From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

2

CONTENTS

PAGE

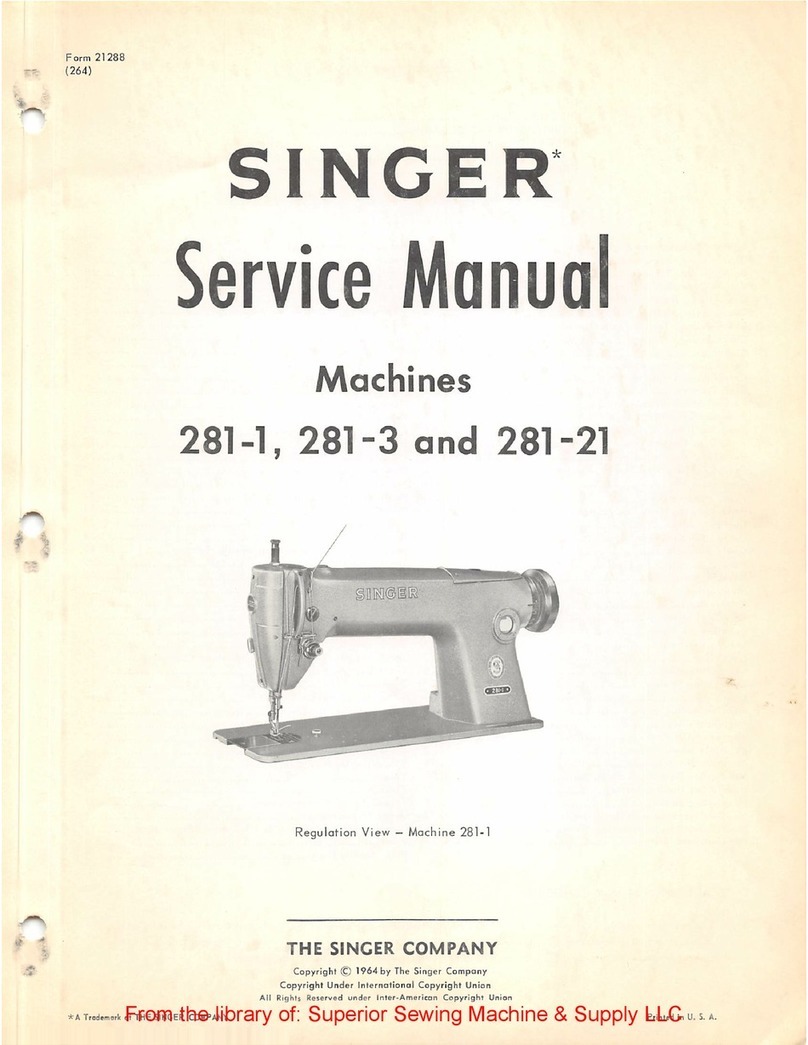

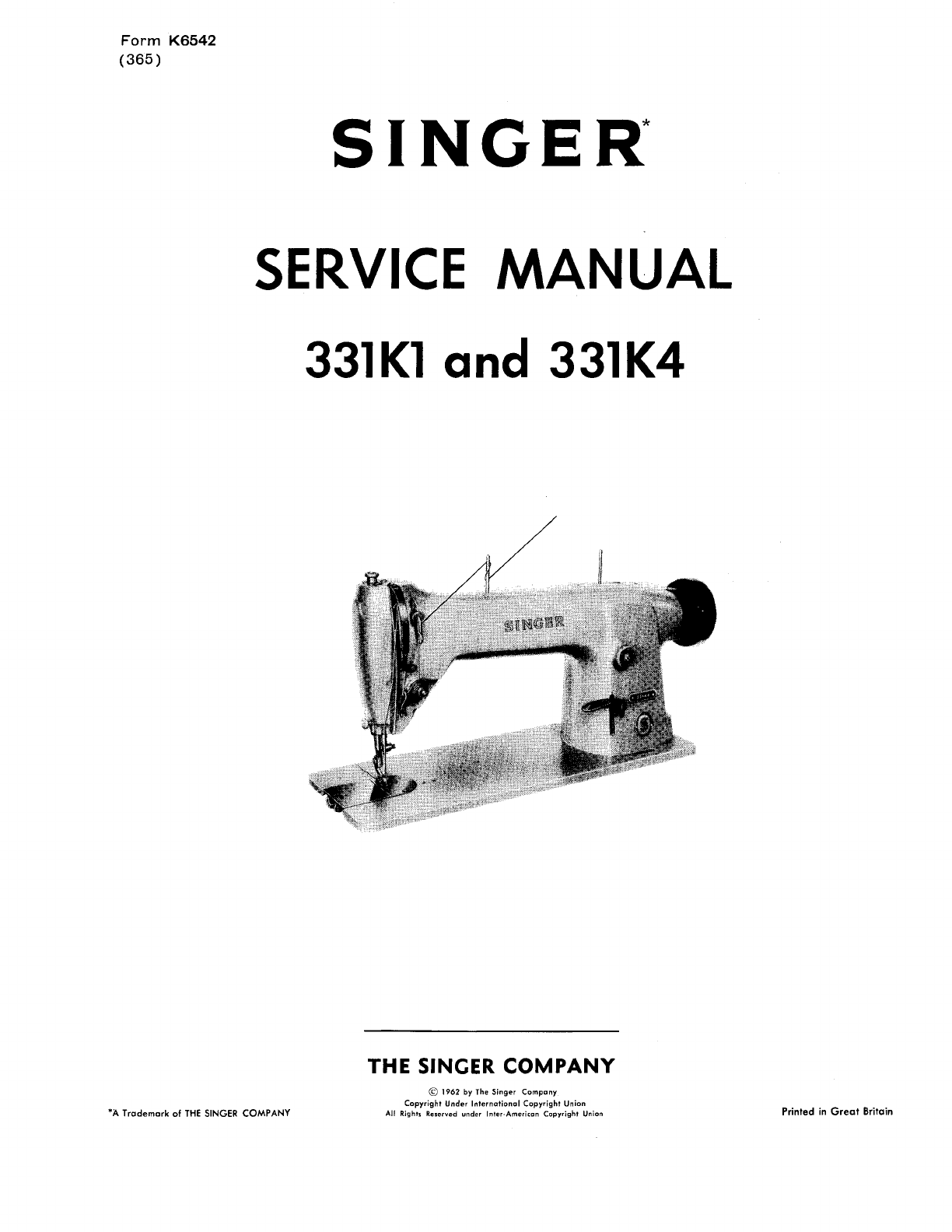

DESCRIPTION

.•.•••••••.•.•••••••.••.•.•••••

3

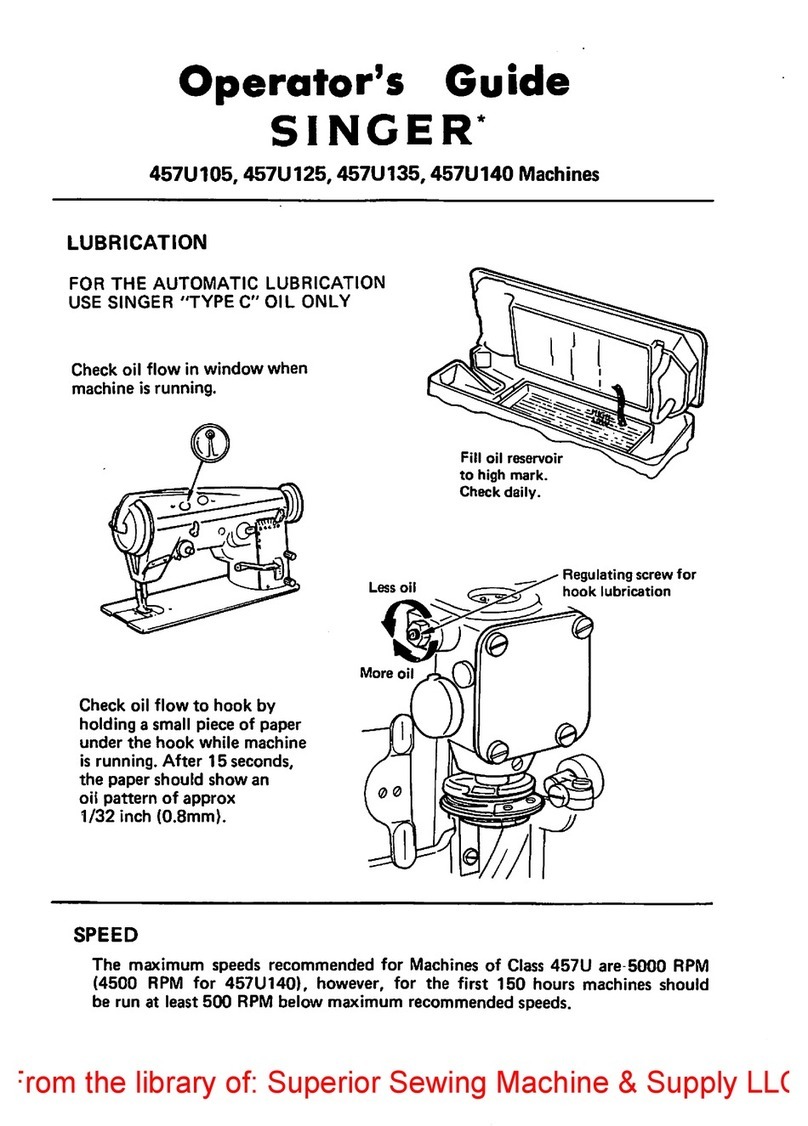

LUBRICATION

AND CLEANING

•••••••••••••••••

4

INFORMATION

FOR

OPERATION

•••••••••••••

4-11

PAGE

ADJUSTMENTS

••••.•••••••••••••••••••••

12-16

PARTS

LIST

.•.•••••••••••••••••••••••••••••

17

INDEX

Bed

Slide (Slide Plate)

••••••••.•••••••••••.•.•

8

Belt Guard

•••••.•••••.•••••••.••••.••••••.•

3

Bobbin and Bobbin

Case

••••••••••.••••••••.

7-9

Bobbin

Winder

•••••••••••••.••••••.•••••••

4, 7

Capacity

of

Machine

•..•.•••••.•.••..•••.•

3,

12

Centralizing Feed Dog

••••.••••••••••••••••••

16

Common

Causes

of

Stitching Troubles

••••••••••••

5

Description

of

Oil

••.•.•.•••..•.••••.••••••••

4

Dimensions

of

Machine

••.••••••.••.•••••••••••

3

Drawing Up Bobbin Thread

•.••••••••••••••••••

8

Feed Dog

••••••••.•••••.•••••••••••••••

1

5,

16

Feed,

Reverse

••••••••.•••••.••••••••••

;

