Simoniz USA S2350 User manual

Part No. A08987 Rev. 0 11/05/04

IMPORTANT

Please make certain that the person who is to use this equipment carefully reads

and understands these instructions before operating.

Operator's Manual

Table of Contents

Safety Guidelines/Definitions . . . . . . .2

Important Safety Instructions. . . . .2–5

Specifications . . . . . . . . . . . . . . . . . . .6

Carton Contents . . . . . . . . . . . . . . . . .6

Assembly Instructions. . . . . . . . . . .6–7

Operating Instructions . . . . . . . . .8–13

Maintenance . . . . . . . . . . . . . . . .14–15

Storage . . . . . . . . . . . . . . . . . . . . . . .16

Troubleshooting Guide . . . . . . . .17–18

Repair Warranty . . . . . . . . . . . . . . . .20

Gas Powered Pressure Washer

S2350

Record All Information and attach sales receipt here for future reference:

Purchase Date:____________________ Serial #: __________________________

Do Not return this product to the retailer! Questions? 1-866-4-SIMONIZ

To extend service life and to avoid overheating, DO NOT leave your

pressure washer idling when not in use.

2- ENG

A08987

IMPORTANT SAFETY INSTRUCTIONS

Do not operate this unit until you have read and understood this

Operator's Manual and the Engine Owner's Manual for Safety,

Operation, and Maintenance Instructions.

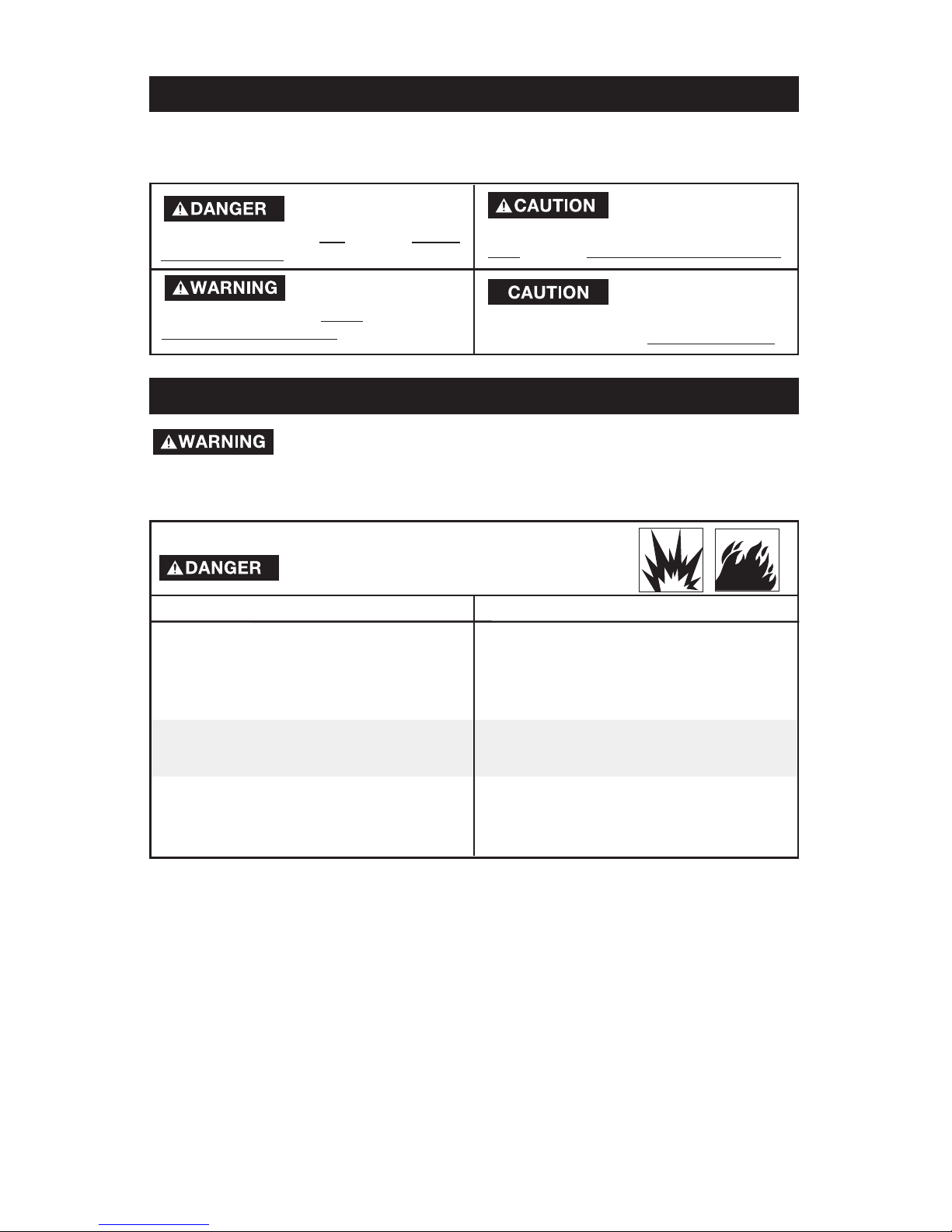

RISK OF EXPLOSION OR FIRE

HAZARD

WHAT CAN HAPPEN HOW TO PREVENT IT

• Spilled gasoline and its vapours can

ignite from cigarette sparks, electrical

arcing, exhaust gases, and hot engine

components such as the muffler.

• Shut off engine and allow it to cool before

adding fuel to the tank.

• Use care in filling tank to avoid spilling fuel.

Move pressure washer away from fueling

area before starting engine.

• Heat will expand fuel in the tank which

could result in spillage and possible fire

or explosion.

• Keep maximum fuel level ½" below top of

tank to allow for fuel expansion.

• Operating the pressure washer in an

explosive environment could result in a

fire.

• Operate and fuel equipment in well

ventilated areas free from obstructions.

Equip areas with a fire extinguisher suitable

for gasoline fires.

READ AND SAVE THESE INSTRUCTIONS

SAFETY GUIDELINES - DEFINITIONS

Indicates an imminently

hazardous situation

which, if not avoided, will result in death

or serious injury.

Indicates a potentially

hazardous situation

which, if not avoided, could result in

death or serious injury.

Indicates a potentially

hazardous situation which, if not avoided,

may result in minor or moderate injury.

Used without the safety

alert symbol indicates a

potentially hazardous situation which, if not

avoided, may result in property damage.

