SILTRONIX LA-600 Instruction and safety manual

SILTRONIX

MODEL LA-600 RF Amplifier

OPERATING/SERVICE MANUAL

SILTRONIX

330 VIA EL CENTRO

OCEANSIDE, CALIFORNIA 92054

Original manual print date unknown

Copyright 2007 Donald W. Thomas, K5ZRQ

Artwork and Diagrams by Bennie Bolin

Copyright Donald W Thomas, K5ZRQ

2

1.0 INTRODUCTION:

In putting together this manual, I used what limited information I could compile. The new updated

schematic, drawings and PCB layout were drawn by B. Bolin and were verified against a LA-600.

The Siltronix Model LA-600 is designed for operation in the 26 to 30 megacycle range. Due to the

high efficiency of the “Single Band” design, it is an excellent amplifier for the Ten Meter Amateur Radio

Operator, or for other services outside the United States.

Figure 1-1 Front Panel

The LA-600 features a High/Low RF transmit output selection and a pre-amplifier which provides

approximately 6 db gain on received signals. The LA-600 is designed with the best of components

available to provide years of trouble free service. It is important, however, the Operating Instructions

should be followed. The RF drive requirements to the amplifier should not be exceeded. Once the

unit has been installed and tuned for proper operation, retuning of the amplifier should not be required.

Even though the rugged 8950’s should provide years of trouble free operation, the most severe

conditions for the tubes exist during the tune-up procedure where the possibility of Off-Resonance

condition allows relatively large amounts of current to be drawn through the tubes. Unnecessary tune-

ups will reduce the life of the 8950’s. Once the unit is properly tuned for operation, major

readjustments should rarely be necessary. Occasional minor touch-up of the “PLATE” tuning to verify

peak performance is recommended. Both “PLATE” and “LOAD” controls may require small

adjustment when changing antennas or switching to and from a dummy load.

Figure 1-2Rear Panel

Copyright Donald W Thomas, K5ZRQ

3

1.1 SPECIFICATIONS:

Power Ratings:

SSB 800 Watts Nominal PEP Output on High Power

AM 500 Watts Nominal Output on High Power

AM 300 Watts Nominal Output on Low Power

Frequency Coverage:

26.0 to 30.0 MC

Tube Complement:

Four 8950’s in grounded grid and one 8950 Driver in grounded cathode.

RF Drive Requirements:

AM Operation -Nominal 3 Watts

Single Sideband -Nominal 7 Watts PEP

Meter:

Reads relative output RF voltage.

Relay Keying:

In SSB position, automatically switches the amplifier into the “Transmit” mode when SSB

modulation is present. Returnsto receive mode after a short delay when no modulation

is present.

In AM position, the AM carrier of the transmitter keeps the amplifier in the

“Transmit” mode as long as the transmitter is keyed.

“PI” Output Circuit:

Matches 52 to 75 ohm load and other impedances where the SWR does not exceed 2.5:1

Pre-Amplifier:

Provides approximately 6 db gain for received signals.

Power Supply:

Computer grade electrolytic capacitors and conservatively rated silicon rectifiers together with a

heavy duty power transformer provide a reliable power source.

AC Input: 117 Volts, 50-60 Hz

Front Panel Controls:

PLATE, LOAD, RELATIVEOUTPUT Meter, Power On Indicator, AC POWER Switch, MODE

Switch, RF POWER Switch, DELAY Switch, PRE-AMP Switch

Rear Panel:

L10 Access Hole, INPUT Jack, OUTPUT Jack, Fuse Holder, GRID TUNING Coil, GROUND Lug

Dimensions:

13” Wide x 5-3/4” High x 10-3/4” Deep

Weight:

27 Pounds

Copyright Donald W Thomas, K5ZRQ

4

2.0 INSTALLATION:

CAUTION: Lethal voltages are present in this amplifier! DO NOT REMOVE the bottom cover or

cabinet while the AC power cord is connected to the wall outlet.

Before removing the covers for any reason, allow at least one minute for the filter capacitors to

discharge after turning amplifier off and disconnecting the AC line cord. Then short the driver and final

plate circuit to ground with an insulated screwdriver before touching any of the components.

1. Select a location for your amplifier. RF amplifiers need ventilation, so choose a location that will

not restrict the air flow around the amp. While turned on, the unit will generate a lot of heat so do

not lay anything on top of the amplifier.

2. Do not exceed the nominal input RF drive requirements listed under “Specifications” by more than

15 percent. Check RF output specifications of the exciter (or, measure the power output with a

wattmeter).

3. Connect a short length of coaxial cable (RG-58 or RG-8) from the exciter (transceiver or

transmitter) to the “INPUT” jack on the rear of the LA-600. A PL-259 connector is required to

connect the coax cable to the amplifier. Coax cable should be as short as possible.

