SIP Protection 2XD2 User manual

EN

VISIP0590 02V/2018: Technical status : 03/08/2018 (subject to adaptions )

SIP PROTECTION, Fabriekstraat 23, B-8850 Ardooie, Belgium

Tel + 32 51 740 800 - +32 51 740 962

http://www.sip-protection.com –mailto: info@sip-protection.com 1/4

Ffff aaaaaffff USER INSTRUCTIONS 0403

Chainsaw protective gloves

PLEASE READ BELOW INSTRUCTIONS CAREFULLY BEFORE WEARING THESE GLOVES

CHECK WITH YOUR SAFETY EGINEER OR YOUR SUPERIOR IF THIS GLOVE IS SUITABLE FOR

YOUR SPECIFIC WORKING ENVIRONMENT .

KEEP THESE INSTRUCTIONS CAREFULLY IN ORDER TO BE ABLE CHECK THOSE ON EACH

MOMENT*

(*) CHECK ON WWW.SIOENAPPAREL.COM IF YOU HAVE THE MOST RECENT VERSION

These gloves meets the requirements of the Personal Protective Equipment (PPE) EU European

Regulation 2016/425 .(solidity, safety, innocuousness, comfort). By means of type approval, the glove

has been certified to the European standard –EN 381-7:1999 (Chainsaw protective gloves) - EN 388 :

2016 (Protective gloves against mechanical risks). The PPE also complies with the. Norm EN

420:2003 (Protective gloves –General requirements and test methods) .

Protective equipment with reference 2XD2 / 2XD3 / 2SB4 / 2SA4 / 2SA5 / 2SA7 / 2SB5 , will be labeled

with above mentioned norms.

Type-examination has been done by Finnish Institute of Occupational Health , Topeliuksenkatu 41 b,

FI-00250 Helsinki, Finland (NB 0403)

If the number 0403 is shown on the right next to the CE pictogram, it means that it is category III PPE

of a complex design that is to protect the user against hazards which are fatal or which can seriously

and irreparably impair one’s health.. This type of PPE is submitted to an EC-quality guarantee system

of the production with supervision (module C2). The supervision has been entrusted to Finnish

Institute of Occupational Health , Topeliuksenkatu 41 b, FI-00250 Helsinki, Finland (NB 0403).

The EU declaration of conformity can be found at the following Internet address: http://sio.to/eudoc

This PPE is in conformity with the REACH regulation. This PPE contains no elements of which is known

today that they can cause allergic reactions or which are known to be carinogenic or mutagenic .. This

product does not contain any substances at such a level that is known or suspected of having harmful

effects on the hygiene or health or the user within the expected conditions of usage. The design does

not cause any irritation or discomfort to the wearer. This personal protection equipment does not contain

materials that are known to provoke allergic reactions. If allergic reactions should occur, consult a

physician immediately and take contact with the manufacturer.

