Singer 211W151 User manual

Other Singer Sewing Machine manuals

Singer

Singer RD51 User manual

Singer

Singer Stylist 834 User manual

Singer

Singer Surjeteuse 46K26 Installation and operation manual

Singer

Singer S0700 User manual

Singer

Singer 431 CONVERTIBLE User manual

Singer

Singer Futura 200 User manual

Singer

Singer SRP-50 User manual

Singer

Singer 211G155 User manual

Singer

Singer 1371A1 Setup guide

Singer

Singer 71-107 Quick start guide

Singer

Singer 7442 User manual

Singer

Singer 3342 User manual

Singer

Singer 62-35 User manual

Singer

Singer Futura 1100 User manual

Singer

Singer 990B3 User manual

Singer

Singer Confidence 7469 User manual

Singer

Singer 319 Installation and operation manual

Singer

Singer 144W101 Quick start guide

Singer

Singer Studio S18 User manual

Singer

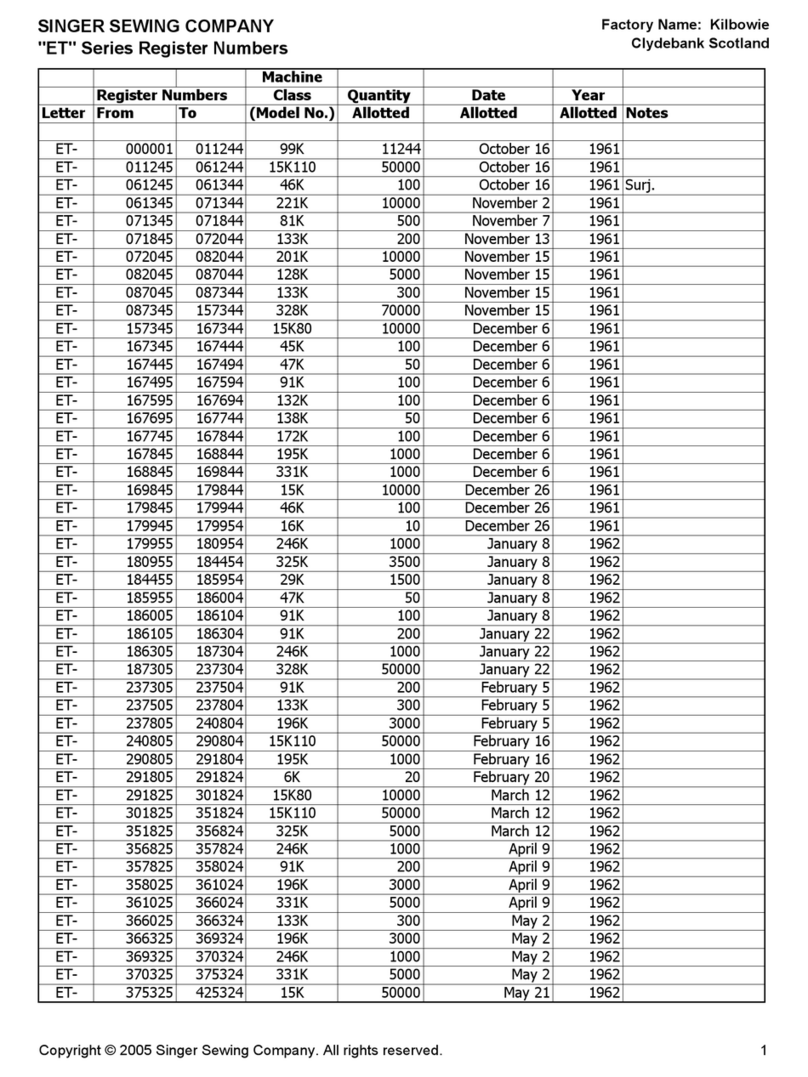

Singer ET Series User manual