4. Connect antenna or suitable high power dummy load to the “OUTPUT” connector on the rear of

the LA-600 using RG8/U coax or similar type coax with a PL-259 connector.

5. The unit should be grounded for R.F. by attaching a ground strap of coaxial shield or 10-12 gauge

wire to the ground post on the amplifier. This should be connected by a short run to a ground rod

or cold water pipe. The idea is to have a short direct earth ground to keep the chassis at radio

frequency ground. In many cases normal operation can be had without such a ground, but a

good ground can help prevent television interference, and make tuning straightforward.

6. The A.C. line cord should be plugged into a three-wire outlet. The electrical circuit should be

capable of handling a 15 ampere load.

Copyright Donald W Thomas, K5ZRQ

5

3.0 CONTROLS:

3.1 Front Panel

Figure 2-1 Front Controls

1.POWER: Switches AC power “On” and “Off”

2.MODE: STDBY Position: Exciter operated directly into the antenna on transmit.

OP Position: Transmitting amplifier will be switched in when the exciter is

in AM and keyed or when the exciter is keyed in SSB with

modulation applied.

3.POWER: LOW Position: Provides 300 Watts AM RF Output for the nominal 3 watts input.

HIGH Position: Provides 500 Watts AM RF Output for the nominal 3 watts input.

4.DELAY: SSB Position: Allows the relay to remain in “Transmit” mode during short

pauses while transmitting.

AM Position: Continuously keeps the LA-600 in the transmit mode so long

as the exciter is in transmit.

5.PRE-AMP: OFF Position: Exciter receives signal directly from antenna.

ON Position: Exciter receives signal from PRE-AMP which provides

approximately 6 db gain. The PRE-AMP switch operates

independently of the mode switch. The PRE-AMP is

disabled during transmit.

6.RELATIVE POWER METER: Reads relative output RF power.

7. PILOT LIGHT: Red lamp indicator shows when amplifier is powered on.

8.LOAD: Used to properly match the amplifier plate circuit to the antenna.

9.PLATE: Used to tune the PA output to resonance.

Copyright Donald W Thomas, K5ZRQ

6

3.2 Rear Panel

Figure 2-2Rear Controls and Connections

1 AC Line Cord

2 FUSE Holder: Accepts Type 3AG 15 Amp fuse.

3 GRID TUNING: Tunes input grid circuit of the 8950 Driver tube.

4 GROUND: GroundLug for attaching ground wire from the chassis of the unit to earth ground.

5. C30: Tunes output plate circuit of the 8950 Driver tube.

6 OUTPUT: Connects RF output of the amplifier to the antenna coax feed line.

7L10 Access Hole: L10 is for tuning RF input to the Preamp circuit.

8INPUT: Connects RF Drive from exciter to input of amplifier.

4.0 OPERATION:

1. Setting the “MODE” switch to the “STDBY” position (or the main “POWER” switch to “Off”) permits

the exciter (transceiver) to operate directly into the antenna. This also allows any adjustment to be

made to the exciter before operating the LA-600. Use this setting for checking drive power.

2. Initial tune-up should be accomplished with the exciter (transceiver) set at the middle range of the

frequencies to be operated. This allows operation over the entire range without re-tuning the

amplifier.

3. The tune-up procedure should initially be accomplished by applying the exciter driving power for

short periods of time, not longer than 30 seconds. Release the push-to-talk button on the

microphone for about 30 seconds between each adjustment. During the final fine adjustments of

the tuning controls the drive may be held on for longer periods, provided only minor adjustments

are made. This method of tune-up will prevent the tubes from overheating during adjustments.

Once the tune-up procedure has been completed, the cooling fan, plus the high quality

components, will provide normal operation indefinitely with only an occasional minor tune-up.

Copyright Donald W Thomas, K5ZRQ

7

4.1 INITIAL TUNE-UP:

Read all of these tune-up instructions before turning the power on or attempting tune-up. It is very

important that the amplifier be properly tuned if it is to provide long life and good performance. Never

operate the amplifier if it is not properly tuned.

1. Set “DELAY” switch to the “AM” position.

2. Set “POWER” switch to the “LOW” position.

3. Set “PLATE” control to “5”.

4. Set “LOAD” control to “5”.

5. Place AC “POWER” switch in the “ON” position. The red pilot light should be on. Always allow at

least one minute warm-up before proceeding with tune-up or operation.

6. Key exciter (transceiver) in transmit mode (AM). If single sideband is the only mode available,

tune-up of the LA-600 can be accomplished by a sustained whistle into the microphone while

holding the push-to-talk button down. In the AM mode, it is only necessary to press the

push-to-talk button on the microphone (do not talk into the microphone in this mode). Either

method will provide the RF drive required for tuning the LA-600.