This manual contains information that is important for you to know and understand. This

information relates to YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. Please

read the manual and pay attention to these symbols below.

3- ENG A08987

RISK TO BREATHING

WHAT CAN HAPPEN HOW TO PREVENT IT

RISK OF EXPLOSION OR FIRE (continued)

HAZARD

WHAT CAN HAPPEN HOW TO PREVENT IT

RISK TO FLUID INJECTION

HAZARD

WHAT CAN HAPPEN HOW TO PREVENT IT

HAZARD

• Materials placed against or near the pres-

sure washer can interfere with proper

ventilation causing overheating and may

ignite materials.

• Never operate pressure washer in an

area containing dry brush, weeds, or any

flammable containers or materials.

• Muffler exhaust heat can damage painted

surfaces, melt any material sensitive to

heat (such as siding, plastic, rubber, or

vinyl), and damage live plants.

• Always keep pressure washer a minimum

of 4' away from surfaces (such as houses,

auto-mobiles, or live plants) that could be

damaged from muffler exhaust heat.

• Improperly stored fuel may ignite. Fuel

improperly secured could get into the

hands of children or other unqualified

persons.

•

Store fuel in an OSHA approved container,

in a secure location away from work area.

• Use of acids, toxic or corrosive chemi-

cals, poisons, insecticides, or any kind of

flammable solvent with this product could

result in serious injury or death.

• Do not spray flammable liquids.

• Breathing exhaust fumes will cause

serious injury or death!

• Operate pressure washer in a well

ventilated area. Avoid enclosed areas such

as garages, basements, etc.

• Never operate unit in a location occupied

by humans or animals.

• Some cleaning fluids contain substances

which could cause injury to skin, eyes, or

lungs.

• Use only cleaning fluids and detergents

specifically recommended for high

pressure washers. Follow manufacturer's

recommendations. Do not use chlorine

bleach or any other corrosive compound.

• Your washer operates at fluid pressures

and velocities high enough to penetrate

human and animal flesh, which could

result in amputation or other serious

injury. Leaks caused by loose fittings or

worn or damaged hoses can result in

injection injuries. DO NOT TREAT FLUID

INJECTION AS A SIMPLE CUT! See a

physician immediately!

• Never place hands in front of nozzle.

• Direct spray away from self and others.

• Make sure hose and fittings are tightened

and in good condition. Never hold onto

the hose or fittings during operation.

• Do not allow hose to contact muffler.

• Never attach or remove wand or hose

fittings while system is pressurized.

• Injuries can result if system pressure

is not reduced before attempting

maintenance or disassembly.

• To relieve system pressure, shut off

engine, turn off water supply, and pull gun

trigger until water stops flowing.

• Use only hoses and accessories rated

for pressure higher than your pressure

washer's PSI.

4- ENG

A08987

RISK OF

ELECTRICAL SHOCK

HAZARD

WHAT CAN HAPPEN HOW TO PREVENT IT

RISK OF

ELECTRICAL SHOCK

RISK OF

ELECTRICAL SHOCK

RISK OF HOT

SURFACES

HAZARD

WHAT CAN HAPPEN HOW TO PREVENT IT

RISK OF

CHEMICAL

BURN

HAZARD

WHAT CAN HAPPEN HOW TO PREVENT IT

RISK OF INJURY OR PROPERTY DAMAGE

WHEN TRANSPORTING OR STORING

HAZARD

WHAT CAN HAPPEN HOW TO PREVENT IT

• Contact with hot surfaces, such as

engines exhaust components, could

result in serious burn.

• During operation, touch only the control

surfaces of the pressure washer. Keep

children and pets away from the pressure

washer at all times. They may not be able

to recognize the hazards of this product.

• Spray directed at electrical outlets or

switches, or objects connected to an

electrical circuit, could result in a fatal

electrical shock.

• Unplug any electrically operated product

before attempting to clean it. Direct spray

away from electric outlets and switches.

• Do not use acids, gasoline, kerosene,

or any other flammable materials in this

product. Use only household detergents,

cleaners and degreasers recommended

for use in pressure washers.

• Wear protective clothing to protect eyes

and skin from contact with sprayed

materials.

• Use of acids, toxic or corrosive chemi-

cals, poisons, insecticides, or any kind of

flammable solvent with this product could

result in serious injury or death.

• Fuel or oil can leak or spill and could

result in fire or breathing hazard, serious

injury or death can result. Fuel or oil

leaks will damage carpet, paint or other

surfaces in vehicles or trailers.

• If pressure washer is equipped with a

fuel shut-off valve, turn the valve to the

off position before transporting to avoid

fuel leaks. If pressure washer is not

equipped with a fuel shut-off valve, drain

the fuel from tank before transporting.

Only transport fuel in an OSHA approved

container. Always place pressure washer

on a protective mat when transporting

to protect against damage to vehicle

from leaks. Remove pressure washer from

vehicle immediately upon arrival at your

destination.

5- ENG A08987

• Reactive force of spray will cause gun/

wand to kickback, and could cause the op-

erator to slip or fall, or misdirect the spray.

Improper control of gun/wand can result in

injuries to self and others.

• Do not overreach or stand on an unstable

support.

• Do not use pressure washer while

standing on a ladder.

• Grip gun/wand firmly with both hands.

Expect the gun to kickback when

triggered.

RISK OF UNSAFE OPERATION

HAZARD

WHAT CAN HAPPEN HOW TO PREVENT IT

RISK OF INJURY FROM SPRAY

HAZARD

WHAT CAN HAPPEN HOW TO PREVENT IT

• If proper starting procedure is not

followed, engine can kickback causing

serious hand and arm injury.

• If engine does not start after two pulls,

squeeze trigger of gun to relieve pump

pressure. Pull starter cord slowly

until resistance is felt. Then pull cord

rapidly to avoid kickback and prevent

hand or arm injury.

• The spray gun/wand is a powerful

cleaning tool that could look like a toy to

a child.

• Keep children away from the pressure

washer at all times.

• Unsafe operation of your pressure

washer could lead to serious injury or

death to you or others.

• Do not use chlorine bleach or any other

corrosive compound.

• Become familiar with the operation and

controls of the pressure washer.

• Keep operating area clear of all persons,

pets, and obstacles.

• Do not operate the product when fatigued

or under the influence of alcohol or drugs.

Stay alert at all times.

• Never remove or alter the safety features

of this product.

