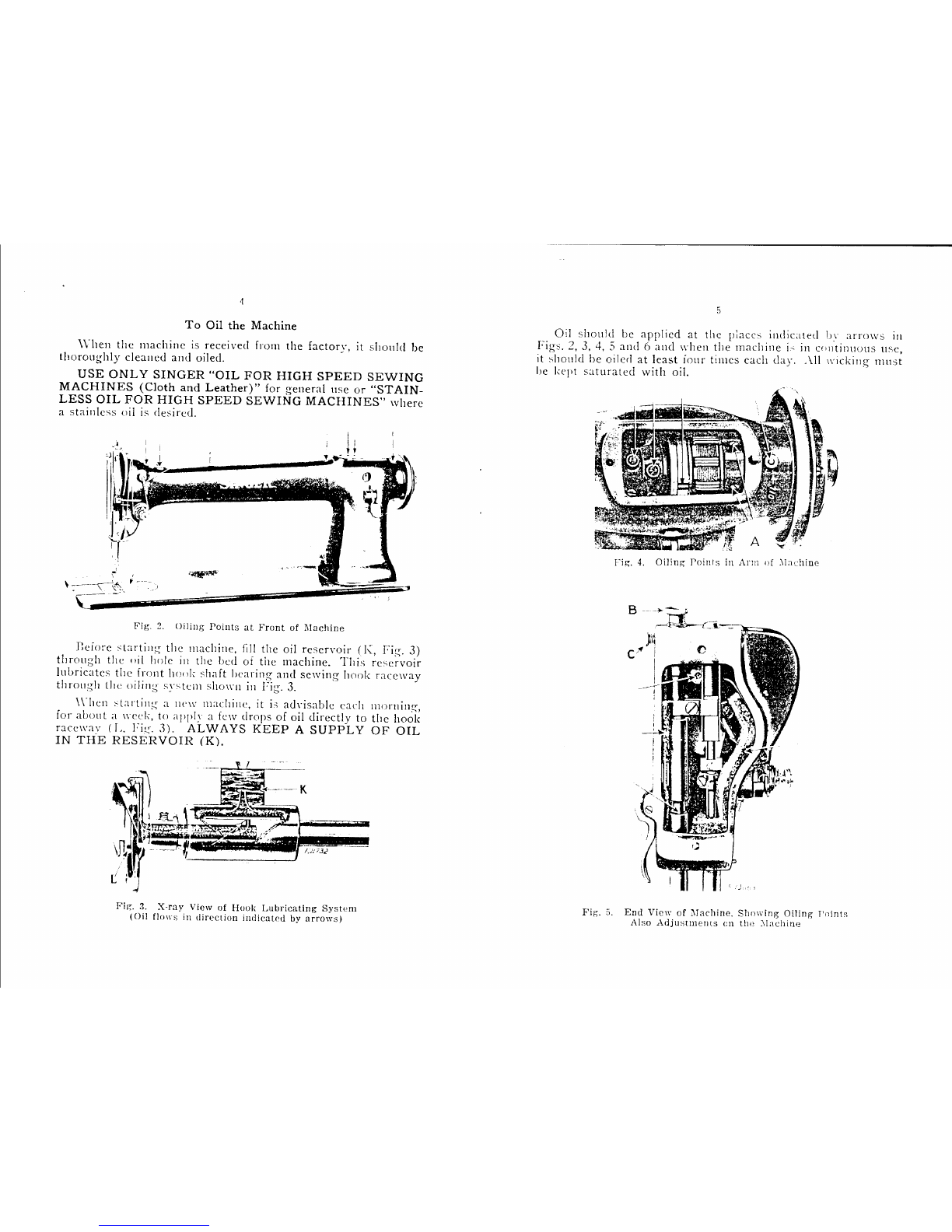

6

Fig.

G.

Oiling

Points

in

Base

of

1\Iachine

Also

Adjustments

on

the

l\Iaclline

To

Ensure

Perfect

Action

of

the

Machine

The

balance

wheel

must

always

turn

over

toward

the

operator.

Do

not

run

the

machine

with

the

presser

foot

resting

on

the

feed

without

cloth

under

the

presser

foot.

Do

not

run

the

111achine

when

both

bobbin

case

and

needle

are

threaded

unless

there

is

material

under

the

presser

foot.

Do

not

try

to

help

the

machine

by

pulling

the

fabric

lest

you

bend

the

needle;

the

machine

feeds

the

work

without

assistance.

The

slide

O\'Cr

the

bobbin

case

should

be

kept

closed

when

the

machine

is in

operation.

7

Needles

l\ecdles

for

l\Iachinc

150\v161

arc

of

Class

an<l

\'

· t

13-

){

ane

y

.)X_

,

sizes 7, 8, 9, 10, 12, 14, 16, 18, 20

and

22.

The

size

of

the

needle

to

be

used

should

be

determined

bv

the

size

of

the

thread

which

must

pass

freely

through

the

eye

<;f

the

needle.

l f

rough

or

uneven

thread

is

used

or

if it

passes

with

difficulty

through

the

eye

of

the

needle,

the

successful

usc

of

the

machi11e \l·ill

!Je

interfered

with.

