Silvert TW 5000 User manual

GB

D

S

F

NL

OPERATORS MANUAL ................................ 2-13

BRUKSANVISNING ..................................... 14-25

MODE D´EMPLOI ........................................ 26-37

GEBRUIKSAANWIJZING ............................ 38-49

BEDIENUNGSANLEITUNG ........................ 50-61

HOT-AIR AUTOMATIC WELDING MACHINE

299001 400 V ~ / 299047 220-230 V ~

CAUTION

The voltage rating stated on the hot-air welding

machine should correspond to the mains voltage.

For personal protection, we strongly recommend

the TW 5000 hot-air welding machine be

connected to an RCCB (Residual Current

Circuit Breaker) before using it on any type of

application.

The TW 5000 hot-air welding machine must be

operated under strict supervision.

The heat can ignite ammable materials which

are not in view.

Protect the TW 5000 hot-air welding machine from

any and all standing water, rain and dampness.

WARNING

DANGER! Always unplug any electronic tool

before opening it as live components and

connections are exposed.

Improper use of the TW 5000 hot-air welding

machine could cause re and/or an explosion

hazard.

Never operate electronic equipment near com-

bustible materials and/or explosive gases.

Touching the element housing and/or nozzle

during or after operation could cause burns.

CAUTION! Element housing and/or nozzle have

hot surfaces.

Allow the hot-air welding machine to cool down.

Do not point the hot-air ow at people or animals.

SAFETY

TABLE OF CONTENTS

PLEASE READ OPERATORS MANUAL CAREFULLY BEFORE USE AND

KEEP FOR FURTHER REFERENCE.

- 2 -

SAFETY................................................... 2

PRODUCT DESCRIPTION.................. 3-4

ASSEMBLY............................................. 5

OPERATION........................................ 6-8

MAINTENANCE................................... 8-9

TROUBLESHOOTING GUIDE................ 10

SERVICE AND REPAIR.......................... 10

ACCESSORIES & SPARE PARTS......... 11

TW 5000 OVERVIEW......................... 12-13

WARNING! To reduce the risk of electric shock, do not expose this product to

rain or moisture. Store indoors. Read operators manual before using.

When servicing use only Sievert identical replacement parts.

! !

▪

▪

▪

▪

▪

▪

▪

▪

▪

▪

▪

▪

GB

- 3 -

PRODUCT DESCRIPTION

▪

▪

▪

▪

▪

▪

▪

▪

Adjustable handle made of sturdy steel.

Separate free rolling wheels for easy transport.

Adjustable front wheels to avoid sliding when

welding at different angles.

Belt and wheels made of silicon rubber.

Four wheel drive system.

Specially designed nozzle and heat protection

cover in stainless steel.

Independent suspension pressure roller.

Powerful drive system.

Equipped with two lifting handles.

Removable additional weights.

Built-in temperature sensor.

Digital LED display showing temperature,

speed and operating status.

Display lamps indicate operation status of the

machine.

Fully adjustable speed, temperature and fan.

Automatic start/stop sensor when hot-air tool

is engaged/disengaged in the drive position.

All electronics are made in accordance to

highest industrial standard.

All electronics are sealed with high degree

coating for maximum humidity protection.

FEATURES

▪

▪

▪

▪

▪

▪

▪

▪

▪

GB

PRODUCT DESCRIPTION

Sievert TW 5000 is an electrical hot-air automatic

overlap welding machine, specially designed for

handling all types of single-ply roong membranes

such as thermoplastic, rubber and modied bitumen

(CSPE, ECB, EPDM, PVC, TPO, SBS, APP).

The machine is equipped with a standard nozzle

for welding seams up to 50mm width. As an option

a separate nozzle is available for handling wider

welding seams. The high power fan and heating

element ensure high quality welding at maximum

speed.

The Sievert TW 5000 has a unique four-wheel drive

system, which assures wrinkle free welding for thin

roong membranes. In addition to this, the front

wheels are adjustable to allow easy operation at

different angles. The powerful motor and efcient

drive system allow climbing ability up to 30°.