• Do not operate machine with missing,

broken, or unauthorized parts.

• Never leave wand unattended while unit

is running.

• Do not use this pressure washer in any

way other than its intended purpose.

• High velocity fluid spray can cause

objects to break, propelling particles at

high speed.

• Light or unsecured objects can become

hazardous projectiles.

• Always wear ANSI approved Z87 safety

glasses. Wear protective clothing to protect

against accidental spraying.

• Never point wand at, or spray, people or

animals.

• Always secure trigger lock when wand

is not in service to prevent accidental

operation.

• Never permanently secure trigger in pull

back (open) position.

6- ENG

A08987

1. Place handle assembly onto frame,

depress the snap buttons, and slide

the handle assembly onto frame

until snap buttons snap into place.

(See Fig. 1)

Handle

Engine Frame and

Wheel Assembly

High-pressure

Hose

Engine

Oil

Spray Gun Multi-Adjustable

Spray Wand

2. Connect wand to gun. Tighten

securely. (see Fig. 2)

3. Attach high-pressure hose to

gun. Tighten securely. (see Fig. 3)

4. Add engine oil (supplied)

to engine. Refer to Engine

Owner's Manual supplied by

engine manufacturer for correct

procedure.

NOTE: There will be a slight amount

of oil in the engine from factory

testing.

NOTE: The pump on this unit is

maintenance-free and requires no oil. If

there is a problem with the pump call:

1-866-4SIMONIZ (1 866 474 6664).

ASSEMBLY INSTRUCTIONS

Bagged Parts

Detergent/cleaning

solvent hose

CARTON CONTENTS

Hex key and

cleaning tool

Engine and Owner's Manual (not shown)

Fig. 1

Fig. 2

Fig. 3

Model: S2350 (39-8670-6)

SPECIFICATIONS

Cleaning units 4935

PSI (water pressure) 2350

GPM (water flow) 2.1

Engine Briggs & Stratton® 5.5 HP

Pump Radial, maintenance-free

7- ENG A08987

OPERATING INSTRUCTIONS

BASIC ELEMENTS OF A

PRESSURE WASHER

High-pressure pump (located inside

the shroud): Increases the pressure

of the water supply.

Engine: Drives the high pressure

pump.

High-pressure hose: Carries the

pressurized water from the pump to

the gun and spray wand.

Spray gun: Connects with spray

wand to control water flow rate,

direction, and pressure.

Multi-adjustable spray wand: Allows

the user to use high or low pressure

and adjusts from a pencil stream (0°)

to a wide angle fan spray (40°). See

How To Use Wand instructions in this

section.

Compare the illustrations with your unit to familiarize yourself with the location

of various controls and adjustments. Save this manual for future reference.

Engine

High-pressure

hose

Spray

gun

Multi-adjustable

spray wand

High-pressure

pump (located

inside the

shroud)

Detergent injection hose: Feeds

cleaning agents into the pump to

mix with the water. See How To

Apply Chemicals/Cleaning Solvents

instructions in this section.

BASIC ELEMENTS OF AN

ENGINE

Refer to the engine manual for

location and operation of engine

controls.

Choke control: Opens and closes

carburetor choke valve.

Throttle control lever: Controls

engine speed.

Starter grip: Pulling starter grip

operates recoil starter to crank

engine.

Fig. 4

8- ENG

A08987

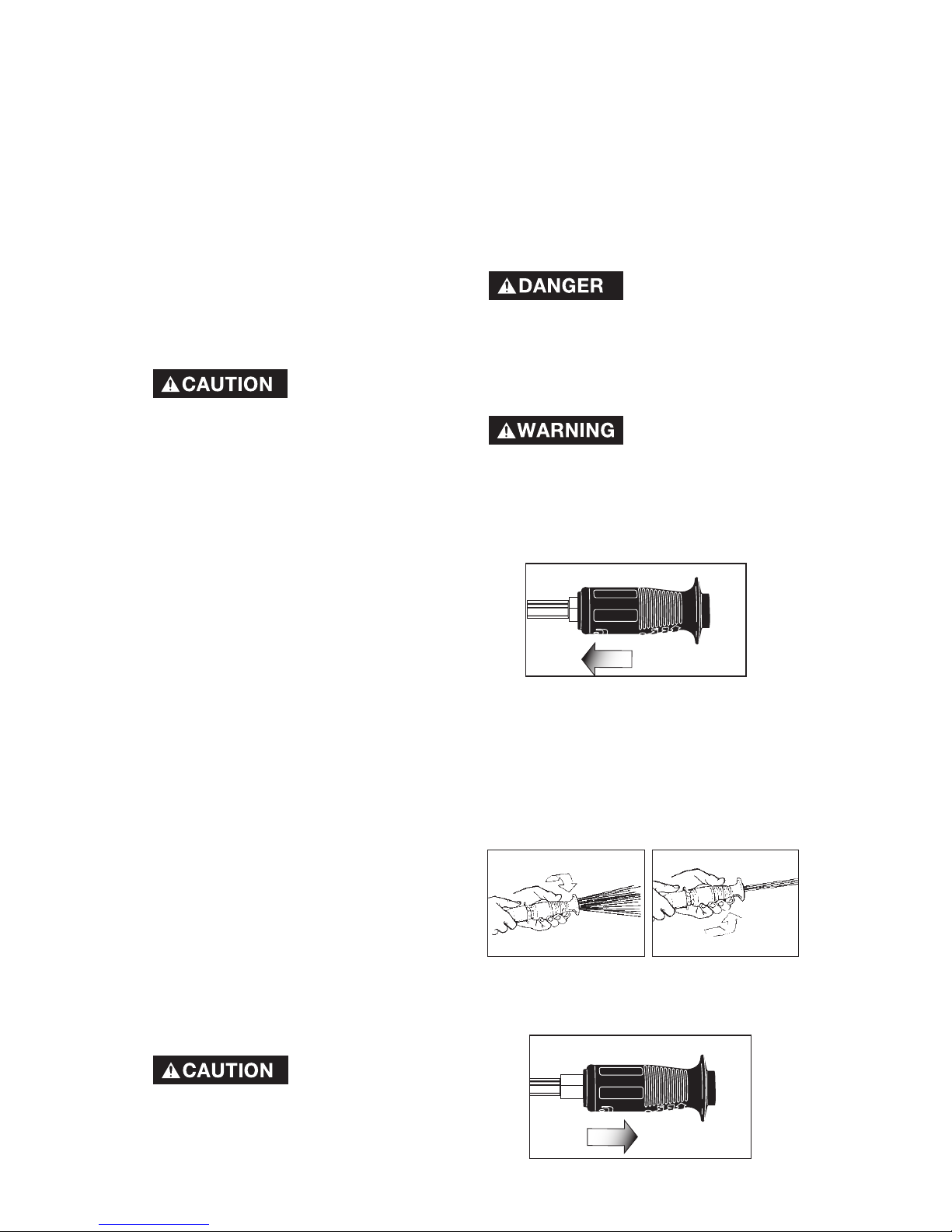

HOW TO USE SPRAY WAND

Your pressure washer is equipped

with a multi-adjustable spray wand

with both high and low pressure

settings. The high pressure setting

is for cleaning and rinsing, the low

pressure setting is for applying

chemicals or cleaning solutions to

surfaces.

