– 1 –

1. Specications

No. Item Application

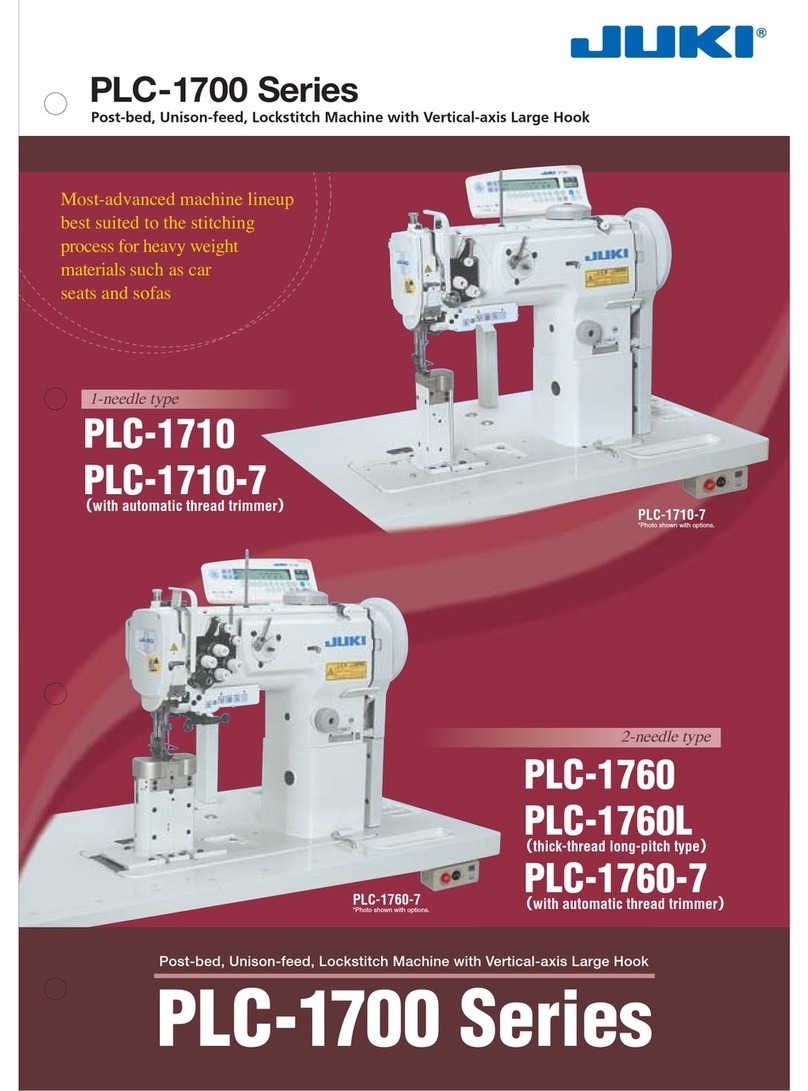

1 Model PLC-2760N PLC-2760NL

2 Model name Post-bed, 2-needle, unison-feed,

lockstitch machine with vertical-axis

large Hook

Post-bed, 2-needle, unison-feed,

lockstitch machine (for thick thread)

3 Application Medium- to heavy-weight materials, car

seat, furniture

Heavy-weight materials, car seat,

furniture

4 Sewing speed Max. 2,500 sti/min

(Refer to "6. SEWING SPEED TABLE"

in the Instruction Manual for the

standard model.)

Max. 2,000 sti/min

(Refer to "6. SEWING SPEED TABLE"

in the Instruction Manual for the

standard model.)

5 Needle GROZ-BECKERT 135 x 17 (Nm 100 to

Nm 180) (Standard : Nm 140)

GROZ-BECKERT 135 x 17

(Nm 140 to Nm 200)

(Standard : Nm 200)

6 Applicable thread size for

sewing #30 to #5 #8 to #0

7 Applicable thread size to

be cut

8 Stitch length Max. 12 mm (forward/reverse feed)

9 Stitch length dial 1-pitch dial

10 Presser foot lift Hand lifter : 10 mm

Knee lifter : 20 mm

11 Stitch length adjusting

mechanism

By dial

12 Reverse stitch adjusting

method

By lever

13 Thread take-up Link thread take-up

14 Needle bar stroke 40 mm

15 Amount of the alternate

vertical movement

1 mm to 9 mm (Alternate vertical dial adjustment type)

16 Hook Vertical-axis 2-fold hook (Latch type)

17 Feed mechanism Box feed

18 Top and bottom feed

actuation mechanism

Timing belt

19 Thread trimming method

20 Lubrication Automatic lubrication by oil tank (with oil gauge)

21 Lubricating oil JUKI New Defrix Oil No. 1 (equivalent to ISO standard VG7)

or JUKI MACHINE OIL No. 7

22 Bed size 643 mm × 178 mm

23 Space under the arm 347 mm × 298 mm

24 Hand wheel size V-belt eective diameter : ø76.0 mm

Outer diameter : ø140 mm

25 Motor/Control box M51N 750W / SC-922A

26 Machine head weight 79 kg

27 Noise - Equivalent continuous emission

sound pressure level (LpA) at the

workstation:

A-weighted value of 84.0 dB;

(Includes KpA = 2.5 dB); according to

ISO 10821- C.6.2 - ISO 11204 GR2

at 2,500 sti/min.

-Sound power level (LWA);

A-weighted value of 86.0 dB;

(Includes KWA = 2.5 dB); according to

ISO 10821- C.6.2 - ISO 3744 GR2 at

2,500 sti/min.

-Equivalent continuous emission

sound pressure level (LpA) at the

workstation:

A-weighted value of 88.0 dB;

(Includes KpA = 2.5 dB); according to

ISO 10821- C.6.2 - ISO 11204 GR2

at 2,000 sti/min.

-Sound power level (LWA);

A-weighted value of 93.5 dB;

(Includes KWA = 2.5 dB); according to

ISO 10821- C.6.2 - ISO 3744 GR2 at

2,000 sti/min.