Simpsons SC213 User manual

CAPTAIN 280 4WD

Pioneer of The Mini Tractor

ENGINE SERVICE MANUAL (SC213)

SIMPSONS

DIESEL ENGINES

SC213 - Tractor Application

WITH

MECHANICAL FUEL INJECTION PUMP

PROVISIONAL

A MEMBER OF THE AMALGAMATIONS GROUP

861/862, Anna Salai, Chennai - 600 002.

2

SC213 Diesel Engines

To ensure the best results from your engine and

to safeguard your own guarantee, fit, only genuine

SIMPARTS

Title : SC213 Workshop Manual - Tractor Application.

1st Issue : March, 2015

Published by : Service Department, Simpson & Co. Ltd., Chennai - 2. INDIA

Every effort is made to ensure that the information

contained in this book is correct at the date of publication

but due to continuous developments, the manufacturers

reserve the right to alter the specification without notice.

3

SC213 Diesel Engines

This manual is designed to be of assistance to

all personnel concerned with the maintenance

and overhaul of the SIMPSONS Diesel Engine.

It presents a complete and detailed description

of the engine, together with precise instruction

on servicing and overhaul procedure and

dimensions which should be closely followed

when overhauling any part of the engine to the

Manufacturers standards.

Effective maintenance can only be carried out if

thepersonnelconcernedarefullyconversantwith

the various components of the engine. Before

maintenance operations are commenced, this

manual should be carefully studied, and it should

at all times be kept where it will be needed in the

FOREWORD

workshop.

A School of Instruction is maintained at

our Product Training Centre. For Details Contact

Service Department, M/s. Simpson & Co. Ltd.,

Chennai 600 002. INDIA

ENGINE PARTS

WheneverpartsareorderedforSIMPSONSEngine,

it is essential that the fullest information possible

is given, always quote the engine number, type of

application and where possible the part number

and description.

4

SC213 Diesel Engines

CONTENTS

Section Description Page No.

A GENERAL INFORMATION … 6

B ENGINE VIEW … 7

ENGINE NUMBER LOCATION … 9

C TECHNICAL DATA … 10

MANUFACTURING DATA AND DIMENSIONS … 11

D OPERATION AND MAINTENANCE … 17

E PREVENTIVE MAINTENANCE … 19

F FUEL SYSTEM … 25

G COOLING SYSTEM – WATER PUMP … 34

H FRONT OIL SEAL … 36

I FLY WHEEL AND REAR END OIL SEAL … 41

J BALANCER UNIT AND OIL PUMP … 43

K CYLINDER HEAD … 46

L TIMING CASE AND DRIVE … 54

M PISTONS AND CONNECTING RODS … 57

N CRANKSHAFT AND MAIN BEARINGS … 61

O CYLINDER BLOCK AND LINERS … 64

P LUBRICATING SYSTEM … 65

APPROVED LUBRICATING OILS … 66

Q ELECTRICAL EQUIPMENT … 67

R TROUBLE SHOOTING … 68

S SERVICE TOOLS … 86

5

SC213 Diesel Engines

SPECIAL FEATURES

Cylinder Block with Integral Housing and Timing case

Cylinder Head with Integral Inlet Manifold

Single side Servicing

Crankshaft with Crankpins at the same side

Balancer shaft for better balancing of unbalanced masses

SC 213 engines provide a very high backup torque and

an excellent fuel economy with low emission levels.

6

SC213 Diesel Engines

SAFETY

The safety measures that always should be performed in

order to avoid risks that is always present.

All servicing normally be carried out with the engine

stationary.

Do not approach the running engine with loose cloth

or long hair.

Be careful of hot surfaces.

Do not open the radiator filler cap when the engine is hot.

Avoid skin contact with oil, fuel or chemicals that can

cause burn. Long term contact with oil can lead to the

skin problem.

Run the engine only in a well-ventilated area.

When lifting the engine use the lifting eyes that are fitted

to the engine.

Never work alone when removing heavy parts.

When cleaning the engine with high-pressure water,

never direct the jet at seals, rubber hoses or electrical

components.

Always prevent diesel or oil from contacting rubber parts

or tubing

Caution: Warns of a risk of injury, serious damage to

the product or serious malfunctions could occur if the

instruction is not followed.

Important: Is used to draw attention to things that could

cause damage to or malfunction of the product.

