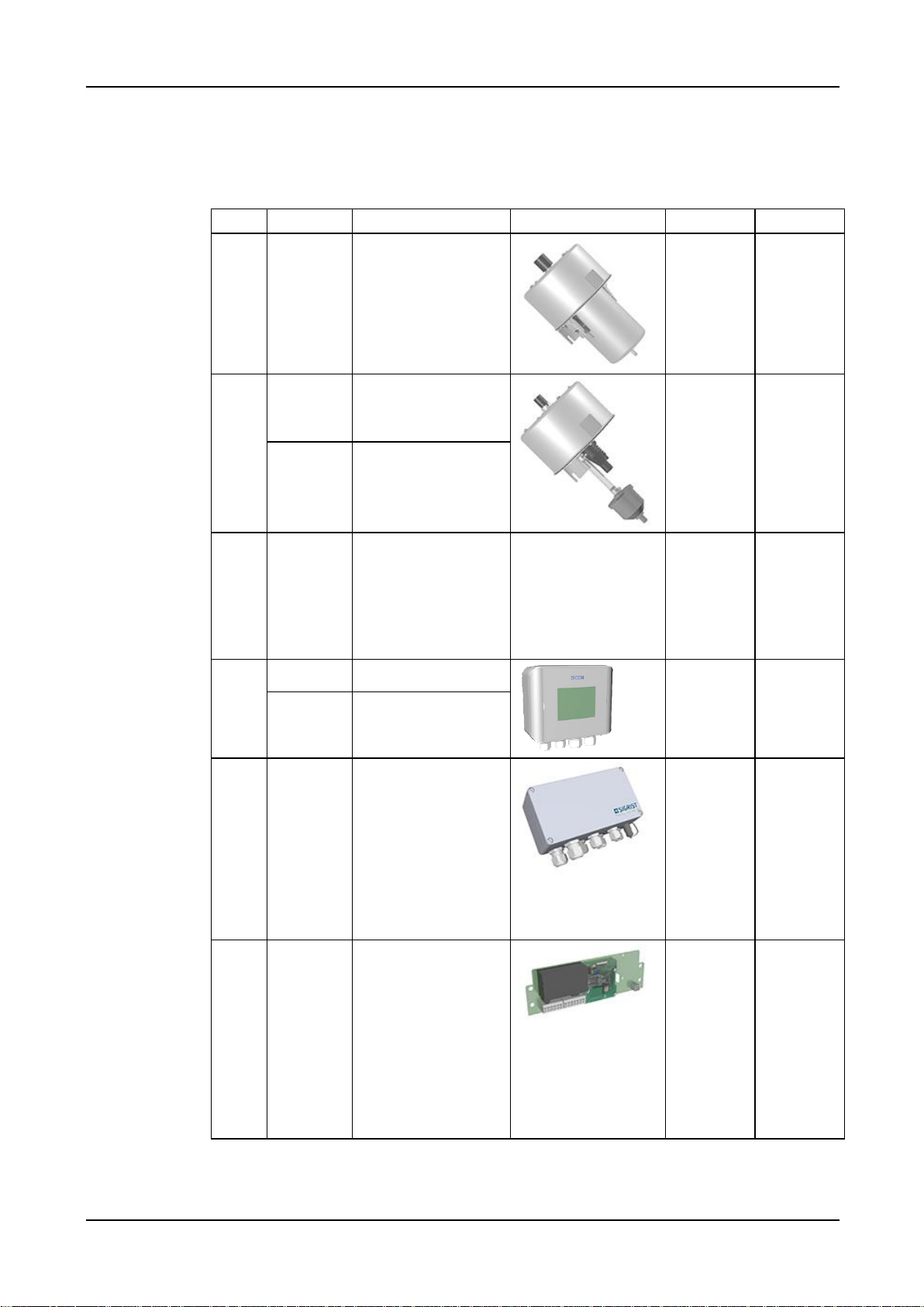

2.5.1 Standard scope of supplyfor the VisGuard 2

Pcs.

Art. no.

