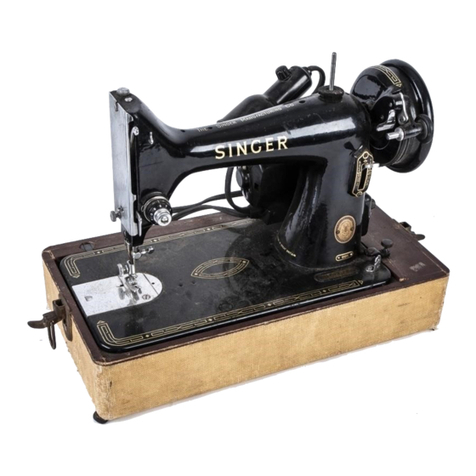

Singer Centurion 121D User manual

Other Singer Sewing Machine manuals

Singer

Singer 95-1 Installation and operation manual

Singer

Singer 95K40 Setup guide

Singer

Singer 196K205 User manual

Singer

Singer 6180 User manual

Singer

Singer 6233 User manual

Singer

Singer 410W1 Quick start guide

Singer

Singer 10uj13 User manual

Singer

Singer 136W105 Quick start guide

Singer

Singer SEQS-6700 User manual

Singer

Singer 176-35 Quick start guide

Singer

Singer XL-150 User manual

Singer

Singer 111W156 Quick start guide

Singer

Singer 99K Series Installation and operation manual

Singer

Singer 655 User manual

Singer

Singer 96-10 User manual

Singer

Singer 63-1 User manual

Singer

Singer 457G140 Setup guide

Singer

Singer Imperial 7005 User manual

Singer

Singer 79-3 User manual

Singer

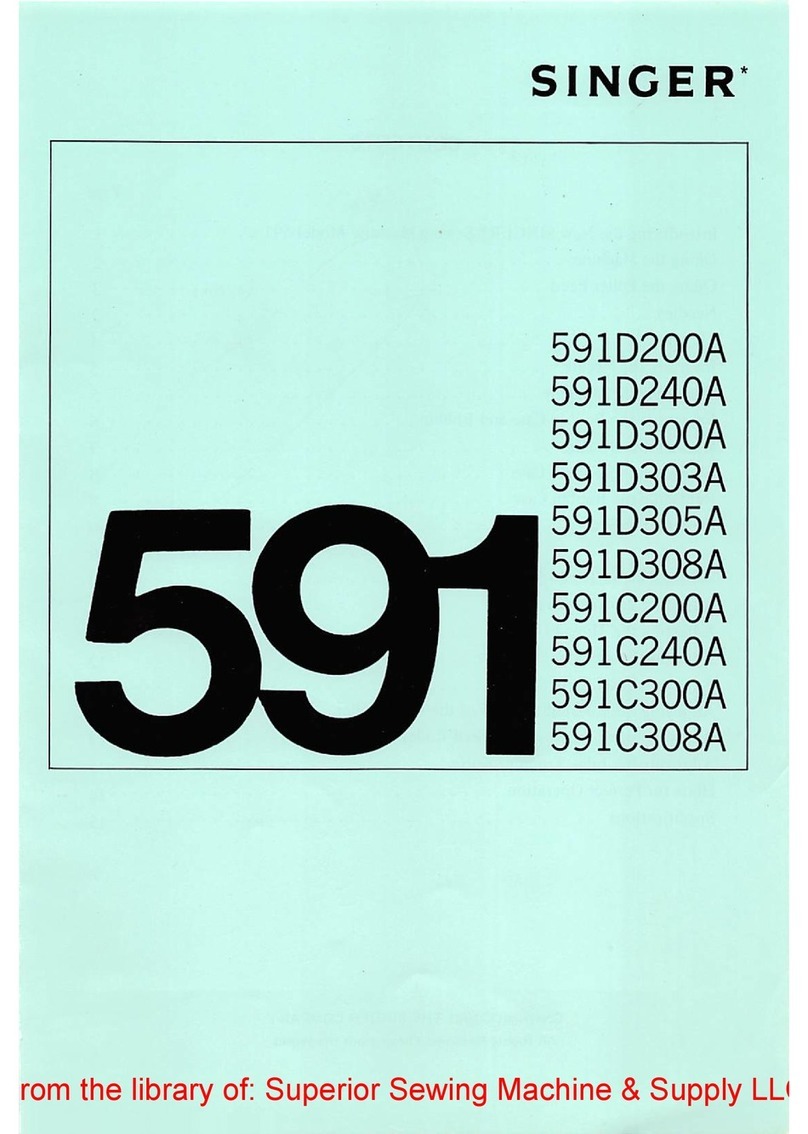

Singer 591D200A User manual