Siqens Ecoport 800 User manual

Fuel Cell System Ecoport 800

User manual

Issue 05/2018

Order number: E-093-000019

Fuel Cell System Ecoport 800

User manual

© Siqens GmbH, 07/2018

Page 2/44

Imprint

© 2018 Siqens GmbH. All rights reserved.

No part of this documentation may be reproduced in any form (print, photocopy

or by any other process) or with the application of electronic systems be

processed, copied or distributed or for other purposes than personal use without

written consent from Siqens GmbH.

Siqens GmbH • Landsberger Straße 318d • 80687 Munich • Germany

Phone.: +49 89 452 44 63-0 • Email: info@siqens.de • www.siqens.de

Document information

Theme:

Operating instructions

Product:

Ecoport

Author:

Siqens GmbH

File name:

Ecoport_800_BA_EN.pdf

Date of issue:

20.07.2017

Version number

2.0

Amendment key

Version

Date

Name

Amendment description

Release

1.0

7/2017

R.Protze

Initial version

21.07.2017

1.1

12/2017

R.Protze

Update of screenshots, further additions

12.12.2017

2.0

05/2018

R.Protze

Changes methanol heated Ecoport

Fuel Cell System Ecoport 800

User manual

© Siqens GmbH, 07/2018

Page 3/44

Content

1Information about the Operating Instructions..................................................................5

1.1 Description of symbols and notices....................................................................................... 5

1.2 Target group .......................................................................................................................... 5

2Technical Information.......................................................................................................6

2.1 Technical product information .............................................................................................. 6

2.2 Process and function description .......................................................................................... 7

2.2.1 Function description .............................................................................................................. 7

2.2.2 Loading cycle.......................................................................................................................... 7

3Safety Information ...........................................................................................................8

3.1 Product liability...................................................................................................................... 8

3.2 Disclaimer .............................................................................................................................. 8

3.3 Guarantee.............................................................................................................................. 8

3.4 Approved use......................................................................................................................... 8

3.5 General Safety Information ................................................................................................... 9

3.6 Product-specific Safety Information .................................................................................... 11

3.6.1 Methanol safety information............................................................................................... 11

3.6.2 Safe battery handling........................................................................................................... 12

3.7 Operating personnel requirements ..................................................................................... 13

4Product Description........................................................................................................14

4.1 Main components................................................................................................................ 14

4.2 Interfaces at Ecoport 800 .................................................................................................... 15

4.3 Interfaces at control panel................................................................................................... 15

5Installation .....................................................................................................................16

5.1 Operating environment ....................................................................................................... 16

5.2 Delivery and transport......................................................................................................... 16

5.3 Montage .............................................................................................................................. 17

5.3.1 Dimensions .......................................................................................................................... 17

5.3.2 Ecoport connections............................................................................................................ 18

5.3.3 Installation instruction for air intake and exhaust air.......................................................... 19

5.3.4 Installation of the mounting kit ........................................................................................... 20

6Operation .......................................................................................................................21

6.1 Initial start-up of the Ecoport .............................................................................................. 21

7Control ...........................................................................................................................28

7.1 Control via Touch Panel ....................................................................................................... 28

7.2 Menu Navigation on the Touch Panel ................................................................................. 29

7.2.1 Functions ............................................................................................................................. 29

Fuel Cell System Ecoport 800

User manual

© Siqens GmbH, 07/2018

Page 4/44

7.2.2 Buttons ................................................................................................................................ 29

7.2.3 Settings ................................................................................................................................ 30

7.2.4 Language.............................................................................................................................. 30

7.2.5 Battery type ......................................................................................................................... 31

7.2.6 Information.......................................................................................................................... 31

7.2.7 Notification .......................................................................................................................... 32

7.3 Refuelling............................................................................................................................. 33

8Maintenance ..................................................................................................................36

8.1 Trouble-shooting ................................................................................................................. 36

8.2 Maintenance Schedule ........................................................................................................ 38

9Decommissioning ...........................................................................................................40

9.1 Storage................................................................................................................................. 40

9.2 Disposal................................................................................................................................ 40

10 Appendix ........................................................................................................................41

11 Glossary / abbreviation list.............................................................................................42

12 Service / Support............................................................................................................42

13 Declaration of Conformity...............................................................................................43