- 4 -

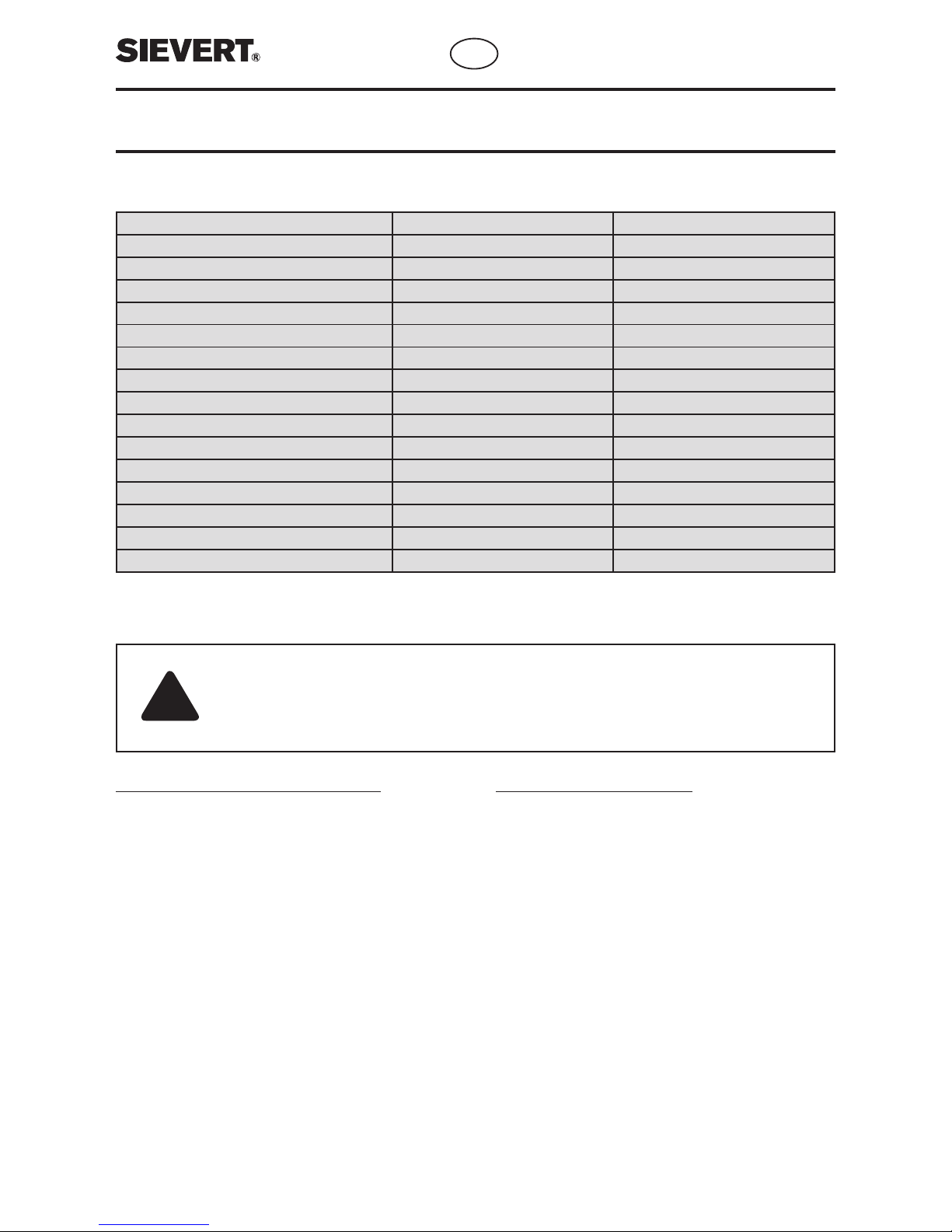

TECHNICAL SPECIFICATIONS

PRODUCT DESCRIPTION

General information for electric supply

The TW 5000 is delivered with power cord: 3 x 2.5 mm²,

earth (ground) is green/yellow; the two other wires are

neutral and phase 1 at single phase connection and

phase 1 and phase 2 at two phase connection.

▪ Use direct supply from main electric distributor or

use a generator.

▪ Use cables with 3 wires. Please note that the earth

(ground) wire is green and yellow.

▪ Recommended diameter of wires minimum 2,5 mm²,

maximum cable length 55 metres. If 1,5 mm² wires

are used, maximum cable length 35 metres.

▪ Use only extension cords with sufcient wire

diameter in accordance with information above.

▪ Your country’s specications of electric tools and

installations should be respected.

POWER SUPPLY AND EXTENSION CORDS

Selecting the right generator

To make sure you choose the right generator,

go through these steps:

▪ Identify the items you want to run.

▪ Calculate the total surge watts required for all items.

▪ Select a generator that exceeds your total surge watts.

