Singer 9800 User manual

Other Singer Sewing Machine manuals

Singer

Singer 72W19 User manual

Singer

Singer 2273 User manual

Singer

Singer 3323 User manual

Singer

Singer Imperial 7005 User manual

Singer

Singer 7-22 User manual

Singer

Singer 2001A User manual

Singer

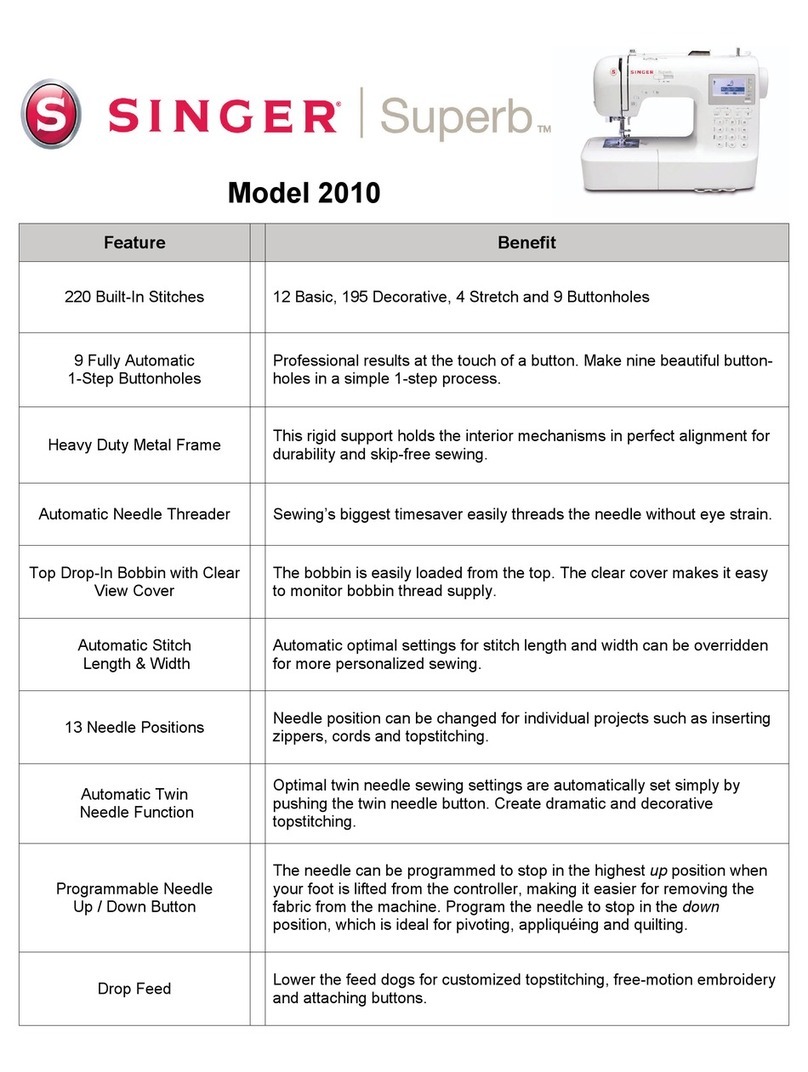

Singer Superb 2010 Owner's manual

Singer

Singer 14T968 User manual

Singer

Singer 262-21 User manual

Singer

Singer Studio S18 User manual

Singer

Singer 136W102 Quick start guide

Singer

Singer 3210 User manual

Singer

Singer 99-31 Installation and operation manual

Singer

Singer 32-64 Installation and operation manual

Singer

Singer QUANTUM STYLIST 9960 User manual

Singer

Singer 3321 User manual

Singer

Singer 110W121 User manual

Singer

Singer 1507 User manual

Singer

Singer 87-1 Installation and operation manual

Singer

Singer 5825 User manual