Note: It is used to draw attention to important information

to facilitate procedure or handling.

TOOLS AND MEASURING EQUIPMENT

Be sure that all necessary tools and equipments are

available before starting work.

Use special tools where they are specified.

Never drop the tools

Use correct tools as specified.

REMOVAL OF PARTS:

First find the cause of the problem and then determine

whether removal or disassembly is required before

starting the job.

INSPECTION OF PARTS:

Eachpartwhen removedshould becarefully inspectedfor

malfunction, deformation, damage and other problems.

All disassembled parts required for reassembling should

be carefully stored.

Ensure to separate and correctly identify the parts to be

replaced from those that will be used again.

CLEANING OF PARTS FOR REUSE:

All parts to be used again should be carefully and

thoroughly cleaned by an appropriate method.

PARTS

When replacing parts, use genuine SIMPSON parts.

Oil seals, Gaskets, O-rings, Lock washers, split pins and

plastic nuts should always be replaced with new ones.

Standardvaluessuchas torqueandadjustments mustbe

strictly observed in the reassembly of all parts.

FITMENT

Use correct tools, gauges and testers for correct fitment

of the parts to standard value.

ELECTRICAL SYSTEM

Be sureto disconnectthebattery cablesfromthe negative

terminal of the battery

Never pull on the wires when disconnecting connectors.

