Simon Vision inno-eye S1006 User manual

S1000 Series

Quick Start Guide

English

Software Release 1.3

www.inno-eye.com

2

Table of Contents

Ⅰ. Product Information ..............................................................................................3

1. Product Types and Specifications..............................................................3

2. Product Components......................................................................................4

Ⅱ. System Configuration...........................................................................................5

1. Hardware Configuration................................................................................5

2. I/O Cable Pin Map ............................................................................................6

3. Installing inno-eye Simulator .....................................................................7

Ⅲ. Setting up inno-eye Inspection..................................................................... 10

1. Video Display……………………………………………………………………………..10

2. Setting up Tools............................................................................................. 12

3. Setting up Trigger......................................................................................... 15

4. Saving Job File................................................................................................ 17

5. Transferring Job File to inno-eye ........................................................... 17

Ⅳ. Executing Inspection using inno-eye ......................................................... 18

Ⅴ. Warranty Information ........................................................................................ 20

3

Quick Start Guide provides a quick and easy guide to install and use inno-eye

S-series for the first-time user.

1.Product Types and Specifications

Category

S1002

S1006

Processing

& Memory

Processor

Dual ARM926EJ-S™ RISC Processor

Data Memory

128Mbit Stacked DDR SDRAM

Flash Memory

1Gbit

Sensor

Resolution

1280 X 960

Frame Rate

720P (1280 X 720) : 60frame/sec

Image Sensor

AR0134 (1/3 inch)

Pixel Size

3.75µm X 3.75µm

Shutter

Global

Output Format

RGB Bayer Raw (12Bit)

I/O Interface

Digital Output

3x Sink type output, Max sink 100mA, 60VDC (VAC Peak)

Digital Input

3x Opto-isolated input

Ethernet

100 Base-T

Serial Communication

RS-232C(EIA-232-C)

Video-out

CVBS1)

Light Control

Drive method : PWM control, 5 steps

·

Mechanical & Electrical Specs

Lens Type

8mm (F2.0)

C,CS-Mount

Manual Lens

Lens Mount

S-Mount (M12)

CS-Mount

Illuminator

Ring Type Built-in Illuminator

External Type

Power Consumption

Max 0.2A (24VDC) –illum. On

Max 0.1A (24VDC) –illum. Off

Max 0.1A (24VDC)

Dimensions

39.4mm X 41.0mm X 84.1mm

39.2mm X 39.2mm X 78.9mm

Weight

152g

120g

Housing

Aluminum, Plastic

Operating Ambient

Temperature

0°~ 45°C

Storage Ambient

Temperature

-30°~ 80°C

Software

Environment

Operating System

Windows 7, 8, 10

CPU

Core i3 or higher

RAM

4GB or higher

Monitor Resolution

1280 X 1024 or higher

Lens and illuminator are not included in S1006 model.

Please purchase them.

1)Composite Video Baseband Signal

Ⅰ. Product Information

4

2.Product Components

inno-eye’s components are as follows.

1) Standard Components

Type

Common

Built-in Lens Type

CS-Mount Type

Built-in Lens Type

×1 ea.

Lens Focusing Jig

x 1 ea.

CS-Mount Type

×1 ea.

Adaptor Ring

for C-Mount inno-eye

×1 ea.

Product Information Guide

×1 ea.

Mounting Bracket ×1 ea.

Hexagon Socket

Head Bolt

for Mounting Bracket

(M4x6mm)×2 ea.

(plus 2 ea. as spares)

Using a bolt other than provided, it might cause mechanical failures or malfunctions.

Do not insert bolt into the bottom hole of inno-eye camera more than 4.0mm.

2) Control Box Kit (optional)

Control Box

(SSC-I01A)

Power Cable

(H3TC-K18F)

Screw Lock Type RJ45 Cable (3M)

(ZSCR-RJ45)

12 Pin Circular Cable (3M)

(HBSM-ACBA)

5

1.Hardware Configuration

inno-eye can be connected to Control Box2), and other accessories as follows :

1) Control Box

Control box is a device to supply Power to inno-eye and connect inno-eye with

other external devices. Control box is linked up with inno-eye through 12 pin

circular cable (HBSM-ACBA) provided. The method of connecting external

devices as follows:

For detailed information on Control Box, refer to the full Manual.