Name

View

In-situ

Extractive

1

120688

VisGuard 2 In-situ

X

1

120686

VisGuard 2 Extractive

(extraction length 30

.. 500 m)

X

120687

VisGuard 2 Extractive

(extraction length up

to 30 m)

1

-

Gas sampling system

GSS5: 0 .. 5 m

GSS30: 5 .. 30 m

GSS500: 30 .. 500 m

GSSM: Multiple

sample

X

1

118342

SICON control unit

X

X

119040

SICON M control

unit

1

SIPORT 2 connection

box with integrated

Option: Instrument

socket with protec-

tion cover 120387

X

X

120287

Profibus DP

120288

StromRel

120289

Modbus RTU

121118

Profinet IO

1

Connection print for

SIPORT 2 without

housing, with in-

tegrated

X

X

120389

Profibus DP

120390

StromRel

120391

Modbus RTU

121119

Profinet IO

Instrument overview Instruction Manual VisGuard 2

14162E/2 17

Attached documents:

Pcs.

Doc. no.

Name

View

Variant

1

14162

Instruction Manual

German

French

English

1

14165

Reference Manual

German

English

1

14166

Brief Instructions

German

French

English

2.5.2 Optional scope of supplyfor the VisGuard 2

PCS.

ART. NO.

NAME

VIEW

VARIANT

1

120290

SICON-C portable

control unit

1

112677

Checking unit

1

120342

Junction box

1

112408

Sample heater

25 W/230 VAC

Instruction Manual VisGuard 2 Instrument overview

18 14162E/2

PCS.

ART. NO.

NAME

VIEW

VARIANT

1

120802

Sample heater

24 VDC/10 W

Reference Manual

1

118358

High-temperature

cable, 8-pin,

length by meter,

for connection to

the SIPORT 2

1

120393

High-temperature

cable, 8-pin incl.

connector, L = 1.5

m, for connection

to the SIPORT 2

with connection

socket

1

118637

High-temperature

cable, 4-pin,

length by meter,

for SICON connec-

tion

1

120790

Current/digi. input

for SIPORT 2

For SIPORT 2

1

118442

Profibus DP inter-

faces print

For SICON (M)

1

118445

Modbus RTU inter-

faces print

For SICON (M)

1

121121

Profinet IO inter-

faces print

For SICON (M)

1

119796

HART module

For SICON (M)

1

119130

4-way current

output

For SICON (M)

Instrument overview Instruction Manual VisGuard 2

14162E/2 19

PCS.

ART. NO.

NAME

VIEW

VARIANT

1

119795

4-way current in-

put

For SICON (M)

1

119045

24 VDC mains de-

vice

20 W, IP66, input

100 to 240 VAC

2.6 Technical data for the VisGuard 2

General:

Data

Values

Measuring principle

Scattered light measurement

Measurement span

0 .. 1000 PLA or 0 .. 3000 mE/m

Wavelength

880 nm

Resolution

± 0.001 mE/m

Reproducibility

± 0.06 mE/m, or ± 1%

Reaction time

2 s

Measuring angle

30 °

Sample pressure

Max. ± 3000 Pa (± 30 mbar)

Ambient temperature

-30 .. 55 °C

Ambient humidity

0 .. 100 % rel. humidity

VisGuard 2 photometer:

Data

Values

Service voltage

24 VDC

Power consumption

7 W + optional heater 10 W

Weight

6.5 kg (In-situ), 5.0 kg (Extractive)

Protection class

IP66 (with splash guard only)

Photometer material

Stainless steel 1.4435 / 1.4571

Cable standard

High-temperature cable:

Length: as needed

Type: 4 x 2 x 0.80 mm2

FE180, E30-E90

Dimensions

ca. Ø 209 mm x 366 mm

Detailed dimension sheet according to Section 16

Instruction Manual VisGuard 2 Instrument overview

20 14162E/2

SICON-C portable control unit:

Data

Values

Service voltage

24 VDC

Power consumption

1.3 W

Display

¼ VGA with touchscreen

Resolution: 320 x 240 pixels with 3.5" diagonal

Protection class

IP66

Weight

0.6 kg

Dimensions

160 x 152 x 60 mm

Detailed dimension sheet according to Section 16

Housing material

ABS

SIPORT 2 connection box:

Data

Values

Service voltage

100 .. 240 VAC; 47 .. 63 Hz

Power consumption

25 W (maximum)

VisGuard 2 In-situ, with sample heater: 24 W / 45 VA

VisGuard 2 In-situ, without sample heater: 12 W / 27 VA

Interfaces

Profibus DP, Modbus RTU with repeater, StromRel module;

optional: Current/Digi. Input, Profinet IO

Maximum operating

altitude

2,000 m above sea level

Protection class

IP66

Weight

1.3 kg

Dimensions

220 x 155 x 91 mm

Detailed dimension sheet according to Section 16

Housing material

Glass-fiber reinforced polyester

Table of contents