Section A

GENERAL INFORMATION

7

SC213 Diesel Engines

Section B

ENGINE VIEWS

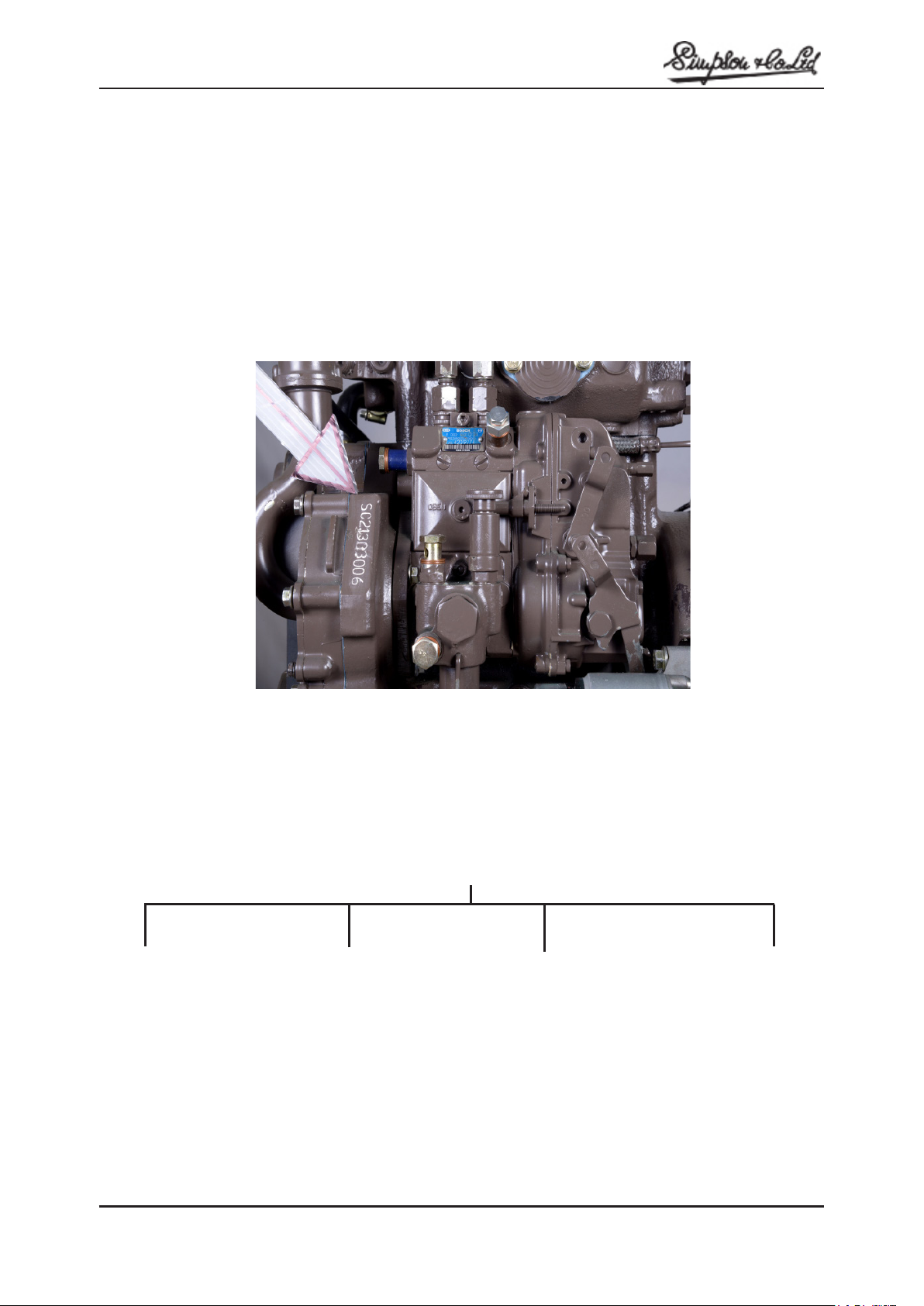

F.I.P SIDE VIEW

FRONT VIEW

8

SC213 Diesel Engines

ENGINE VIEWS

EXHAUSTSIDEVIEW

REAR VIEW

9

SC213 Diesel Engines

Engine number is stamped on the F.I.P side of the engine on the Timing Case .

When requesting information regarding the engine, the complete engine number should be quoted.

SC213 03006

ENGINE NUMBER LOCATION

SC-Simpsons

Compact

2–No. of

Cylinders

03006

Engine Sl.No.

13–1.29 ltrs (Cube

Capacity)

Note : IF THE ENGINE NUMBER REACHES 99999,ONE DIGIT WILL BE REPLACED BY LETTER “A” AS SHOWN A00001.

When requesting information regarding the engine, the complete engine number should be quoted.

10

SC213 Diesel Engines

Section C

TECHNICAL DATA

Engine Type : 2 Cylinder. 4 Stroke. Inline Water Cooled

Aspiration : Natural

Combustion : Direct Injection

Bore (Nominal dia.) : 3.740 inch (95.0 mm)

Stroke : 3.58 inch (91 mm)

Cubic Capacity : 78.7 cu.inch (1.29 Lts.)

Compression ratio : 18.3 : 1

Rotation : Anti-clock wise from the flywheel end

Firing order : 1, 2

Valve Tip Clearance : 0.006 inch (0.15 mm) inlet and exhaust

Atomiser setting pressure : 250 bar (6 Spray Nozzle)

Inlet valve opens : 12° B.T.D.C.*

Exhaust valve closes : 12°A.T.D.C.**

Total inlet open period : 232°

Total exhaust open period : 236°

Fuel Injection Pump : Bosch inline, flange mounted, pressure feed

lubrication from engine, mechanical governor with

fine adjusting device.

Injection timing : 14° ± 1° B.T.D.C

When No.1 piston at TDC compression stroke.

Fuel feed pump : Integrated feed pump driven by F.I.P camshaft

Application : Tractor - (TREM IIIA)

Engine Rating : 25 HP @ 2500 RPM

APPROXIMATE ENGINE WEIGHTS :

Basic weight (with starter motor & flywheel) : Approximate 148 kg

ENGINE DIMENSION :

Height :31.90 inch/ (810 mm). Length: 30.62 inch (778 mm). Width: 20.00 inch (508 mm)

* B.T.D.C. – Before Top Dead Center ** A.T.D.C. – After Top Dead Center

11

SC213 Diesel Engines

MANUFACTURING DATA AND DIMENSIONS

The following data of clearances and tolerances are given as a guide for personnel engaged in major overhauls and the

figures are those used in the factory for production purposes.

Cylinder Block

Height of cylinder block (Top to bottom faces) … 12.498 / 12.501 inch (317.45 / 317.55 mm)

Parent bore dia. for Cylinder Liner … 3.740 / 3.741 inch (95.00 / 95.02 mm)

Main bearing parent bore … 2.440 / 2.442 inch (62.00 / 62.03 mm)

No. 1 Bore for Camshaft … 1.930 / 1.931 inch (49.025 / 49.050 mm)

No. 2 Bore for Camshaft … 1.939 / 1.949 inch (49.25 / 49.50 mm)

No. 3 Bore for Camshaft … 1.939 / 1.949 inch (49.25 / 49.50 mm)

Balancer Shaft Bore Dia 1 and 2 ... 1.023 / 1.024 inch (26.00 / 26.02 mm)

Pistons :

Type … Aluminum alloy Piston with re-entrant bowl.