Fuel Cell System Ecoport 800

User manual

© Siqens GmbH, 07/2018

Page 5/44

1Information about the Operating Instructions

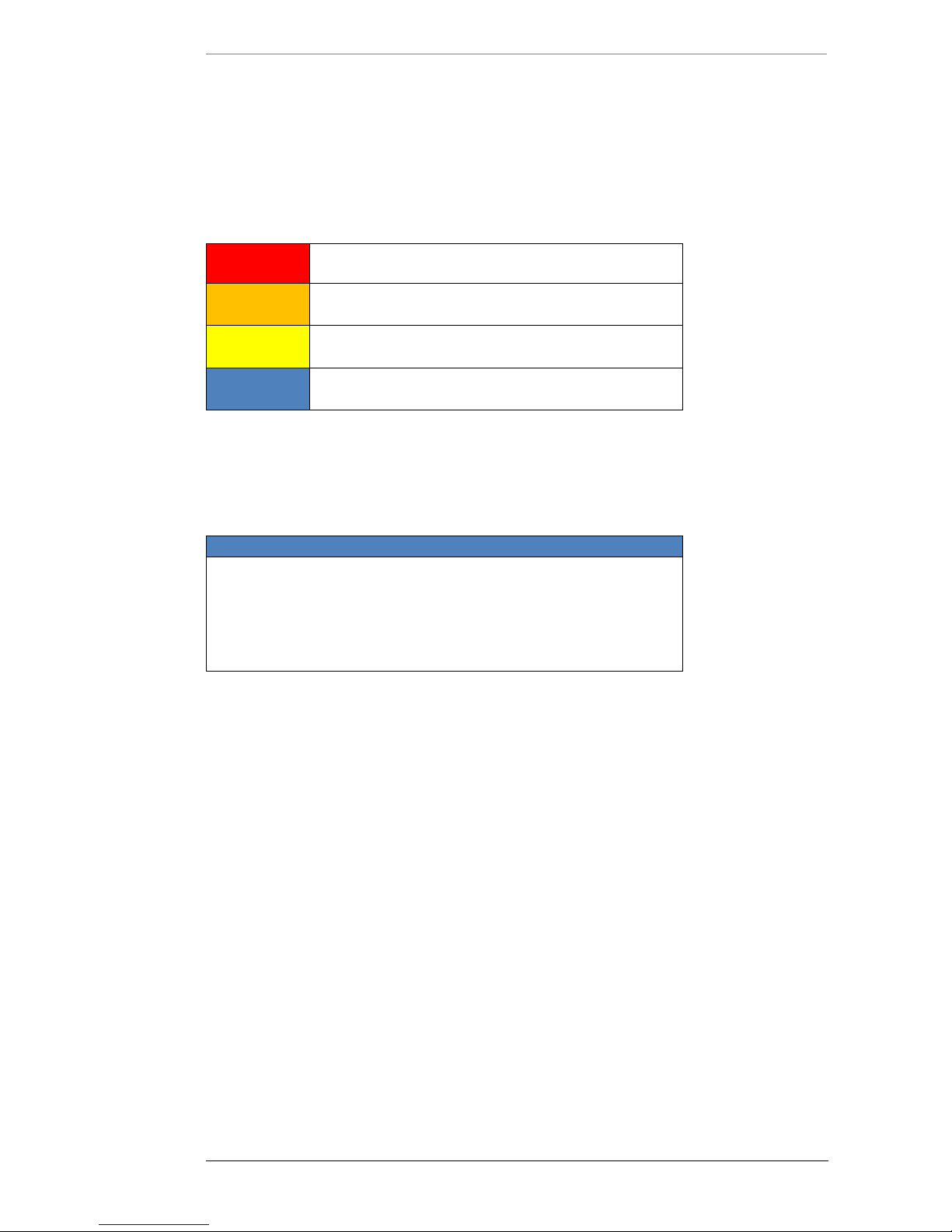

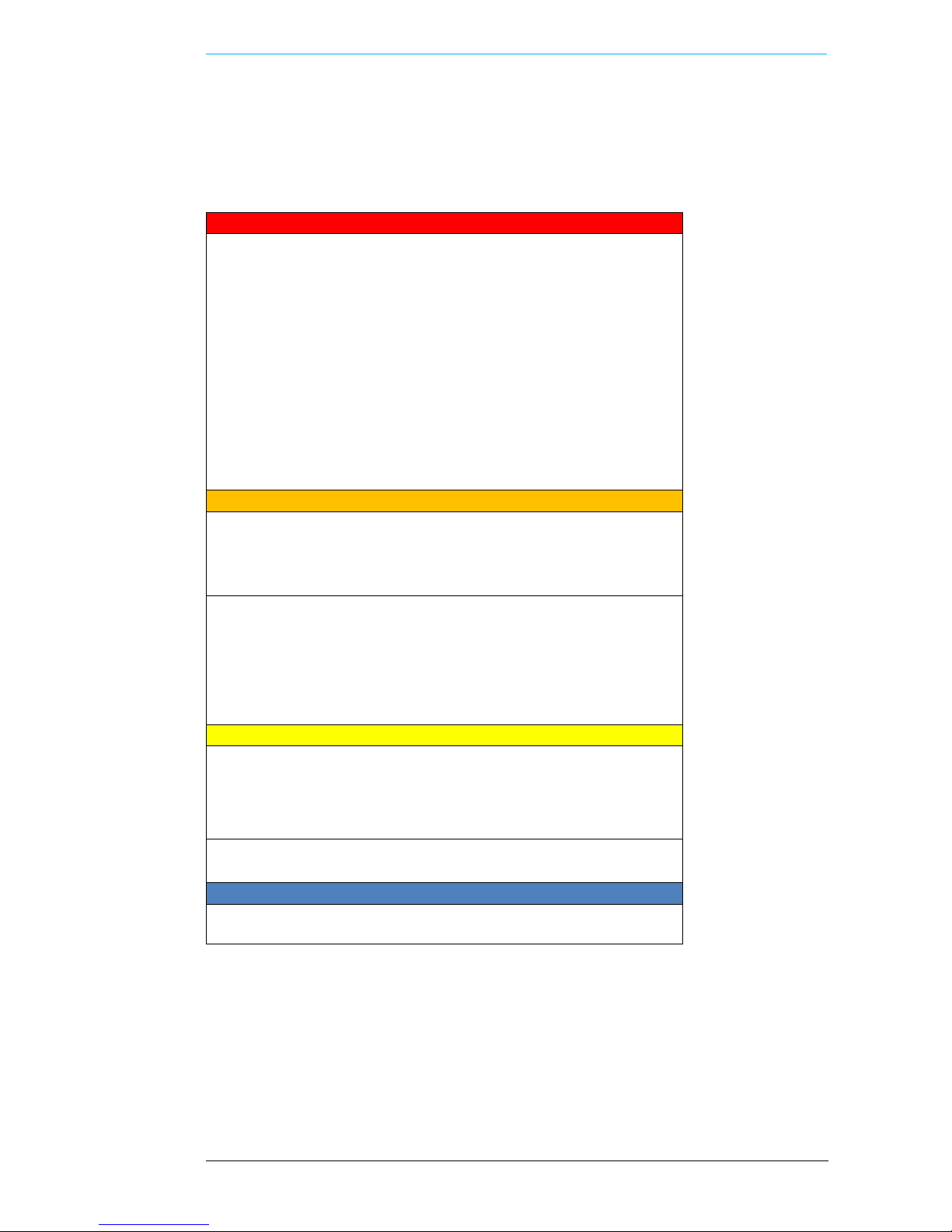

1.1 Description of symbols and notices

(according to ANSI)

DANGER

Indicates an imminent danger that leads to serious injury or

death.

WARNING

Indicates a potentially hazardous situation that could result

in serious injury or death.

ATTENTION

Indicates a potentially dangerous situation that could result

in minor bodily injury.

NOTICE

Indicates a notice that needs special attention.

1.2 Target group

The operating instructions target group includes all persons who install, maintain

and operate the Ecoport.

IMPORTANT NOTICES

Read the manual carefully before commissioning the Ecoport. Retain the

instructions for later reference! If you hand over the device to other

people for use, hand over the instructions as well.

Personnel assigned to work with the Ecoport must have read the

operating instructions before starting work, especially the chapter

"Safety".

Fuel Cell System Ecoport 800

User manual

© Siqens GmbH, 07/2018

Page 6/44

2Technical Information

2.1 Technical product information

Technology

High Temperature Fuel Cell with 4Cycle-

Tec

Fuel

Methanol Class AA (IMPCA)

Nominal performance

–at lifecycle start in Watts

800 W max performance

500 W at operation site