When using the

high pressure

setting, DO NOT allow the jet-like

spray to come in contact with

unprotected skin, eyes, or with any

pets or animals. Serious injury can

occur.

Risk of injection or

injury to person.

DO NOT direct discharge stream

toward persons.

For high pressure operation, pull back

the nozzle of the multi-adjustable

spray wand as shown in Fig. 5.

The nozzle at the end of the multi-

adjustable spray wand can be rotated

to change the high pressure spray

pattern from a 0º pencil stream to

a 40º fan spray, as shown in fig. 6 a

and 6b. Markings have been placed

on the nozzle to help you select the

spray pattern.

For low pressure operation, extend

the nozzle of the multi-adjustable

spray wand as shown in Fig. 7.

PRESSURE WASHER

TERMINOLOGY

PSI: Pounds per Square Inch. The

unit of measure for water pressure.

Also used for air pressure, hydraulic

pressure, etc.

GPM: Gallons Per Minute. The unit of

measure for the flow rate of water.

CU: Cleaning Units. GPM multiplied

by PSI. GPM x PSI = CU

Bypass mode: Allows water to

re-circulate within pump when the

gun trigger is not pulled.

Allowing the unit to

run for more than

two minutes without the gun trigger

pulled could cause overheating and

damage to the pump.

Detergent injection system: Mixes

cleaners or cleaning solvents with

the water to improve cleaning

effectiveness.

Water supply: All pressure washers

must have a source of water. The

minimum requirements for a water

supply are 20 PSI and 5 gallons per

minute.

PRESSURE WASHER

OPERATING FEATURES

PRESSURE ADJUSTMENTS

The pressure setting is preset at the

factory to achieve optimum pressure

and cleaning. If you need to lower the

pressure, it can be accomplished by

these methods.

1. Back away from the surface

to be cleaned. The further away

you are, the less the pressure will

be on the surface to be cleaned.

2. Rotate the nozzle at the end

of the multi-adjustable spray

wand to widen the fan spray.

The wider fan spray will minimize

the pressure on the surface to be

cleaned.

DO NOT attempt

to increase pump

pressure. A higher pressure setting

than the factory set pressure may

damage pump. Low

Pressure

High

Pressure

40º fan spray 0º pencil stream

Fig. 5

Fig. 6a Fig. 6b

Fig. 7

9- ENG A08987

The powerful

spray from your

pressure washer is capable of

causing damage to surfaces such

as wood, glass, automobile paint,

auto striping and trim, and delicate

objects such as flowers and shrubs.

Before spraying, check the item to be

cleaned to assure yourself that it is

strong enough to resist damage from

the force of the spray.

READ AND UNDERSTAND ALL WARNINGS BEFORE STARTING UNIT

When using the high-pressure setting, DO NOT allow the

spray to come in contact with unprotected skin, eyes, or

with any pets or animals. Serious injury can occur.

Your washer operates at fluid pressures and velocities high enough to

penetrate human and animal flesh, which could result in amputation or other

serious injury. Leaks caused by loose fittings or worn or damaged hoses can

result in injection injuries. DO NOT TREAT FLUID INJECTION AS A SIMPLE

CUT! See a physician immediately!

NEVER fill fuel tank when engine is running or hot. Do not

smoke when filling fuel tank.

NEVER fill fuel tank completely. Fill tank to 1/2" below top of tank to provide

space for fuel expansion. Wipe any fuel spillage from engine and equipment

before starting engine.

NEVER run engine indoors or in enclosed, poorly ventilated areas. Engine

exhaust contains carbon monoxide, an odorless and deadly gas.

NEVER carry pressure washer with engine running, turn engine off and allow

it to cool before carrying pressure washer.

DO NOT let hoses come in contact with hot engine muffler during or

immediately after use of your pressure washer. Damage to hoses from contact

with hot engine surfaces will NOT be covered by warranty.

NEVER pull water supply hose to move pressure washer.

This could damage hose and/or pump inlet.

DO NOT use hot water, use cold water only.

NEVER turn water supply off while pressure washer engine is running or

damage to pump will result.

DO NOT stop spraying water for more than two minutes at a time. Pump

operates in bypass mode when spray gun trigger is not pressed. If pump is

left in bypass mode for more than two minutes internal components of the

pump can be damaged.

If you do not understand these precautions, please call 1-866-4SIMONIZ

(1 866 474 6664).

10- ENG

A08987

HOW TO APPLY

DETERGENT/CLEANING

SOLVENTS

Applying detergent/cleaning solvents

is a low pressure operation. NOTE:

Use only detergent/cleaning solvents

designed for pressure washer use. Do

not use bleach.

To Apply detergent/cleaning

solvents:

1. Press detergent injection hose

onto barbed fitting located near

high pressure hose connection of

pump as shown in Fig. 8.

2. Place other end of detergent

injection hose with filter

on it into container holding

detergent/cleaning solution.

NOTE: For every 7 gallons

of water pumped 1 gallon of

detergent/cleaning solution will

be used.

3. Set multi-adjustable nozzle to

low pressure setting. See How

To Use Wand paragraph in this

section.

4. After use of detergent/cleaning

solvents, place detergent

injection hose into container

of clean water and draw

clean water through detergent

injection system to rinse system

thoroughly. If detergent/cleaning

solutions remain in the pump

it could be damaged. Pumps

damaged due to detergent/

cleaning solvents will not be

covered under warranty.

NOTE: Detergent/cleaning solvents

will not siphon when spray wand is in

the high pressure setting.