••

3,

10

Feed Timing

•••••••••••••••••.•••••••••••••

15

Graduated Stitch Indicator

••••••••••••••••••••

10

Knee

Lifter

•••••.••••••••.•••••••••••••••••••

3

Length

of

Stitch

••••••..••••..•••••.•.•.•••

3,

10

Light Fixture

••.•.•••••••••••••••••••••••••••

3

Link

Take-up

••••••••••.•••••••••••••••••••

3, 6

Lint, Removal

of

Excess

••.••••.••••••••••..•.••

4

Machine

Dimensions

•••••••••••••••••••••.••••

3

Machine Pulley

•••••.•••••••••••••••••••••

3,

11

Needles

••••••••••.•••.•.••••••••••••.••••••

5

Needle Bar

••••..•••••.••••••.•.•••••

3, 12, 13

Needle Setting

...•..••••••••••••••.•••••••••

5

Needle to Shuttle, Clearance

•••••••.••••••

13,

16

Perfect Stitch

••••••.••••••••.•••...••••••••••

8

Preparation

for

Sewing

..•••.••.••••••.•••.•••

8

Presser Bar

••••.•••••..•••••••

·

•••••.•••••••

12

Presser

Bar Guide Bracket

•••••••.•••••••••••

12

Presser

Foot

•••••••.••••••••.••••••.••

3, 12, 15

Pressure

of

Presser

Foot

•.••••••••••••••••.••

9,

15

Pulley

••••••••••••••••••••••••••••••••••

3,

11

Reverse

Feed

••••••••••••••.•••••••••••••

3,

10

Rotary

Tens

ion

••••••...••••..•••••••••••••

3, 9