Offset of combustion bowl in piston crown should

be on the FI Pump side while assembling piston in

engine. An arrow mark is stamped on piston top

surface for identification. Arrow should face front of

Engine.

Piston Height in relation to cyl. block top face … 0.0138 inch (0.35 mm) - Above block surface /

0.002 inch ( 0.05 mm) - Below block surface

Bore Dia. for Gudgeon Pin … 1.1025 / 1.1027 inch (28.005 / 28.01) mm

Top ring Groove Width … 0.102 / 0.103 inch (2.59 / 2.61 mm)

2nd ring Groove Width … 0.1 / 0.100 inch (2.54 / 2.56 mm)

3rd ring Groove Width … 0.119 / 0.120 inch (3.03 / 3.05 mm)

Piston Rings

Top Compression … Chromium inlaid, cast iron ring)

2nd Compression … Cast Iron. Taper land

3rd Oil Control … Conformable oil control ring

Piston Ring Width

Top and 2nd ring width ... 0.097 / 0.098 inch (2.47 / 2.49 mm)

3rd ring width … 0.117 / 0.118 inch (2.97 / 2.99 mm)

Ring clearance in Piston Groove :

Top ring clearance in Groove … 0.0039 / 0.0055 inch ( 0.10 / 0.14 mm)

2nd ring clearance in Groove … 0.0019 / 0.0035 inch (0.05 / 0.09 mm)

3rd ring clearance in Groove … 0.0015 / 0.0031 inch (0.04 / 0.08 mm)

Ring Gaps

Ring Gap – Top … 0.012 / 0.020 inch (0.30 / 0.50 mm)

Ring Gap – 2nd … 0.025 / 0.037 inch (0.65 / 0.95 mm)

Ring Gap – 3rd … 0.010 / 0.018 inch (0.25 / 0.45 mm)

12

SC213 Diesel Engines

NOTE : The ring gaps given above are for when checking in the unworn portion of the cylinder bore. When

checking ring gaps in a worn bore. 0.003’’ (0.08 mm) should be added to these ring gaps for every 0.011 inch

(0.03 mm) increase in bore diameter

Gudgeon Pin

Type … Fully Floating

Outside dia. of gudgeon pin … 1.102 / 1.1025 inch (27.995 / 28.00 mm)

Fit in piston boss … Transition

Clearance fit in Small end Bush … 0.0011 / 0.0019 inch (0.03 / 0.05 mm)

Small End Bush

Type … ci Steel Backed. Lead Bronze Lined

Outside Dia … 1.220 inch (31.00 mm)

Length … 1.378 inch (35.00 mm)

Inside Dia after reaming … 1.151 / 1.155 inch (29.35 /29.35 mm)

Connecting Rod

Type … “H” Section

Big end Parent Bore Dia … 2.008 / 2.0086 inch (51.006 / 51.019 mm)

Small end Parent Bore Dia … 1.220 / 1.221 inch (31.00 / 31.25 mm)

Big end Width … 1.244 / 1.248 inch (31.60 / 31.70 mm)

Big end side clearance on Crankpin … 0.012 / 0.020 inch (0.3 / 0.5 mm)

Length between bore centers … 5.825 / 5.827 inch (147.975 / 148.025 mm)

NOTE :The numbered side of connecting rod and cap should be on the fuel injection pump side.

Connecting Rod Bearings

Type … Pre-finished. Steel Backed low carbon steel

AluminumTin / Silicon

Inside Dia. (Big end bearing) … 1.949 / 1.950 inch (49.53 / 49.52 mm)

Bearing Running Clearance … 0.0015 / 0.003 inch (0.04 / 0.079 mm)

Recommended sizes in service … 0.010” (0.25 mm); 0.020” (0.51 mm); 0.030” (0.76 mm)

Crankshaft

Material ... Chromium molybdenum alloy steel forging.

Statically balanced. Main journals and crank pins

are induction hardened.