Nominal voltage

24 Volt DC

Start time

30-60 minutes*

Battery types

Lithium battery, lead acid battery, lead

gel battery, AGM battery

Maximum loading current at 24 V

33 A

Constant charging current at 24 V

21 A

Power consumption in idle state

< 0.17 A

Methanol usage (at operation site)

Approx. 0.5 –0.75 l/kWh

Electrical efficiency at operation site

> 35 %*

Weight (unpacked)

48 kg

Measurements (LxHxB)

770 x 350 x 420 mm (113 L)

Data interfaces

Ethernet, start signal

Lifespan (guaranteed)

3,000h or 500 cycles (depending on

occurrence)

Recommended minimal battery capacity

100 Ah**

Ambient temperature (min. / max.)

-20°C / +50°C

Humidity at maximum ambient

temperature

10 –90 %

Protection class

IP20

Maximum angle of inclination in full

condition

10°

Noise level in operation

< 29 dB(A)

Exhaust air exit temperature

< 65°C (exhaust air into outside

necessary)

* Dependent on surrounding conditions

** Dependent on whole system

Subject to technical modifications.

Fuel Cell System Ecoport 800

User manual

© Siqens GmbH, 07/2018

Page 7/44

2.2 Process and function description

2.2.1 Function description

The Ecoport is used as a charger for a wide variety of battery types. The following

battery types can be selected in the control panel, or a battery type can be

defined.

When selecting the battery type, the following charge end voltages are set.