Setting Up Machine

•••.•••••.••••••••••••••••

3

Shuttle

•••••••••••••••••••••••••••••••••

13,

14

Shuttle to Needle Clearance

•...•••••.•••••

13,

16

Specifications

•••.••.••••.••.••••..•••••••

3,

12

Speed

•••.••••••••••••••.•••••••••••••.••••

3

Starting to Sew

•••••...•••.•.••••••••••••

8,

11

Spillage, to Avoid

••••.•.•••.•..••••••••••••••

7

Stand

•••••••••••••••••••••••••.••••••••••••

3

Stitch Indicator

•••••••••••••••••••••••••.••

10

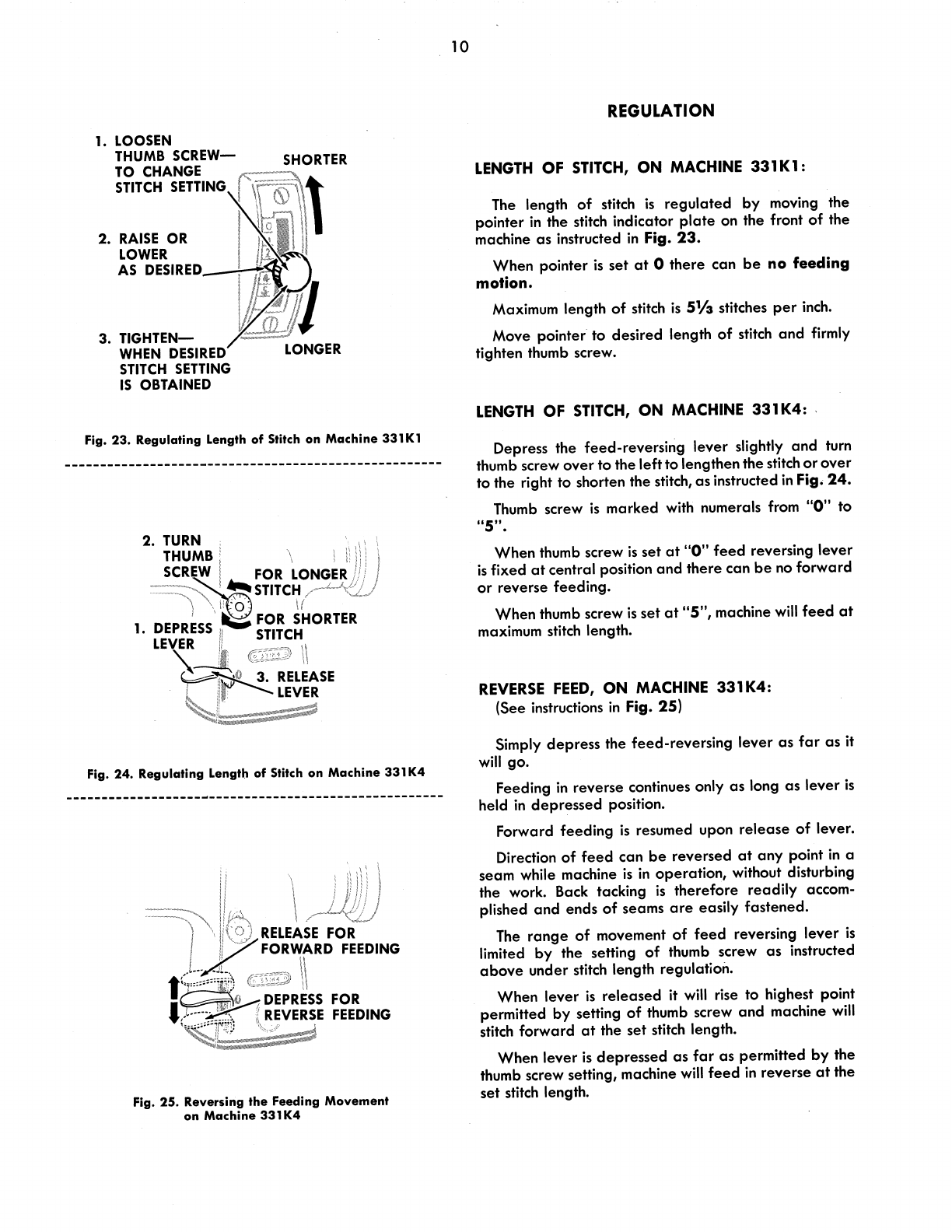

Stitch Length

•••••••••••••••••••••••••••••••

10

Stitch Type

•••••••••••••••••••••••••••••••••

3

Stitching Troubles,

Causes

of

••.••••••••••••••••

5

Stop Motion

••.•..•••••••••.••.••••••••••••

11

Table

•.••.••.•.••••••••••••••••••••••.•••••

3

Tacking

•••••.••••.••••••••••••••••••••••••

10

Take-up Lever

•••••••••••••••••••••.••••••

3, 6

Take-up Lever Guard

..••••.•••.••••••••••••••

3

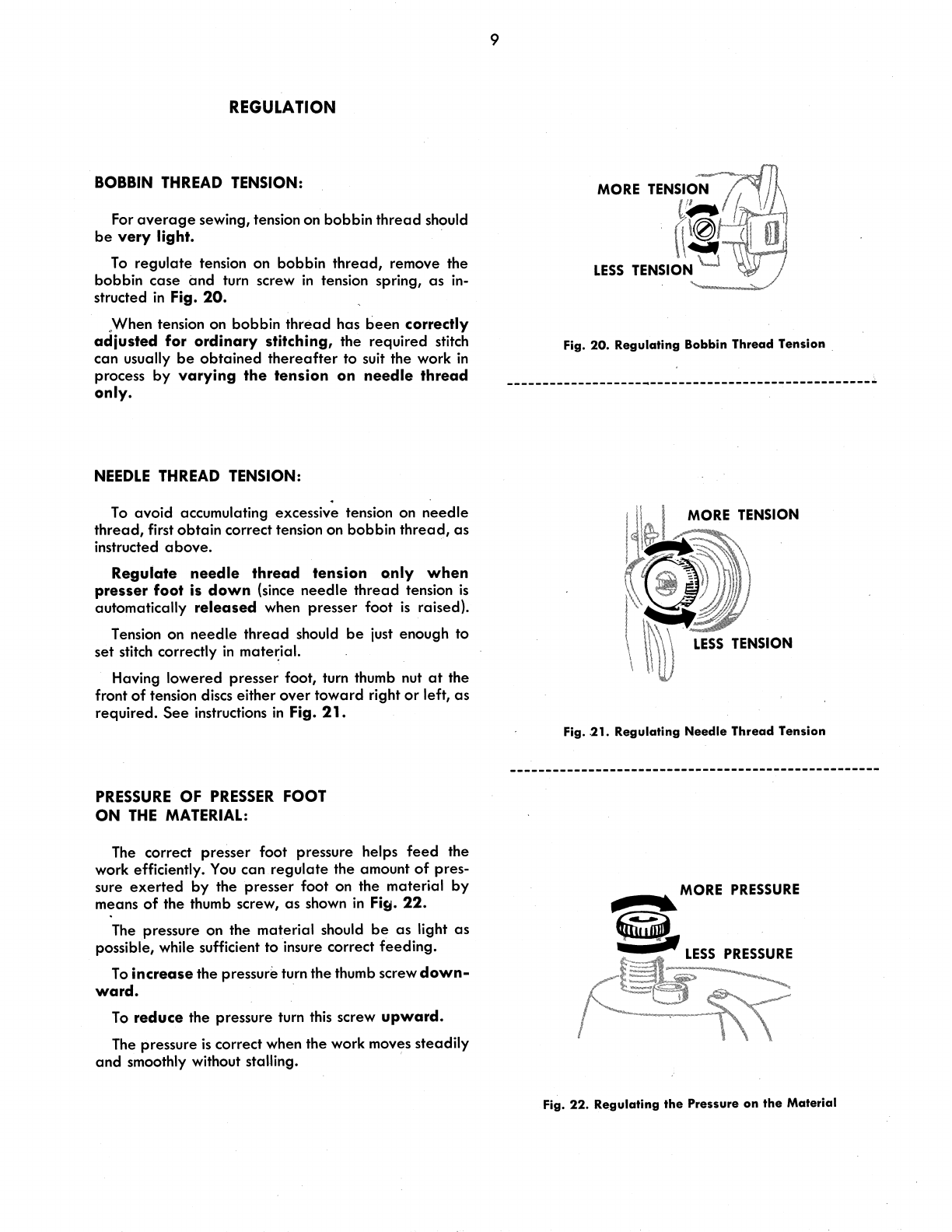

Tension,

Check Spring

•.•••...•.•••••••••••••

1

4

Tension,

Threads

••.••••••••.•.•••••••••••••

8, 9

Thread

.•••••••••••••••••••.•.••••••••••••••

5

Threading, Bobbin Case

•••••••••••••••••••••••

7

Threading,

Upper

(Needle)