Main Journal Dia. (Std.) … 2.282 / 2.283 inch (57.98 / 58.00 mm)

Crank pin Dia. (Std.) … 1.889 / 1.890 inch (47.98 / 48.00 mm)

Main Journal length - Nos.1 … 1.311 / 1.326 inch (33.30 / 33.70 mm)

Main Journal Length – No.2 … 1.338 / 1.341 inch (34.01 / 34.08 mm)

Main Journal Length – No.3 … 1.330 / 1.346 inch (33.80 / 34.20 mm)

Crankpin length … 1.260 / 1.264 inch (32.00 / 32.10 mm)

Main Journal fillet radii Nos. 1 … 0.098 / 0.118 inch (2.50 / 3.00 mm)

Main Journal fillet radious No. 2 and 3 … 0.098 / 0.118 inch (2.50 / 3.00 mm)

Crankpin fillet radii … 0.098 / 0.118 inch (2.50 / 3.00 mm)

Surface finish (all Pins and Journals) … 0.4 microns (Maximum)

Crankshaft end Float … 0.003 / 0.006 inch (0.07 / 0.15 mm)

Crankshaft rear end Seal … Lip Type

Regrind Under sizes. Main Journal and Crank Pins … 0.010”(0.25mm);0.020”(0.51mm);0.030”(0.76mm)

13

SC213 Diesel Engines

NOTE: When regrinding the crank pin length should not exceed 1.5748 inch (40.00 mm) and the rear main

journal length should not exceed 1.8610 inch (47.27 mm) and Nos.2 and 4 main Journals width should not exceed

1.2275 inch (31.1785 mm) maximum. The maximum permissible undersize is 0.0299 inch (0.76 mm)

Crankshaft Thrust Washers

Type … Steel Back - Low carbon steel - 1.8 mm incl.

Aluminium Tin (or) Copper Lead

Position in engine … Cylinder Block Centre Main Bearing Housing

Thickness-Standard Size … 0.105 / 0.107 inch (2.67 / 2.72 mm)

Thickness-Oversize … 0.1283 / 0.1303 inch (3.26 / 3.31 mm)

NOTE : While locating the Thrust Washers ensure that the plain surface/Steel back is towards the block and the rear

main bearing cap.

Main Bearings

Type … Pre-finished. Steel Back low carbon steel.

AluminiumTin Silicon or Copper Lead

Inside Dia. (fitted) … 2.362 / 2.363 inch (60.02 / 60.03 mm)

Running clearance … 0.0015 / 0.003 inch (0.04 / 0.079 mm)

Recommended size in service … 0.010” (0.25 mm) ;0.020” (0.51 mm) ;0.030” (0.76 mm)

Camshaft

Type … Chilled cast iron

No. 1 Journal Dia. … 1.927 / 1.928 inch (48.95 / 48.975 mm)

No. 2 Journal Dia. … 1.927 / 1.928 inch (48.95 / 48.975 mm)

No. 3 Journal Dia … 1.927 / 1.928 inch (48.95 / 48.975 mm)

Running Clearance – All Camshaft Journals … 0.002 / 0.004 inch (0.05 / 0.10 mm)

Oil way for cam shaft lubrication … From main oil gallary to centre cam journal

Cam Lift - Inlet … 0.393 inch (10 mm)

- Exhaust … 0.393 inch (10 mm)

Camshaft end float … 0.004 / 0.014 inch (0.10 / 0.35 mm)

Cylinder Head

Cylinder head total height … 4.410 inch (112 mm)

Leak Test … 4 Bar for 1 minute

Valve seat angle … Inlet 45° / Exhaust 45°

Permissible cylinder head bow

Transverse and Longitudinal … 0.001 / 0.002 inch (0.03 / 0.05 mm)

Valve Layout ... E, I, E, I

NOTE : Valve stem seal (with Sintered metal insert) is fitted in both inlet and exhaust valves.

