Singer 675 User manual

Other Singer Sewing Machine manuals

Singer

Singer 3300 Series User manual

Singer

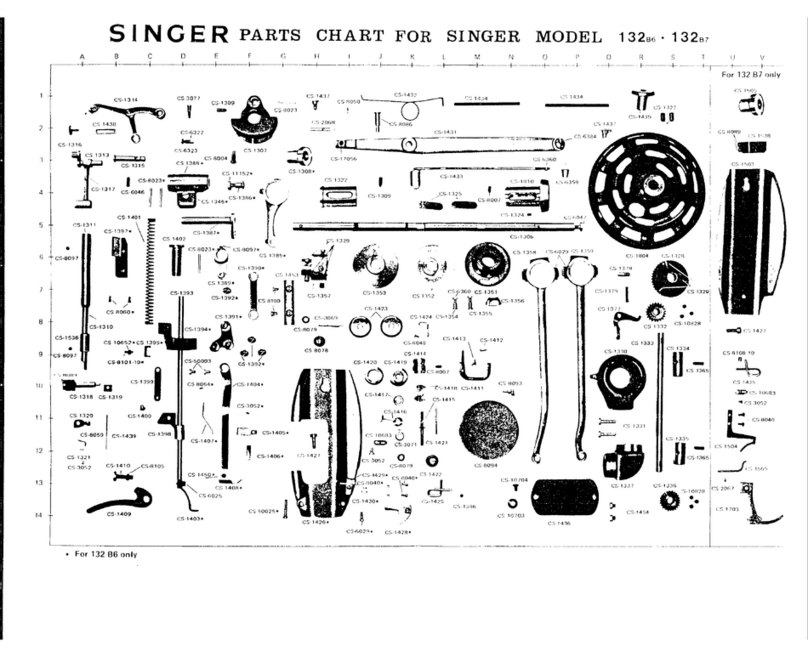

Singer 132B6 User manual

Singer

Singer 14U10 Manual

Singer

Singer Stylist 7258 User manual

Singer

Singer 52-60 User manual

Singer

Singer 221K Installation and operation manual

Singer

Singer S0705 User manual

Singer

Singer 128-4 User manual

Singer

Singer Fashion Mate User manual

Singer