The multiplying factor between rated and surged

watts for TW 5000 and TH 1650 is approx. 1.2. For

instance if you run one TW 5000 (220 V) and one TH

1650 (120 V) your total surge watts will be 8040 W

((5000+1700)*1.2). Thus in this case we recommend

selecting minimum a 10,000 W generator with 50-

amp service.

Be sure to verify wattage requirements for starting

and running. Start one item at a time beginning with

the largest and ending with the smallest.

CAUTION! To provide continued protection against risk of electric shock, connect to properly

grounded outlets only.

CAUTION! To reduce the risk of electric shock, keep extension cord connection dry and off

the ground.

!

Type no. 299001 299047

Voltage 400 V ~ ± 10% 220 / 230 V ~ ± 10%

Cable Connection 400 V L1-L2 220 V L1-L2 / 230 V N-L1

Power Consumption 6300 W 5000 W

Frequency 50 Hz 60 Hz / 50 Hz

Temperature, fully adjustable 40°C – 650 °C / 100°F - 1200°F 40°C – 650 °C / 100°F - 1200°F

Drive, fully adjustable 0 – 7 m/min / 0 – 20 ft/min 0 – 7 m/min / 0 – 20 ft/min

Air ow, fully adjustable 0 - 48 l/s / 0 – 12.7 gal/s 0 - 48 l/s / 0 – 12.7 gal/s

Emission level 70 dB 70 dB

Nozzle 40 mm / 1.58” 40 mm / 1.58”

Width of welding seam 40 – 50 cm / 1.5” – 2” 40 – 50 cm / 1.5” - 2”

Dimensions 56x38x25 cm / 22”x15”x10” 56x38x25 cm / 22”x15”x10”

Weight (4 kg / 8.8 lb built-in weight) 30 kg / 68 lb 30 kg / 68 lb

Additional weight (included) 8 kg / 17.6 lb 8 kg / 17.6 lb

Additional weight (not included) 4 kg / 8.8 lb (art no 299301) 4 kg / 8.8 lb (art no 299301)

Power cord length 91 cm / 3 ft. 91 cm / 3 ft.

GB

- 5 -

ASSEMBLY

▪ Attach the handle by sliding it into

place over the two receptacles on the

machine.

▪ Adjust the handle to a suitable height

for the operator.

▪ Lock with the two screws provided.

▪ Unassembled parts.

(1) Handle

(2) Screws

▪ Attach the mains cable to the cable

hook on the handle.

▪ Connect the machine to the mains.

3

2

1

5

4

CAUTION! The voltage rating

stated on the hot-air welding

machine should correspond

to the mains voltage.

!