Barbed Fitting

STARTING

Prior to starting, refer to your Engine

owner's manual for proper starting

procedures.

1. In a well-ventilated outdoor

area add fresh, high-quality,

unleaded gasoline with a pump

octane rating of 86 or higher. Do

not overfill. Wipe up spilled fuel

before starting the engine. Refer

to Engine Owner's Manual for

correct procedure.

2. Check engine oil level. See

Engine Owner's Manual for

correct procedure. NOTE: There

will be a slight amount of oil in

the engine from factory testing.

3. Verify the filter screen is in water

inlet of pump (see Fig. 9). NOTE:

Cone side faces out.

4. Connect water supply to pump

inlet (see Fig. 10). NOTE: Water

supply must provide a minimum of

5 gallons per minute at 20 PSI.

5. Connect high pressure hose to

pump outlet (see Fig. 10).

6. If applying a detergent or

cleaning solvents, see How

To Apply Detergent/Cleaning

Solvents instructions in this

section.

7. Turn water supply on.

NOTE: Failure to do so could

cause damage to the pump.

Filter Screen

High-pressure

hose hook-up

Fig. 8

Fig. 9

Water supply

Fig. 10

11- ENG A08987

8. Start engine. See Engine

Owner's Manual for correct

procedure. NOTE: When engine

rope is pulled, pressure starts

building in the gun. If the engine

does not start after two pulls,

pull the gun trigger to relieve this

pressure.

9. Depress trigger on gun to

start water flow. NOTE: Stand

on a stable surface and grip

gun/spray wand firmly with both

hands. Expect the gun to kick

when triggered.

10. Release trigger to stop water

flow.

11. Adjust nozzle spray for the

task being performed. See How

To Use Wand instructions in this

section.

SHUTTING DOWN

1. After each use, if you have

applied detergents or cleaning

solvents, place end of detergent/

cleaning solvent hose into

container of clean water and draw

clean water through detergent

injection system to rinse system

thoroughly. NOTE: Failure to do

so could cause damage to the

pump.

2. Turn engine off. See Engine

Owner’s Manual. NOTE: NEVER

turn the water off with the engine

running.

3. Turn water supply off.

4. Pull trigger on spray gun to

relieve any water pressure in hose

or spray gun.

5. See Storage section in this

manual for proper storage

procedures.

MAINTENANCE

When performing

maintenance, you

may be exposed to hot surfaces,

water pressure, or moving parts

that can cause serious injury or

death!

Before performing any maintenance

or repair, disconnect spark plug

wire, let engine cool and release

all water pressure. The engine

contains flammable fuel. DO NOT

smoke or work near open flames

while performing maintenance.

To ensure efficient operation and

longer life of your pressure washer, a

routine maintenance schedule should

be prepared and followed. If the

pressure washer is used in unusual

conditions, such as high-temperatures

or dusty conditions, more frequent

maintenance checks will be required.

ENGINE

Consult the Engine Owner's

Manual for the manufacturer's

recommendations for any and all

maintenance.

PUMP

The pump on this unit is maintenance

free and requires no oil. If there is a

problem with the pump call

1-866-4SIMONIZ (1 866 474 6664).

NOZZLE CLEANING

If the nozzle becomes clogged

with foreign matter, such as dirt,

excessive pressure may develop. If

the nozzle becomes partially clogged

or restricted, the pump pressure will

pulsate. Clean the nozzle immediately

using the nozzle kit supplied and the

following instructions:

12- ENG

A08987

1. Shut off the pressure washer

and turn off the water supply.

2. Disconnect spark plug wire to

ensure the unit will not start while

performing maintenance.

3. Pull trigger on gun handle to

relieve any water pressure.

4. Disconnect the wand from the

gun.

5. Remove the nozzle from the

end of the wand with the 2mm

hex key provided as shown in Fig.

11.

6. Clean the nozzle using the

nozzle cleaner provided or a

straightened paper clip. Insert

into the nozzle end and work

back and forth until obstruction is

removed. (see Fig. 12)

7. Direct water supply into nozzle

end to backflush loosened particles

for 30 seconds. (see Fig. 13)

8. Reconnect spark plug wire

9. Reassemble the nozzle to

the wand. Tighten securely to

prevent leaks.

10. Reconnect wand to gun and

turn on water supply.

11. Start pressure washer and

place wand into high pressure

setting to test.

Fig. 11

Fig. 12

Fig. 13

HOW TO CLEAN THE WATER

INLET FILTER

This screen filter should be checked

periodically and cleaned if necessary.

1. Remove

filter by

grasping

end and

removing it

from water

inlet of pump

as shown in Fig. 14.

2. Clean filter by flushing it with

water on both sides.

3. Re-insert filter into water inlet

of pump. NOTE: Cone side faces

out.

NOTE: Do not operate pressure

washer without filter properly installed.

Filter Screen

Fig. 14

13- ENG A08987

PRESSURE WASHER

1. Drain all water from high

pressure hose, coil it, and store

it in cradle of the pressure

washer handle.

2. Drain all water from spray gun

and wand by holding spray

gun in a vertical position with

nozzle end pointing down and

squeezing trigger. Store in gun

holder.

3. Store detergent injection hose

so it is protected from damage.