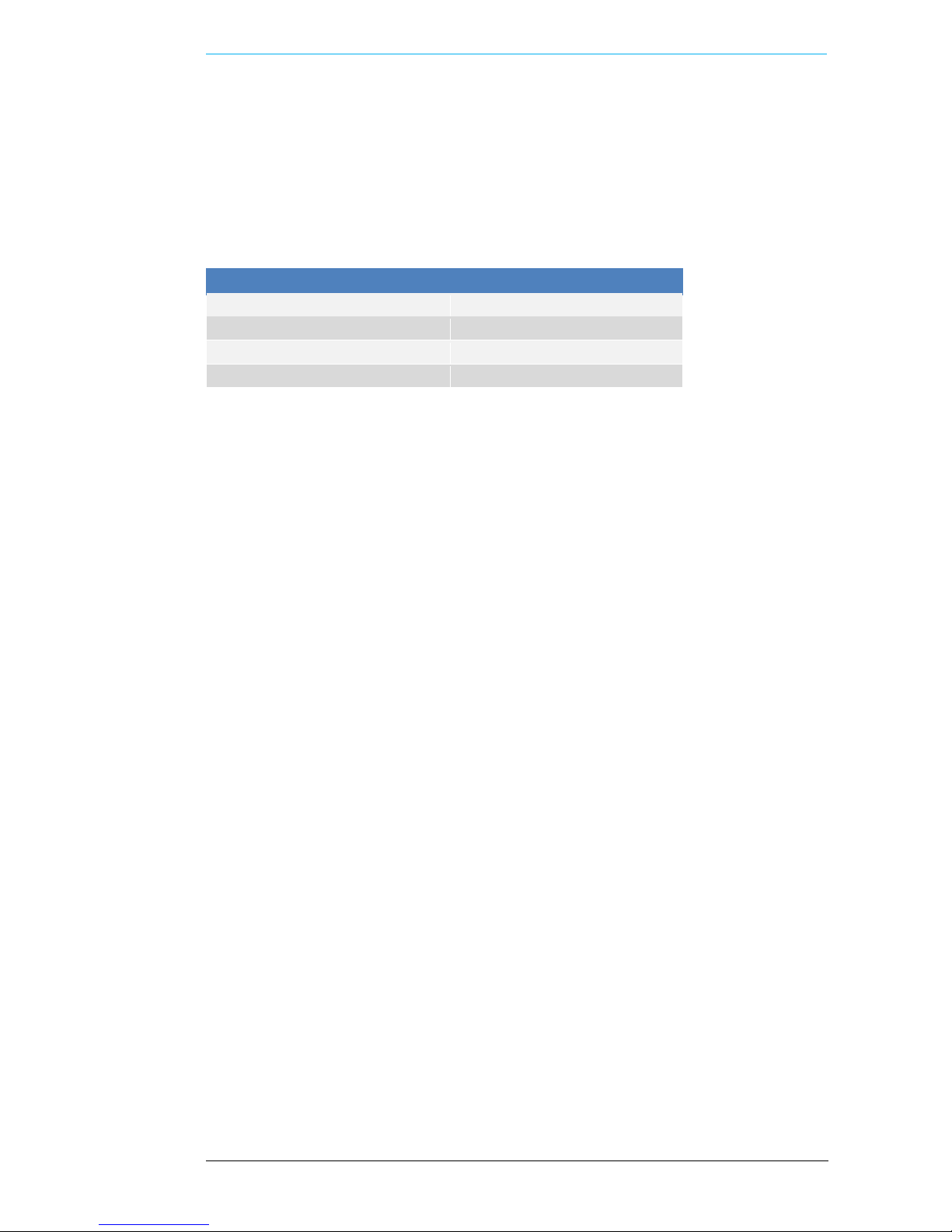

Battery type

Charging end voltage

Lithium battery

29.0 V

Lead acid battery

28.8 V

Lead AGM battery

29.4 V

Lead gel battery

29.0 V

2.2.2 Loading cycle

An Ecoport loading cycle follows this procedure:

System starts from Ready mode at the defined lower voltage threshold and

when heating up to operating temperature

Charging phase with almost constant power until the final charging voltage

determined by the battery type is reached

Cool off phase

Fuel Cell System Ecoport 800

User manual

© Siqens GmbH, 07/2018

Page 8/44

3Safety Information

3.1 Product liability

In the following cases, the intended protection of the device may be impaired.

The liability for the device function is then transferred to the operator:

The Ecoport is not used according to the operating instructions.

The Ecoport is used beyond application areas specified in this document.

The user makes unauthorised functional or constructional changes to the

Ecoport.

3.2 Disclaimer

The manufacturer is not liable for damages to persons and/or property in the

case of neglect for safety information.

3.3 Guarantee

The manufacturer warrants that the delivered product is free from defects in

material and workmanship and will repair or replace any defective parts free of

charge. The limit for claims of defects is 24 months after delivery. Deviating

regulations may be agreed in writing in the delivery contract. This excludes

expendable parts.

Spare parts must comply with the technical requirements specified by the

manufacturer. This is always guaranteed with original spare parts. Using anything

other than the original spare parts will result in the loss of the warranty claim for

the Ecoport.

3.4 Approved use

The Ecoport is intended solely for power supply by means of a methanol-

operated system according to the technical data.

Any other or further use is considered improper use. The manufacturer and

supplier are not liable for any resulting damage. Any risk is undertaken by the

user alone.

The Ecoport is built according to the state of the art and the recognized safety

rules. Nevertheless, dangers to the life of the user or third parties, or

impairments of the Ecoport and other property may arise during use.

Only operate the Ecoport in technically suitable conditions. In particular,

eliminate faults that could impair safety!

Fuel Cell System Ecoport 800

User manual

© Siqens GmbH, 07/2018

Page 9/44

3.5 General safety information

DANGERS

MORTAL DANGER THROUGH BLOCKED OR LEAKING EXHAUST TRACT

Never operate the Ecoport inside a house or garage without a functioning

exhaust system even if doors and windows are open. The exhaust system

must always have a connection to the outside.

The exhaust gas may contain carbon-monoxide, this must always be

ventilated to the outside. It is a colourless and odourless toxic gas.

Inhalation of exhaust gas can cause unconsciousness and be fatal.

FIRE OR EXPLOSION DANGER

The disregard of safety instructions can lead to danger to persons as well as

property damage.

ELECTRIC SHOCK HAZARD

Failure to follow the instructions in this manual may result in accidents such

as electric shock. The generator generates electrical energy, which can lead

to electric shock when misused, which can be fatal.

WARNINGS

The exhaust gases of the device may contain harmful components! Do not

inhale exhaust gases directly or permanently. Instead lead them out into the

open air with the supplied exhaust system.

Do not smoke when handling the Siqens fuel cell or Siqens fuel cartridges.

Keep away from heat and ignition sources.

Methanol is highly flammable! Read the Methanol Safety Sheet carefully.

Siqens Ecoport fuel cells and QE CHARGE methanol cartridge –including

empty or partially empty fuel cartridges must be kept away from children.

The Ecoport and QE CHARGE methanol cartridge may not be opened.

Modifications to the device endanger the safety and result in the loss of the

operating license and the expiration of the warranty and guarantee.

ATTENTION

The fuel cell must be installed by a Siqens service technician.

The Ecoport must not be tilted when filled, otherwise damage to the device

may occur. In case of problems, contact a Siqens service technician.

Improper use or improper connection to other electrical equipment may

result in damage.