GB

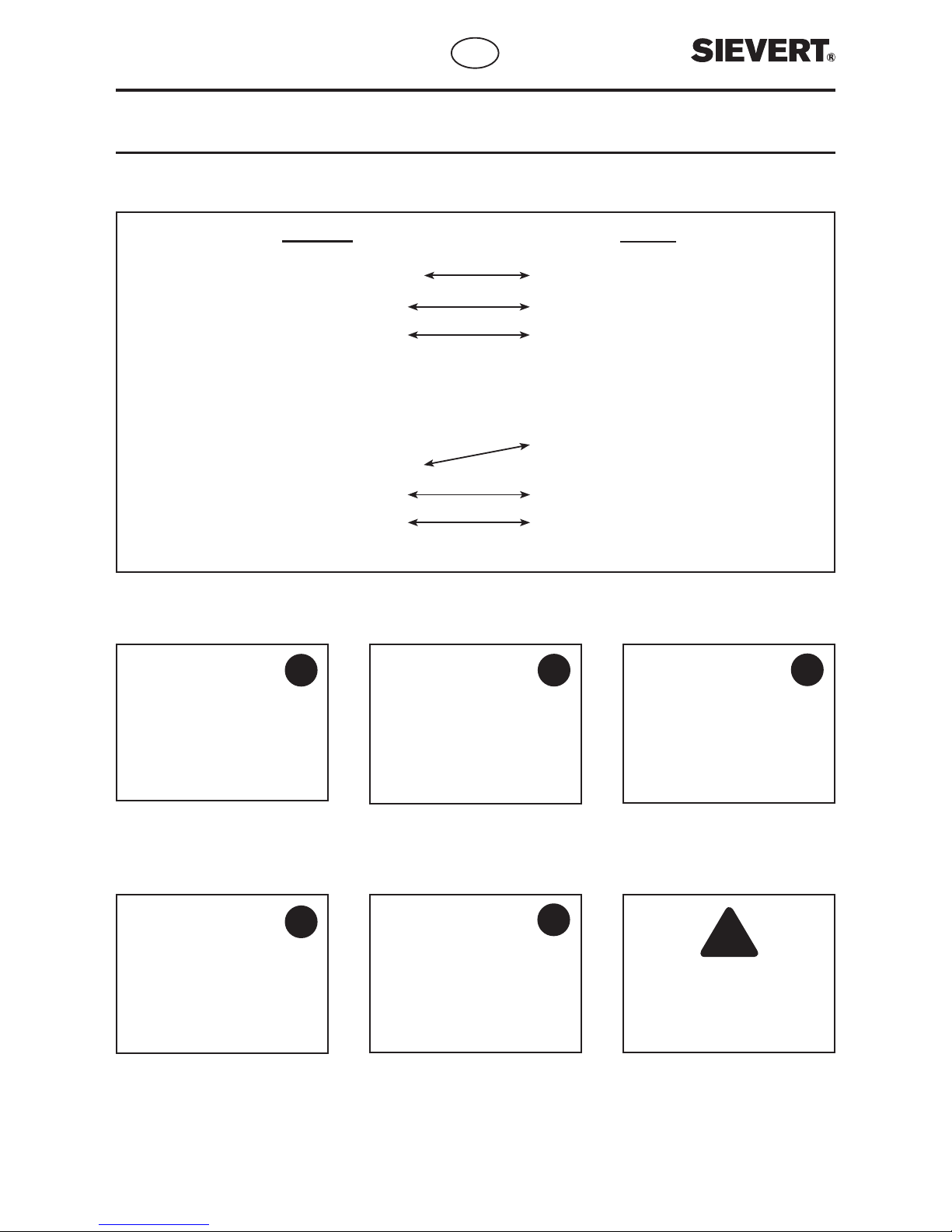

MACHINE ASSEMBLY

CABLE CONNECTIONS

TW 5000 MAINS

Earth*

L1

L2

1-PH

230 V Europe

Earth*

L1

L2

2-PH

400 V Europe

220 V USA

Earth*

Neutral

L2 Phase

Earth*

Neutral**

L2 Phase

L1 Phase

L3 Phase**

FemaleMale

*Green/Yellow

**Not used

- 6 -

DISPLAY UNIT

OPERATION

PUT THE MACHINE IN CORRECT POSITION

▪ The machine is equipped with

separate transportation wheels for

easy transport.

▪ Tip the machine as shown on

picture and easily move it to your

desired location.

▪ Align the machine to its correct

position with the overlap edge of the

membrane.

▪ Turn the power on at the main

switch below the control panel. Wait

until you see text on the display.

▪ Adjust the temperature with the red

knob to desirable temperature.

3

▪ Select between °C/meter and °F/feet

by pushing the button. The machine

will remember last used setting.

2

1

▪ Adjust the fan speed with the blue

knob to desirable speed.

5

▪ Push the fan button to start heating

up the machine. The red wait indicator

will light up.

6

It will take a few minutes for the machine to heat up to its programmed temperature. Wait until the red

indicator light is switched off and the green ready indicator light comes on. Now the machine is ready

to start welding.

7

▪ The adjustable guide wheel and the

welding belt should be in line with the

edge of the overlapped membrane

according to the picture.

123

▪ Adjust the machine speed with the

grey knob to desirable speed.

4

GB

START WELDING

- 7 -

OPERATION

IMPORTANT! Always perform sample welds before welding actual production membrane to

ensure proper setting of temperature, air ow and speed. See test and control of welding seam.

▪ If you are welding at an angle,

adjust the front wheels by turning the

front wheel adjustment knob located

at the base of the frame until you

achieve proper, straight movement of

the machine.

▪ Release the welding nozzle with the trigger, then lower and guide it to the

left underneath the overlapping membrane until it locks. The machine will start

automatically when the nozzle is in its locked position. For instruction on how

to stop the machine, please see section on “Stopping the machine and cooling

down”. If the automatic system is failing, you can start and stop the machine

manually with the run button.

!

The machine is equipped with adjustable front wheels to avoid sliding when welding at different angles.

The front wheels are preset in the factory for welding in a horizontal position.

123

TEST AND CONTROL OF THE WELDING SEAM

Always conduct test welds before you begin any

job. Materials will vary between manufacturers

therefore the machine settings will vary as well.