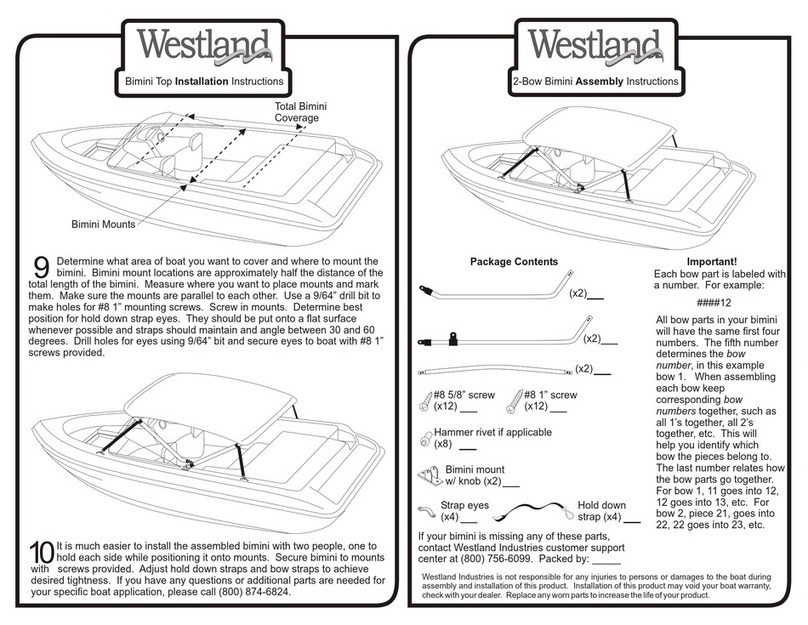

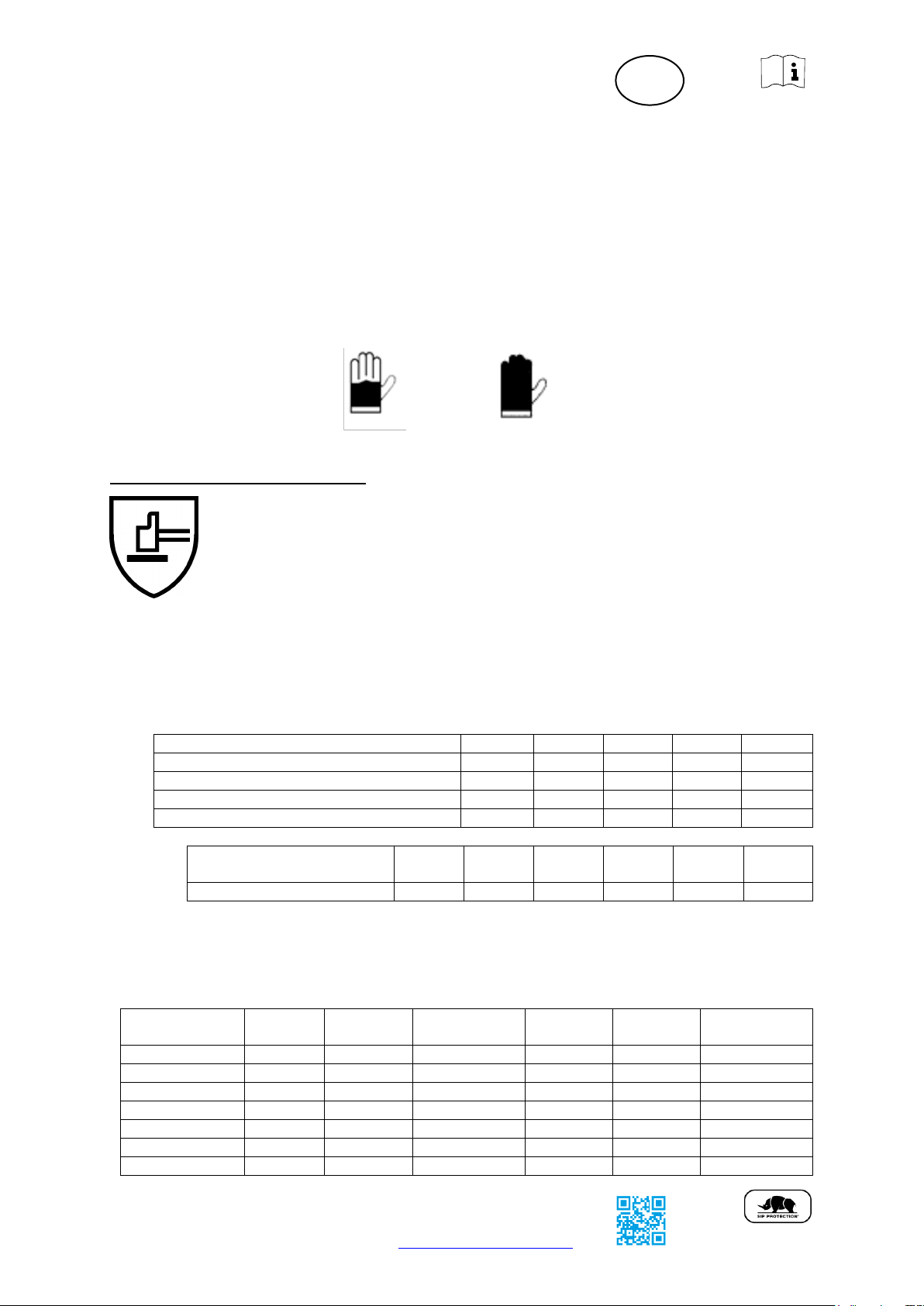

Chain saw protection

EN 381-7: 1999

Design x , class x

Reference

Design

Protection

Class

Chain speed

(m/s)

2XD2

A

Left hand only

1 (20 m/s)

2XD3

A

Left and right hand

1 (20 m/s)

2SA4

A

Left and right hand

1 (20 m/s)

2SA5

A

Left and right hand

1 (20 m/s)

2SB4

A

Left and right hand

1 (20 m/s)

2SB5

A

Left hand only

1 (20 m/s)

2SA7

A

Left hand only

1 (20 m/s)

EN

VISIP0590 02V/2018: Technical status : 03/08/2018 (subject to adaptions )

SIP PROTECTION, Fabriekstraat 23, B-8850 Ardooie, Belgium

Tel + 32 51 740 800 - +32 51 740 962

http://www.sip-protection.com –mailto: info@sip-protection.com 2/4

The glove does not give you protection on the places where there is no protective material.

Reference 2XD2 , 2SB5, 2SA7 is left hand protection

Reference 2XD3 , 2SA4, 2SA5 , 2SB4 is both hand protection.

The class to which the glove performs, the chain speed and the area of the glove which is covered by

protective material specified by a certain design, is mentioned on the label

Classification according to chain speed : class 1 : 20 m/s class 2 : 24 m/s class 3 : 28 m/s

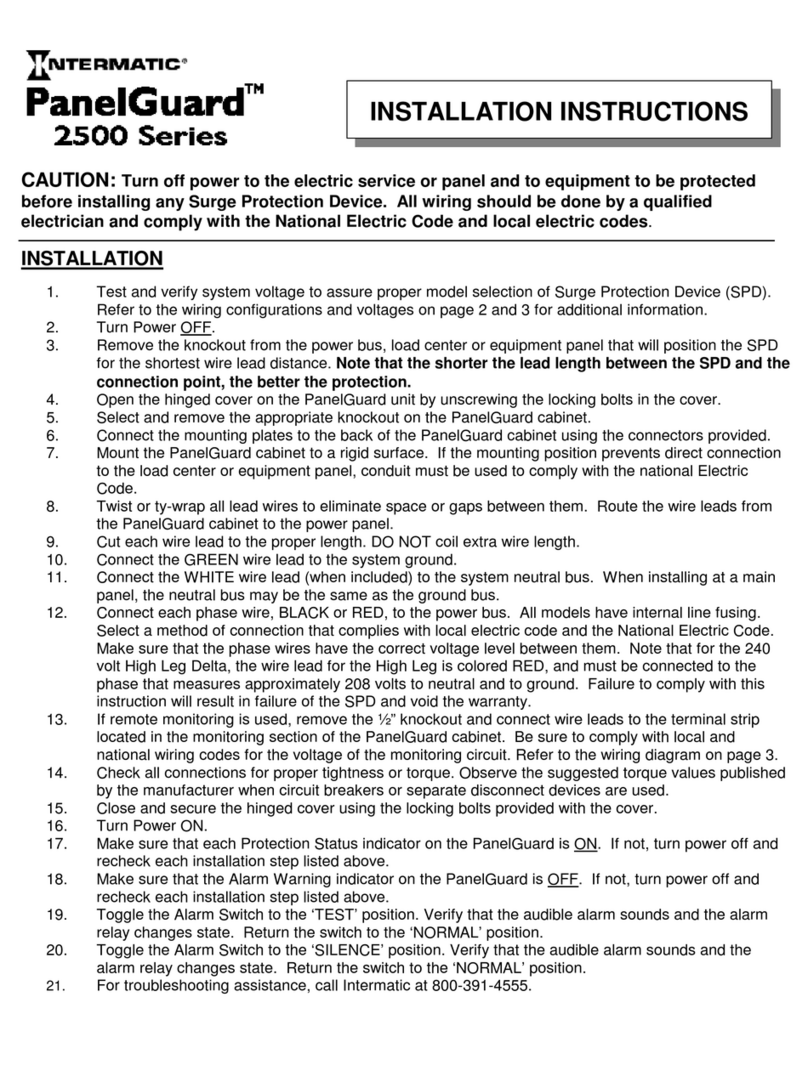

Design A applies to five finger gloves without chainsaw protection in the fingers or thumb.

Design B is protective gloves or mitts with specific chainsaw protection as in design A

and on the back of the fingers but not on the thumb

Glove Design A Glove Design B

Protection against mechanical risk

An “x” indicates that the glove has not been submitted to this test.

A “0” indicates that the glove has been tested but no protection level

was reached.

EN 388:2016

This standard describes 4 mechanical risks : abrasion, blade cut, tear resistance, puncture resistance

and if applicable impact protection.

A protective glove against mechanical risks shall have performance level of 1 or above for at least one

of the properties (abrasion, blade cut, tear and puncture) or at least level A of the EN ISO 13997:1999

TDM cut resistance test.

Level 1

Level 2

Level 3

Level 4

Level 5

Abrasion resistance (number of cycles)

100

500

2000

8000

-

Blade cut resistance ( index)

1.2

2.5

5

10

20

Tear resistance (N)

10

25

50

75

-

Puncture resistance (N)

20

60

100

150

-

Niveau

A

Niveau

B

Niveau

C

Niveau

D

Niveau

E

Niveau

F

TDM cut resistance (N)

2

5

10

15

22

30

The gloves have been tested in accordance with EN 388 and achieved following results. (see label)

The achieved test levels are guaranteed on new and unwashed gloves. The effect of washing the

gloves have not been tested.

This protection do not apply to the finger.

Reference

Achieved

level

Abrasion

resistance

Blade cut

resistance

Tear

resistance

Puncture

resistance

TDM cut

resistance

2XD2

3 1 3 1 X

3

1

3

1

X

2XD3

3 1 3 1 X

3

1

3

1

X

2SA4

3 1 3 2 X

3

1

3

2

X

2SA5

3 1 3 2 X

3

1

3

2

X

2SB4

3 1 3 2 X

3

1

3

2

X

2SB5

3 1 3 2 X

3

1

3

2

X

2SA7

3 1 3 2 X

3

1

3

2

X

EN

VISIP0590 02V/2018: Technical status : 03/08/2018 (subject to adaptions )

SIP PROTECTION, Fabriekstraat 23, B-8850 Ardooie, Belgium

Tel + 32 51 740 800 - +32 51 740 962

http://www.sip-protection.com –mailto: info@sip-protection.com 3/4

Attention:

* No PPE can provide total protection against injury due to a chainsaw. The degree of protection

depends on numerous factors (e.g. speed of the chainsaw, engine torque, angle at which the bar

contacts the glove, working position –stooping or upright, etc...)

* This cut retardant glove is no substitute for safe operation of a power tool. Incorrect use of a power

tool can result in accidents. It is therefore essential to observe all local safety regulations, standards and

ordinances as well as the safety precautions and instructions given in the owner’s manual of your power

tool. It’s responsibility of the employers together with the user to analyze if each glove protects against

the risk that can appear in any given work situation.

* This glove is provided with pads constructed from several layers loose woven material, so that, when

in contact with a moving chain, the threads are torn out and clog the chain saw drive mechanism. DO

NOT REPAIR OR STITCH THROUGH THE PROTECTIVE MATERIAL

HOWEVER, no item will provide full protection, therefore never intentionally let the chain make contact

with any part of this glove. Remember a chainsaw is a machine which should always be treated with

extreme caution according to the instructions of the chainsaw supplier (use both hands!!)