7. Quickly adjust “PLATE” control for maximum meter reading. There should be a definite maximum

meter reading and as the “PLATE” control is moved in either direction the reading should decrease.

8. Quickly adjust the “LOAD” control for maximum meter reading.

9. Steps #7 and #8 should be repeated several times until no greater reading can be obtained. Do

this as rapidly as possible.

10. Now switch RF “POWER” switch to “HIGH” and repeat Steps #7 and #8 several times until a

maximum reading is again obtained.

11. The “POWER” switch can now be used to select “LOW” or “HIGH” power output.

4.2 OPERATION AFTER TUNE-UP:

AM Operation: “DELAY” switch should be in the AM position. When the exciter (transceiver) is keyed

into the transmit mode, the LA-600 will automatically go into transmit. During AM

modulation a slight downward deflection may be noted on the meter. This is a normal

state and will not affect the audio quality of the transmitted signal.

SSB Operation: “DELAY” switch should be in the SSB position. If there is a long pause between

words during a transmission, the antenna switching relay in the LA-600 will return to

the receive position. Talking into the microphone will automatically return the

antenna switching relay to the transmit position. This relay action is normal.

Copyright Donald W Thomas, K5ZRQ

8

5.0 CIRCUIT DESCRIPTION:

The LA-600 is a classic TV Sweep Tube Amplifier using five 8950 tubes. One of the tubes is a grid

driven driver stage and the other four are the PA tubes in grounded grid final operation. It has a low

and high power output setting and features a pre-amplifier which provides approximately 6 db gain on

received signals.