•••••••••••.••.•••••

6

Throat Plate

••••••••••••••••.••••••••••••

3,

16

Treated Material, Speed when Sewing

•••••••••••

3

Treadling Procedure

•••••••••••••.••••••••••

11

Turning a Corner

•.•••••••••.•••••••••••••••••

8

Twist

of

Thread

••••••.••.••••••••••••••••••••

5

Unwinder

••••••••••••••••.••••••••••••••••

3, 6

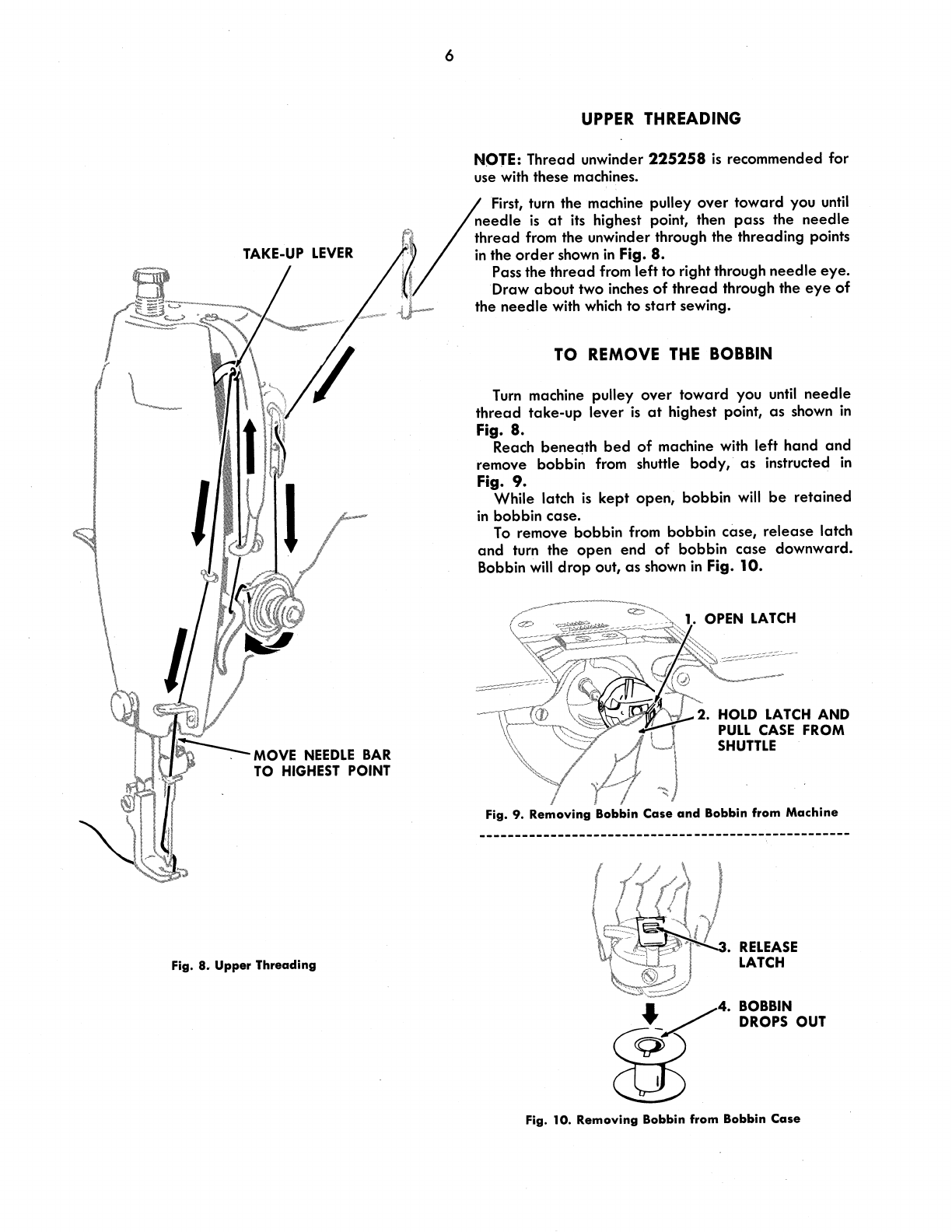

Upper Threading

••••••••.••••••••••••••.••••

6

Winder

(Bobbin)

•••••••••••••••••••••••••••

4, 7