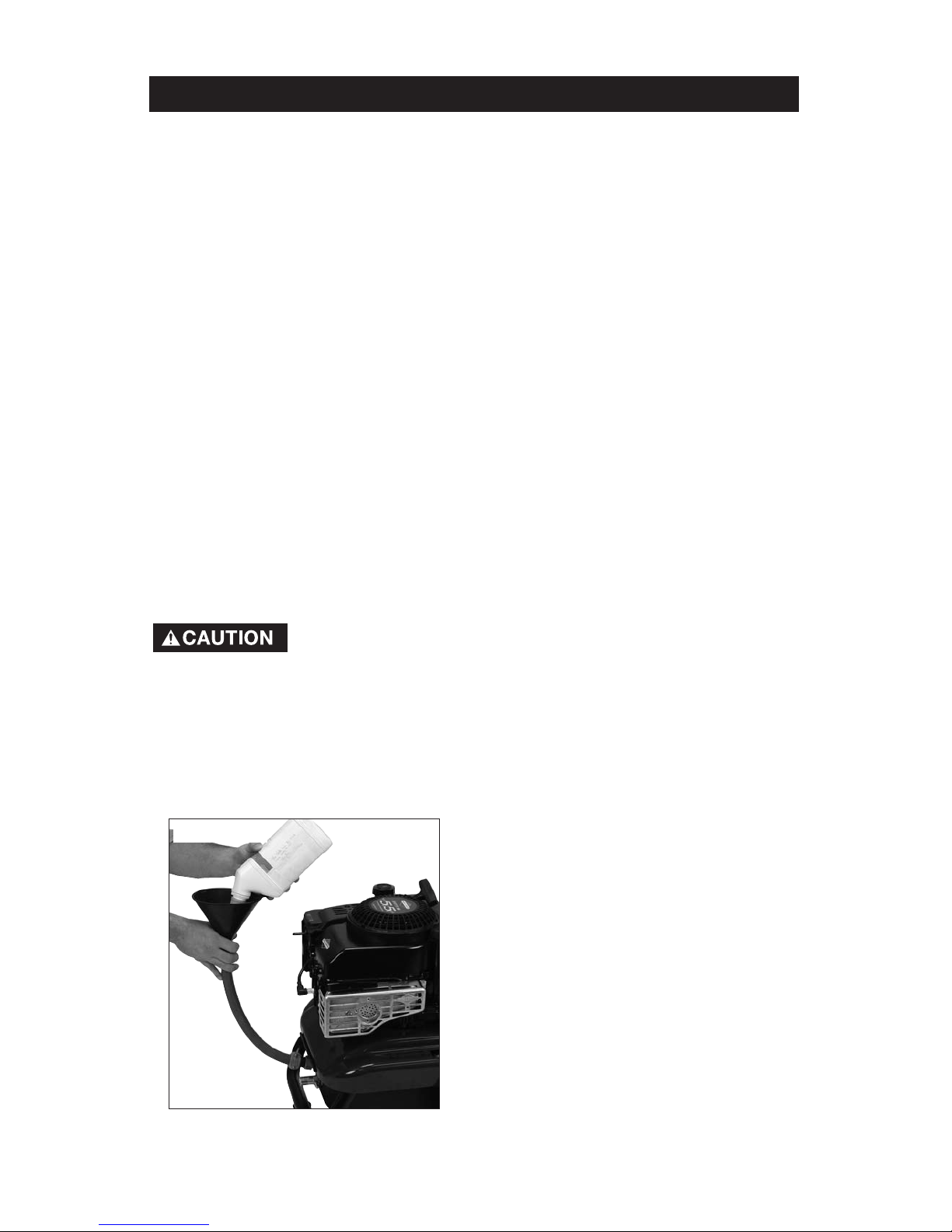

1. Obtain a funnel, 6 oz. of RV*

antifreeze, and 16–36" of garden

hose with a male hose connector

attached to one end.

Use only RV

antifreeze. Any

other antifreeze is corrosive and

can damage pump.

2. Disconnect spark plug wire.

3. Connect a hose to water supply

inlet of pump.

4. Add RV* antifreeze to hose as

shown in Fig.15.

STORAGE

ENGINE

Consult the Engine Owner's

Manual for the manufacturer's

recommendations for storage.

5. Pull engine starter rope slowly

several times until antifreeze

comes out of high pressure hose

connection of pump.

6. Remove hose from water supply

inlet.

7. Reconnect spark plug wire.

*Windshield washer fluid may also be

used

PUMP

The manufacturer recommends using

a pump protector/winterizer when

storing the unit for more than 30 days

and/or when freezing temperatures

are expected. If a pump protector/

winterizer is not available, RV*

antifreeze needs to be run through the

pump as outlined in the steps below.

NOTE: Using a pump protector/

winterizer or RV* antifreeze is to

provide proper lubrication to the

internal seals of the pump regardless

of temperature or environment.

Fig. 15

14- ENG

A08987

TROUBLE SHOOTING GUIDE

PROBLEM

Engine will

not start (see

Engine Manual

for further

engine

troubleshooting)

No or low

pressure

(initial use)

CAUSE CORRECTION

No fuel. Add Fuel.

Pressure builds up after two pulls

on the recoil starter or after initial

use.

Squeeze gun trigger to relieve

pressure.

Spark plug wire not attached. Attach spark plug wire.

Spray wand not in high pressure. See How to Use Spray Wand

instructions in the Operation

Section.

Low water supply. Water supply must be at least 5

GPM @ 20 PSI.

Leak at high pressure hose fitting. Repair leak. Apply sealant tape

if necessary.

Nozzle obstructed. See Nozzle Cleaning instructions

in the Maintenance section.

Water filter screen clogged. Remove and clean filter.

Air in hose. Turn off the engine, then the

water supply. Disconnect the

water supply from the pump inlet

and turn the water supply on

to remove all air from the hose.

When there is a steady stream

of water present, turn water

supply off. Re-connect water

supply to pump inlet and turn on

water supply. Squeeze trigger to

remove remaining air

High pressure hose is too long. Use high pressure hose under

100 feet.

Choke lever in the "Choke"

position on a "hot" engine or an

engine that has been exposed to

thermal heat for a long period of

time.

Move choke lever to the "No

Choke" position.

Choke lever in the "Choke" position. Move choke lever to the "No

Choke" position.

Choke lever in the "No Choke"

position.

Move choke lever to the "Choke"

position.

Throttle control lever is not in the

"Fast" position.

Move throttle control lever to the

"Fast" position.

15- ENG A08987

Water

leaking at

pump

Water leaking

at gun/

spray wand

connection

No or low

pressure

(after period

of normal

use)

PROBLEM CAUSE CORRECTION

Spray wand not in low pressure. See How to Use Spray Wand

paragraph in the Operation

Section.

Screen on end of detergent

injection hose not in cleaning

solution.

Clean filter.

Detergent or cleaning solvent too

thick.

Dilute detergent or cleaning

solvent. Detergent or cleaning

solvent should have the same

consistency as water.

Pressure hose is too long Lengthen water supply hose

instead of high pressure hose.

Detergent/cleaning solvent build-up

in detergent injector system.

Have parts cleaned or replaced

by certified mechanic.

Worn seal or packing

Call: 1-866-4SIMONIZ (1 866 474 6664)

Worn or obstructed valves.

Call: 1-866-4SIMONIZ (1 866 474 6664)

Worn unloader piston.

Call: 1-866-4SIMONIZ (1 866 474 6664)

Check and replace.

Loose hose connection.

Loose connections.

Tighten.

Piston packings worn.