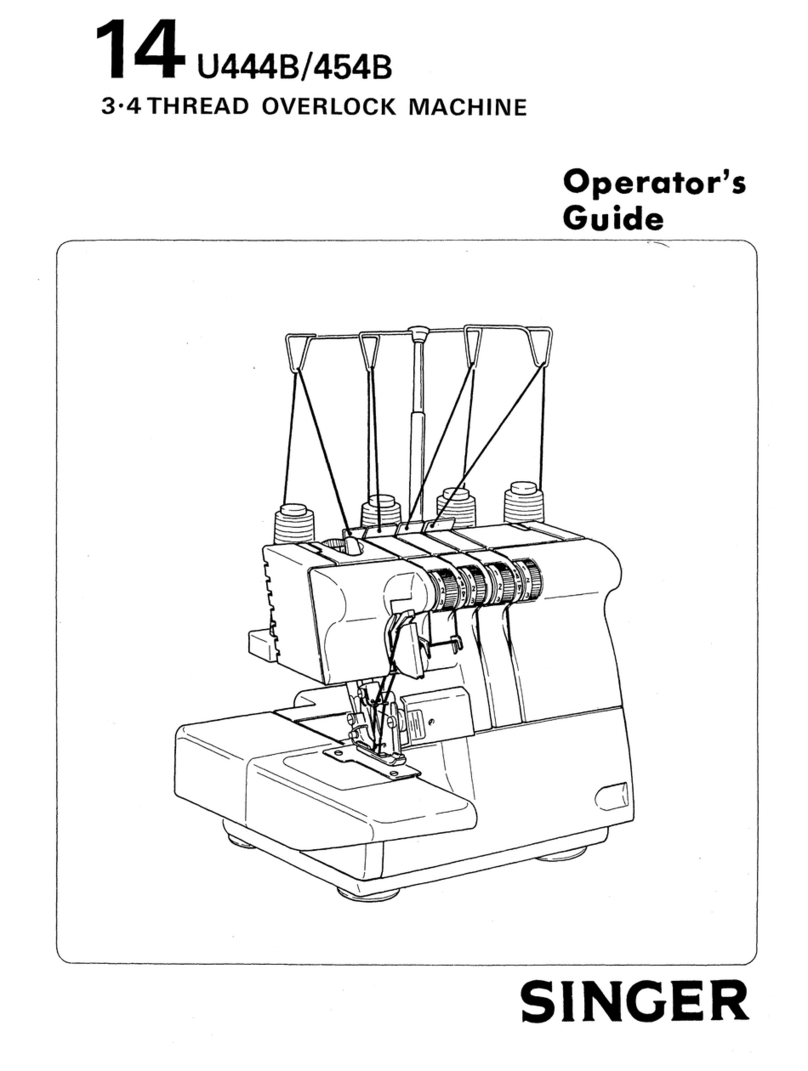

Singer 14 U444B Manual

Singer

Singer 246-2 User manual

Singer

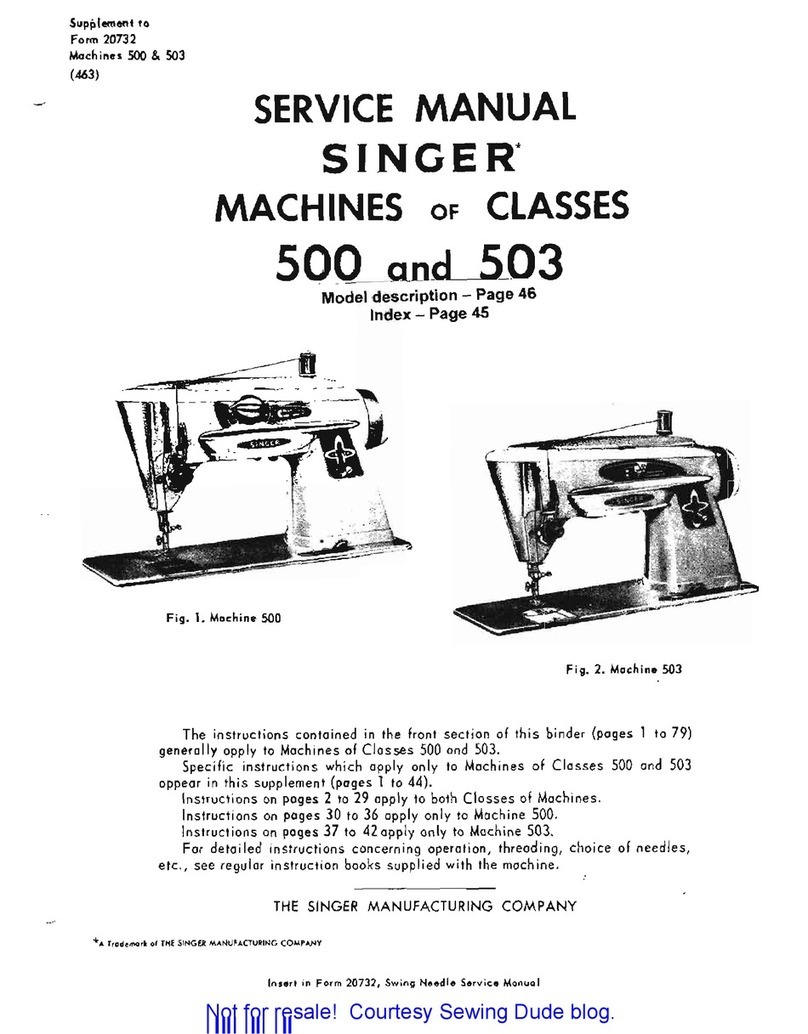

Singer 500 SERIES User manual

Singer

Singer 1120 User manual

Singer

Singer Quantum User manual

Singer

Singer 4411 User manual

Singer

Singer 5160 User manual

Singer

Singer 1507WC User manual

Singer

Singer 146-33 Quick start guide

Singer

Singer 107-1 Installation and operation manual

Singer

Singer Stylist 7258 User manual