2Singer Furura XL-550

Index

Service tools.................................................................................................................................................4

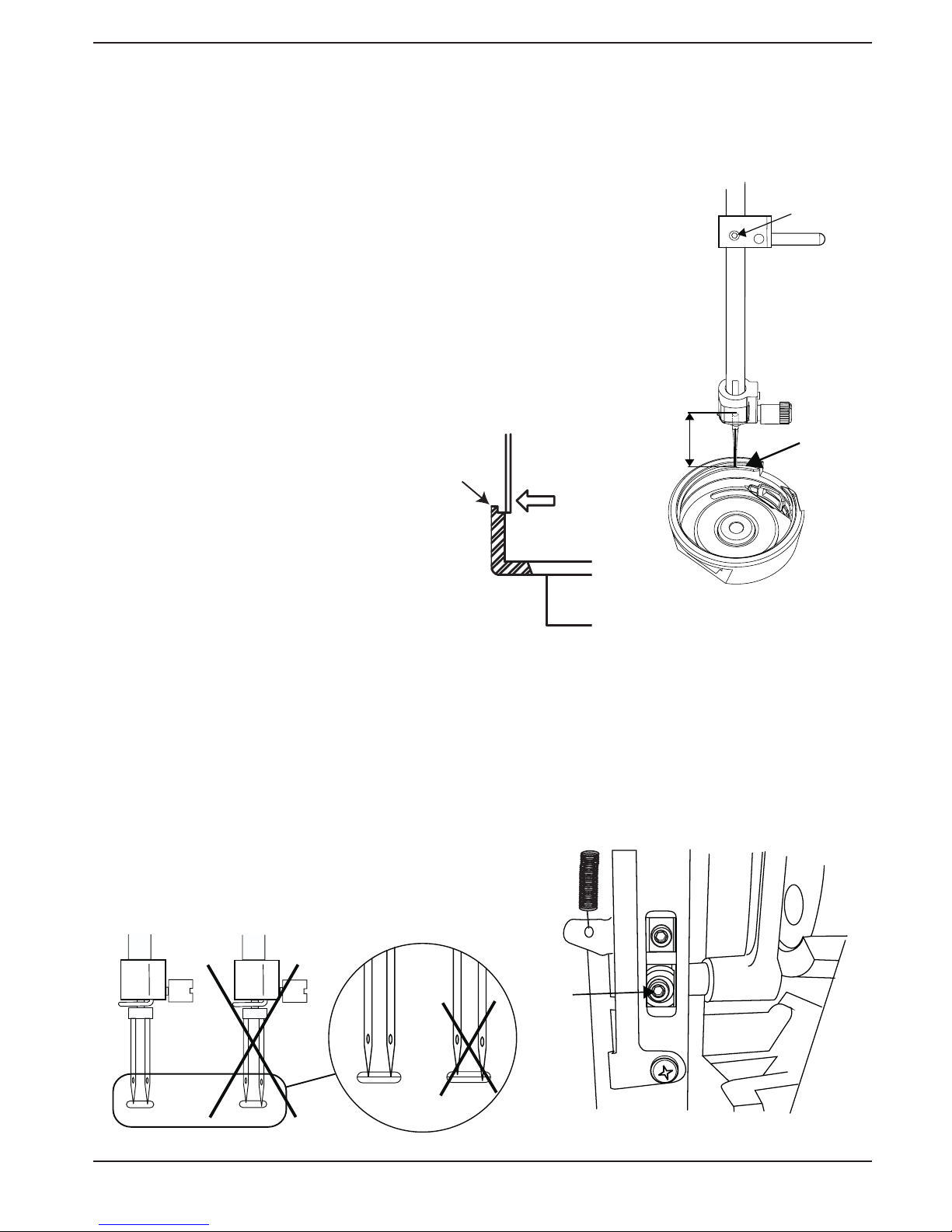

1. Needle bar height ....................................................................................................................................5

2. Needle threader height ............................................................................................................................6

3. Presser foot height ..................................................................................................................................8

4. Presser foot parallelism to the needle hole in needle plate......................................................................9

5. Presser foot parallelism to the needle plate feed dog slot’s...................................................................10

6. Feed-dog height ....................................................................................................................................11

7. Feed timing ............................................................................................................................................12

8. Positioning of Step motor for feeding - Feed balance basic point.........................................................13

9. Feed Balance .........................................................................................................................................14

10. Basic positioning of zigzag step motor ................................................................................................15