14

SC213 Diesel Engines

Inlet and Exhaust Valves

Valve Stem Dia (Inlet) … 0.3101 / 0.3095 inch (6.95 / 6.97 mm)

Valve Stem Dia. (Exhaust) … 0.3096 / 0.3090 inch (6.93 / 6.95 mm)

Clearance fit of valve in guide (Inlet) … 0.0004 / 0.0015 inch (0.01 / 0.04 mm)

Valve face Angle (Inlet) … 45°

Valve face Angle (Exhaust) … 45°

Valve depth above or below cylinder head face … 0.015 inch (0.4mm)

Valve head Dia. Inlet … 1.590 / 1.598 inch (40.40 / 40.60 mm)

Valve head Dia. Exhaust … 1.492 / 1.500 inch (37.90 / 38.10 mm)

Valve Spring

Free length … 1.968 inch (50 mm)

Fitted length … 1.102 inch (28 mm)

Load at fitted length … 250 N (25 kg)

Tappet

Outside Dia. of Shank … 1.061 / 1.063 inch (26.96 / 27.00 mm)

Rocker Shaft

Outside Diameter … 0.629 / 0.630 inch (15.976 / 15.984 mm)

Rocker Lever

Bush Bore Diameter … 0.787 / 0.788 inch (20.00 / 20.02 mm)

Running clearance of Bush on Shaft … 0.011 / 0.002 inch (0.022 / 0.048 mm)

Timing Gears

Crankshaft gear … 20 Teeth

Idler gear … 25 Teeth

Camshaft gear … 40 Teeth

Fuel Pump gear … 40 Teeth

Balancershaft gear … 20 Teeth

Camshaft Gear

Gear Bore Diameter … 0.944 / 0.945 inch (24.00 / 24.013 mm)

Clearance fit of Gear on Spigot … 0.000 / 0.0019 inch (0.00 / 0.05 mm)

Idler Gear and Hub

Bore Dia of gear … 1.025 / 1.026 inch (26.040 / 26.061 mm)

Diameter of hub … 0.984 / 1.024 inch (25.00 / 26.00 mm)

Clearance of gear on hub … 0.002 / 0.003 inch (0.040 / 0.082 mm)

Gear Hub Width … 0.659 / 0.661 inch (16.75 / 16.80 mm)

Bearing length of hub … 1.6019 / 1.5940 inch (40.69 / 40.49 mm)

Gear end-float … 0.002 / 0.006 inch (0.060 / 0.140 mm)

NOTE :The bore and faces of bushes should be finished to the specified dimensions by machining after pressing

the bushes in the gear bore.

15

SC213 Diesel Engines

Crankshaft Gear

Diameter of Bore … 1.4996 / 1.5011 inch (38.090 / 38.13 mm)

Spigot Dia of crankshaft … 1.5005 / 1.5000 inch (38.113 / 38.10 mm)

Transition fit of Gear on Crankshaft … 0.011 / 0.0015 inch (0.03 / 0.04 mm)

Fuel Pump Gear

Diameter of Bore … 48.035 /48.056 mm

Pump adaptor Dia. … 48.000 / 47.975 mm

Clearance fit of gear on spigot … 0.0039 / 0.0022 inch (0.100 / 0.056 mm)

Timing Gear Backlash

All Gears … 0.002 / 0.005 inch (0.06 / 0.14 mm) (min.)

Lubricating Oil Pump

Oil Pump type … Lobe type

Number of inner rotor lobes … 9

Number of outer rotor lobes … 10

Balancer Shaft end float ... 0.003 / 0.006 inch (0.075 / 0.150 mm)

Lubricating Oil Pump Clearances

Inner Lobe to Outer Lobe … 0.0005 / 0.0025 inch (0.01 / 0.06 mm)

Inner Lobe end clearance … 0.0015 / 0.003 inch (0.04 / 0.08 mm)

Outer Lobe end clearance … 0.0005 / 0.0025 inch (0.01 / 0.06 mm)

Outer Lobe to Pump Body … 0.011 / 0.013 inch (0.28 / 0.33 mm)

Lubricating Oil Pressure at maximum engine

speed and normal working temperature … 3.5 kgf/ cms²

Lubricating Oil Relief Valve

Type … Spring Loaded Plunger

Pressure Setting … 3.569 kgf / cm ²

Lubricating Oil Filter

Type … Spin on

Element … Replaceable Paper / Canister

By-pass Valve Setting … 12.94 / 17.06 psi (0.91 / 1.20 kg/ cm²)

Sump Capacity … 1.160 gal (4.391 lts). Sump capacity vary

according to application

Cooling System

Type … Water cooled

Coolant capacity–Engine only … 1.057 gal (4 lts). (approximate)

