Singer 246K21 User manual

Other Singer Sewing Machine manuals

Singer

Singer 66-18 User manual

Singer

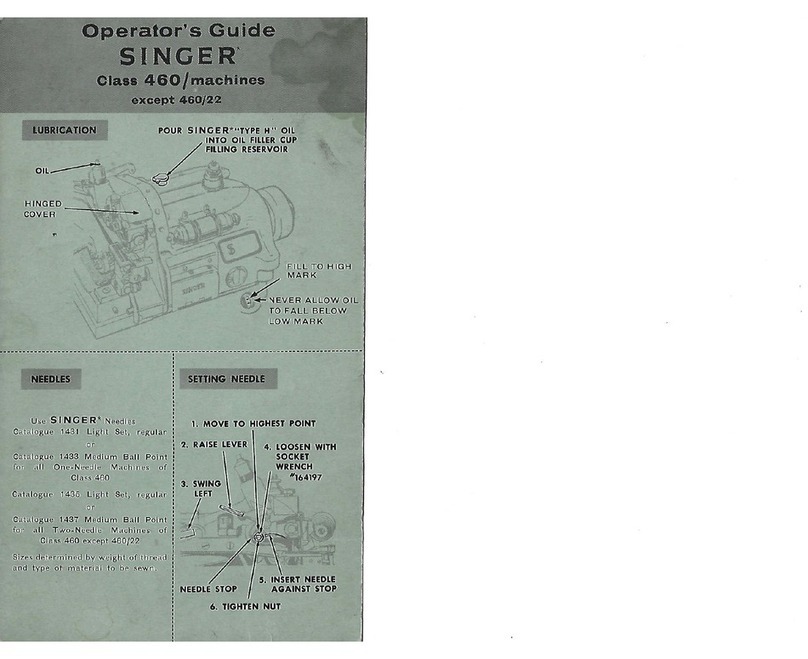

Singer 460 series Manual

Singer

Singer 114W100 User manual

Singer

Singer FEATHERWEIGHT FW-75 User manual

Singer

Singer Fashion Mate 3333 User manual

Singer

Singer 3229 User manual

Singer

Singer 14SH654 User manual

Singer

Singer 152-1 Quick start guide

Singer

Singer 142W25 Quick start guide

Singer

Singer 8780 Curvy User manual

Singer

Singer 299U User manual

Singer

Singer 212 User manual

Singer

Singer 97-1 Installation and operation manual

Singer

Singer 300wl03 User manual

Singer

Singer CXL User manual

Singer

Singer 960 Series User manual

Singer

Singer 52-67 User manual

Singer

Singer 15-125 User manual

Singer

Singer 66-8 User manual

Singer

Singer Surjeteuse 46K26 Installation and operation manual