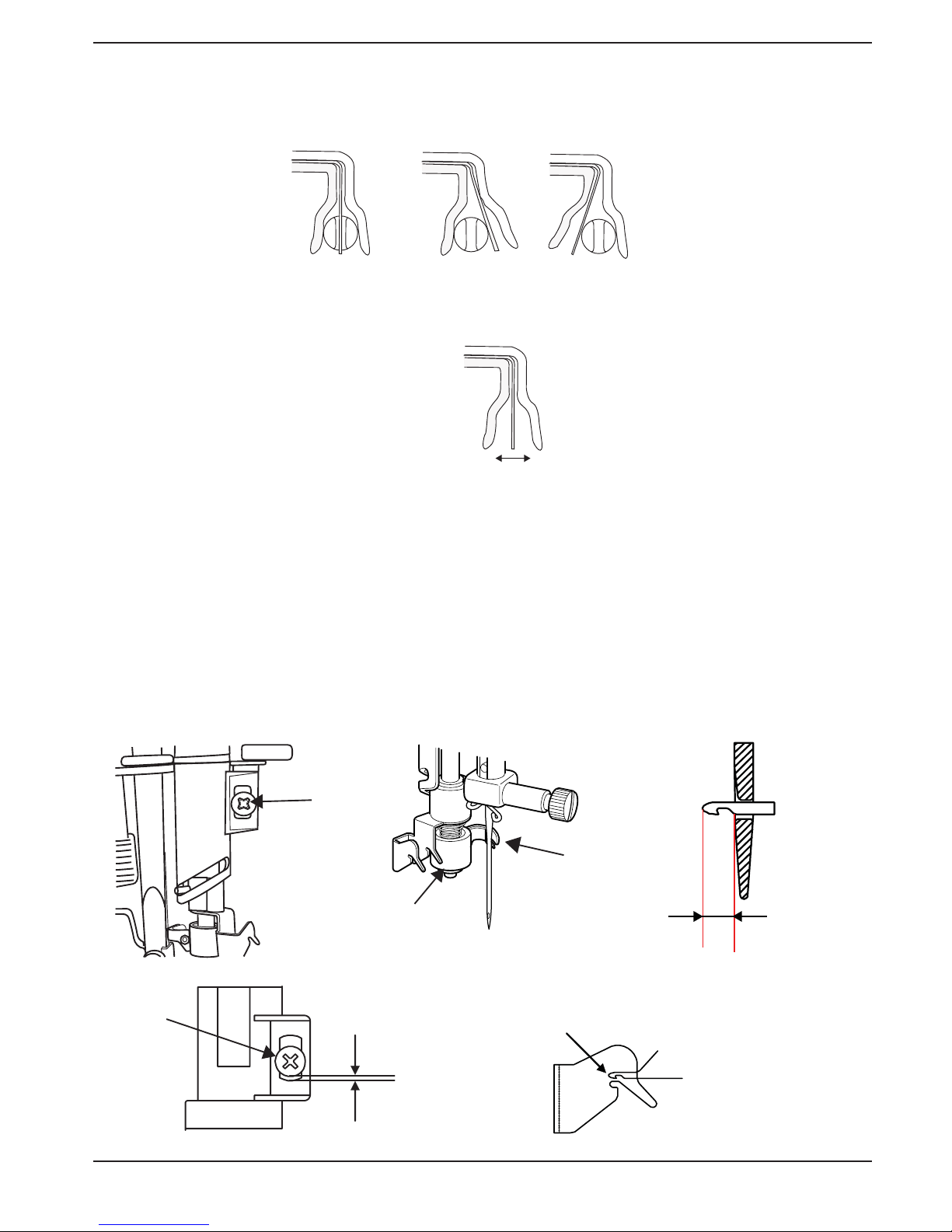

11.Adjustment of needle at center position................................................................................................16

12. Tension of timing belt............................................................................................................................17

13.The timing of the hook in relation to the needle ....................................................................................18

14. Play of hook gears................................................................................................................................19

15. Retaining bracket for bobbin case........................................................................................................20

16. The Timing of take-up lever in relation to the hook...............................................................................21

17. Play of gears for take-up lever..............................................................................................................22

18.Parallelity of needle bar swing...............................................................................................................23

19. Needle clearance to hook ....................................................................................................................24

20. Alignment of needle plate to hook ........................................................................................................25

21. Bobbin case thread tension .................................................................................................................26

22. Upper thread tension unit....................................................................................................................27

Function mode of sewing machine - thread sensor deactivated. ...............................................................28

Test mode of sewing machine....................................................................................................................29

Apply to model XL-550...............................................................................................................................29

Test mode for sewing machine...................................................................................................................30

Error code list .............................................................................................................................................31

Test mode for sewing machine with embroidery unit..................................................................................32

Removing face, thread cutter , bobbin winding and covers ......................................................................34

Removing base , front and back covers.....................................................................................................35

Removing base , front and back covers cont. ............................................................................................36

Remove the top cover.................................................................................................................................38

Remove Hoop carrier cover........................................................................................................................39

Adjustment origin position of embroidery foot along X & Y axis.................................................................40