Always check with the material manufacturer for

the proper specications and machine settings

for their material. It should be noted that ambient

temperature plays a large part in the machine

settings. The warmer it is outside the faster you

can run the machine. If you are welding in cold

climates, you will have to slow the machine and

increase the temperature. Additional weights for

the machine are available to add if needed. Start

your test weld without the weights and add them

accordingly until you achieve an optimum weld.

Set the machine´s temperature, speed, and weight

according to the manufacturer’s specications and

environmental/ambient conditions. Run test welds

and take samples before production welding.

Test the welds to ensure that the tests are within

manufacturer specications. Save the test samples

for proof that you conducted test welds before you

started the job. Test welds should be done again

if the environmental/ambient conditions change

during the day.

By means of visual inspection you can check the

quality of the welds. The material must be welded

all the way to the edge of the overlap. This can be

checked with a probe tool, similar to an awe. Run

the probe along the seam to test the integrity of your

welds. With PVC you will nd a bead of PVC that

has formed along the seam, called bleed through.

This is acceptable and indicates a proper weld, as

long as it is not darkened or shows any burning.

With TPO materials you will not see this bead.

GB

After you have nished welding, press the release

trigger positioned under the nozzle and guide

the nozzle all the way to the right. The drive will

immediately stop when you move the nozzle to the

right. Set the nozzle in a position pointing upwards.

To activate the cooling down sequence simply

push the fan button and wait. Text “Cooling!” will

appear in the display window. The heat is turned off

immediately but the fan will continue to run and will

stop automatically after the temperature has dropped

to a sufcient cool down level.

Wait until the cooling process is nished before you

turn off the power at the main switch.

STOPPING THE MACHINE AND COOLING DOWN

- 8 -

OPERATION

▪ Stop the machine as described and remove the plug from designated power source.

CHANGING THE HEATING ELEMENT

!WARNING! To reduce the risk of re or electric shock, make sure that the TW 5000 hot-air

welding machine is disconnected from the supply circuit before changing the heating element.

WARNING! Touching the element housing and/or nozzle during or after operation could cause

burns.

CAUTION! Element housing and/or nozzle have hot surfaces. Allow the hot-air welding machine

to cool down before you exchange the heating element.

!

CAUTION! Hot surface; avoid

contact. This cooling process is

necessary to avoid damage to

the heating element.

!

1

2

3

MAINTENANCE

GB

- 9 -

MAINTENANCE

▪ Do not clean the TW 5000 hot-air welding machine

with a water spray or similar.

▪ Clean the welding nozzle with a brass wire brush.

▪ For optimum machine performance keep the silicone

wheels and belt clean from dirt.

▪ Annual maintenance shall be carried out by an

authorized service centre.

CLEANING

▪ Store product indoors when not in use – out of the reach of children.

▪ Always transport and store the TW 5000 in the provided steel box, to prevent the machine from being damaged

or exposed to improper weather conditions.

STORAGE AND TRANSPORT

WARNING! Touching the element

housing and/or nozzle during or after

operation could cause burns.

!

▪ Unscrew the three screws and

remove the heat shield on nozzle and

unplug the sensor carefully.

1

▪ Take off the nozzle by turning it

clockwise and pulling it away from

the fan housing.

3

▪ Important! Replace the tube for

the heating element, to prevent air

passing in between the nozzle and

the element.

5

▪ Replace the nozzle and turn it until

screws are locked. Tighten the screws.

▪ Plug in the sensor and replace the

heat shield on nozzle.

6

▪ Remove used heating element by

pulling it away from its connection.

Insert new heating element for 230 V

or 400 V respectively.

4

▪ Release the four screws on the

nozzle ange.

2

GB

- 10 -

TROUBLESHOOTING GUIDE

PROBLEM CAUSE CORRECTION

Will not start 1. No Power 1. Check the electric supply or the

fuses

The desired temperature is not

reached

1. The temperature is set to 0˚C/0˚F

2. Wrong heating element is used

3. Tube for heating element missing

4. Defective heating element

1. Set correct temperature

2. Change heating element

3. Replace tube

4. Insert a new heating element

The machine is not mowing 1. Defective cog belt

2. Defective drive engine

1. Replace cog belt

2. Contact service centre

The machine is not functioning.

Fan running, text on display:

“TEMPSENSOR FAILURE”

1. The temperature sensor is not

plugged in properly

2. Faulty temperature sensor

1. Plug in temperature sensor

correctly

2. Replace temperature sensor

The machine is not functioning.