When connecting the power cables, ensure that the polarity is correct.

The Ecoport must be operate and stored in a horizontal position.

The Siqens fuel cell is not waterproof! Make sure that no water can

penetrate the device.

Do not operate the Siqens fuel cell and Siqens fuel cartridges at

temperatures above 45°C and do not store at temperatures above 50°C.

NOTICE

Observe the safety instructions in the operating manual. Follow all

instructions in the manual. Keep the operating instructions with the device.

Fuel Cell System Ecoport 800

User manual

© Siqens GmbH, 07/2018

Page 10/44

Modifications endanger the safety and lead to the loss of the operating

permit, the expiry of the warranty and guarantee.

Only use original Siqens equipment.

Protect the device and QE CAHRGE methanol cartridge from heat and direct

sunlight.

Only operate Siqens fuel cell in accordance with the installation instructions

and ensure the exhaust system is connected to the outside.

Fuel Cell System Ecoport 800

User manual

© Siqens GmbH, 07/2018

Page 11/44

3.6 Product-specific safety information

3.6.1 Methanol safety information

DANGER

Highly flammable liquid and vapor. (H225) Toxic if swallowed, contact with

skin or inhalation. (H301 + H311 + H331) Causes damage to organs. (H370).

Use only undamaged containers with suitable terminals with SIQENS fuel cell.

Follow operating instructions. IF SWALLOWED: Immediately call a NATIONAL

POISONS INFORMATION SERVICE. (UK (00 44) (1 71) 6 35 - 91 91 ).

Keep away from heat, hot surfaces, sparks, flames and other ignition sources.

Do not smoke. (P210) Take precautionary measures against static discharge.

Do not inhale vapor. (P260)) Store in a cool, well-ventilated place. Keep

container tightly closed. (P403 + P233). Do not open or empty the cartridge

by force. Dispose of empty containers in accordance with current

regulations. Protect from temperatures > 50 ° C or direct sunlight. Do not

leave in a parked car in hot climates. Store and transport upright. Fuel cell

cartridge intended for single use only. Sale only to authorized persons over

18 years.

WARNING

Methanol is highly flammable! You will receive methanol in safe, tested QE

CHARGE methanol cartridges, which will protect the contents from leakage

during appropriate use. Storage and transport may be subject to legal

regulations.

Methanol is toxic if inhaled, ingested and in contact with the skin. There is a

serious risk of irreversible damage through inhalation, skin contact and

ingestion. In case of direct contact, an accident or if you feel unwell, seek

medical advice immediately and show the QE CHARGE methanol cartridge

label, the methanol safety data sheet or the user guide.

ATTENTION

CONTAMINANTS IN THE METHANOL

The original QE CHARGE methanol cartridges contain methanol approved by

Siqens for the Ecoport. Contaminants or foreign components in the methanol

can cause irreversible damage to the unit and may void the warranty or

guarantee.

Only use methanol according to the degree of purity stated in the data sheet.

NOTICE

Proper use of the Ecoport and QE CHARGE methanol cartridges will prevent

exposure to methanol.

Fuel Cell System Ecoport 800

User manual

© Siqens GmbH, 07/2018

Page 12/44

3.6.2 Safe battery handling

NOTICE

It is imperative that another person is present, in case of emergencies, when

working on the batteries.

These instructions must be observed in addition to the instructions of the battery

manufacturer.

DANGER

ACID BURN HAZARD

Keep soap and water ready in case battery acid contacts skin.

Wear eye protection and protective clothing. Do not touch your eyes

while working on the battery.

Wash off acid splashes on the skin or clothing with plenty of soap and

water.

If acid gets into your eyes, rinse immediately with clean water until no

more burning is felt. Seek medical help immediately.

EXPLOSION DANGER

Do not smoke near or around the batteries.

No open fire. Danger of explosion in the vicinity of the battery.

BURN DANGER

Do not wear a bracelet or watch during installation. Short circuit of the

battery can be generated resulting in skin burns.

WARNING

Only use cycle-resistant, deep-discharge capable batteries, no starter

batteries.

Never charge frozen batteries.

Avoid battery short-circuits.

Ensure good ventilation of the battery to dissipate any gases.

Carefully lay the battery connection cable and check for improper

heating under load. Periodically check the battery in the area of vibrating

components for chafing and insulation problems.

NOTICE

Cover battery poles to prevent damage from tools.

Protect all battery contacts against unintentional contact.

Check battery connection terminals for stability prior to each operation.

Fuel Cell System Ecoport 800

User manual

© Siqens GmbH, 07/2018

Page 13/44

3.7 Operating personnel requirements

The operator must be adequately trained in the use, servicing, setting and

operation of the Ecoport.

IMPORTANT NOTICES

Follow the instructions in this manual for the use of the Ecoport. Failure

to observe or follow the instructions may result in accidents, such as

electric shock or suffocation.

Observe legal minimum age! Children should not have access to the

device without supervision.