Thermostat

Type … Wax with bypass blanking

Opening temperature … 73° ± 2°C

Fully open … 83° ± 2°C

Water Pump

Type … Centrifugal

Pulley bore dia … 0.944 inch (24 mm)

Interference fit of pulley on shaft … 0.005 inch (0.121 mm)

Clearance between impeller blades and body ... 0.008 / 0.020 inch (0.2 / 0.5 mm)

Distance between impeller rear face to body … 3.929 inch (99.80 mm)

16

SC213 Diesel Engines

Fuel System

Fuel oil specification … Fuel Oil conform IS : 1460 / 2000 grade special

or Grade ‘A’

Fuel Filter Type … BOSCH single spin on with hand primer

Fuel Feed Pump … Plunger type flange mounted on cylinder block,

driven by engine cam shaft ecentric.

Fuel Injection Pump

Make … BOSCH

Type … Inline

Mounting … Flange mounted to engine timing case

Drive … Gear

Pump Rotation … Anti-clock wise (when viewed from fly wheel end)

Governor … Mechanical with fine adjusting device.

Starter Motor

Make … LUCAS TVS

Type … M70 12 Volts

No. of teeth on pinion … 10

Starter Cable Resistance … 0.0017 ohms maximum

Rotation … Clockwise when viewed from fly wheel end

Note : The above electrical data is general and can vary with individual application

17

SC213 Diesel Engines

Section D

OPERATION AND MAINTENANCE

PREPARATION FOR STARTING

Check the coolant level with radiator.

Check the oil level in engine sump.

Check the fuel oil level in the tank

Check the battery is fully charged and that all electrical

connections are properly made and all circuits in order.

STARTING THE ENGINE

Turn starter switch in clockwise direction to the “ON”

position and then to start position

As soon as the engine starts, release the switch to the

“ON” position.

TO STOP THE ENGINE

1.Pull the stop control knob and hold until the engine

ceases to rotate.

2. Push and ensure the stop control knob returns to the

run position.

3. Turn start switch to the ‘Off’ position.

Note: Where an electrical shut off solenoid is provided,

turn the start key to “Off” position to stop engine.

Always be sure that the starter pinion has stopped

revolving before re-engaging the starter.

RUNNING-IN PROCEDURE

It is not necessary to gradually run-in a new engine and

any prolonged light load running during the early life of

the engine and in fact prove harmful to the bedding in

of piston rings and liners.

Full load can be applied on a new engine as soon as the

engine is used, provided that the engine coolant is first

allowed to reach a temperature of at least 140oF (60oC).

POST-DELIVERY CHECKOVER

After a customer has taken delivery of his diesel engine, it

isadvisable, ageneral check-overof theengine becarried

out after the first 25 hours in service.

It is also recommended that the following procedure

be adopted where an engine has been laid up for a

considerable period before it is again put into service.

1.Drain lubricating oil sump and re-fill up to the full mark

on the dipstick with new clean oil (Do not overfill).

2. Renew the lubricating oil filter (canister).

3. Check external nuts for tightness.

4. Check/ adjust valve tip clearances to 0.15 mm (0.006’’

to inlet and exhaust valve in cold.

5. Check fuel pipes from tank to fuel injection pump for

leaks.

6. Check for lubricating oil leaks and rectify if necessary.

7. Check hose clips for tightness.

8. Check cooling system for leaks and inspect radiator

water level.

9. Check fan belt for tension.

10.Carryouttestto checkgeneralperformanceofengine.

11. Check engine mounting bolts for tightness.

12.Checkthe electricalequipmentsuch asrateofcharge,

effectiveness of connections and circuits, etc.

Thereaftermaintenanceperiods shouldbe inaccordance

with the instructions given. (Ref. Section E).

PRESERVATION OF LAID-UP ENGINES

It is recommended that the following procedure

be adopted and applied immediately the unit is

withdrawn from service:

1. Thoroughly clean all external parts of the engine.

2. Run the engine until well-warmed. Stop the engine

and drain lubricating oil from sump. Remove the oil filter.

3. Drain coolant from radiator and engine cylinder

block.

4. Replace the oil filter, fill sump to correct level

with clean, new lubricating oil or with a suitable

preservative fluid.

5. Remove atomisers and spray into cylinder bores

100 ml of lubricating oil divided between the

cylinders.

6. Turn engineslowly overcompressionand replace

atomisers.