Text on display:

“INPUT VOLTAGE < 180V”

1. Too low incoming voltage 1. Check power supply

The machine is not functioning.

Text on display:

“INPUT VOLTAGE > 450V”

1. Too high incoming voltage 1. Check power supply

The machine is not functioning.

Fan running, text on display:

“HIGH AMBIENT TEMPERATURE”

1. Fan unit overheated 1. Make sure that the air intake is

clean and not clogged

SERVICE AND REPAIR

All service and repair should be done only by an authorized Sievert Service Centre.

For a service centre near you, please see contact information on the backside or at www.sievert.se

GB

ACCESSORIES & SPARE PARTS

- 11 -

Only ofcial and approved Sievert accessories and spare parts shall be used.

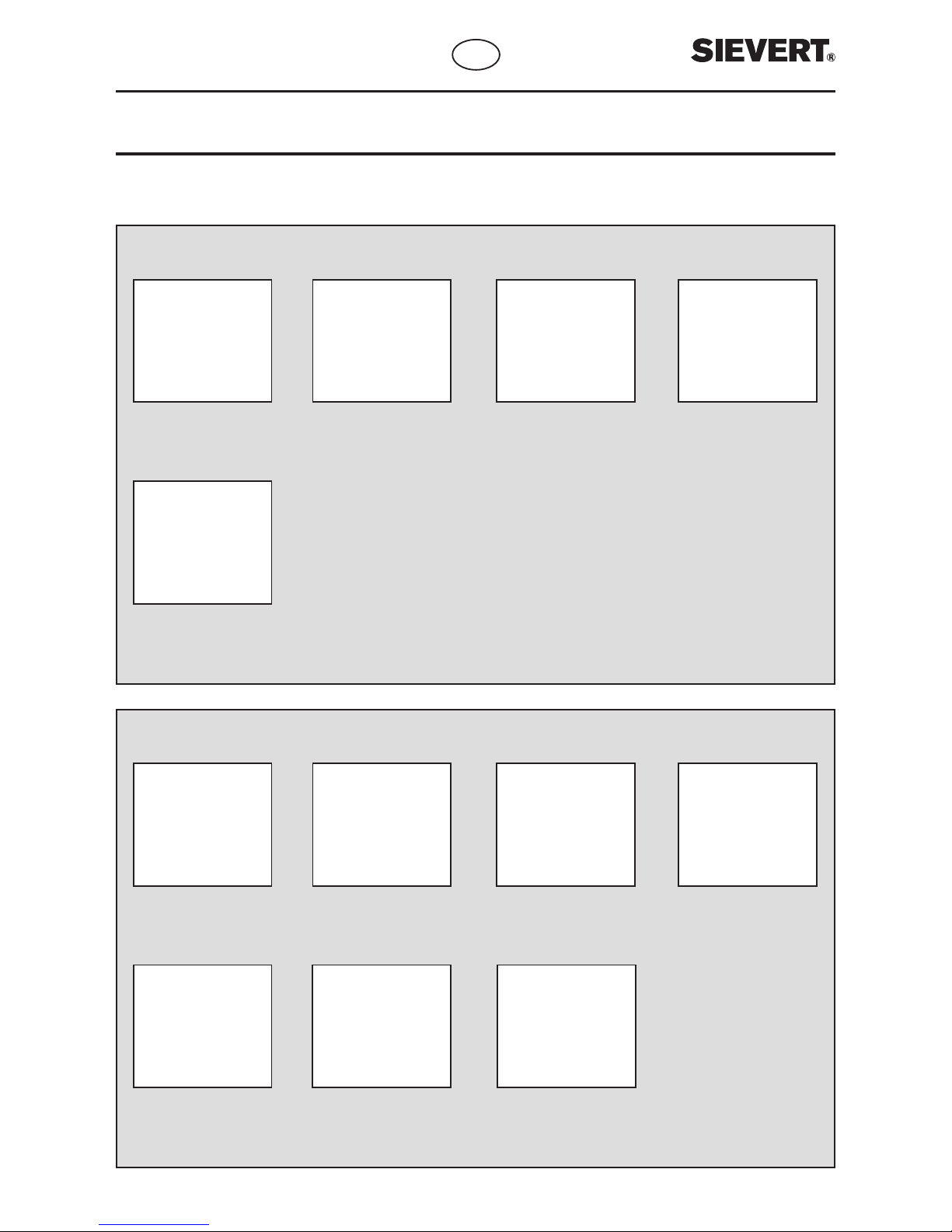

ACCESSORIES

Art no. 299301

Additional weight 4 kg

Art no. 799070

Metal transport box

Art no. 799080

Cleaning brush with

brass wire

Art no. 799001

Replacement heating

element 400 V ~

Art no. 799047

Replacement heating

element 230 V ~

Art no. 799020

Drive belt

Art no. 799030

Nozzle 40 mm

Art no. 799040

Temperature sensor

Art no. 799050

Fan complete

Art no. 799060

Electronic display unit

Art no. 799090

Screw repair kit

SPARE PARTS

Art no. 799010

Welding belt

GB

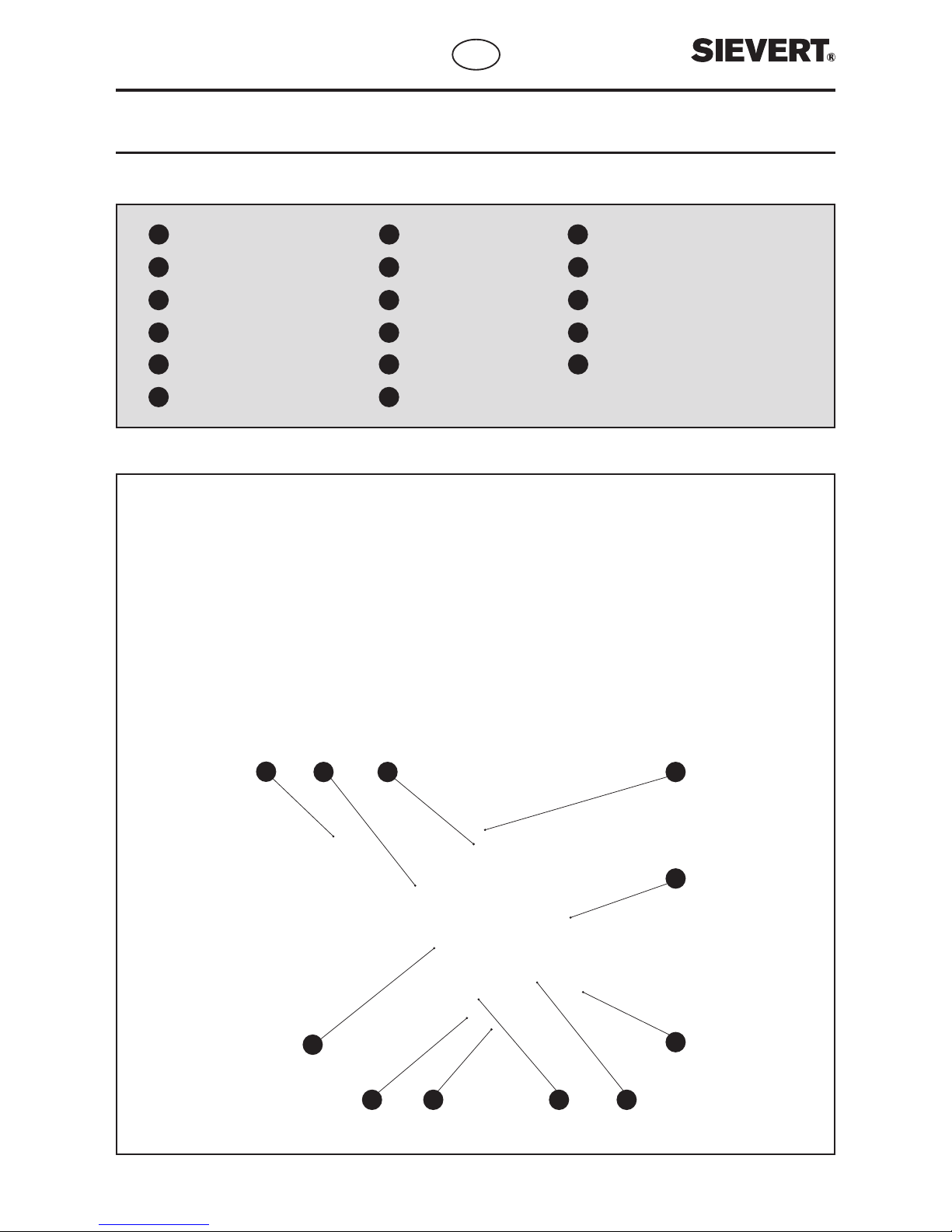

6

5

12

234

9

10 8

2

7

1

11

- 12 -

TW 5000 OVERVIEW

GB

3,00 m/min

550°C *

*

13

14

15

16

17

18

20 19

21

23

24

25

22

Adjustable handle

Cable hook

Handle adjustment knob

Nozzle heat shield

Welding nozzle

Tube for heating element

Heating element

Weight 8 kg / 17.6 lb