Fuel Cell System Ecoport 800

User manual

© Siqens GmbH, 07/2018

Page 14/44

4Product Description

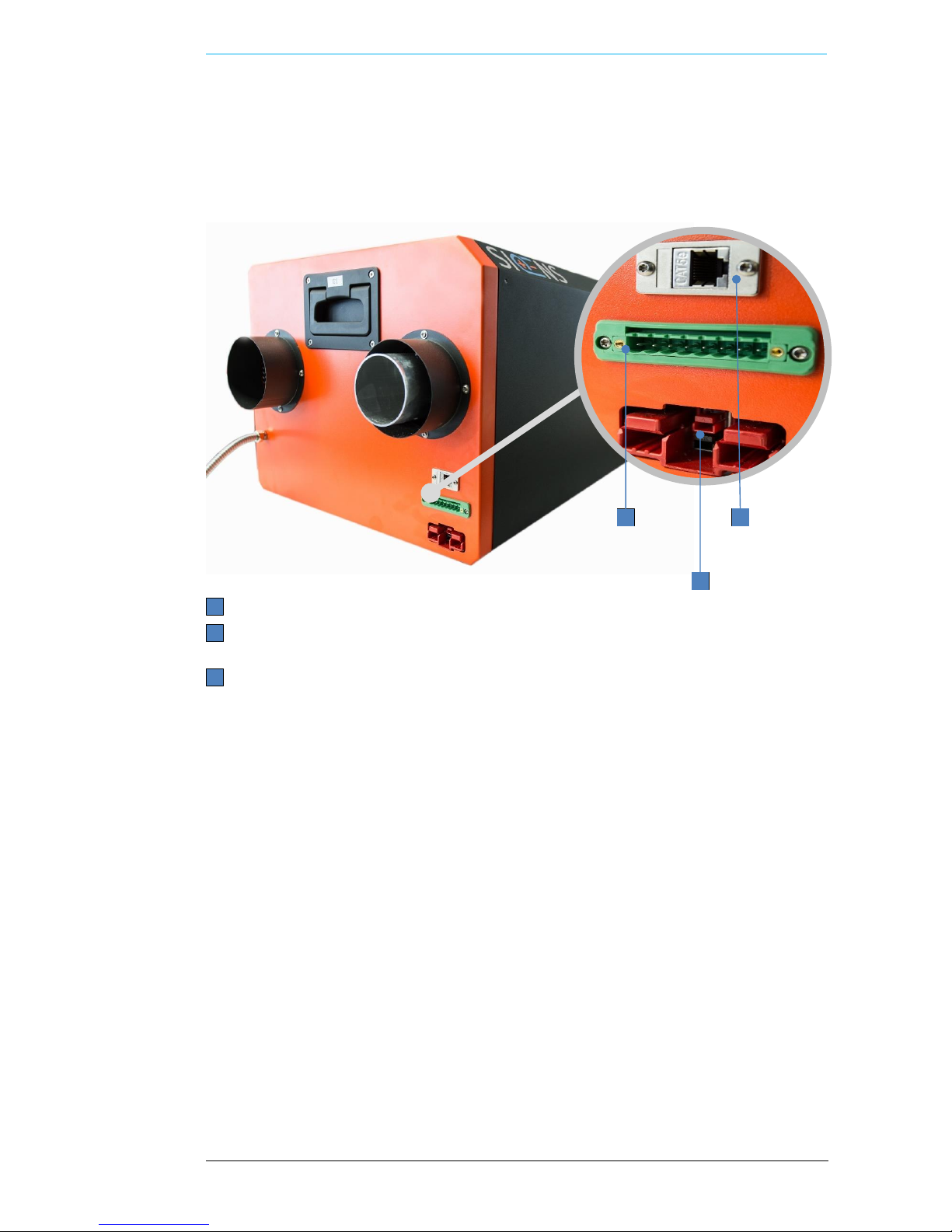

The Ecoport fuel cell system is a methanol-operated power supply system with a

power output of max 800 watts.

= Ethernet socket (RJ 45)

= Power output with battery voltage metering (right contact plus, left

contact minus)

= Ethernet socket (RJ 45)

4.1 Main components

The device consists of these main components:

Reformer unit for the conversion of methanol to hydrogen

Fuel cell for the electro-chemical conversion of hydrogen together with

oxygen (air) into electricity

Charge controller for the charging of lithium, lead gel, lead acid, lead AGM

battery

Ignition boiler for heating the fuel cell and reformer unit

Subsystems for the device-internal media supply (methanol, air, water)

Electronics for the device-internal regulation and control

Supply air intake for the reaction and cooling air supply (with air filter)

Exhaust air exhaust fumes system for the combined discharge of exhaust air

and exhaust gas

The fuel cell system Ecoport operates automatically; it starts automatically from

Ready mode - depending on the voltage of the battery or external signals.

1

2

3

1

2

3

Fuel Cell System Ecoport 800

User manual

© Siqens GmbH, 07/2018

Page 15/44

4.2 Interfaces at Ecoport 800

Data interface for control panel (RJ-45)

Power output with battery voltage metering to battery (Anderson SBE 80)

Digital contact to start the Ecoport via a potential-free contact

(Phoenix Contact FKC 2,5/ 8-STF-5,08)

Plug connection

1. Start signal digital input 24V

2. Start signal digital input GND

3. Not connected

4. Not connected

5. Not connected

6. Not connected

7. Not connected

4.3 Interfaces at control panel

Ethernet for laptop or network connection (RJ-45)

Optional modem for LTE network connection (2 antennas)

Communication wire to Ecoport 800 (RJ-45 max. 30 m)

1

Fuel Cell System Ecoport 800

User manual

© Siqens GmbH, 07/2018

Page 16/44

5Installation

5.1 Operating environment

Requirements of the installation site

Firm ground

Max slope 10° in relationship to all axes

Non-inflammatory and temperature-stable ground

Protect from direct sunlight

Observe temperature limits specified in the data sheet

Secured air intake and exhaust air

5.2 Delivery and transport

Delivery:

Ecoport with 1.5 metre methanol feed line

Control Panel

Operating Instructions, Quickstart Guide and Safety Data Sheet with barrel

wrench

Data cable RS232 –RJ45, 3 metres length

Charging cable with battery voltage line, 2 metres length, 16mm² diameter,

power connector on Ecoport, ring cable lugs M8 (battery contacts)

Mounting kit consisting of 4 pieces mounting elements,

4 pieces screw M6x14

Air intake kit consisting of: 1x corrugated pipe ø 100mm (approx. 1 metre), 2x

pipe clamp, 1x ventilation grille

Exhaust air kit consisting of: 1x corrugated pipe Ø100mm (approx. 1 metre),

1x corrugated pipe Ø70mm (approx. 1 metre), 3x pipe clamp, 1x ventilation

grille

Fuel Cell System Ecoport 800

User manual

© Siqens GmbH, 07/2018

Page 17/44

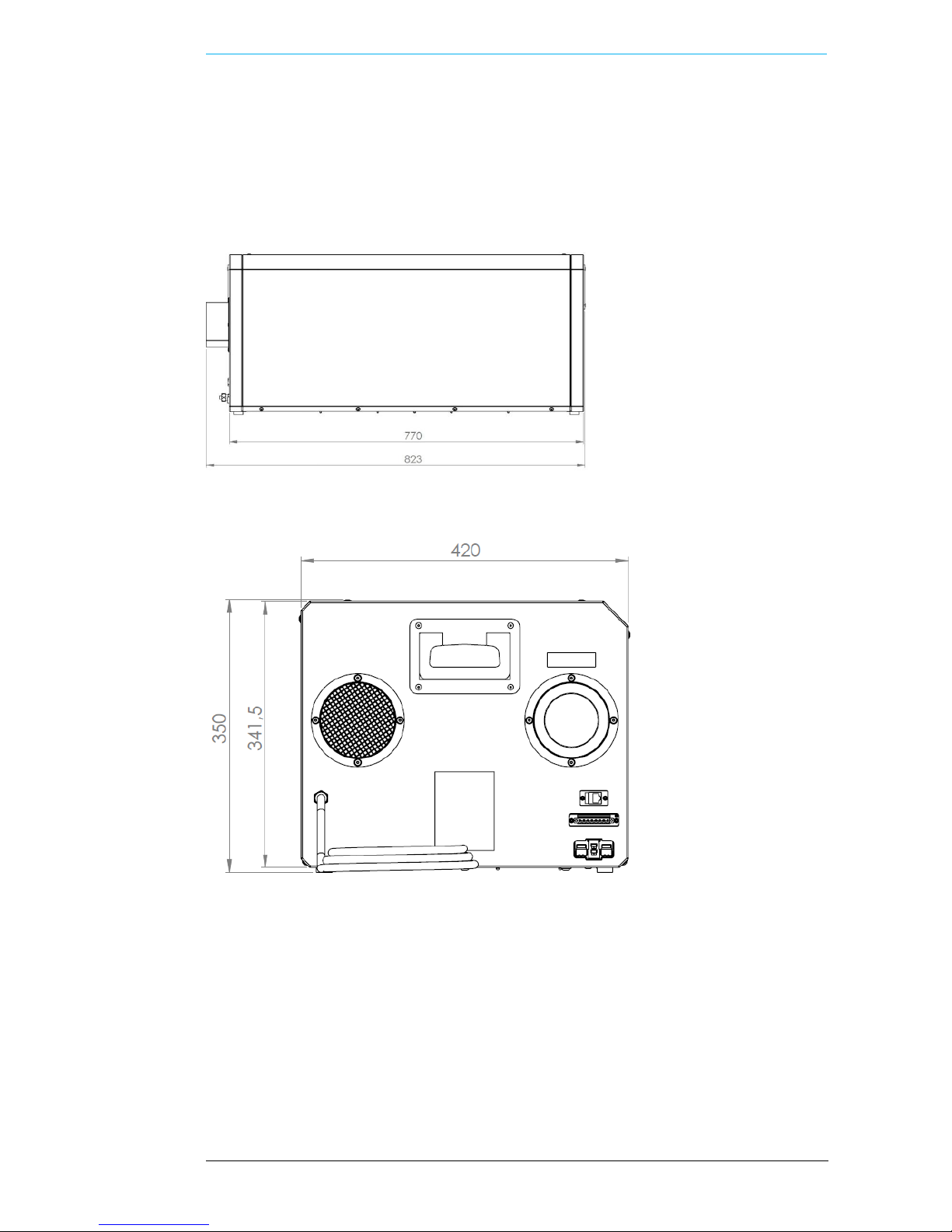

5.3 Montage

5.3.1 Dimensions

Side view

Front view

Fuel Cell System Ecoport 800

User manual

© Siqens GmbH, 07/2018

Page 18/44

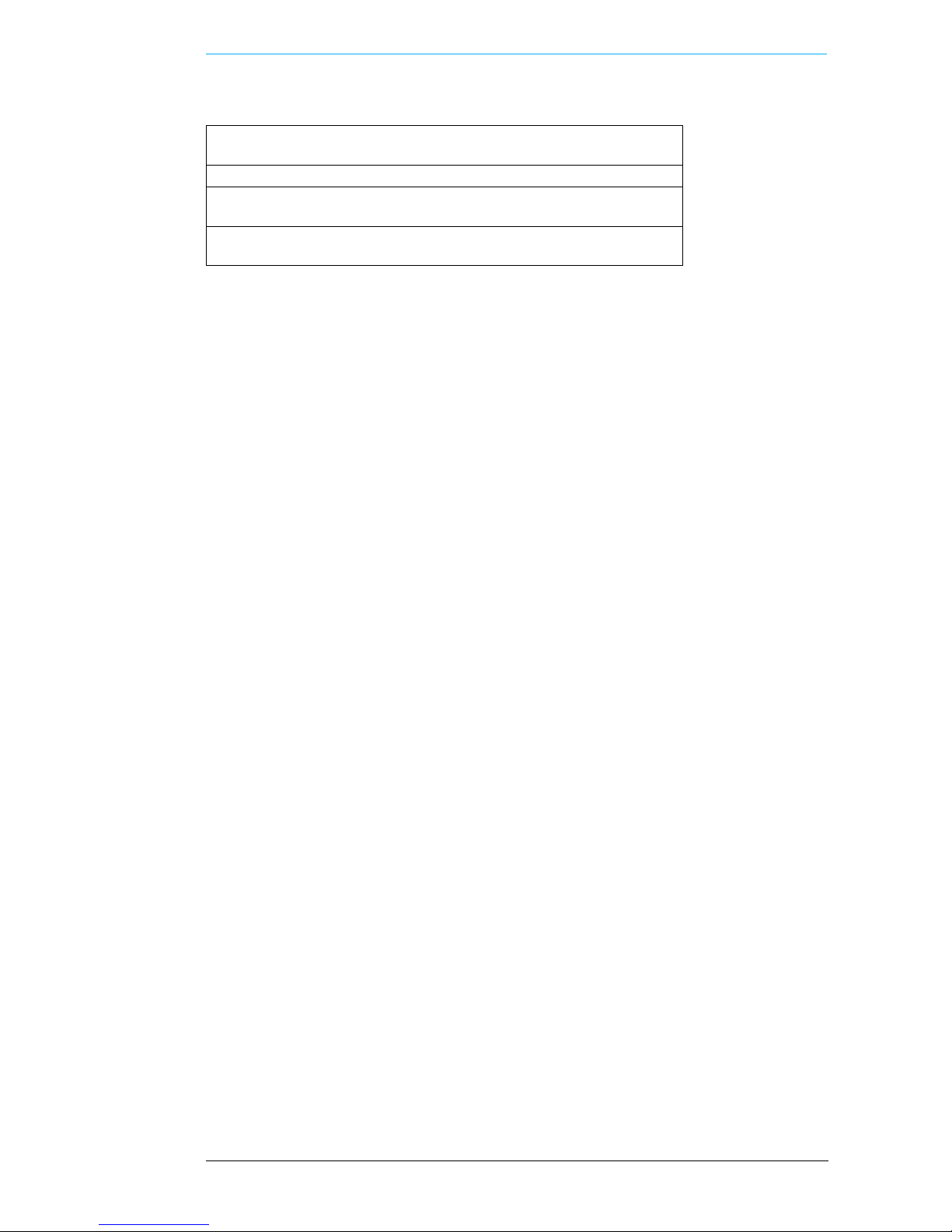

5.3.2 Ecoport connections

1: Methanol feed; 2: Inlet air; 3: Exhaust air; 4: Signal plug; 5: Power plug with

battery voltage metering; 6: Data socket to control panel

Recommended cable diameter from the Ecoport 800 to the battery

Cable length

Diameter

13 m

16 mm²

25 m

25 mm²

NOTICE

The exhaust air must be directed outside! The supplied

exhaust hose must be installed in the minimum length of

1m, so that the exhaust air temperature of 65°C is reached.

1

2

3

4

5

6

Fuel Cell System Ecoport 800

User manual

© Siqens GmbH, 07/2018

Page 19/44

5.3.3 Installation instruction for air intake and exhaust air

The following steps are necessary for installing the air intake and exhaust air set.

