Singer Safety 491D Manual

Singer

491D

Sewing

Machine

Operator's

Guidebook

SINGER

INDUSTRIAL

PRODUCTS

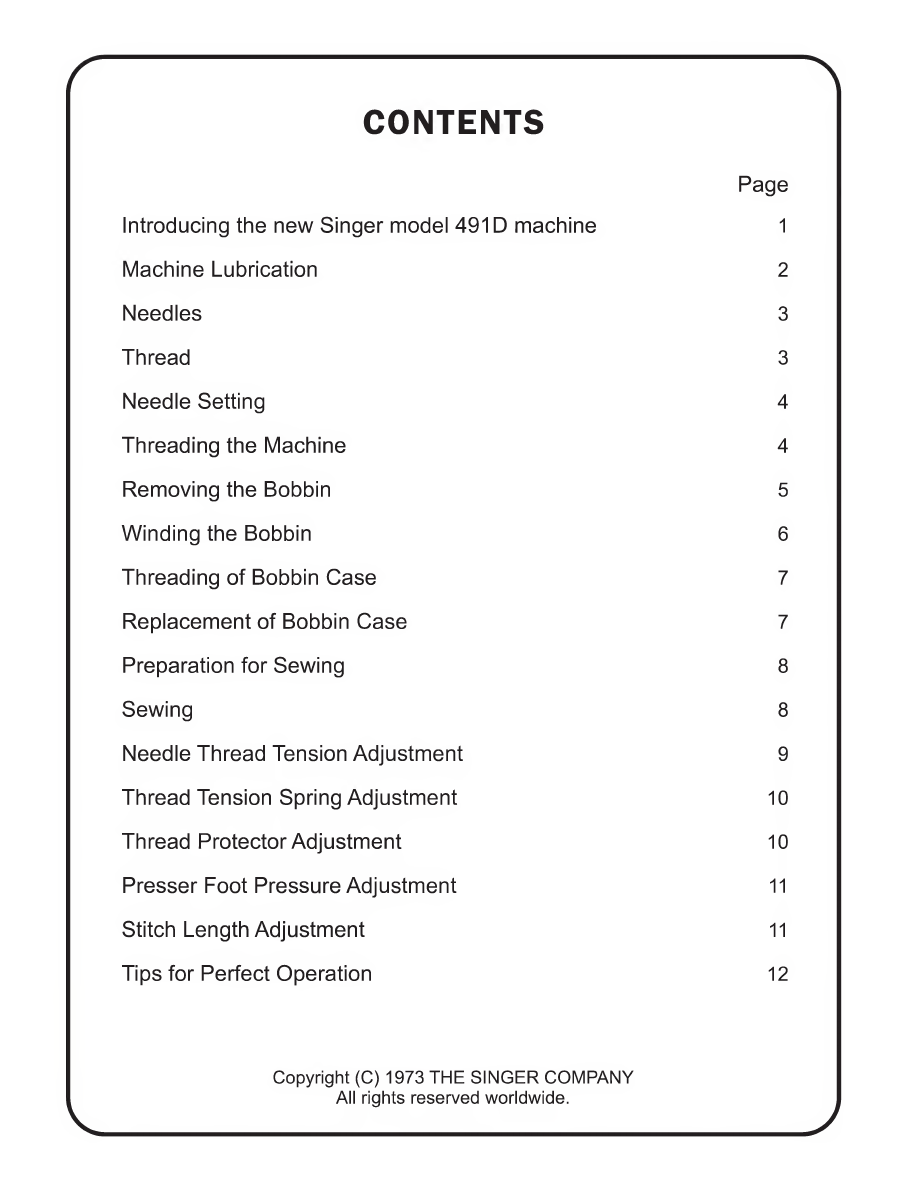

CONTENTS

Page

Introducing

the

new

Singer

model

491D

machine

1

Machine

Lubrication

2

Needles

3

Thread

3

Needle

Setting

4

Threading

the

Machine

4

Removing

the

Bobbin

5

Winding

the

Bobbin

6

Threading

of

Bobbin

Case

7

Replacement

of

Bobbin

Case

7

Preparation

for

Sewing

8

Sewing

8

Needle

Thread

Tension

Adjustment

9

Thread

Tension

Spring

Adjustment

10

Thread

Protector

Adjustment

10

Presser

Foot

Pressure

Adjustment

11

Stitch

Length

Adjustment

11

Tips

for

Perfect

Operation

12

V.

Copyright

(C)

1973

THE

SINGER

COMPANY

All

rights

reserved

worldwide.

J

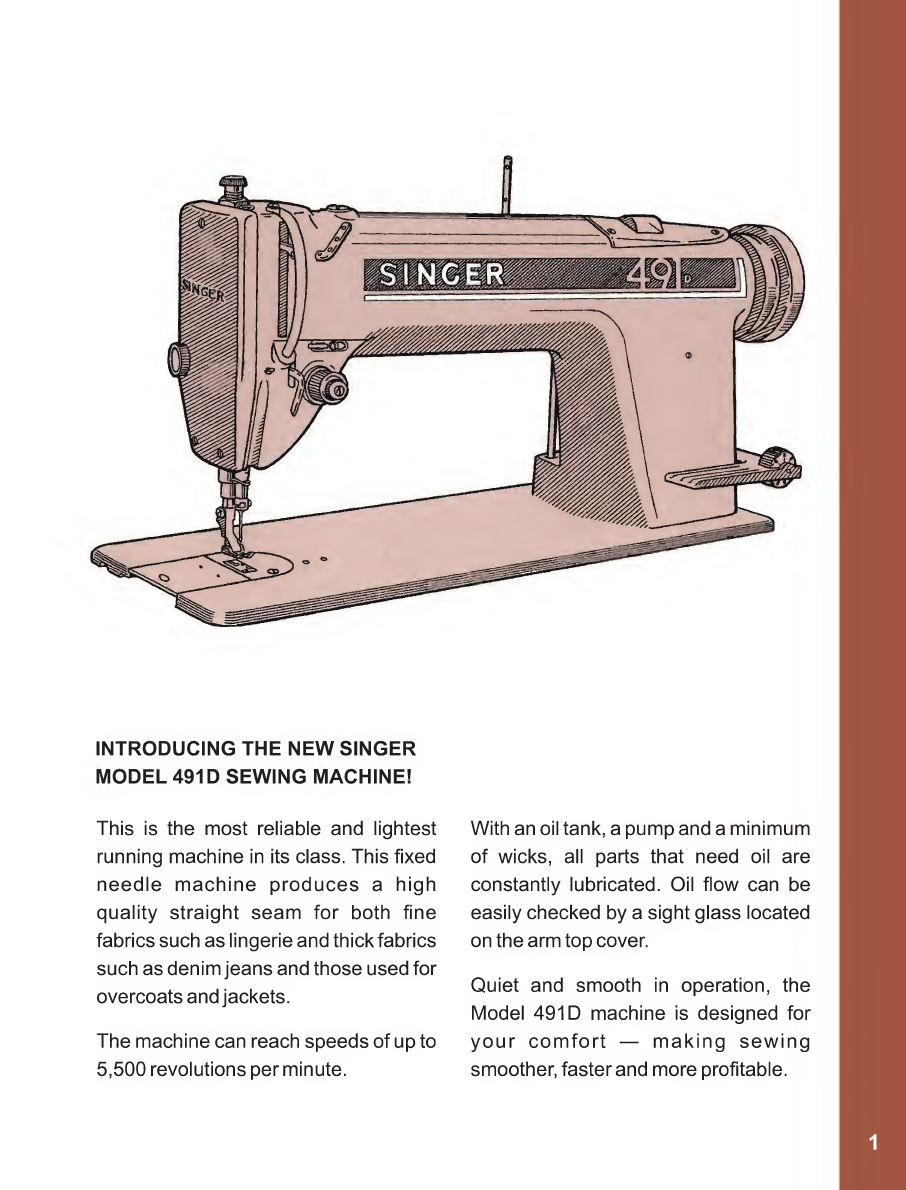

INTRODUCING

THE

NEW

SINGER

MODEL

491D

SEWING

MACHINE!

This

is

the

most

reliable

and

lightest

running

machine

in

its

class.

This

fixed

needle

machine

produces

a

high

quality

straight

seam

for

both

fine

fabrics

such

as

lingerie

and

thick

fabrics

such

as

denim

jeans

and

those

used

for

overcoats

and

jackets.

The

machine

can

reach

speeds

of

up

to

5,500

revolutions

per

minute.

With

an

oil

tank,

a

pump

and

a

minimum

of

wicks,

all

parts

that

need

oil

are

constantly

lubricated.

Oil

flow

can

be

easily

checked

by

a

sight

glass

located

on

the

arm

top

cover.

Quiet

and

smooth

in

operation,

the

Model

491D

machine

is

designed

for

your

comfort

—

making

sewing

smoother,

faster

and

more

profitable.

1

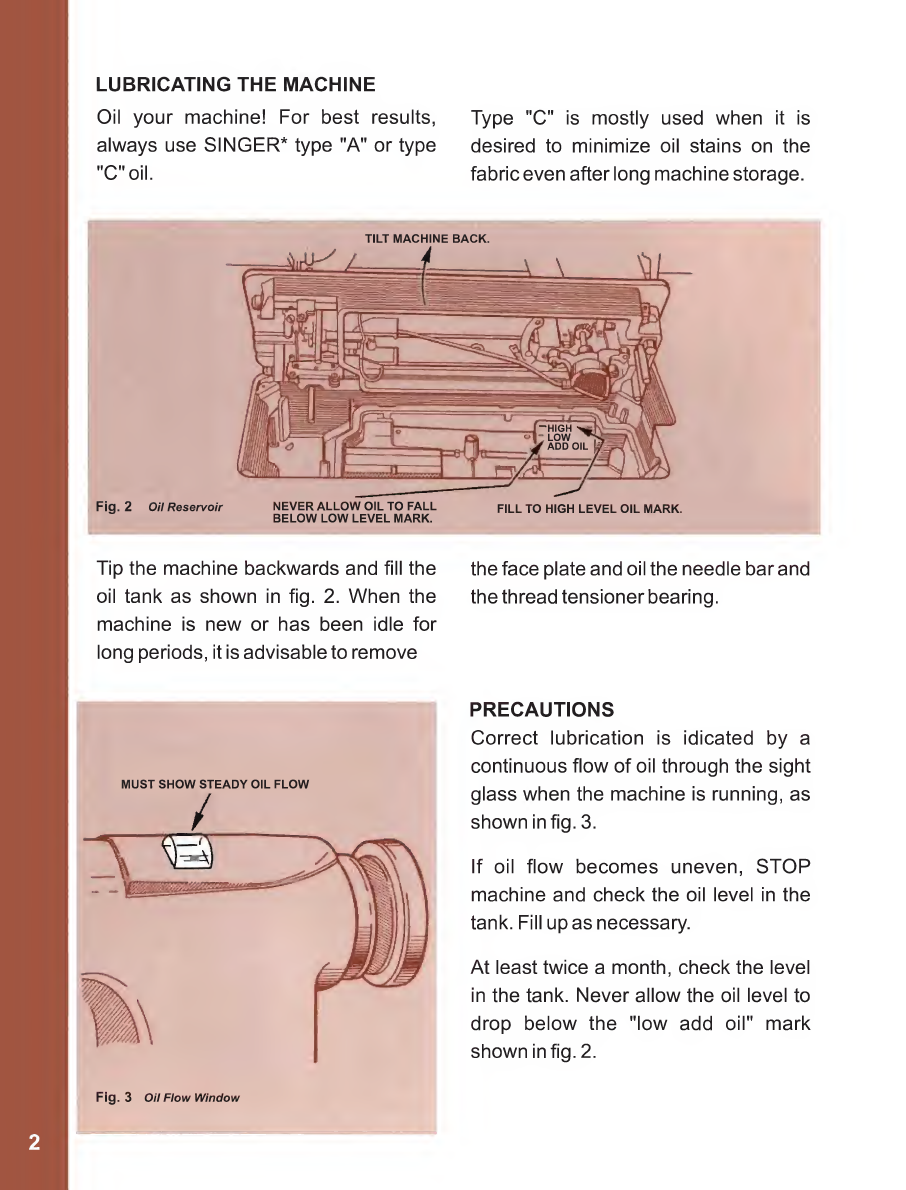

LUBRICATING

THE

MACHINE

Oil

your

machine!

For

best

results,

Type

"C"

is

mostly

used

when

it

is

always

use

SINGER*

type

"A"

or

type

desired

to

minimize

oil

stains

on

the

"C"

oil.

fabric

even

after

long

machine

storage.

Tip

the

machine

backwards

and

fill

the

oil

tank

as

shown

in

fig.

2.

When

the

machine

is

new

or

has

been

idle

for

long

periods,

it

is

advisable

to

remove

MUST

SHOW

STEADY

OIL

FLOW

/

the

face

plate

and

oil

the

needle

bar

and

the

thread

tensioner

bearing.

PRECAUTIONS

Correct

lubrication

is

idicated

by

a

continuous

flow

of

oil

through

the

sight

glass

when

the

machine

is

running,

as

shown

in

fig.

3.

If

oil

flow

becomes

uneven,

STOP

machine

and

check

the

oil

level

in

the

tank.

Fill

up

as

necessary.

At

least

twice

a

month,

check

the

level

in

the

tank.

Never

allow

the

oil

level

to

drop

below

the

"low

add

oil"

mark

shown

in

fig.

2.

Fig.

3

Oil

Flow

Window

NEEDLES

The

needles

you

use

directly

affect

the

quality,

strength

and

appearance

of

the

stitching

produced

by

your

machine.

That

is

why

the

use

of

SI

NGER

needles

is

so

important,

according

to

the

table

below:

NEEDLES

CATALOG

No.

CLASS

AND

VARIETY

SIZES

1901

135x7

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,21,22,

23

&

24

1955

A

bent

needle

will

cause

stitch

failures

A

needle

with

a

damaged

or

burred

tip

and

sewing

irregularity.

results

in

poor

work

finish

and

may

damage

the

fabric.

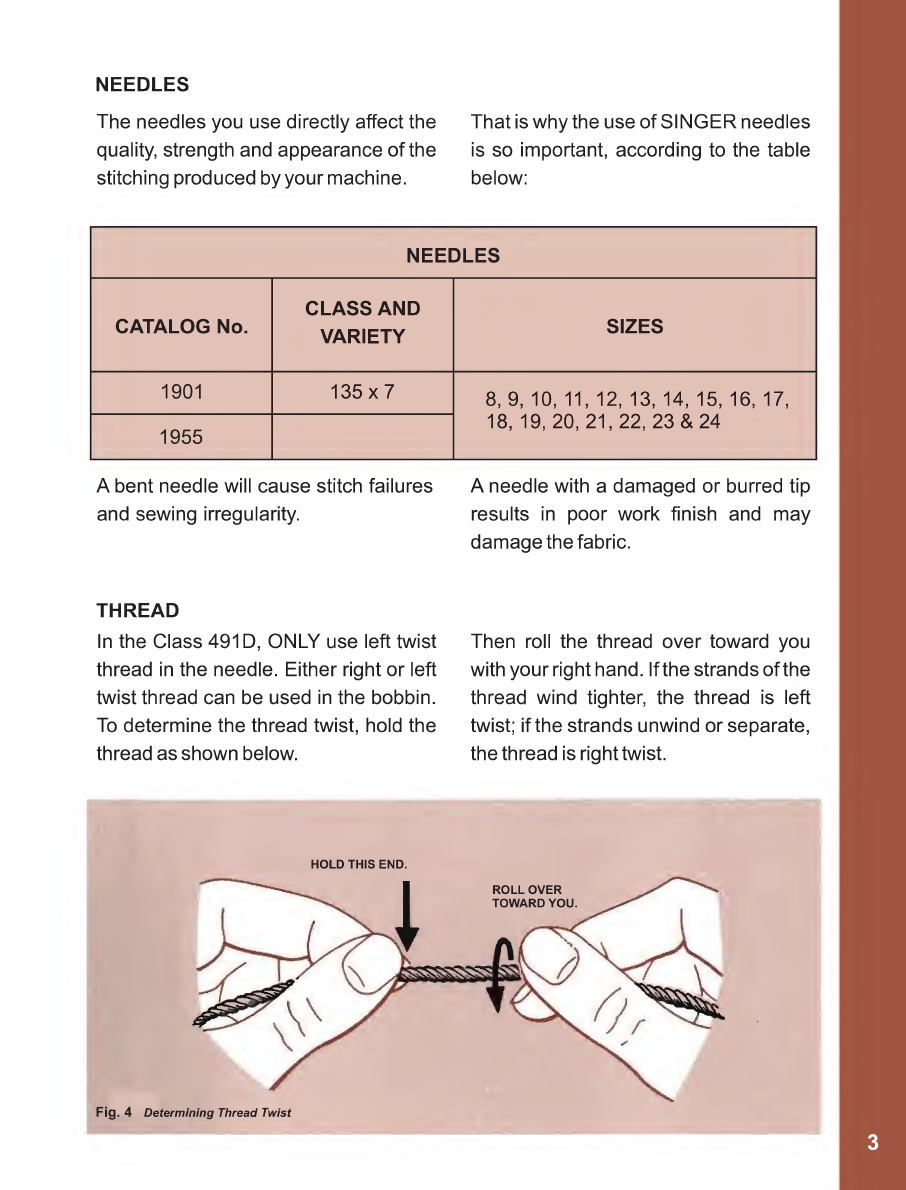

THREAD

In

the

Class

491D,

ONLY

use

left

twist

thread

in

the

needle.

Either

right

or

left

twist

thread

can

be

used

in

the

bobbin.

To

determine

the

thread

twist,

hold

the

thread

as

shown

below.

Then

roll

the

thread

over

toward

you

with

your

right

hand.

If

the

strands

of

the

thread

wind

tighter,

the

thread

is

left

twist;

if

the

strands

unwind

or

separate,

the

thread

is

right

twist.

HOLD

THIS

END.

Fig.

4

Determining

Thread

Twist

TO

SET

THE

NEEDLE

MOVE

TO

HIGHEST

POINT.

LOOSEN

SCREW.

(

I

N

S

E

R

T

NEEDLE

UP

AS

FAR

AS

POSSIBLE.

LONG

GROOVE.

Setting

the

Needle

Fig.

5

Rotate

the

machine

pulley

over

toward

you

until

the

needle

bar

moves

to

its

highest

point.

After

loosening

the

needle

set

screw,

insert

the

needle

up

to

the

top

as

shown

in

fig.

5.

The

long

groove

of

the

needle

should

face

the

left

end

of

the

machine,

as

shown

in

fig.

5.

Then

firmly

tighten

the

needle

set

screw.

Threading

the

Needle

Upper

Threading

THREADING

THE

MACHINE

First

rotate

the

machine

pulley

over

toward

you

until

the

needle

reaches

its

highest

point,

then

pass

the

needle

thread

from

the

unwinder

through

the

threading

points

in

the

order

shown

in

fig.

6.

Pull

about

two

inches

of

thread

through

the

eye

of

the

needle.

Fig.

6

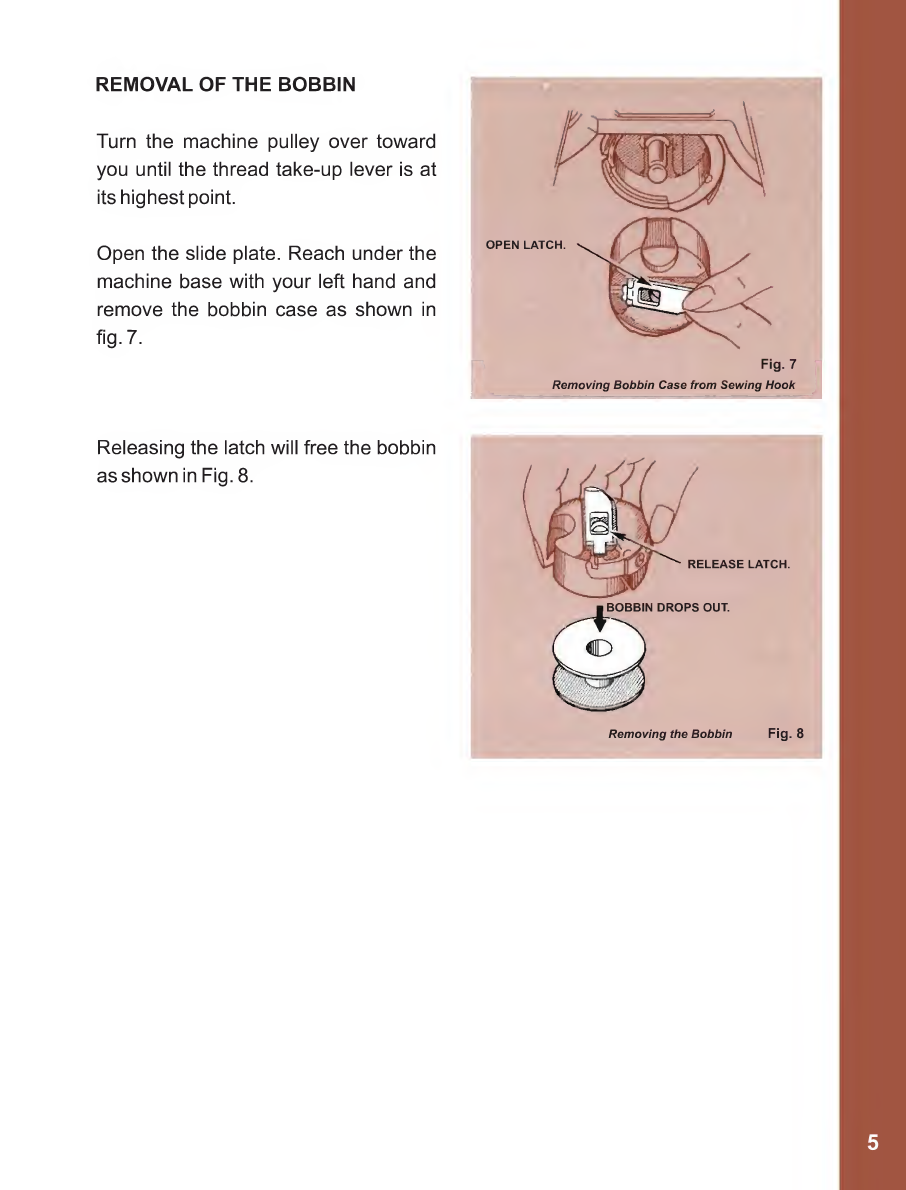

REMOVAL

OF

THE

BOBBIN

Turn

the

machine

pulley

over

toward

you

until

the

thread

take-up

lever

is

at

its

highest

point.

Open

the

slide

plate.

Reach

under

the

machine

base

with

your

left

hand

and

remove

the

bobbin

case

as

shown

in

fig.

7.

Releasing

the

latch

will

free

the

bobbin

as

shown

in

Fig.

8.

WINDING

THE

BOBBIN.

Place

the

bobbin

on

the

shaft

C

of

the

bobbin

winder

by

pushing

it

on

as

far

as

it

will

go

and

pass

the

thread

through

the

threading

points

as

shown

in

fig.

9.

Wind

end

of

thread

around

the

bobbin

a

few

times.

Press

down

on

the

thumb

latch,

pushing

driving

pulley

over

against

belt.

Start

the

machine.

The

bobbin

winder

stops

automatically.

For

more

thread

on

the

bobbin,

turn

screw

A

clockwise;

for

less

thread,

rotate

it

counterclockwise.

When

winding

a

bobbin

with

fine

thread,

light

tension

should

be

used.

Adjust

knurled

screw

D,

fig.

9,

to

regulate

the

tension.

If

the

thread

winds

unevenly

on

the

bobbin,

loosen

screw

B

and

move

the

tension

lever

left

or

right

as

necessary.

Tighten

screw

B.

Bobbins

can

be

wound

while

sewing

at

the

same

time.

Lubricate

the

thread

filler

periodically.

Put

a

few

drops

of

oil

on

the

filler

lubrication

point

shown

in

fig.

9.

THREADING

THE

BOBBIN

CASE

Hold

the

bobbin

so

that

the

thread

will

unwind

in

the

direction

shown

in

fig.

10.

Hold

the

bobbin

case

as

shown

in

fig.

10,

and

place

the

bobbin

inside

as

shown

in

fig.

11.

BOBBIN

CASE

REPLACEMENT

After

winding,

hold

the

bobbin

case

by

the

latch

with

your

left

hand

and

place

it

on

the

center

stud

of

the

bobbin

case

holder

as

shown

in

fig.

12.

Release

the

latch.

Press

the

bobbin

case

back

until

the

latch

catches

the

groove

near

the

stud.

Leave

about

two

inches

of

thread

to

hang

free.

Fig.

11

REPLACE

BOBBIN

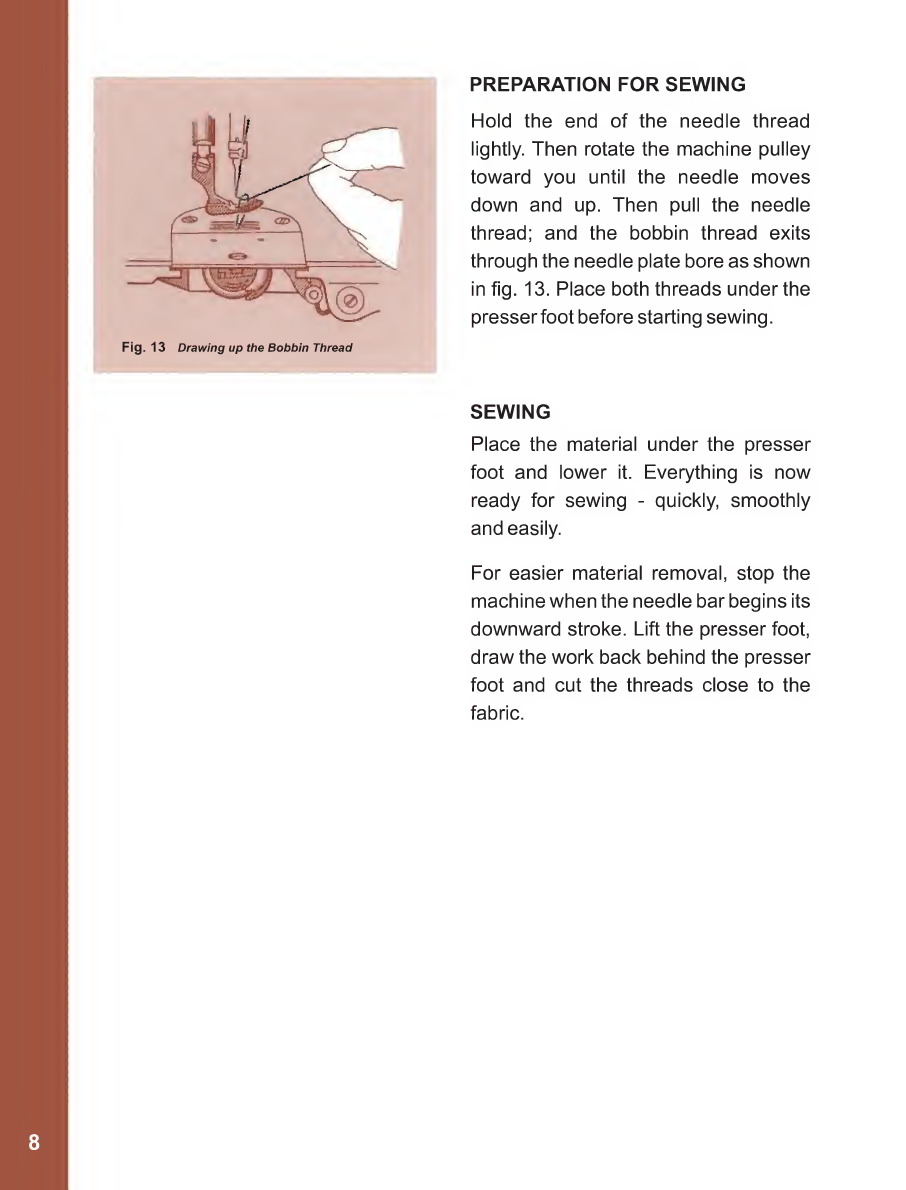

PREPARATION

FOR

SEWING

Hold

the

end

of

the

needle

thread

lightly.

Then

rotate

the

machine

pulley

toward

you

until

the

needle

moves

down

and

up.

Then

pull

the

needle

thread;

and

the

bobbin

thread

exits

through

the

needle

plate

bore

as

shown

in

fig.

13.

Place

both

threads

under

the

presserfoot

before

starting

sewing.

SEWING

Place

the

material

under

the

presser

foot

and

lower

it.

Everything

is

now

ready

for

sewing

-

quickly,

smoothly

and

easily.

For

easier

material

removal,

stop

the

machine

when

the

needle

bar

begins

its

downward

stroke.

Lift

the

presser

foot,

draw

the

work

back

behind

the

presser

foot

and

cut

the

threads

close

to

the

fabric.

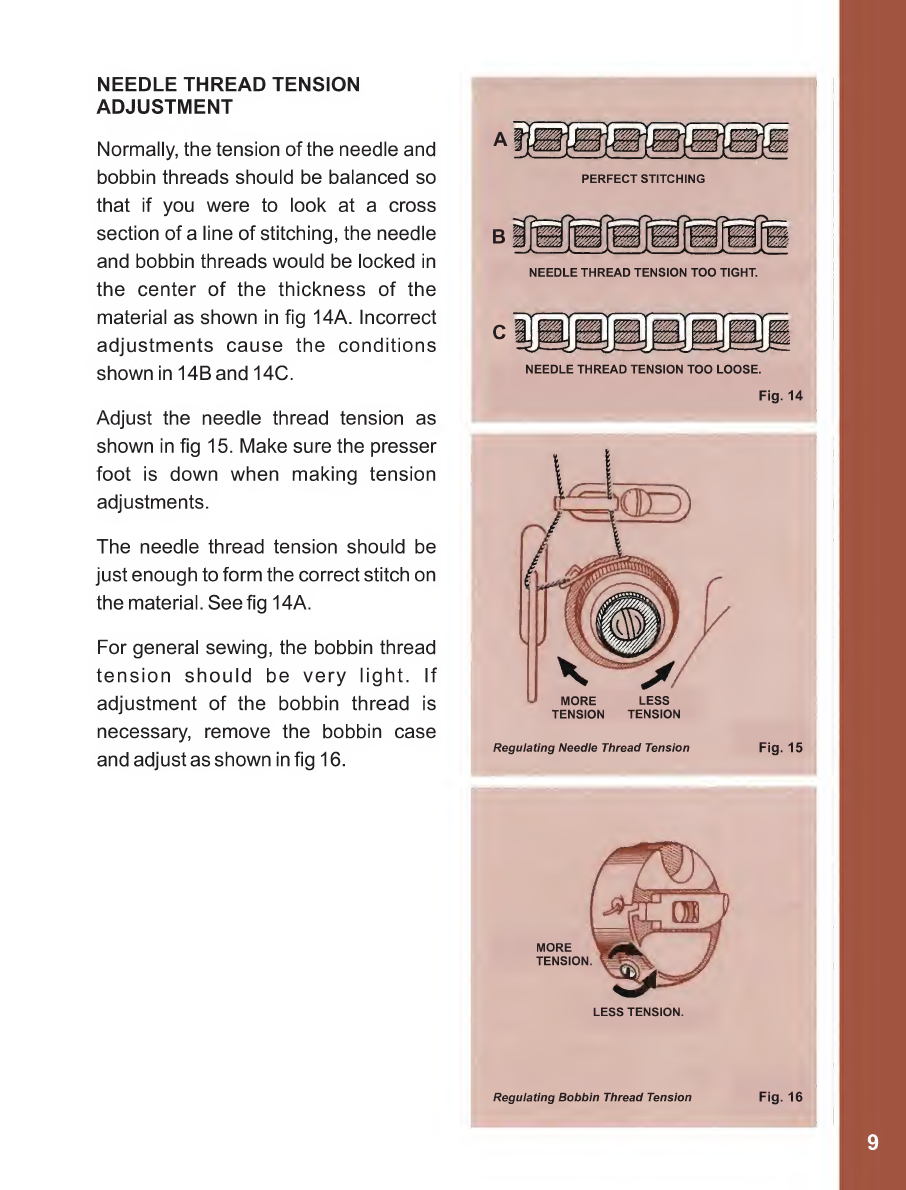

NEEDLE

THREAD

TENSION

ADJUSTMENT

Normally,

the

tension

of

the

needle

and

bobbin

threads

should

be

balanced

so

that

if

you

were

to

look

at

a

cross

section

of

a

line

of

stitching,

the

needle

and

bobbin

threads

would

be

locked

in

the

center

of

the

thickness

of

the

material

as

shown

in

fig

14A.

Incorrect

adjustments

cause

the

conditions

shown

in

14B

and

14C.

Adjust

the

needle

thread

tension

as

shown

in

fig

15.

Make

sure

the

presser

foot

is

down

when

making

tension

adjustments.

The

needle

thread

tension

should

be

just

enough

to

form

the

correct

stitch

on

the

material.

See

fig

14A.

For

general

sewing,

the

bobbin

thread

tension

should

be

very

light.

If

adjustment

of

the

bobbin

thread

is

necessary,

remove

the

bobbin

case

and

adjust

as

shown

in

fig

16.

PERFECT

STITCHING

NEEDLE

THREAD

TENSION

TOO

TIGHT.

NEEDLE

THREAD

TENSION

TOO

LOOSE.

Fig.

14

MORE

LESS

TENSION

TENSION

Regulating

Needle

Thread

Tension

Fig.

15

LESS

TENSION.

Regulating

Bobbin

Thread

Tension

Fig.

16

THREAD

PROTECTOR

ADJUSTMENT

To

achieve

perfectly

interlaced

stitches,

taking

into

account

material

thickness

and

stitch

length,

adjustments

to

the

thread

protector

D

may

be

required,

which

can

be

adjusted

by

moving

left

or

right

as

illustrated

in

fig.

18.

THREAD

TENSION

SPRING

ADJUSTMENT

The

tension

and

stroke

of

spring

movement

of

the

thread

tensioner

A

may

require

different

adjustments

depending

on

the

thread

thickness

and

the

material

used.

Thicker

threads

and

thicker

materials

require

higher

tension,

while

delicate

materials

require

lower

tension.

Also

the

movement

of

the

tensioner

spring

must

be

increased

to

ensure

correct

thread

control.

Using

a

screwdriver

on

screw

B,

turn

it

counterclockwise

to

decrease

tension

or

counterclockwise

to

increase

tension

as

shown

in

fig.

17.

To

adjust

the

height

of

the

tensioner

spring,

loosen

screw

C

(fig.

18)

and

turn

the

entire

tensioner

assembly

to

the

left

if

you

wish

to

lower

it

and

shorten

it,

or

to

the

right

to

raise

it

and

increase

it.

Firmly

tighten

screw

C.

For

thick

materials

or

long

stitches,

move

the

thread

protector

to

the

right.

For

thin

materials

or

short

stitches,

move

the

thread

protector

to

the

left.

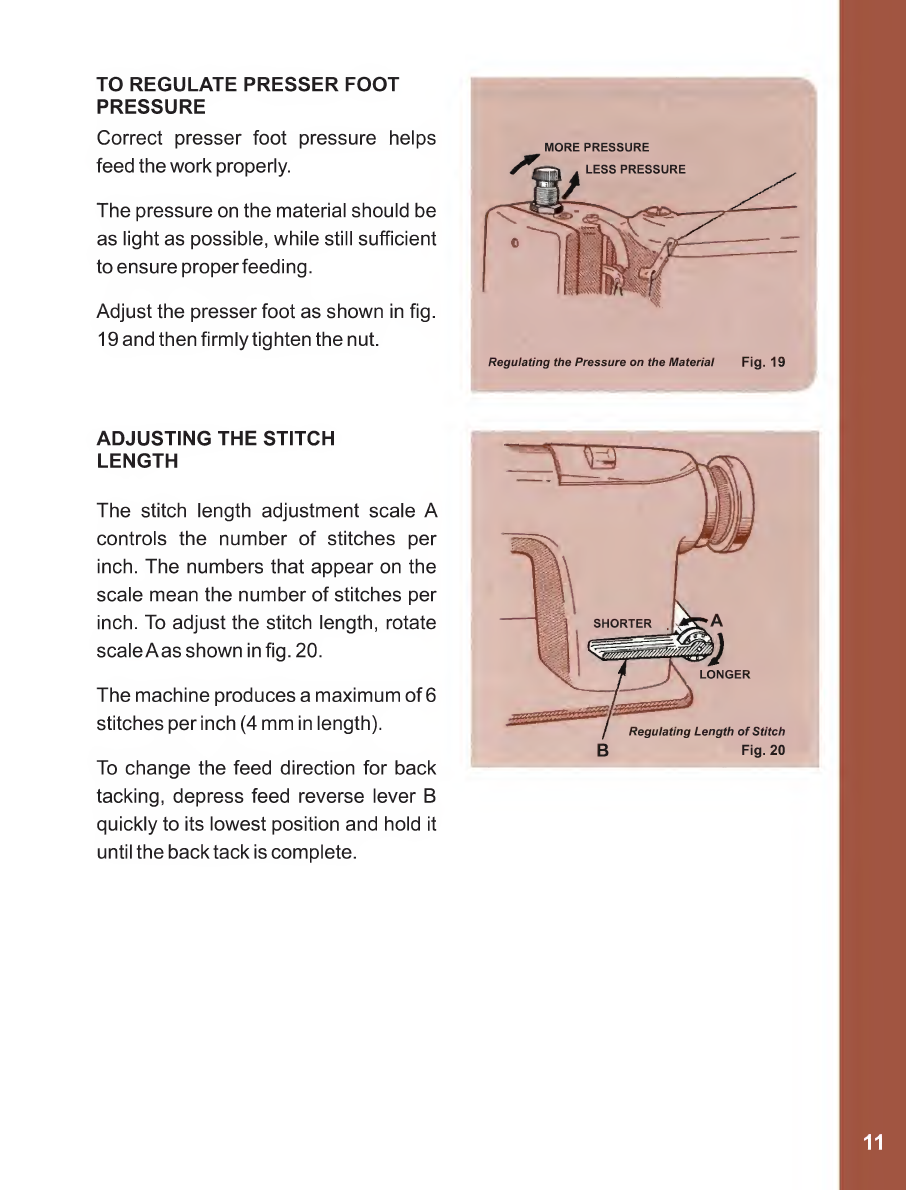

TO

REGULATE

PRESSER

FOOT

PRESSURE

Correct

presser

foot

pressure

helps

feed

the

work

properly.

The

pressure

on

the

material

should

be

as

light

as

possible,

while

still

sufficient

to

ensure

properfeeding.

Adjust

the

presser

foot

as

shown

in

fig.

19

and

then

firmly

tighten

the

nut.

ADJUSTING

THE

STITCH

LENGTH

The

stitch

length

adjustment

scale

A

controls

the

number

of

stitches

per

inch.

The

numbers

that

appear

on

the

scale

mean

the

number

of

stitches

per

inch.

To

adjust

the

stitch

length,

rotate

scale

Aas

shown

in

fig.

20.

The

machine

produces

a

maximum

of

6

stitches

per

inch

(4

mm

in

length).

To

change

the

feed

direction

for

back

tacking,

depress

feed

reverse

lever

B

quickly

to

its

lowest

position

and

hold

it

until

the

back

tack

is

complete.

11

TIPS

FOR

PERFECT

OPERATION

•

Always

keep

the

oil

level

in

the

oil

reservoir

at

the

"HIGH"

mark.

•

When

turning

the

machine

pulley,

always

turn

it

over

towards

you.

•

Always

keep

the

bed

slide

plate

closed

when

the

machine

is

in

operation.

•

Clean

out

any

lint

or

other

waste

around

the

hook

and

between

the

feed

rows

on

the

underside

of

the

throat

plate.

•

Do

not

try

to

'help'

the

machine

by

pulling

the

fabric.

•

Never

press

the

knee

lifter

while

the

machine

is

running.

•

Do

not

run

the

machine

when

threaded

unless

there

is

material

under

the

presserfoot.

THE

SAME!

BUY

PARTS

AND

NEEDLES

MADE

BY

SINGER.

TO

BE

DOUBLY

SURE

...

of

new

machine

performance,

make

sure

that

all

replacement

parts

and

needles

are

exactly

the

same

as

those

in

new

SINGER

machines.

A

LOOK

FOR

THE

TRADEMARK

1.

on

every

package

or

container.

2.

on

the

needle

or

numbered

part.

Needles

in

packaging

marked

"For

Sinqer

Machines"

are

NOT

made

by

SINGER.

TO

ALL

WHOM

IT

MAY

CONCERN:

The

improper

placing

of

the

"SINGER"

trademark,

or

any

other

trademark

of

The

Singer

Company

(all

of

which

are

duly

registered

trademarks)

on

any

machine

that

has

been

repaired,

rebuilt,

refurbished,

or

altered

in

anyway,

outside

a

SINGER

factory

or

an

authorized

SINGER

agency

is

prohibited.

v

A

registered

trademark

of

THE

SINGER

COMPANY.

J

Translated

from

Portuguese

edition

Available

on

www.archive.org

Table of contents