Call: 1-866-4SIMONIZ (1 866 474 6664)

Worn or broken o-rings.

Call: 1-866-4SIMONIZ (1 866 474 6664)

Pump head or tubes damaged

from freezing.

Call: 1-866-4SIMONIZ (1 866 474 6664)

Will not draw

detergent/

cleaning

solvent

Make sure end of detergent

injection hose is fully submerged

into cleaning solution.

Filter on end of detergent injection

hose clogged.

Worn or broken o-ring.

Tighten.

Nozzle obstructed. See Nozzle Cleaning paragraph in

the Maintenance section for the

correct procedure.

Pump

Pulsates

16- ENG

A08987

WARRANTY

Engine Warranty

The first year of the engine warranty is the responsibility of Briggs & Stratton®

Corporation. For complete details, please refer to the Briggs & Stratton®

Operating & Maintenance Instructions.

For the second year of engine warranty, please call 1-866-4SIMONIZ

(1 866 474 6664).

Gas Powered Pressure Washer Warranty

This Simoniz product carries a two (2) year repair warranty against defects in

workmanship and materials. This product is not guaranteed against wear or

breakage due to misuse and/or abuse. Hose, gun, wand and accessories carry

a ninety (90) day warranty against defects in workmanship and materials.

The warranty commences on the date of purchase. The warranty herein is

expressly conditioned upon the customer's compliance with all precautions and

instructions contained within the Operator's Manual.

The warranty is void if any devices or accessories, other than those distributed

or recommended by Trileaf Distribution, are attached to or connected with the

equipment in such a manner that the original factory construction is altered.

Warranty is void if repairs are attempted by anyone other than an Authorized

Service Centre. For an Authorized Service Centre nearest you, please call

1-866-4SIMONIZ (1 866 474 6664).

This warranty shall not apply to any problem which is due to misuse, neglect,

accident, abuse, improper handling, freezing, normal wear and tear, use of

improper detergents/chemicals, or non-compliance with precautions and

instructions contained within the Operator's Manual. Warranty is void if the

pressure washer is used for commercial or industrial purposes. This warranty is

non-transferable.

The liability of Trileaf Distribution is limited to repair of the product and/or

replacement of parts and is given to the purchaser in lieu of all other remedies

including incidental and consequential charges. There are no expressed

warranties other than those specified herein.

Briggs & Stratton is a registered trademark used under licence by Trileaf

Distribution.

Part No. A08987 Rev. 0 11/05/04

IMPORTANT

Vous devez lire toutes les instructions et vous assurer de bien les comprendre

avant d'utiliser le pulvérisateur.

Guide d'utilisation

Table des matières

Définitions des symboles de sécurité . . . .2

Consignes de sécurité . . . . . . . . . . . . . .2–5

Fiche technique. . . . . . . . . . . . . . . . . . . . . .6

Contenu de la boîte . . . . . . . . . . . . . . . . . .6

Instructions d'assemblage . . . . . . . . . . . . .6

Ne retournez pas cet article chez le détaillant.

Si vous avez des questions, composez le 1 866 474-6664.

Utilisation . . . . . . . . . . . . . . . . . . . . . . . .7–11

Entretien. . . . . . . . . . . . . . . . . . . . . . . .11–12

Entreposage . . . . . . . . . . . . . . . . . . . . . . .13

Guide de dépannage . . . . . . . . . . . . .14–15

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Pulvérisateur haute pression à essence

S2350

Écrivez les renseignements ci-dessous et attachez votre reçu de caisse ici.

Date d'achat : ______________________ No de série : ______________

Pour prolonger la vie utile du pulvérisateur et éviter qu’il surchauffe, ne le laissez

pas tourner au ralenti lorsque vous ne vous en servez pas.

2- FR

A08987

CONSIGNES DE SÉCURITÉ IMPORTANTES

N'utilisez pas le pulvérisateur tant que vous n'avez pas lu

et compris les consignes de sécurité et les instructions

d'utilisation et d'entretien du guide d'utilisation du pulvérisateur et de celui du moteur.

RISQUE D'INCENDIE OU D'EXPLOSION

CE QUI PEUT SE PRODUIRE PRÉCAUTIONS À PRENDRE

CONSERVEZ CES INSTRUCTIONS

DÉFINITIONS DES SYMBOLES DE SÉCURITÉ

Identifie des situations

dangereuses qui

causeront des blessures corporelles

sérieuses ou la mort.

Identifie des

situations

potentiellement dangereuses qui pourraient

causer des blessures corporelles sérieuses

ou la mort.

Identifie des situations

potentiellement

dangereuses qui pourraient causer des

blessures corporelles mineures.

Lorsqu'utilisé sans

symbole d'alerte,

le mot attention identifie des situations

dangereuses qui pourraient endommager le

pulvérisateur.

Le présent guide contient des renseignements que vous devez bien comprendre pour assurer

VOTRE SÉCURITÉ et LE BON FONCTIONNEMENT DE L'APPAREIL. Veuillez prendre le

temps de lire le guide et portez une attention particulière aux symboles suivants.

• Des objets placés contre le pulvérisateur

ou à proximité de ce dernier peuvent

nuire à la ventilation du moteur et le

faire surchauffer. Les objets en question

pourraient même prendre feu.

• N'utilisez jamais le pulvérisateur dans un

milieu où il y a des broussailles ou des

liquides et des matériaux inflammables.

• La chaleur du silencieux peut

endommager les surfaces peintes,

faire fondre tout matériau sensible à la

chaleur (plastique, caoutchouc, vinyle) et

endommager les plantes.

• Assurez-vous qu'il y a toujours au moins

quatre pieds d'espace libre autour du

pulvérisateur durant l'utilisation.

• L'essence et ses vapeurs peuvent être

enflammées par une cigarette, un arc

électrique, des gaz d'échappement et

certaines pièces chaudes du moteur, telles

que le silencieux.

• Éteignez le moteur du pulvérisateur et

laissez-le refroidir avant de remplir le

réservoir d'essence.

• Soyez prudent lorsque vous remplissez

le réservoir pour éviter les déversements.

Avant de faire démarrer le moteur du

pulvérisateur, éloignez ce dernier de

l'endroit où vous avez rempli le réservoir.

• L'essence se dilate dans le réservoir sous

l'effet de la chaleur, ce qui peut entraîner

un déversement et accroître les risques

d'explosion et d'incendie.