7. Remove air cleaner intake pipe and Remove

exhaust pipe and seal opening in manifolds.

8. Disconnect battery and store in fully charged

condition. Before storing the battery, terminals

should be treated to prevent corrosion.

The fuel system be drained or charged with a suitable

preservative designed for the prevailing climatic

18

SC213 Diesel Engines

conditions or alternatively, it may be left primed with

normal fuel oil.

If the engine is laid for several months then the fuel oil

contained in the remainder of the fuel system should

also be dispelled and the fuel filter renewed, following

which the system may then be recharged with fresh

clean fuel oil.

Before starting, the engine should be cranked over by the

starter motor with the stop control in the ’off’ position

until oil pressure is recorded or the oil warning light is

extinguished. Do not rapidly accelerate the engine after

initial start; allow it to run at slow speed for approximately

two minutes to ensure good oil circulation before

accelerating to higher speeds.

Note: Where a preservative is used in the lubricating oil

sump, this should be drained off and replaced by normal

lubricant prior to restarting the engine at the end of the

storage period.

FROST PRECAUTIONS

Precautions against damage by frost should be taken if

the engine is to be left exposed to inclement weather

either by adequately draining the water system or where

this is not convenient an anti-freeze of reputable make

and incorporating a suitable corrosion inhibitor may be

used.

The coolant solution containing 25 per cent anti-

freeze manufactured to BS 3151 in water in a properly

maintained engine should maintain its anti-freeze and

anti-corrosive properties throughout the winter season

and in general, a safe life of 12 months may be

reasonably expected.

Remove the radiator pressure cap, drain the cooling

system by opening the radiator drain tap and the cylinder

block drain tap.

When draining the cooling system ensure that the engine

is in level.

Operatorsare advisedto takeprecautions whenoperating

in temperatures below freezing point:

1. Before starting the engine, turn the fan and water

pump by hand. If freezing has taken place, this

should free any ice formation.

2. If it is impossible to turn the pump by hand, the

radiator and engine should be filled with warm

water.

After an anti-freeze solution has been used, the cooling

system should be thoroughly flushed in accordance

with the manufacturer’s instructions before refilling with

normal coolant.

19

SC213 Diesel Engines

DAILY OR EVERY 8 HOURS WHICHEVER

OCCURS FIRST:

Keep Engine Clean.

Check level of coolant.

Check oil level in sump.

Check oil pressure.

Check for water in the fuel filter.

EVERY 250 HOURS OR 12 MONTHS:

Drain and renew lubricating oil.

Renew lubricating oil filter (canister).

Check drive belt tension.

Clean and Renew lubricating oil from wet type air cleaner.

Clean fuel lift pump pre-filter (where fitted).

Check engine for leakage of oil and water.

EVERY 500 HOURS OR TWO YEARS.

Check hoses and clips.

Check atomisers.

Check valve tip clearances.

Examine valve springs.

Inspect valve rocker shaft assembly for lubrication.

Clean and treat battery terminals.

Replace fuel filter element. (Spin on type).

EVERY 1,000 HOURS:

Drain fuel tank, remove and clean.

Flush radiator with clean water.

DRY TYPE AIR CLEANER MAINTENANCE

In extreme dust condition clean the air cleaner daily.

Check Air restriction indicator in air cleaner (when engine

is running).

1st Cleaning after 100 Hrs.

2nd cleaning after 200 Hrs.

Discard the element if found complete choked.

Main Outer Element can be cleaned twice only with

pressurised air (applying from inside to outside) before

replacement.

Safety cartridge/ inner element is to be replaced along

with the third fitment of Main outer Element.

Remove the dust every after 50 Hrs. from dust unloader

by press opening the lip.

Note : The interval of cleaning the air cleaner element

depends on operating conditions; therefore under

extremely dusty conditions, the time interval to be

shortened.

The correct maintenance of the air cleaner will help in

extend the life of the engine.

FUEL FILTERS MAINTENANCE

(Make: BOSCH , India)

Do not clean filter canister.

Drain filter bowls after every 125 hrs. of operation by

loosening sludge screws (wherever provided), until clean

fuel flows out.

Fuel filter single canister type spin on element should be

replaced after every 500 hours of operation.

Section E

PREVENTIVE MAINTENANCE

Table of contents