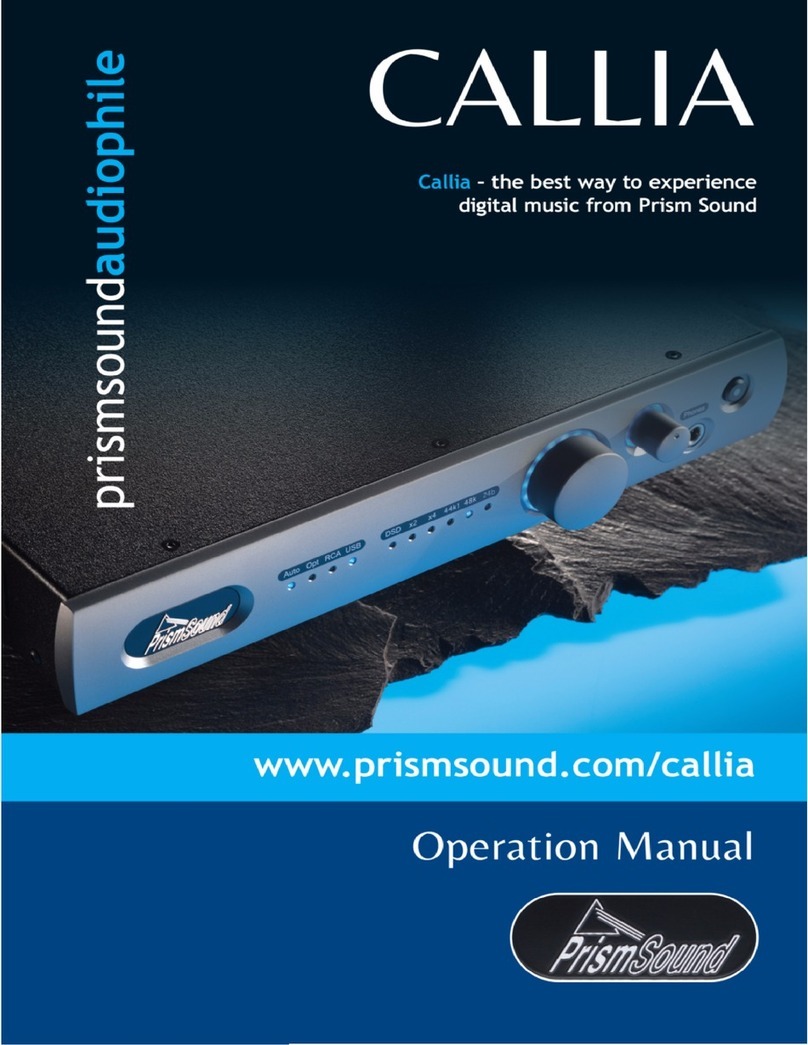

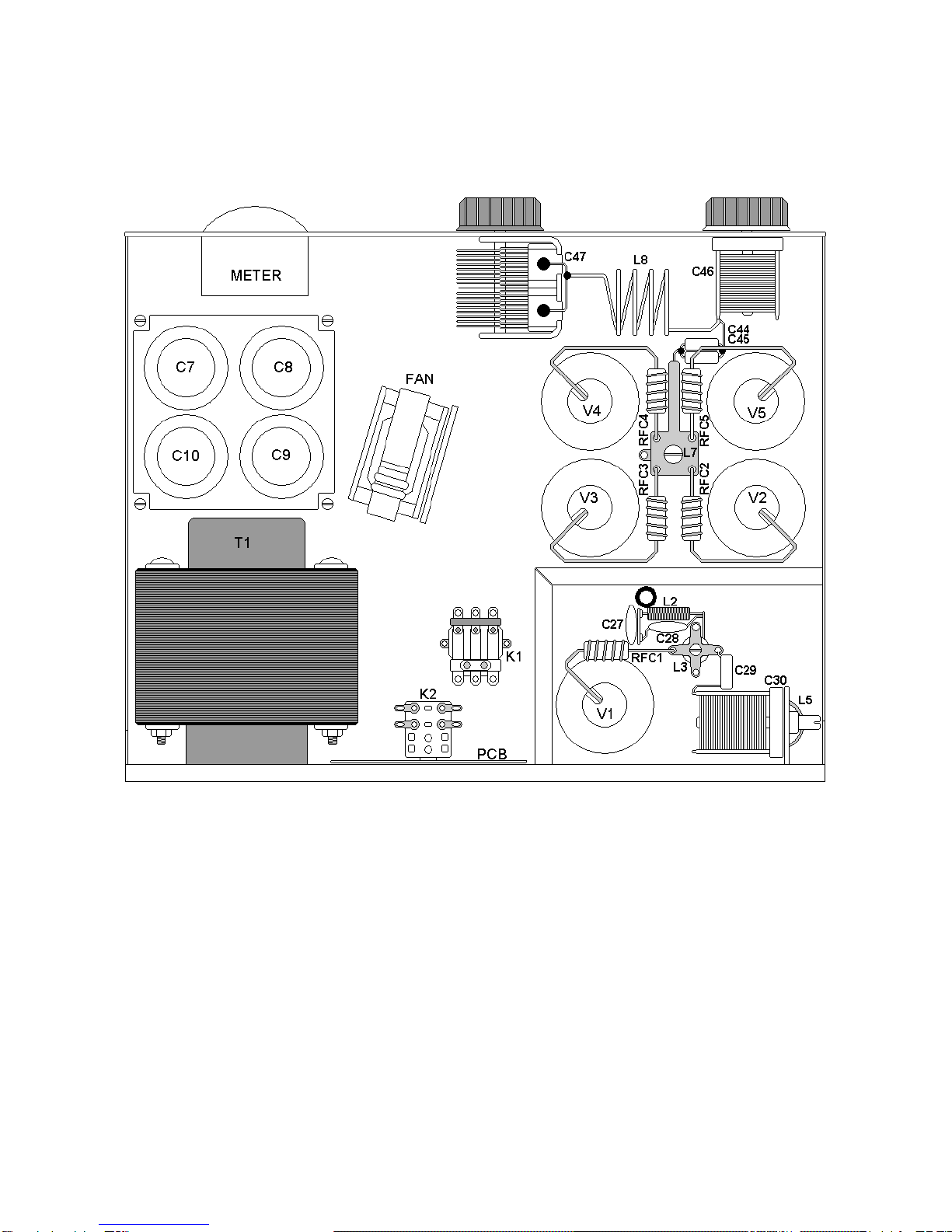

Figure 5-1 Chassis Layout

In the figure above, you can see the Driver Section in the lower right corner. The variable capacitor

C30 to the right of the Driver tube is for tuning the Driver output and is accessed thru a small hole in

the side of the top cover. The four PA Tubes are just above the driver section. You can see the Plate

Cap connections with their Plate Parasitic Suppressors. Above them you will find the Plate Load and

Plate Tune capacitors used for tuning the finals for proper operation. In the bottom center, K1 is the

main relay for switching the PA in and out of line. K2 is mounted on the PCB and it functions to switch

the Preamp in and out of line as the PA is keyed. To the left is the main Power Transformer. Above it

are the four capacitors that make up the high voltage power supply filter. The Fan in the center of the

chassis runs continuously as long as the Amplifier is turned on providing air circulation for the tubes.