In order to optimize the protection this glove should always be worn with suitable shoes, clothing, helmet,

ear protectors. The cut-retardant material in protective gloves helps provide protection only if it has not

been pinched, twisted or modified. It is therefore important to take this into account before choosing a

specific working technique.

Before using the chain saw consult your supplier to ensure that your protective clothing is compatible

with the machine. Gloves shall not be worn when there is a risk of entanglement by moving parts of

machines.

* Ensure that this safety glove is not damaged by sharp or pointed implements (saw chain, thorns, metal

tools, etc. ) as well as aggressive substances, such as acids, oil, solvents, fuel, animal excrements , etc.

It must also be kept away from hot objects (exhaust mufflers, etc. ) and other heat sources (naked lights,

heaters, etc.). This protective glove has been designed for the users of handheld chainsaws. It does not

provide protection against other risks (e.g. other areas of operation such as construction work, contact

with electric energy/current, when operating cut-off machines, pressure washers , etc.)

* Only gloves of a suitable size will guarantee a secure grip. Gloves which are either too loose or too

tight will restrict the movements and will not provide the optimum level of protection. Please note that

moisture can affect the grip of the gloves.

* Never stitch through the protective pad, because then the long fibres won’t be easily removed from the

pad to clog the drive mechanism of the chain saw.

* When not in use, store the gloves in a well ventilated area away from extremes of temperature. If the

gloves are wet, reshape it by hand and allow it to dry fully before placing it into storage.

* The protective material and area of coverage must not be altered. If the gloves are damaged it will no

longer provide the optimum level of protection, and therefore should be replaced immediately. Damaged

gloves should be immediately destroyed or marked to prevent them from being worn again. NEVER

wear damaged gloves.

*Advisory lifespan depends on the level use, care, storage. UV light, soiling. Less intensive use extend

the lifespan accordingly.

* Always check the condition of the product before each use.

Care instructions

Washing not allowed.

Bleaching not allowed with product based on chlorine .

The gloves cannot be ironed .

Dry cleaning not allowed .

The glove cannot be dried in a tumble dryer nor in a tunnel dryer : .

Soiled or damaged gloves reduce the level of protection. Long-lasting exposure to dirt, eg chemicals

such as oils, greases, etc., can also damage the protective properties .

Gloves subjected to wet conditions should be allowed to dry naturally in a cool and dry environment.

away from direct heat sources. Force drying can cause deterioration of the materials.

EN

VISIP0590 02V/2018: Technical status : 03/08/2018 (subject to adaptions )

SIP PROTECTION, Fabriekstraat 23, B-8850 Ardooie, Belgium

Tel + 32 51 740 800 - +32 51 740 962

http://www.sip-protection.com –mailto: info@sip-protection.com 4/4

As all Personal Protective Equipment, this product does not offer protection against all risks

(see your specific risk-analyse)

Making alterations to this clothing (without permission from the manufacturer) is not permitted

Check if you have the right size and if there is no visible damage to the gloves

Hand measurements : GLOVE SIZE CIRCUMFERENCE (b) HAND LENGTH (a)

8 203 mm 182 mm

9 229 mm 192 mm

10 254 mm 204 mm

11 279 mm 215 mm

12 304 mm 226 mm

Tractability: On the label you find the necessary information. Style number /Order number/date of

Production

Storage instructions : When you are not wearing the gloves, you should store it dry, uncompressed,

in a well-ventilated room. Avoid extreme temperatures and avoid direct sunlight to prevent colour

changes from occurring. Complaints about colour changes will not be entertained.

SIOEN cannot be held responsible in any way whenever a PPE is not used 100 % according to the

above instructions.

Please do not hesitate to contact us when further information needed.

ba

This manual suits for next models

6

Table of contents