Place the Ecoport 800 in the required location.

Prepare two openings into the outside with a diameter of Ø 100 mm.

Make sure that the space between supply air and exhaust air is sufficient

to prevent the return air from being drawn in again. The corrugated

aluminium pipes can be extended to a maximum of 1000 mm.

Attach the extended corrugated aluminium pipe with Ø 70mm to the

inner exhaust port of the Ecoport and fix it with the pipe clamp.

Mount the Ø 100 mm corrugated aluminium pipe hose for the Ecoport

cooling air over the small exhaust air hose and fix it on both sides with a

pipe clamp.

Insert the extended Ø 100 mm corrugated aluminium supply air hose with

pipe clamps.

Pull all three pipe clamps tight to prevent the aluminium hose from

slipping.

Mount the supply and exhaust air grille at the end of the aluminium pipe.

Check the secure hold of the supply air and exhaust system.

Check that the supply and exhaust hoses are free and ensure a safe supply

and exhaust air flow.

Observe the safety instructions in this operating manual during installation.

If you require different or additional lengths for the exhaust system, please

contact Siqens technical support.

Exhaust air

Supply air

Fuel Cell System Ecoport 800

User manual

© Siqens GmbH, 07/2018

Page 20/44

5.3.4 Installation of the mounting kit

The Ecoport 800 can be fixed to suitable ground using the mounting brackets.

Remove the 4 flange head M6 screws next to the rubber feet.

Screw the 4 mounting brackets to the housing with the 4 countersunk screws.

Check the mounting points for stability.

In case of special fixture needs, please contact Siqens technical support.

Other manuals for Ecoport 800

4

Table of contents