Copyright Donald W Thomas, K5ZRQ

9

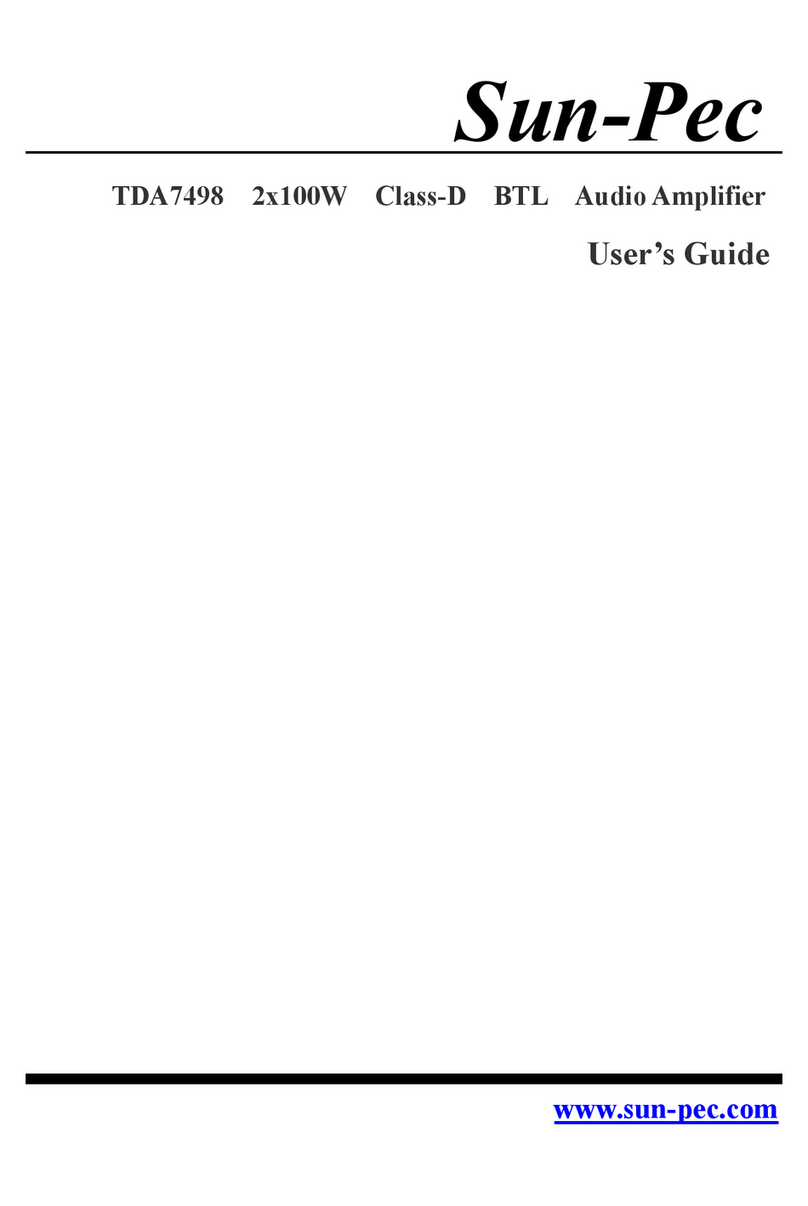

6.0 PCB LAYOUT:

The PCB is mounted on the back wall of the amplifier. Itcontains the Receive Preamplifier Q1,

Transmit detector Q2, Power Amp relay driver Q3, Preamp relay driver Q4, and Relay K2 for switching

the preamp in and out of the circuit. There are 12 points shown in the drawing by a number inside a

circle. These points are connections from the PCB to various points in the LA-600 as indicated by the

labeling.

Figure 6-1 PCB

The wire connections to the PCB are as listed below:

1. Wire from PCB to relay K2 NO contact.

2. Connects to RF Input Jack.

3. Connects to Delay switch SSB contact.

4. Connects one end of R42, the other end of R42 is connected to the RF Output Jack.

5. Connects to the front panel meter.

6. Connects to Preamp switch.

7. Connects to Preamp switch.

8. Connects to the common contact of the Mode switch.

9. Connects to the +16V line.

10. Wire from PCB to relay K2 NC contact.

11. Connects to Relay K1A NC contact.

12. Connects to Preamp switch.

13. Hole on PCB ground trace that is unused.

Copyright Donald W Thomas, K5ZRQ

10

7.0 ALIGNMENT:

ALIGNMENT –LA-550, LA-600, LA-650

This alignment procedure applies to the LA-550, LA-600, and LA-650 amplifiers.

1. Driver Neutralization

A. Connect RF Voltmeter to the cathodes of the four PA tubes. If a RF Voltmeter is not

available, an Oscilloscope with a bandwidth over 30 Mhz can be used with a 10X Probe.

B. With linear amplifier off, key your transmitter, depress relay K-1 with an insulated tool, and

adjust the neutralization trimmer (it is under the driver tube) for a dip or minimum

reading on the RF Voltmeter or Oscilloscope. The amplifier is now neutralized.

2. Bias (Driver)

A. Connect a DC Voltmeter to Pin 2 of the driver tube (the cathode).

B. Turn linear amplifier on, set to high power position.

C. Adjust bias pot (one closest to power supply) for a .5 VDC reading on Pin 2.

3. Bias (Power Amp)

A. Connect DC Voltmeter across the one ohm, 10 watt resistor in the cathode of the power amp.

B. Turn linear amplifier on, set to high power position.

C. Depress relay using insulated tool. Adjust power amplifier bias pot for a .05 reading on your

voltmeter.