• Laissez toujours au moins 1/2 po

d'espace libre dans le réservoir pour

permettre la dilatation du carburant.

• L'utilisation du pulvérisateur dans un

milieu explosif peut entraîner un incendie. • Utilisez le pulvérisateur et remplissez le

réservoir dans un endroit bien aéré et

dégagé. Assurez-vous qu'il y a à proximité

un extincteur convenant aux feux

d'essence.

3- FR A08987

RISQUE D'INTOXICATION PAR INHALATION

CE QUI PEUT SE PRODUIRE PRÉCAUTIONS À PRENDRE

RISQUE D'INCENDIE OU D'EXPLOSION (suite)

CE QUI PEUT SE PRODUIRE PRÉCAUTIONS À PRENDRE

RISQUE DE BLESSURES CORPORELLES

CE QUI PEUT SE PRODUIRE PRÉCAUTIONS À PRENDRE

• Du carburant qui n'est pas rangé

adéquatement peut prendre feu. Le

carburant est aussi très dangereux s'il

est manipulé par des enfants ou des

personnes inexpérimentées.

• Conservez le carburant dans un contenant

homologué, et rangez ce dernier dans un

endroit sûr, éloigné du milieu de travail. .

• L'utilisation d'acides, de poisons,

d'insecticides, de produits chimiques

toxiques ou corrosifs et de tout solvant

inflammable avec le pulvérisateur

peut entraîner de sérieuses blessures

corporelles ou même la mort.

• N'utilisez jamais le pulvérisateur pour

vaporiser des liquides inflammables.

N'utilisez le pulvérisateur qu'aux fins pour

lesquelles il est conçu.

• L'inhalation des gaz d'échappement peut

causer de sérieuses blessures ou même

entraîner la mort.

• Utilisez le pulvérisateur dans un endroit

bien aéré. Évitez les endroits clos comme

le garage, le sous-sol, etc.

• N'utilisez jamais le pulvérisateur dans un endroit

où il y a des personnes ou des animaux.

• Certains nettoyants contiennent des

substances qui peuvent causer des lésions

aux yeux, à la peau et aux poumons.

• N'utilisez que des nettoyants conçus pour

les pulvérisateurs, et suivez les instructions

du fabricant. N'utilisez jamais d'eau de

javel ni aucune autre substance corrosive.

• Le jet du pulvérisateur est assez puissant

pour pénétrer la chair humaine et causer

de sérieuses blessures qui pourraient

donner lieu à une amputation. Le liquide

qui fuit du tuyau et des raccords du

pulvérisateur peut aussi pour pénétrer

la chair humaine. NE TRAITEZ JAMAIS

L'INJECTION DU LIQUIDE SOUS LA

PEAU COMME UNE SIMPLE COUPURE.

Consultez un médecin sans tarder !

• Ne mettez jamais les mains devant la

buse du pulvérisateur.

• Ne dirigez jamais le jet du pulvérisateur

vers vous ni vers aucune autre personne.

• Assurez-vous que le tuyau est en bon

état et que les raccords sont bien serrés.

Ne tenez jamais le tuyau ni les raccords

durant l'utilisation.

• Assurez-vous que le tuyau n'entre jamais

en contact avec le silencieux.

• Ne raccordez jamais le tuyau ni les

raccords et ne les débranchez jamais

lorsque l'appareil est sous pression.

• Vous risquez de vous blesser si vous

tentez de démonter ou d'entretenir

le pulvérisateur sans d'abord le

dépressuriser.

• Pour dépressuriser le pulvérisateur,

éteignez le moteur, coupez l'alimentation

en eau et appuyez sur la gâchette de

la lance jusqu'à ce que l'eau cesse de

couler.

• N'utilisez qu'un tuyau et des accessoires

dont la pression nominale est supérieure

à celle du pulvérisateur.

4- FR

A08987

RISQUE DE CHOCS

ÉLECTRIQUES

CE QUI PEUT SE PRODUIRE PRÉCAUTIONS À PRENDRE

RISQUE DE BRÛLURES

CE QUI PEUT SE PRODUIRE PRÉCAUTIONS À PRENDRE

RISQUE DE BRÛLURES

CHIMIQUES

CE QUI PEUT SE PRODUIRE PRÉCAUTIONS À PRENDRE

RISQUE DE DOMMAGES MATÉRIELS ET DE

BLESSURES CORPORELLES

CE QUI PEUT SE PRODUIRE PRÉCAUTIONS À PRENDRE

• N'utilisez jamais le pulvérisateur pour

vaporiser un acide, de l'essence, du

kérosène ni aucune autre substance

inflammable. N'utilisez que des nettoyants

domestiques recommandés pour les

pulvérisateurs.

• Portez des vêtements protecteurs et des

lunettes de sécurité.

• L'utilisation d'acides, de poisons,

d'insecticides, de produits chimiques

toxiques ou corrosifs et de tout solvant

inflammable avec le pulvérisateur

peut entraîner de sérieuses blessures

corporelles ou même la mort.

• Il y a risque de choc électrique si le jet

du pulvérisateur est dirigé vers une prise

de courant ou un interrupteur, ou vers un

appareil sous tension.

• Débranchez tout appareil électrique

avant de le nettoyer et ne dirigez jamais

le jet vers une prise de courant ou un

interrupteur.

• Vous pouvez vous brûler si vous touchez

les surfaces chaudes du système

d'échappement du moteur.

• Durant l'utilisation, assurez-vous de

ne toucher que les commandes du

pulvérisateur. Tenez les enfants à l'écart,

car ils ne pourraient apprécier les dangers

inhérents du pulvérisateur.

• Lorsque vous transportez le pulvérisateur

dans un véhicule ou une remorque, de

l'essence ou de l'huile pourrait fuir et

provoquer un incendie, ou endommager

le tapis et les surfaces peintes et autres

du véhicule. Les vapeurs d'essence

pourraient aussi vous intoxiquer si vous

les respirez.

• Si le système d'alimentation du

pulvérisateur est muni d'une valve

d'arrêt, fermez-la avant de transporter

le pulvérisateur. S'il n'y a pas de valve

d'arrêt, videz le réservoir d'essence

et transportez le carburant dans un

contenant homologué. Pour éviter

qu'une fuite d'huile endommage le

véhicule, mettez un tapis protecteur

sous le pulvérisateur durant le transport.

Sortez le pulvérisateur du véhicule dès

que vous arrivez à destination.

Table of contents

Languages: