SENSTAR FPS-3 Original operating instructions

FPS System

Fence Protection System

G2DA0302-001, Rev A

First edition

September 15, 2009

FPS-3

Installation &

Operation Guide

Senstar Corporation

119 John Cavanaugh Drive

Carp, Ontario

Canada K0A 1L0

Tel: +1 (613)-839-5572

Fax: +1 (613)-839-5830

Website: www.senstar.com

Email address: info@senstar.com

G2DA0302-001, Rev A

First edition

September 15, 2009

Senstar is a registered trademark, and the Senstar logo is a trademark of Senstar Corporation. Product names and Company

names used in this document are included for identification purposes only, and are the property of, and may be trademarks of,

their respective owners. Copyright © 2009 Senstar Corporation. All rights reserved. Printed in Canada.

The information provided in this guide has been prepared by Senstar Corporation to the best of its ability. Senstar Corporation is

not responsible for any damage or accidents that may occur due to errors or omissions in this guide. Senstar Corporation is not

liable for any damages, or incidental consequences, arising from the use of, or the inability to use, the software and equipment

described in this guide. Senstar Corporation is not responsible for any damage or accidents that may occur due to information

about items of equipment or components manufactured by other companies. Features and specifications are subject to change

without notice. Any changes or modifications to the software or equipment that are not expressly approved by Senstar

Corporation void the manufacturer’s warranty, and could void the user’s authority to operate the equipment.

Senstar’s Quality Management System is IS0 9001:2000 registered.

Limited Warranty

a) The Company warrants that the electronic components of the products manufactured by the Company are free from all

manufacturing defects. The Company's warranty does not extend to the performance of the products, which may vary depending

on environmental conditions, use and installation practices. The Company's liability under this warranty shall be limited to, at its

option, either repairing or replacing the defective components of the products or granting a credit for the products or parts thereof.

The Company's liability shall apply only to products which are returned to the factory or authorized repair point, transportation

charges prepaid by the Buyer within one (1) year from the shipment date of the product from the Company and which are, after

examination, disclosed to Company's satisfaction to be defective due to defects in workmanship and/or materials. This warranty

shall not apply to any products which have been installed, repaired or altered by other than personnel certified by the Company, or

to products which have been subject to physical or electrical abuse, misuse, or improper storage or to products which have not

been used or maintained in compliance with any applicable recommendations of the Company. This warranty does not apply to

any parts or components of the products, which are normally consumed in operation, including but not limited to batteries, fuses

and light bulbs.

b) The Company specifically disclaims any and all warranties, expressed or implied, including but not limited to any warranties

or merchantability or fitness for a particular purpose. Under no circumstances be it due to a breach ofwarranty or any other

cause arising out of the performance or non-performance of the Product shall the Company be liable to the Buyer for incidental or

consequential damages, including but not limited to: lost profits, loss of property due to the freight, plant downtimes, or suits by

third parties.

5

INSTALLATION AND OPERATION INSTRUCTIONS — FENCE PROTECTION SYSTEMS

CONTENTS

PAGE

1QUICK START...................................................................... 1

2GENERAL ...........................................................................10

3THEORY OF OPERATION .................................................. 11

4FENCE CONDITIONS .........................................................14

5INSTALLATION ..................................................................18

6SYSTEM START UP AND TESTING ....................................45

7MAINTENANCE/TROUBLESHOOTING ............................. 52

ADDENDUM I – FIELD PERFORMANCE ANALYZER ................... A-1

iv

INSTALLATION AND OPERATION INSTRUCTIONS — FENCE PROTECTION SYSTEMS

v

LIST OF FIGURES PAGE

Figure 1 Typical MX-5300/FPS System Connections ..... 2

Figure 2 Fence Mounted FPS Dual Zone Pre-Amp ......... 3

Figure 3 Cable Tie Installation................................................ 4

Figure 4 Dual Zone Pre-Amp Cable Connections ........... 4

Figure 5 MPS-4100 Microwave Installation....................... 5

Figure 6 MPS Connections to FPS-3 via

Dual Zone Relay Input Card................................... 6

Figure 7 MX-5300 Power Supply Connections ................ 7

Figure 8 Central Controller Connections ........................... 8

Figure 9 MX-5300 Loop Connections.................................. 9

Figure 10 FPS-3 System .............................................................. 10

Figure 11 Alarm Zone Connections ....................................... 12

Figure 12 Block Diagram ............................................................ 13

Figure 13 Loose Fabric at Fence Posts ................................... 14

Figure 14 Loose Fabric at Diagonal Stiffeners .................... 14

Figure 15 Loose Fabric at Wire Stiffeners ............................. 15

Figure 16 Dangling Barbed Wire ............................................. 15

Figure 17 Improperly Secured Brackets................................ 15

Figure 18 Missing Vertical Locking Posts.............................. 15

Figure 19 Excessive Play............................................................. 16

Figure 20 Loose Chain and Lock.............................................. 16

Figure 21 Roller and Rail Play................................................... 16

Figure 22 Signs Not Securely Attached................................. 16

Figure 23 Fence-mounted Pre-amp ....................................... 19

Figure 24 Pre-Amp Remote Mounting .................................. 21

Figure 25 Pre-Amp Pedestal Mounting................................. 22

Figure 26 Unreeling Cable ......................................................... 23

Figure 27 Cable Tie Installation................................................ 24

Figure 28 Transducer Cable Around Fence Post ................ 25

Figure 29 Transducer Cable Service Loop ............................ 25

Figure 30 Increasing Transducer Cable Sensitivity ........... 26

Figure 31 Zone Overlap .............................................................. 27

Figure 32 Helisensor/Sensor Cable Termination-

Single Run .................................................................... 30

Figure 33 Helisensor/Sensor Double Run Installation/

Termination ................................................................. 31

Figure 34 Transducer Cable Routing in Condulet ............. 32

Figure 35 Transducer Cable Connection .............................. 32

7

INSTALLATION AND OPERATION INSTRUCTIONS — FENCE PROTECTION SYSTEMS

LIST OF FIGURES PAGE

Figure 36 End-of-Line Termination ......................................... 33

Figure 37 Splice Termination .................................................... 33

Figure 38 End-of-Line Termination With 2 Megaohm

Resistor.......................................................................... 33

Figure 39 EOL Condulet Attached To Fence........................ 34

Figure 40 Condulet Splice Attached To Fence.................... 34

Figure 41 Condulet “G”Attached To Fence .......................... 34

Figure 42 Transducer Service Kit ............................................. 36

Figure 43 Transducer Cable Preparation .............................. 36

Figure 44 Hinged Gate Installation......................................... 37

Figure 45 Telegate Installation ................................................. 38

Figure 46 Telegate Support Post Location........................... 39

Figure 47 MPS Microwave System .......................................... 41

Figure 48 Pre-Amp Cable Connections ................................. 42

Figure 49 Central Controller Cable Connections ............... 43

Figure 50 Dual Zone Relay Input Card Wiring .................... 44

Figure 51 Interface Board Connections and Controls ..... 46

Figure 52 Dual Zone Card.......................................................... 46

Figure A-1 Field Performance Analyzer ................................ A-3

LIST OF TABLES

Table 1 Sensor Cable Capacitance...................................... 13

Table 2 Field Measured Gain and Count Settings......... 51

Table 3 FPS-3 Troubleshooting Table ................................ 56

Table 4 Interface Board Fault Isolation Matrix................ 58

vi

1

INSTALLATION AND OPERATION INSTRUCTIONS — FENCE PROTECTION SYSTEMS

FENCE PROTECTION SYSTEMS

1 QUICK START

Qualified technicians may follow these simplified procedures to install and test the FPS-3 Fence

Protection System.Prerequisites for using the quick start procedures are:

• Attendance at one or more Magal-SenstarFPS-3 training class.

• Prior MX-5000 or MX-5300 field installation experience.

Before proceeding, VERIFY that you have a complete site layout showing zone extents, processor

locations, and conduit interconnections. If you are not familiar with any of the procedures described in

this section, refer to the appropriate manual for more detailed information.

IMPORTANT PROCEDURES

Throughout the installation it is very important that certain procedures are observed:

Install ground rods and proper grounding at the MX-53OO,all FPS-3 fence-

mounted pre-amps, and all microwave locations.

Use only the approved multiconductor shielded cable for connecting the MX-

5300 FPS-3 Central Controller to the FPS and MPS units.

Terminate wiring and shields exactly as shown. Improper terminations will cause

system noise and degrade performance.

The FPS-3 Central Controller must be installed within 100 feet of the MX-5300.

INSTALLATION AND OPERATION INSTRUCTIONS — FENCE PROTECTION SYSTEMS

2

Installation

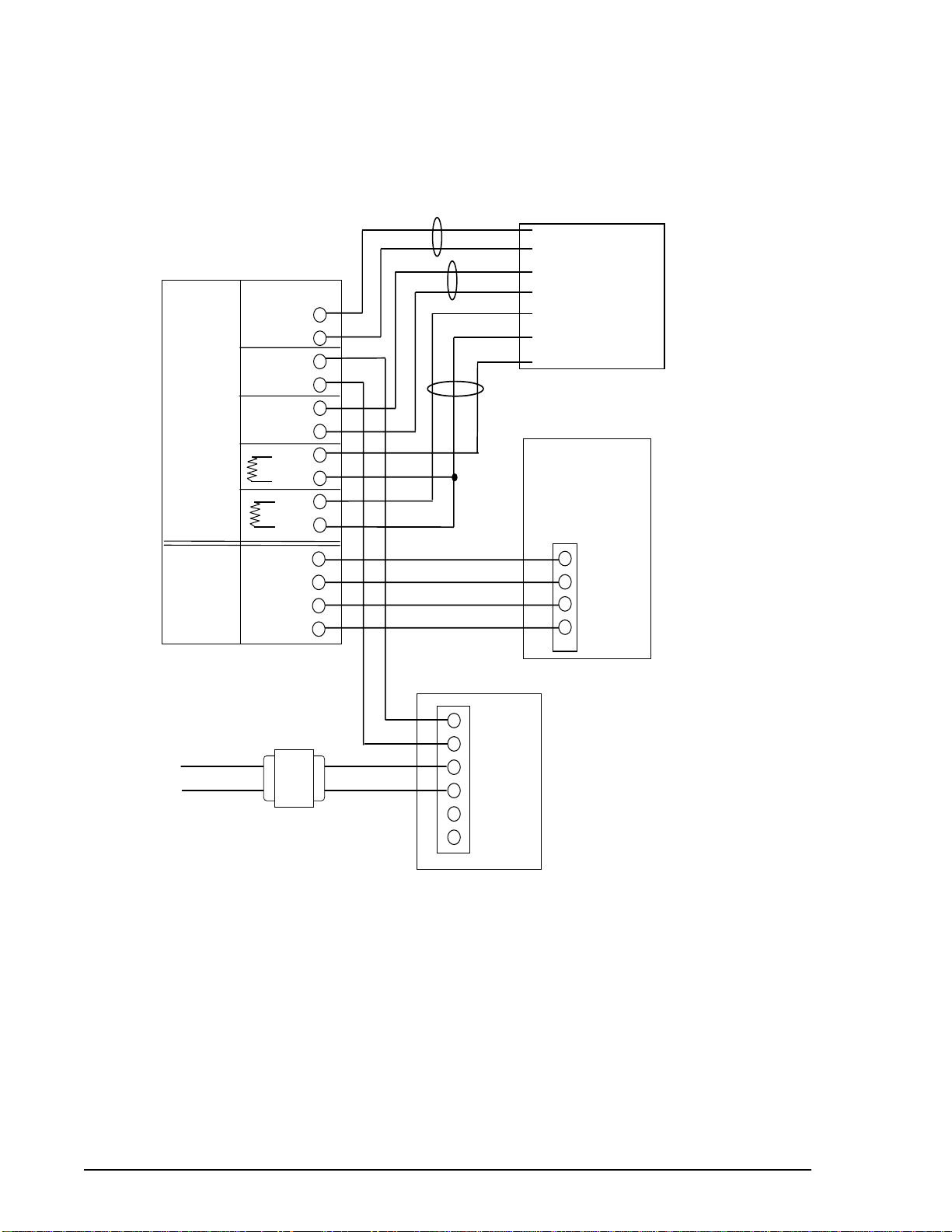

Figure 1 shows the typical wiring interconnection of components.

•The interconnect wiring should be run in conduit, either underground or along the base of the

fence.

•The interconnect cable must be an approved two-pair, 24-gauge, individually shielded twisted

pair low capacitance cable, with high density polyethylene jacket, such as the Magal-Senstar

FPS Interconnect Cable or factory-approved equal.

Figure 1. Typical MX-5300 / FPS System Connections

3

INSTALLATION AND OPERATION INSTRUCTIONS — FENCE PROTECTION SYSTEMS

Mount each FPS-3 Dual Zone Pre-Amp processor as shown in Figure 2.

• Use metal brackets or Unistrut-type mounting material to provide a solid backing. A fence post

will provide a solid mounting.

• Arrange the conduit/control wiring entrance as shown.

• Install a copper-clad ground rod at each processor location, and connect a minimum 8-gauge

ground wire to the processor bolt as shown. IMPORTANT: Connect the ground wire directly to

the enclosure stud as shown.

Figure 2. Fence Mounted Dual Zone Pre-Amp

Ground MUST be

attached to grounding

stud here.

Unistrut type

mounting

Approx. 12" apart

on center.

Install copper-clad

ground rod per

National Electrical Code

To FPS-3 Central

Controller

Watertight com-

pression fittings

GROUND ROD

CONNECTION

FPS-3

DUAL ZONE

PRE-AMP

INSTALLATION AND OPERATION INSTRUCTIONS — FENCE PROTECTION SYSTEMS

4

Run the sensor cable from each FPS-3 dual zone pre-amp as shown in Figures 2 and 3.

NOTE: Your installation may utilize either standard "black" sensor cable or Helisensor.

Observe special requirements for each type sensor.

• Attach the sensor cable to the

fence at approximate 12-inch

intervals with black UV cable ties

as shown in Figure 3. Use ONLY

the approved black UV-protected

cable ties.

• Provide service loops every 50 feet

and increased sensitivity loops at

each corner or end post. Provide

cable overlap at adjacent zones.

Install TSK termination boxes at

each sensor end-of-line (single-run

cable) and splices if necessary.

• Connect each sensor cable to the

Pre-Amp as shown in Figure 4.

• Connect the control wiring to each

dual zone pre-amp as shown in

Figure 4.

Figure 3. Cable Tie Installation

Figure 4. Pre-Amp Cable Connections

Approx. 12"

REMOVABLE

TERMINAL BLOCKS

DUAL ZONE PRE-AMP.

CIRCUIT BOARD

1 2

CENTER

SHIELD

1 2 1 2

CENTER

SHIELD

1 2

SHIELD

ZN 1-1

ZN 1-2

ZN 2-1

ZN 2-2

SEE WIRING

DETAIL

WIRING TO

CENTRAL CONTROLLER

SHIELD

ZN 1-1

ZN 1-2

ZN 2-1

ZN 2-2

RED

BLK

SHIELD

GRN

WHT

TO

CENTRAL

CONTROLLER

NOTE: WIRING COLORS SHOWN MATCH THE

Magal-Senstar CABLE

LEFT ZONE

SENSOR CABLE

RIGHT ZONE

SENSOR CABLE

Lightly shaded cables

indicate return sensor

cable terminations in a

double run installation

1 MEG 1 MEG

5

INSTALLATION AND OPERATION INSTRUCTIONS — FENCE PROTECTION SYSTEMS

Mount each MPS-4100 microwave unit (pair) as

shown in Figure 5.

•Install each piece of equipment generally as

shown.

Figure 5. MPS-4100 Microwave Installation

a

a

a

a

a

a

a

aa

a

aa

aaa

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

aa

a

aa

aaa

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

MPS-4100 TRANSMITTER

MPS-4100 RECEIVER

To FPS-3 Central

Controller

INSTALLATION AND OPERATION INSTRUCTIONS — FENCE PROTECTION SYSTEMS

6

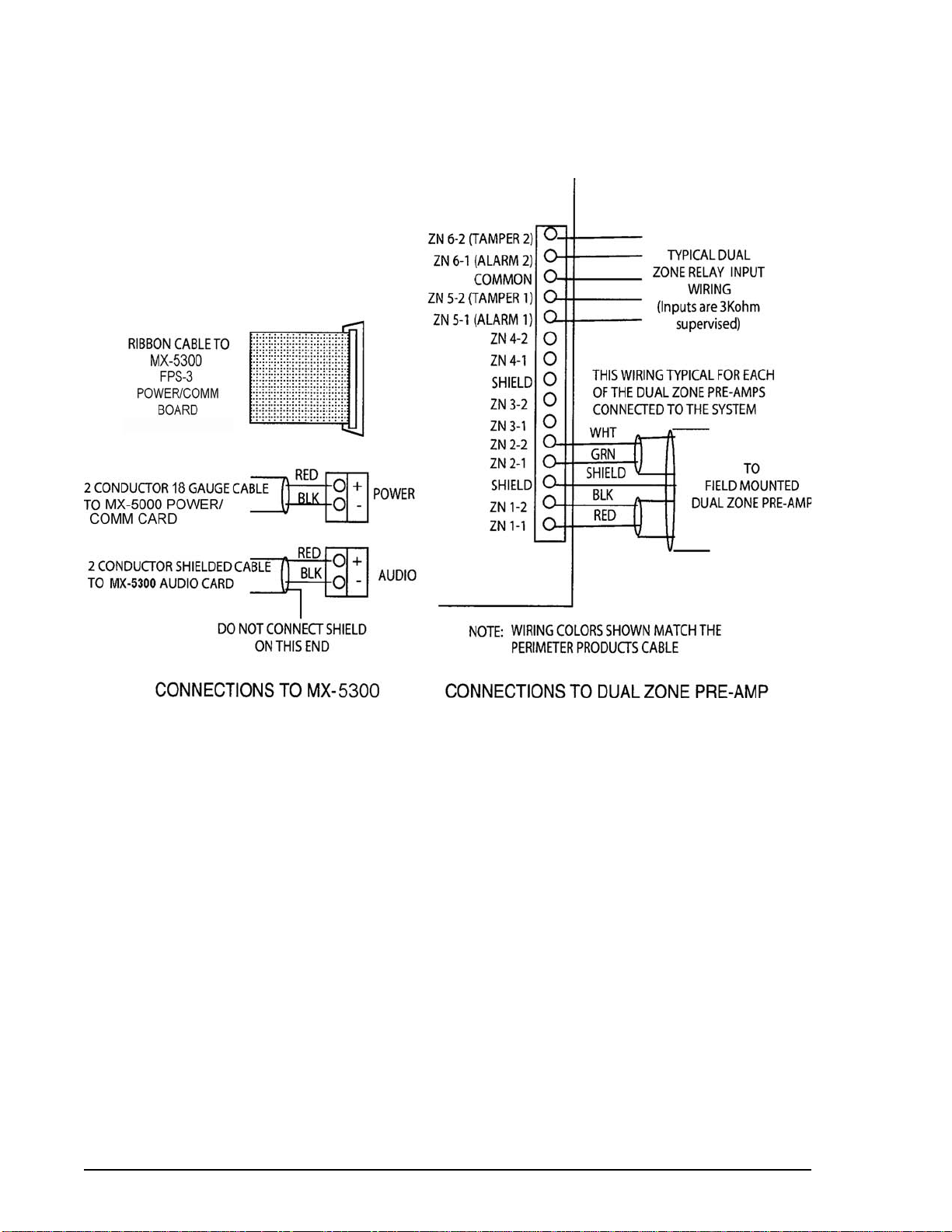

Figure 6. MPS Connections to FPS-3 via Dual Zone Relay Input Card

•Run interconnecting cables and connect as shown in Figure 6.

Position the FPS-3 Central Controller and the MX-5300 Control Unit in the control room as appropriate

for proper viewing and operation.

MPS 4100 TRANSMITTER

+DC OUT

RTN

AC IN

AC IN

BAT +

BAT -

UPS-PFI POWER SUPPLY

CLASS 2

TRANSFORMER

115V/60HZ 16.5 VAC

AUDIO +

AUDIO -

+12 VDC

COMMON

DATA/TEST +

DATA/TEST -

TAMPER

TAMPER

ALARM

ALARM

TB 1

MPS 4100 RECEIVER

3K

COMMON

+12V DC

TAMPER

TAMPER

TAMPER

TAMPER

COMMON

+12V DC

TB 2

AUDIO

ALARM

DUAL ZONE RELAY INPUT

CARD IN FPS-3 CENTRAL

CONTROLLER

TEST

3K

May select

3K at Tx or

N/C here

N/C output

or 3K output

and N/C at

Receiver

TAMPER

COMMON

7

INSTALLATION AND OPERATION INSTRUCTIONS — FENCE PROTECTION SYSTEMS

Connect the power supply transformer and battery as shown in Figure 7.

Figure 7. MX-5300 Power Supply Connections

INSTALLATION AND OPERATION INSTRUCTIONS — FENCE PROTECTION SYSTEMS

8

Field wiring connections to the FPS-3 Central Controller will be made as shown in Figure 8.

Figure 8. Central Controller Connections

9

INSTALLATION AND OPERATION INSTRUCTIONS — FENCE PROTECTION SYSTEMS

Figure 9. MX-5300 Loop Connections

Connections from the FPS-3 Central Controller to the MX-5300 will be made as shown in Figure 9.

Apply power to the MX-5300 and FPS-3 Central Controller by connecting the AC power first, then the

battery system. Perform initial programming to acknowledge initial alarms.

Perform initial testing of each zone using the self-test function and audio probe of the FPS-3 Central

Controller. Measure the optimum gain and count at each dual zone pre-amp using the MSI Field

Performance Analyzer (FPA). Perform fence quieting procedure if necessary.

Complete MX-5300 programming by performing the programming steps needed for your system. For

programming reference,refer to MX-5300 Installation Manual,Table 2.

Set the FPS-3 dual zone card gain switches for each zone based on your field measurements using the

FPA. Program the counts for each zone on the MX-5300.

Perform final testing, including climb test, in each zone as required by the system specifications.

1 2 3 4 5 6 7 8

LOOP 3

AUDIO

LOOP 2

AUDIO

Tie shield to

chassis ground lug.

2 pair shielded cable to

FPS-3 central controller.

AUDIO TERMINAL BOARD

TB 2

FPS-3 POWER/COMM BOARD

TB 3

AUDIO +

COMMON

LOOP 1

AUDIO

1 2

-+

POWER/COMM

BOARD

25 conductor ribbon cable

to FPS-3 central controller.

RED

BLK

BLK

RED

INSTALLATION AND OPERATION INSTRUCTIONS —FENCE PROTECTION SYSTEMS

10

2 GENERAL

Magal-Senstar manufactures a unique outdoor perimeter detection system called the FPS-3

Fence Protection System.The FPS-3 system consists of the fence-mounted transducer sensor cable

connected to the fence-mounted dual zone pre-amp and the FPS-3 Central Controller connected to

the MX-5300 Command and Display System. See Figure10.The FPS-3 system is designed for easy

installation and maintenance while providing superior detection if someone attempts to climb, lift the

fabric or cut through the fence.When the transducer cable is installed on the fence, the transducer

cable AND THE FENCE become the fence protection sensor system.

This manual covers all FPS-3 system installations. Just two FPS-3 models are required to accommodate

all types of installations:

FPS-3 Dual Zone Pre-Amp is used when installing standard fence mounted transducer sensor cable.

FPS-3H Dual Zone Pre-Amp is used when installing Helisensor cable.

The FPS-3 Central Controller and the MX-5300 Command and Display System are used in all FPS-3

system installations.

Figure 10. FPS-3 System

11

INSTALLATION AND OPERATION INSTRUCTIONS —FENCE PROTECTION SYSTEMS

3 THEORY OF OPERATION

Concept

When the Transducer Sensor Cable experiences small mechanical shocks or vibrations, an electrical

signal is generated between the center conductor and the outer shield.The Signal Processor then

analyzes that signal and makes the determination as to whether the vibration is intruder related or

from natural causes such as wind, rain, hail, etc. Should there be an intruder, the signal processor will

generate an alarm output.

The FPS-3 system features the Magal-Senstar exclusive EDAPT alarm processing system.The

EDAPT system utilizes a computer modeling program to analyze the fence activity of all alarm zones

and automatically adjust the alarm threshold based on current fence conditions and historical data.

Alarm processing

The MSI FPS system is a strain-sensitive cable sensor system, meaning that a mechanical disturbance in

the fence causes a small strain on the sensor cable that is converted to an electrical signal.

The sensor cable is a small coaxial cable specially manufactured with a permanent electrical charge

throughout its entire length.Any movement in the fence causes a small voltage to appear at the

sensor cable output. Magal-Senstar tests every foot of the sensor cable to verify that the alarm

sensitivity will be uniform over the entire length.

The sensor cable connects to the FPS-3 dual zone pre-amp mounted on or near the fence at the

beginning of the detection zone.The mechanical disturbance detected by the sensor cable is sent to

the dual zone pre-amp. Each FPS-3 dual zone pre-amp contains two independent zones of perimeter

protection (see Figure 11).The typical FPS-3 dual zone pre-amp will have up to a 1000-foot alarm zone

running in each direction.

1. The dual zone pre-amp sends the alarm and tamper information to the FPS-3 Central Controller

for processing. All alarm event processing is accomplished at the FPS-3 Central Controller, away

from the harsh outdoor environment of the fence.The Central Controller contains individual

plug-in cards for alarm processing, system diagnostic lamps and a built-in test system that allows

you to test each zone.

2. The FPS-3 Central Controller forwards alarm event information to the MX-5300 Control Station.

The MX-5300 utilizes advanced EDAPT processing,which uses the alarm data in a unique calcula-

tion to best determine the occurrence of an actual alarm condition over the external physical

forces (wind, rain, etc.) and the aging conditions of the fence installation.

The dual zone pre-amp is capable of monitoring a transducer cable in excess of 1000 feet, depending

on the total capacitance of the cable attached to the sensor input. The graph,Table 1, indicates the

sensor cable capacitance relative to length. The maximum allowable capacitance is 100,000 pf. In

addition to the transducer cable,it is possible to use nonsensitive cable (30MNS) to connect transducer

cable to the processor as long as the maximum capacitance is not exceeded. This is sometimes desir-

able in cases where the processor is not located near the fence.

INSTALLATION AND OPERATION INSTRUCTIONS —FENCE PROTECTION SYSTEMS

12

The ultimate goal of the fence protection system is reliable detection of cutting and/or climbing with

minimum nuisance alarms. Since the FPS sensor system is mounted to the fence fabric, care must be

taken when installing and maintaining the fence. A fence installed to normal professional standards

will provide an acceptable basis for the FPS system. However, a fence improperly installed and/or

missing tie wires and clamps can cause nuisance alarms.

Figure 11. Alarm Zone Connections

FPS-3

DUAL ZONE

PRE-AMP.

END OF LINE

TERMINATION**

LEFT ZONE RIGHT ZONE

EARTH GROUND

WIRING TO FPS-3

CENTRAL CONTROLLER

END OF LINE

TERMINATION**

SENSITIVE

TRANSDUCER

CABLE

SENSITIVE

TRANSDUCER

CABLE

** Double runs of sensor cable

return to termination located

inside dual zone pre-amp.

13

INSTALLATION AND OPERATION INSTRUCTIONS —FENCE PROTECTION SYSTEMS

Table 1. Sensor Cable Capacitance

Figure 12. Block Diagram

TRANSDUCER

CABLE INPUT

FILTERS

OUTPUT TO

MX-5300

DIFFERENTIAL

AMPLIFIER

ALARM

EVENT

REGISTER

LINE

DRIVER

AMP.

THRESHOLD

DETECTOR

RECEIVER/

BUFFER

DATA

MANAGER

AUDIO

MANAGER

I/O

DECODER

ADDRES

S

SIGNAL

CONDITIONER

TEST

MANAGER

TEST

SELECT

ZONE PROCESSOR

INTERFACE BOARD

DUAL ZONE PRE-AMP

(field mounted)

500 1000 1500

50,000

100,000

T

RANSDUCER LENGTH - ft.

T

ypical FPS Transducer Cable Capacitance - pF

MAXIMUM

SENSOR LOAD

CAPACITANCE

INSTALLATION AND OPERATION INSTRUCTIONS —FENCE PROTECTION SYSTEMS

14

4 FENCE CONDITIONS

Fence Conditions

When the FPS Transducer Sensor Cable is installed on the fence, the sensor cable and the fence be-

come the fence protection system. In effect, the sensor cable listens to the fence to detect the signals

caused by climbing, jacking, or cutting the fence.

It is recommended that you walk the entire length of the fence line to determine if the fence requires

maintenance prior to installation. Grab the fabric between each and every line post, pull it to you, and

let it go. Listen to it! The fence can flex, but if you hear any bangs, clangs, etc., they can be a source of

nuisance alarms and should be corrected. Keep a log of any potential problems so they can be identi-

fied and repaired before the fence protection system is operational. Refer to Fence Quieting later in

this section.

Typical Source or Locations of Trouble Spots

The following photographs (Figures 13 through 22) show examples of the most common problems

found with fence installations.

Figure 13 Loose fabric at fence posts or

horizontal rails

Figure 14 Loose fabric at diagonal

stiffeners

Table of contents

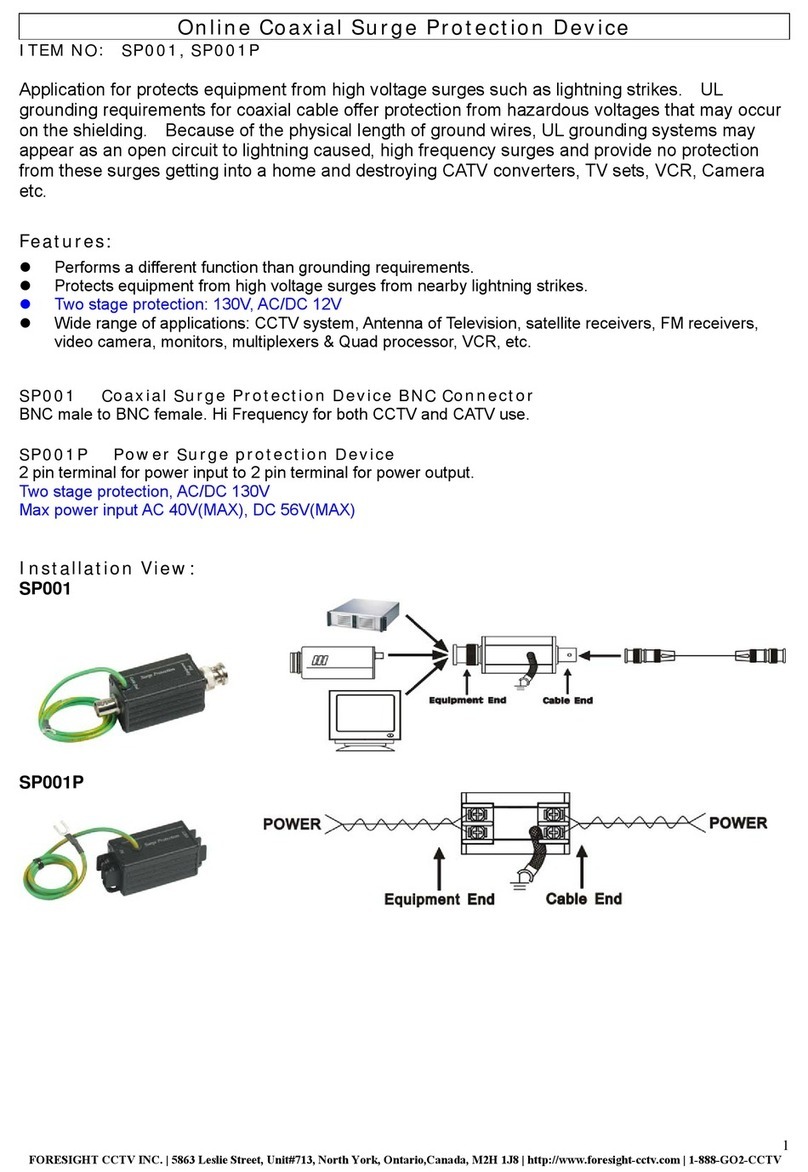

Popular Protection Device manuals by other brands

FORESIGHT

FORESIGHT SP001 quick start guide

ACARiS

ACARiS HORSE PROTECTOR installation manual

Manson Engineering Industrial

Manson Engineering Industrial SSB-2180 user manual

3M

3M Peltor Optime H510A manual

i4Technology

i4Technology BugHunter DAudio bda-4 Voice user manual

Toshiba

Toshiba GRE110 instruction manual