4. Tune Up:

A. Adjust Driver Grid Tuning and Plate tune output capacitor for maximum power out.

B. Adjust power amplifier front panel Plate and Load for maximum power out.

Copyright Donald W Thomas, K5ZRQ

11

8.0 PARTS LIST:

Capacitors

Ref# Description NOTES:

C1 .01uF Ceramic Disc AC Input bypass

C2 .01uF Ceramic Disc AC Input bypass

C3 .0022uF Ceramic Disc HV Section

C4 .0022uF Ceramic Disc HV Section

C5 .0022uF Ceramic Disc HV Section

C6 .0022uF Ceramic Disc HV Section

C7 225uF 300VDC Electrolytic HV Section, CG2250T300B1

C8 225uF 300VDC Electrolytic HV Section, CG2250T300B1

C9 225uF 300VDC Electrolytic HV Section, CG2250T300B1

C10 225uF 300VDC Electrolytic HV Section, CG2250T300B1

C11 100uF 150VDC Electrolytic Bias Power Supply

C12 100uF 150VDC Electrolytic Bias Power Supply

C13 250uF 20VDC Electrolytic LV Power Supply

C14 .002uF Ceramic Disc PA Section V2 socket

C15 .002uF Ceramic Disc PA Section V3 socket

C16 .002uF Ceramic Disc PA Section V4 socket

C17 .002uF Ceramic Disc PA Section V5 socket

C18 .002uF Ceramic Disc Driver Section

C19 1.5 –20 pF Compression Trimmer Driver Section, Marked 404

C20 50pF Mylar Driver Section

C21 100uF 250VDC Electrolytic HV Section, Bottom chassis term strip

C22 .002uF Ceramic Disc Driver socket pin 11

C23 .002uF Ceramic Disc Driver socket pin 3

C24 .002uF Ceramic Disc Driver socket pin 2

C25 3.3pF 3KV Ceramic Disc Driver Section

C26 3.3pF 3KV Ceramic Disc Driver Section

C27 .002uF 2KV Ceramic Disc Driver Section

C28 .002uF 2KV Ceramic Disc Driver Section

C29 270pF 2.5KV Mica, CM35FK271JN3 Driver Section

C30 46pF, Air Variable Driver Section, Marked 074-063

C31 120pF, Compression Trimmer PA Section, Marked 302M

C32 .002uF Ceramic Disc PA Section

C33 .002uF Ceramic Disc PA Section

C34 .002uF Ceramic Disc PA Section V2 socket

C35 .002uF Ceramic Disc PA Section V2 socket

C36 .002uF Ceramic Disc PA Section V3 socket

C37 .002uF Ceramic Disc PA Section V3 socket

C38 .002uF Ceramic Disc PA Section V4 socket

C39 .002uF Ceramic Disc PA Section V4 socket

C40 .002uF Ceramic Disc PA Section V5 socket

C41 .002uF Ceramic Disc PA Section V5 socket

C42 .002uF 2KV Ceramic Disc PA Section

C43 .002uF 2KV Ceramic Disc PA Section

C44 270pF 2.5KV Mica, CM35FK271JN3 PA Section

C45 270pF 2.5KV Mica, CM35FK271JN3 PA Section

Copyright Donald W Thomas, K5ZRQ

12

Capacitors

Ref# Description NOTES:

C46 105pF, Air Variable, PA TUNE PA Section

C47 710pF, Air Variable, PA LOAD PA Section, Marked 074-062ASP7341

C48 39 pF Ceramic Disc On PCB

C49 33 pF Ceramic Disc On PCB

C50 .01uF Ceramic Disc On PCB

C51 10 pF Ceramic Disc On PCB

C52 .01uF Ceramic Disc On PCB

C53 .002uF Ceramic Disc On PCB

C54 30 MFD 15V Electrolytic On PCB

C55 .002uF Ceramic Disc On PCB

C56 30 MFD 15V Electrolytic On PCB, SSB delay cap

C57 .002uF Ceramic Disc On PCB

C58 .002uF Ceramic Disc On PCB

C59 .002uF Ceramic Disc On PCB

Resistors

Ref# Description NOTES:

R1 470K 1W HV Section

R2 470K 1W HV Section

R3 470K 1W HV Section

R4470K 1W HV Section

R5 39K 6W, DALE FP33 6W HV Section

R6 39K 6W, DALE FP33 6W HV Section

R7 39K 6W, DALE FP33 6W HV Section

R8 39K 6W, DALE FP33 6W HV Section

R9 1K 1W Bias Power Supply

R10 4.7K 1W VR1 and term strip

R11 4.7K 1W Across VR1

R12 6.8K 1W Tied to VR1

R13 10K 1/2W Driver Section, Bottom chassis term strip

R14 12K 10W HV Section, Bottom chassis term strip

R15 10K 10W HV Section, Bottom chassis term strip

R16 100 5W Driver Section, Bottom chassis term strip

R17 27K 1W On bottom chassis terminal strip

R18 4.7K 1W By VR2

R19 4.7K 1W By VR2

R20 47K 1W PA Grid resistor V5

R21 47K 1W PA Grid resistor V4

R22 47K 1W PA Grid resistor V3

R23 47K 1W PA Grid resistor V2

R24 100 5W Mounted behind Preamp Switch

R25 1 10W Mounted behind Preamp Switch

R26 75 20W Mounted behind Mode and Power Switch

R27 47K 1/2W Mounted by K1

R28 12K 2W Driver Section

Copyright Donald W Thomas, K5ZRQ

13

Resistors

Ref# Description NOTES:

R29 2.2K 2W Driver Section

R30 68K 1/2W On PCB

R31 1K 1/2W On PCB

R32 10K 1/2W On PCB

R33 220 1/2W On PCB

R34 470 1/4W On PCB

R35 22K 1/4W On PCB

R36 220 1/2W On PCB

R37 6.8K 1/4W On PCB

R38 3.3K 1/2W On PCB

R39 22K 1/4W On PCB

R40 1K 1/4W On PCB

R41 15K 1/4W On PCB

R42 10K 2W One end connected to PCB

R43 150 1/2W On Terminal Strip

Potentiometers

Ref# Description NOTES:

VR1 5K Bottom Chassis

VR2 25K Bottom Chassis

VR3 10K On PCB

Diodes

Ref# Description NOTES:

D1 1N4822 HV Section

D2 1N4822 HV Section

D3 1N4822 HV Section

D4 1N4822 HV Section

D5 1N4005 Bias Power Supply, On Terminal Strip

D6 1N4005 LV Power Supply, On Terminal Strip

D7 1N914 On PCB, Keying detector

D8 1N4005 Across K1

D9 1N914 On PCB

D10 1N4005 On PCB Across K2

D11 1N34A On PCB, Meter detector

Transistors

Ref# Description NOTES:

Q1 2N5814 On PCB, Preamp

Q2 2N5814 On PCB, Keying control

Q3 2N5814 On PCB, Relay driver

Q4 2N5814 On PCB, Relay driver

Copyright Donald W Thomas, K5ZRQ

14

Tubes

Ref# Description NOTES:

V1 8950 Driver Section

V2 8950 PA Section

V3 8950 PA Section

V4 8950 PA Section

V5 8950 PA Section

Switches, Fuses, Relays, Lamp, Misc

Ref# Description NOTES:

F1 15 Amp

S1 SPST AC POWER Switch

S2 SPDT MODE Switch

S3 DPST RF POWER Switch

S4 SPDT DELAY Switch

S5 DPST PREAMP Switch

K1 3PDT

K2 DPDT Potter Brumfield, 12V, KT11D

K3 DPDT AZ531-09-1

LAMP # 1815 14V 200Ma, 2.8 Watts, T3.25

SCREW Top Cover, 8-32 x 1/4” Binder Head 6 each

SCREW Bottom Cover, 6 each

Inductors, RFC, Transformer

Ref# Description NOTES:

L1 4 uH Filament Choke

L2 17 uH Driver Plate HV Choke

L3 55 uH Driver Plate HV Choke

L4 55 uH PA Cathode Choke

L5 Wire Coil Driver Section, Pi Network

L6 17 uH PA Plate HV Choke

L7 55 uH PA Plate HV Choke

L8 Wire Coil PA Section, Pi Network

L9 30 uH PA Section, Mounted under C49

L10 Preamp Tuning Coil On PCB, Tunes Preamp Input

L11 GRID TUNING Coil Access on back of chassis

RFC 1 47 2W with 4 Turns Metal Strip Driver Section

RFC 2 100 2W with 5 Turns 14ga Wire PA Section

RFC 3 100 2W with 5 Turns 14ga Wire PA Section

RFC 4 100 2W with 5 Turns 14ga Wire PA Section

RFC 5 100 2W with 5 Turns 14ga Wire PA Section

T1 Power Transformer 271-025

Copyright Donald W Thomas, K5ZRQ

15

9.0 POWER TRANSFORMER:

USING TRANSFORMER 271-025 (10 LEADS) WITH LA-550, LA-600, and LA-650

The original power transformer used in the LA-550, 600 and 650 series linear amplifiers was the 9

or 8 lead version of the 271-025. If the linear uses 6LF6 tubes it has the 9 lead version, because of

the requirement to provide 6 volts to the filament of the driver tube. If the linear uses 8950 tubes the 8

lead version may have been used as there is no requirement for a 6 volt center tap. The 8950 has a

12 volt filament.

Because the 10 lead version of 271-025 has no 6 volt filament tap it cannot be used to replace the

transformer in a linear with 6LF6 unless a simple modification is performed. This consist of replacing

the driver tube with an 8950 and re-wiring the filament pin (pin #1) to the 12 VAC filament source. The

other socket pin connections remain the same. The driver stage must be re-aligned and re-

neutralized because the internal capacitances of the two different tube types are not the same.

Also when using the 10 lead transformer,the two primary windings must be wired in parallel. For

the 110V AC source the 2 windings are (1) orange and brown and (2) yellow and green. To wire them

in the proper phase the orange and yellow leads are both connected to the unswitched line cord lead

at the term strip (this is the line cord lead that is not connected to the fuse holder). The green and

brown leads are both connected to the adjacent terminal. This terminal has a wire leading to the

power switch.

10.0 REPAIR TIP:

SWITCH REPAIR TIP

If you have a switch like this and it is being intermittent or not working at all, it probably just needs

cleaning. This is a DPST switch and if you cannot find a suitable replacement, this is how to

disassemble and clean the old one. When removing switch, make sure you remember to identify

which wire connects to which terminal. Word of caution, the AC POWER and the PREAMP switch are

used to secure the front panel to the chassis.

Figure 10-1

Copyright Donald W Thomas, K5ZRQ

16

Disassembly: Carefully drill off the braded end of the two rivets holding the switch together using a

small drill bit. Then push the rivets out of the switch while holding the switch front and back. Once the

rivets are removed, the internal spring will be pushing the switch apart. Lift the top cover off while

watching where all the pieces are located. The picture above shows a switch before repairing and one

disassembled showing all the parts and the two bolts to put it back together with. Remove the three

piece part (cap, spring, and guide) and lay to the side. Remove the brass roller that looks like a mini

dumbbell and clean it to remove any oxidation. Next using a Q-tip and alcohol, clean the contacts

inside the switch housing. It’s possible the bottom contacts have worn down some over time. If so,

the raised track running down the middle of the housing may now be holding the brass roller up

preventing it from making firm connection with the bottom contacts. Using a small knife point, carefully

scrape both sides of the track a small amount by the contacts. You can also scrape down the top a

very small amount. Do not remove much material, just scrape a little off. The track also acts as a wall

between the contacts. This should allow the roller better contact if the track was holding it up.

Reassembly:Put brass roller back into the housing and push it to the end with the side contacts. Put

the three piece part back in with the grooved guide end riding on the middle of the brass roller. Place

the two insulators back on the sides of the housing. Move toggle on top cover to the side labeled “ON”.

While holding the housing and insulators together, slide the top cover down over the housing. The

bottom of the toggle lever fits into the top plastic cup of the three piece part as it goes together. If you

have it backwards, the “ON” position will be “OFF”. Just turn the top around if needed to put it right.

Two small nails that will fit thru the holes will hold it together while finishing up. You can check the

“ON and “OFF” with an ohmmeter at this point easily. The two bolts and nuts needed to replace the

rivets are size 2-56. The bolt is 2-56 x 3/4in. The bolts will fit the holes in the top cover, but will have

to be threaded thru the housing. Remove one of the nails and insert a bolt. Screw it in all the way

down and watch the housing bottom as you tighten it. You only want to tighten enough to barely

compress the housing. Place a nut on the end and tighten only enough to barely compress the

housing from that side. If tightened too much, you may distort the housing where the brass roller may

bind and not move freely. Now put in the other bolt and nut. Tighten the same way. You only need

them snug to hold the switch together properly. Verify the switch is working properly. You can use a

drop of nail polish to secure the nuts if needed.

Copyright Donald W Thomas, K5ZRQ

17

Of course, no manual would be complete without the manufacturer’s equipment warranty.

WARRANTY POLICY

SILTRONIX CORPORATION warrants, to the original purchaser, this equipment to be free of defects

in material or workmanship, except for tubes, transistors and diodes, under normal service for a period

of six months from the date of original purchase. Tubes, transistors and diodes are covered under the

warranty policy for a period of 90 days. This warranty is valid only if the enclosed card is properly

filled out and mailed to the factory within ten days of purchase.

Do not ship equipment to the factory without prior authorization. This warranty is limited to repairing or

replacing only the defective parts, and is not valid if the equipment has been tampered with, misused,

or damaged. All returns for repairs must be freight prepaid. This equipment is manufactured for use

on such frequencies as authorized by the FCC. Siltronix does not accept any responsibility for

un-authorized use of such equipment.

Table of contents