2)Connect PLC with inno-eye Control Box for the inspection.

Ⅱ. System Configuration

Ext. INPUT

inno-eye

RS232

AC IN

Ext. OUTPUT

DC OUT

6

2) PC

PC is connected to inno-eye through the ethernet cable (ZSCR-RJ45) provided.

By using inno-eye Simulator installed in PC, we can setup inspection conditions

and monitor the results of inspection.

3) Composite Video Monitor

Video-out(CVBS) port on monitor is connected to inno-eye mono video out

port through Phone Jack ↔RCA Cable, and used to monitor the inspection

results.

For detailed information, Please refer to the Full Manual Part 2. Instruction.

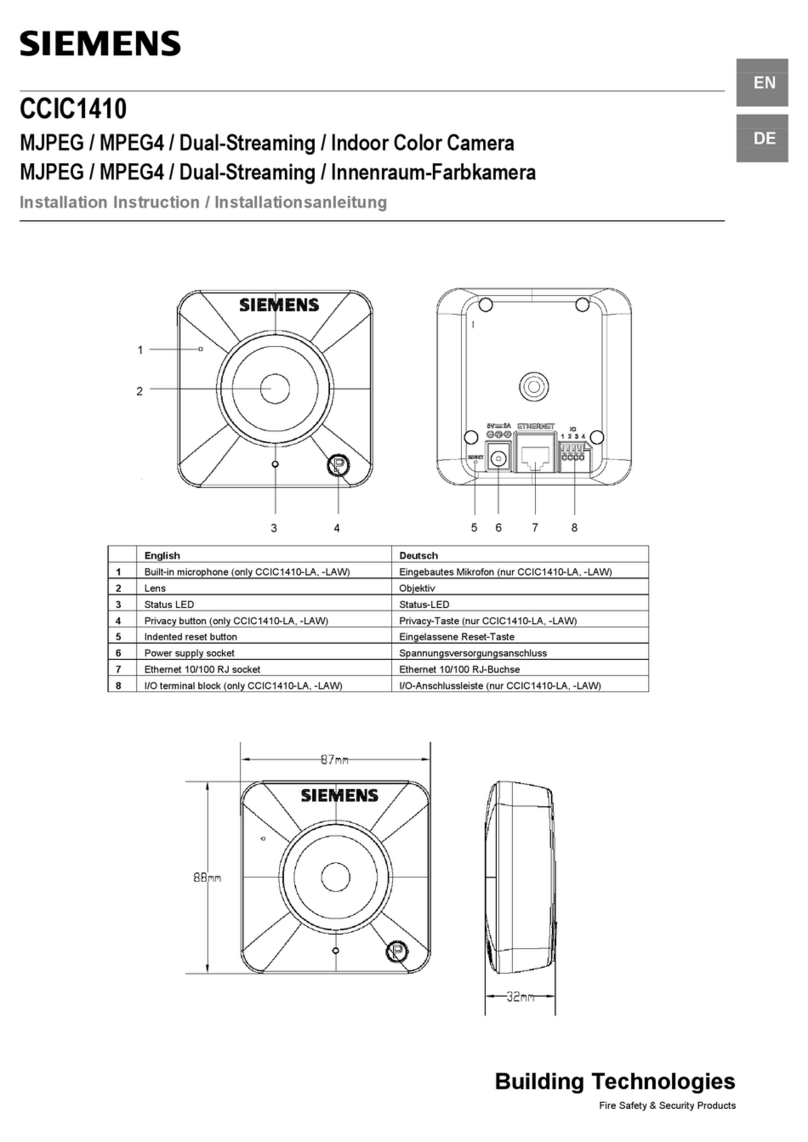

2.I/O Cable Pin Map

In case of not using a control box, you can connect inno-eye and PLC

(or corresponding process control devices) by referring to I/O cable pin map.

Pin No.

Signal Name

Connector Diagram

1

24VDC+ Input

2

GND Terminal

3

External Trigger Input Terminal

(EXT_TRIG)

4

External Input 0 (EXT_DI0)

5

External Input 1 (EXT_DI1)

6

Common Ground for Input Terminal

(EXT_DI_COM)

7

External Output 0 (EXT_DO0)

8

External Output 1 (EXT_DO1)

9

External Output 2 (EXT_DO2)

10

Common Ground for Output Terminal

(EXT_DO_COM)

11

232_RX(Serial Rx)

Backside 12 Pin Circular

Connector of inno-eye

12

232_TX(Serial Tx)

7

3.Installing inno-eye Simulator

Download inno-eye Simulator and install on PC3).

inno-eye Simulator can be downloaded at

http://inno-eye.coreicc.net/kr/support/support.php. After clicking

inno-eye download site, User enter client name, company name,

email address and click ‘’OK button’’, The compressed file including

inno-eye simulator and license key will be sent to the email

address entered.

User must install security module to use inno-eye simulator.

Security module is installed if User executes “driver_install.bat”file

that is included in sent compressed file. At this time, file “haspdinst.exe”

must be in same path where file “driver_install.bat”is located.

Installing security module takes about 1minute to 5 minutes.

But if user executes inno-eye Simulator without installing security module,

error occurs. In case of deleting security driver, User must

execute “driver_install_1.bat”and “driver_install_2.bat”in order.

Next, if user executes inno-eye Simulator, Message box appears to

inform user of registering “License Key”. Same message box will be

shown in case of clicking License Registration button at Connect inno-eye

Menu. License registration will be completed when user enter the license

3) It is recommended to use Window 7 based PC or higher.

DONG IL TECHNOLOGY is not responsible for any failures or damages caused by not following

instructions described in this guide.

8

key received by email and click the Registration button in order.

License means that PC obtains certification which have a permission

to use inno-eye Simulator. So, User must register another license

by receiving additional license key to use inno-eye Simulator at another PC.

Serial number on inno-eye’s cover must be registered to connect inno-eye

it inno-eye Simulator. User can enter Serial number at Connect inno-eye

Tab.

1) inno-eye Simulator

inno-eye simulator is a PC software that controls inno-eye and enables

to select inspection tools to be applied, set inspection specification

which decide good or bad products, and monitor the inspection results

in real time.

9

inno-eye Simulator is comprised as follows :

A. Connect inno-eye : Menu for connecting inno-eye to inno-eye Simulator

B. Setup Camera : Menu for setting up conditions of taking images, I/O and

Illuminator.

C. Setup Tools : Menu for selecting tools to be applied for inspection and setting

up the inspection specifications such as parameters.

D. Control Job File : Menu for managing job file, e.g. transferring the job file

to inno-eye

E. Menu for monitoring inspection results in real time

F. Select Mode : Menu for selecting operational mode which are as follows:

Run mode, Setup mode, and Experimental mode

G.

Checking whether the failure images or result images are saved or not

H. Menu for triggering method for inspection and test button for experimental

trigger test.

I. Menu for displaying selected tools list

J. Buttons for managing the acquired images and job file

K. Descriptions of tools and help related to the current step and more

K

10

1.Video Display

Display video after connecting inno-eye and PC.

①Connecting inno-eye to inno-eye Simulator installed on PC

After Connecting inno-eye and PC by using ethernet cable, then run

inno-eye Simulator.

②Click [ Connect inno-eye > Connect inno-eye ]and then, inno-eye dialog

box is shown up.

③Enter inno-eye camera IP address, command port, and video port in

Connect inno-eye dialog box. The first three digit group of inno-eye

IP address in four digit group must be the same with the first three

digit group of PC IP address connected to inno-eye. Default options of

inno-eye areas follows :

Different IP address must be given to each inno-eye to link up with

additional inno-eye.

④Click Connect button to connect inno-eye and simulator.

Ⅲ. Setting up inno-eye Inspection

IP Address

Command

Video Port

192.168.2.86

5000

5001

11

inno-eye is automatically set to Run mode when it boots. For displaying

images and setting up inspection parameter, change mode option into

Setup mode. After that, View Images button can be toggled between

Pause View and View Images when user click it.

For detailed information for inno-eye Run mode, Refer to the Full

Manual Part 2.

12

2.Setting up Tools

inno-eye Simulator provides 17 kinds of tools for you to execute more

accurate inspection. You can register more than one tool according to

the purpose of inspection.

Set inspection parameter at Pause View mode for your correct inspection.

4) Objects : Products to be inspected by inno-eye.

5) Good product : Objects inno-eye has verified that it is suitable to sell commercially.

Bad product : Objects inno-eye has verified that it is not suitable to sell commercially.

Category

Tool

Descriptions

Position

Alignment

Tool

Position Alignment

(Shift)

Calculate the rotation, and position shift of objects14)

to be examined(Suitable for rotation within 5°)

Position Alignment

(Rotation)

Calculate the rotation, size conversion, and shift information of

a part to be examined(Suitable for rotation of 5°and over)

Presence/

Absence

Tool

Brightness

Determines the presence of objects

by using the brightness of a specified area

Standard Deviation

Determine the presence of objects by using

the Standard Deviation of a specified area

Similarity

Determine the presence of objects by checking similarity degree

of registered patterns and the specified area

Contrast

Determine the presence of objects by using

the contrast of the specified area

Pixel Count

Determine the presence of objects based on the number

of pixels separated by threshold in specified area

Counting

Tool

Classifier

Count the number of registered patterns found in the specified area

Inspection

Tool

Shape Analysis

Verify the good and bad products5)by using

its size, perimeter, angle and the center of mass

Diameter

Measure the diameter of a circular object or a hole

Circularity

Measure how circular objects correspond with real circle

Concentricity

Measure the distance between the centers of two circles.

Distance

Measure the distance among a point, a line, a circle or blob in object.

Angle

Measure the angle of objects in degree.

Surface Detect

Measure the size and circumference of scratches

or flaws on the surface of objects

Recognition

Tool

Character Recognition

Register character to be recognized and by using them,

recognize the registered characters of object in a specific area

Classifier

Classify acquired images based on the registered pattern

13

Example 1 : Position Alignment Tool

It is hard to say that the position of inspection object is always located at the same

position under the camera view. By using Position Alignment tool, you can execute

inspection regardless of the rotation and shift of objects.

①Click [ Setup Tools>Position Alignment>Position Alignment(Shift)]

→Refer to the Box A

②Click View ROI, and designate the two sets of Detection area and Pattern

area.

(It is recommended to select Inspection area in the unique area where it is

not similar to any other area)→Refer to the Box B

③Click Register Pattern, and save the designated area as a pattern.

The Value of Uniqueness is displayed at the bottom of the pattern when

user register the specific pattern.

Uniqueness means how unique the patterns are in the detection area,

which expressed in figures. As the value of uniqueness is higher, User can

acquire more exact results of position alignment. (Uniqueness is not

applicable to Position Alignment(Rotation) →Refer to the Box C, D

④Click Add button to register Position Alignment Tool to the tool list.

→Refer to the Box E, F

14

Example 2 : Distance Tool

Measure the distance between the two designated areas of tested object.

①Click [ Setup Tools> Inspection Tool > Distance ]

②Designate the Inspection area of 1 and 2.

Distance Tool finds the nearest point of objects edge from the center of

inspection area, and measures the distance of two points.

(In case of selecting Point to Point)

③Click Test button to check the measured distance and then, enter the

inspection specifications to be accepted as a good product

15

④Click Add button to register Distance Tool to the tool list.

3.Setting up Trigger

Trigger is a timing signal to take images using a camera of inno-eye.

Once a trigger signal is received, inno-eye acquires images simultaneously

and automatically executes inspection by using acquired images.

inno-eye provides 3 kind of triggers:

A. External Trigger : Taking images by synchronizing the trigger signal

from external device such as PLC or position sensor etc.

B. Internal Trigger: Analyzing an acquired image at each frame,

and then triggering by using image information at user’s set position.

C. Time Interval Trigger: Generating trigger at regular intervals user set

in inno-eye, and then taking image user want.

16

To set Trigger, click [ Setup Camera>Setup Trigger ]

Selected trigger type is displayed on upper right side of inno-eye Simulator.

As inno-eye operates by trigger signal, setting trigger is essential.

In case the trigger user set is hardly applicable, click Simulation Trigger Test

button so that inno-eye can receive the test trigger signal from Simulator.

By using Simulation Trigger Test, you can check whether inno-eye is

operating properly and monitor the inspection results.

17

4.Saving Job File

Click Save Job File to save all inspection specifications that is set before

as a single Job file.

A Job File consists of camera configuration, master image and inspection tool

sets

. (Job file is saved at C://DIVision/job as default.)

5.Transferring Job File to inno-eye

You can start and execute an inspection by transferring job file in

PC to inno-eye.

Click [ Control Job File > Control File > PC inno-eye ]

18

You can easily check the results after executing your inspection by inno-eye.

①Once the Job File is sent to inno-eye, inno-eye will reboot automatically.

②After the reboot, inno-eye is set to Run mode and execute inspections

by itself according to the user-set trigger method.

(In case external trigger is set as its trigger type on Simulator,

inno-eye executes inspection as it sensed the trigger signal from

external device. If inno-eye cannot receive the external trigger signal

from it, click Simulation Trigger test button so that inno-eye can execute

inspection by using the trigger signal PC sends.

③Inspection results can be monitored on Simulator or composite video

Monitor connected to inno-eye in real time.

In case of inspection monitering using both of the simulator and

the video monitor, inno-eye can take more inspection time.

(To monitor the inspection results on Simulator, click [ Connect inno-eye >

Connect inno-eye ] and then, activate View Images button)

You can monitor the inspection results using video-out(CVBS)

on a monitor without PC.

Ⅳ. Executing Inspection using inno-eye

Control Box

Composite Video Monitor

inno-eye Simulator

19

When Simulator is used for monitoring inspection, inspection results will be shown

in 1/4 sizes on Simulator display.

You can download full manual at www.inno-eye.com

More information about inno-eye and operation of tools are available in

full manual.

20

DONG IL TECHNOLOGY warrants that this product is free from defective material and

workmanship. We will warrant repair of the product free of charge or with charge when

product fail to operate properly. To get product warranty, please visit

www.inno-eye.com and click Product Registration at Support menu where you can find

Product registration form. (※Serial No. of the product must be filled out in the form)

1. Warranty Coverage

We cover the warranty for one year from the download date of inno-eye Simulator. If Simulator download

date is not identifiable, instead the shipping date or the sale date recorded in our system will be used.

DONG IL TECHNOLOGY offers free repairs or product exchange for any performance or functional

defects under normal working condition within warranty period, and offers paid repairs for any defects

caused by user’s misuse or negligence.

Issues

Coverage

Under

Warranty

Warranty

expired

Performance or

functional defects

caused under

normal working

conditions

Performance or functional defects

under normal working condition

Repair free

Paid repair

Identical error occurred three times

under normal working condition

Product

exchange

Loss of the product on repair

at Service center

Product

exchange

·

Unable to repair as parts are not in stock

(Within parts retention period)

Unable to repair while parts are in stock

(Within parts retention period)

User’s fault or etc.

Failure or damage caused by user’s mishandling

(e.g. falling, flooding, physical shocks, damage,

unreasonable operation, etc.)

Paid repair

Failure or damage caused by user’s improper

usage or negligence

Failure and damage caused by using parts

provided by other companies

(e.g. accessories, expendable parts etc.)

Failure caused by using inno-eye

under misuse against guideline in the manual

Failure or damage caused by natural disaster

(e.g. fire, flooding, earthquake,

malfunction of power system

Failure caused by working-life expiration.

Failure caused by external factors

other than described

※Parts retention period : 5 year after the end of production

2. Others

1) Product must be installed and used as prescribed method in this guide.

2) This guide is a recommendation and we do not warrant any defects caused by user’s negligence

3) In case PC Label on the front and backside cover of camera is removed, warranty coverage is not

applicable.

4) User should use the parts provided by DONG IL TECHNOLOGY

5) Warranty is provided only to the original purchaser and not allowed to pass on others.

6) User should keep a warranty document for getting warranty repair.

7) Repairing fees and Price of relevant parts is not covered for getting warranty repair.

8) Any parts of inno-eye are not covered under warrant.

Ⅴ. Warranty Information

This manual suits for next models

1

Table of contents