Pressure wheel

Silicone welding belt

Adjustable front wheels

Fan release trigger

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18 °C/m or °F/f

Automatic start indicator

Drive indicator

Status “wait” indicator

Status “ready” indicator

Temp. adjustment knob

Fan unit

Start button

Fan adjustment knob

Manually run button

Speed adjustment knob

Power indicator

Temperature indicator

Speed indicator

Lifting handle

Display unit

Lifting handle

Power cord

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

Transportation wheel

Front wheels adjustment knob

Guide wheel adjustment bolt

Guide wheel

Main switch on/off

29

28

27

26

31 34

33

35

31

32

30

- 13 -

TW 5000 OVERVIEW

GB

- 62 -

NOTES

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

- 63 -

NOTES

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

51499 ©Sievert AB. All rights reserved. Sievert is a registered trademark of Sievert AB.

DESIGN AND QUALITY

SIEVERT AB SWEDEN SINCE 1882

www.sievert.se

Sievert Industries, Inc.

5255 Zenith Parkway

Loves Park, IL 61111

Ph: +1 815 639 1319

US

James Lister & Sons Ltd.

Sandwell Industrial Estate

Spon Lane South, Smethwick

West Midlands, B66 1QJ

Ph: +44 121 506 1818

Sievert AB

P.O Box 1366

SE-171 26 Solna

Ph: +46 8 629 22 00

Oy Primus Ab

PL 116

FIN-02201 Espoo

Ph: +358 9 525 9360

Primus AS

Postboks 58, Alnabru

NO-0614 Oslo 6

Ph: +47 23 384 320

Andersen & Nielsen København A/S

H.J Holst Vej 6

DK-2610 Rødovre

Ph: +45 364 102 00

Sievert GmbH

Ettore-Bugattistr. 43

Gewerbepark II