Orders

for

needles

must

specify

the

quantity

:-equired,

the

size

number,

abo

the

class

and

variety

numbers

c;cparatecl

by

the

let

tcr

:--:..

The

t<Ji!mving

IS

an

example

of

an

intelligible

order:

"100

'\o.

14,

L\.~x21

:\

tTd!t·s."

Tl1e

l!l·'t

results

will

be

obtained

in

u,;ing

the

needle:-;

fm-

ni,;hed

ln· tht• :-;ingcr :-;ewing

.\lacllinc

l·on1pany.

Thread

Left

twi~t

thread

5hould

he

u~ed

in

the

needle.

Either

right

or

left

t11·ic-t

can

!Je

used

in

the

lJObb111.

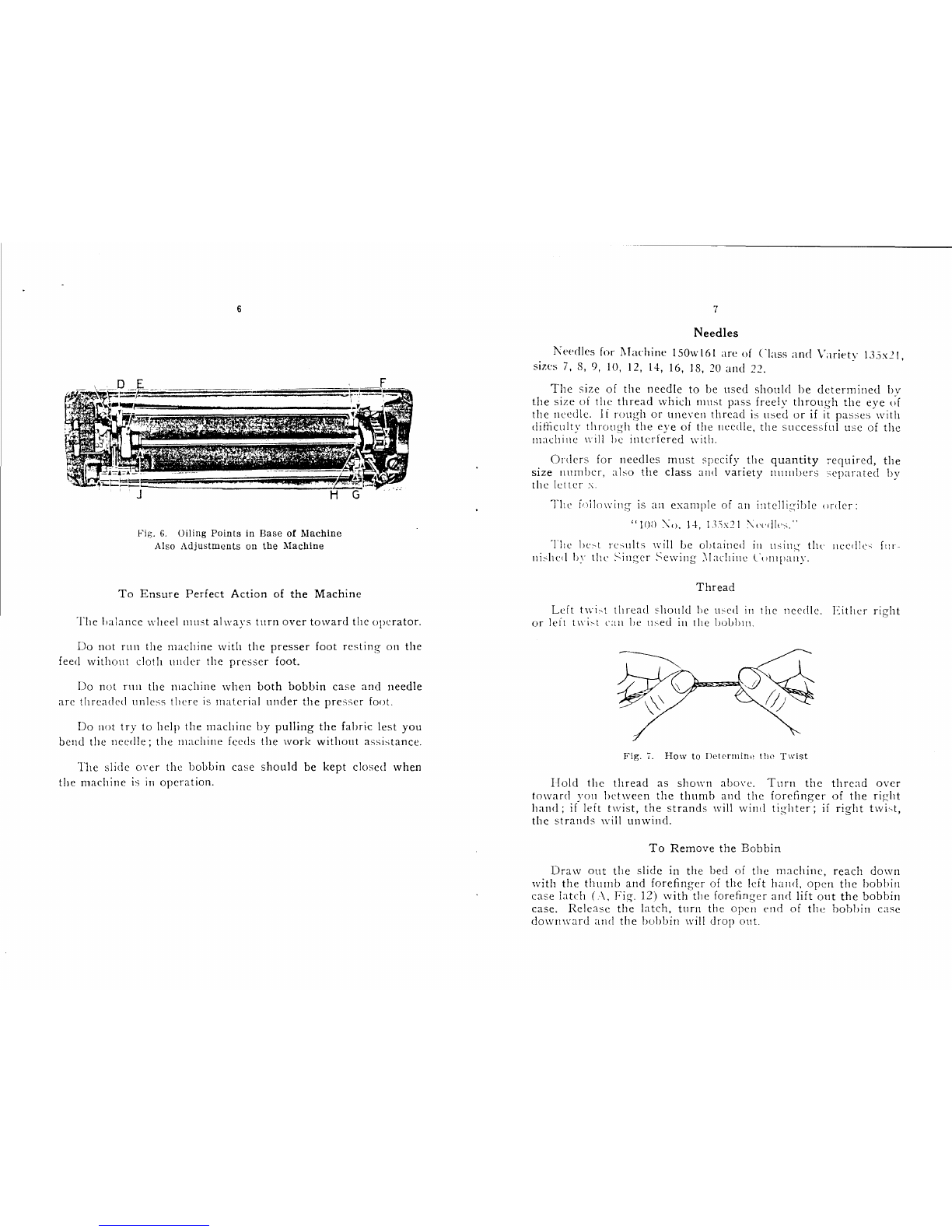

Fig.

7.

How

to

Iletermirw

the

Twist

IIolcl

the

thread

as

shown

abm·e.

Turn

the

thread

over

toward

you

between

the

thumb

and

the

forefinger

of

the

ric;ht

hand;

if

left

twist,

the

strands

will

wind

tighter;

if

right

twi'>t,

the

~trands

will

unwind.

To

Remove

the

Bobbin

Draw

out

the

slide

in

the

bed

of

the

machine,

reach

down

with

the

thumb

and

forefinger

of

the

leit

hand,

open

the

bobbin

case

latch

(

.\,

Fig.

12)

with

the

forefinger

an<i

lift

out

the

bobbin

case.

Release

the

latch,

turn

the

open

end

of

the

bobbin

case

downward

and

the

bobbin

will

drop

ouL