DE-51149 Köln/Porz

Ph: +49 2203 953 10

S.A Sievert

Antwerpsesteenweg 59

BE-2630 Aartselaar

Ph: +32 3 870 87 87

Sievert N.V

Antwerpsesteenweg 59

BE-2630 Aartselaar

Ph: +32 3 870 87 87

Intergros Handels AG

Alter Zürichweg 21

CH-8952 Schlieren

Ph: +41 175 577 77

Stag S.A

Poligono Industrial de Vallecas

C/ Luis I, Nave 6-A2

E-280 31 Madrid

Ph: +34 91 777 0866

Ferrutat Colimar SPA

Viale Monza 338

IT-20128 Milano

Ph: +39 0227 000 607

Petroprimus ZAO

Kantimirovkaja UL D.7

RU-194100 St. Petersburg

Ph: +7 812 327 4418

Rothenberger Hellas SA

249 Sigrou Avenue

GR-171 22 N. Smirni

Ph: +30 210 940 7302

Patimex Ots

NA Zizkove 523

CZ-364 52 Zlutice

Ph: +420 353 393 642

Rothenberger Polska SP.ZO.O

UL. Cyklamenow 1

PL-04-798 Warszawa

Ph: +48 22 612 77 01

S

D

F

N

DK

FIN

GB

I

E

CH

RU

CZ

PL

GR

NL B

Table of contents

Popular Welding System manuals by other brands

Silverline

Silverline 105A Inverter ARC Welder user manual

Stanley

Stanley RW30 user manual

BUG-O

BUG-O BGW-1000 Instructions and parts manual

Lincoln Electric

Lincoln Electric AIR VANTAGE IM10065 Operator's manual

Lincoln Electric

Lincoln Electric Ranger 200 Operator's manual

EWM

EWM Saturn 301 FKG operating instructions

ESAB

ESAB Aristo YardFeed 2000 instruction manual

Lincoln Electric

Lincoln Electric SAE-300 HE Service manual

JESS WELDING

JESS WELDING MIG 325 operating instructions

Matco Tools

Matco Tools MM200 LCD Operator's manual

Telwin

Telwin INVERPULSE 320 MIG-TIG-MMA instruction manual

Miller Electric

Miller Electric M-10 Gun owner's manual