Skalmex SK30 User manual

1

2

Table of contents …………………………………………………………………………….……………………………………………….. 2

Technical data …………………………………………………………………………………………..…………………………………….. 3

Introduction ………………………………………………………………………………………………………………….………………….. 4

Construction…………………………………………………………………………………………………………………….……………….. 5

Description connectors ………………………………………………………………………………………………………..…………... 6

Assembly operations …………………………………………………………………………………………….………………………….. 8

Operation ……………………………………………………………………………………………………………………………………….. 12

Warranty ……………………………………………………………………………………………………………………………….……….. 15

3

Technical data

-cooperation with two readers sending data in Wiegand (other standards on request)

-response time: up to 0.5s (after receiving data from the reader)

-Non-volatile memory: up to 512 KB

-timer: a dedicated RTC with battery backup

-system bus: via built-in Ethernet or RS-485 (9600 bps, 7, E, 1)

-additional interfaces: the serial synchronous (output only), asynchronous RS-232 or RS-485 (bi-

directional)

-signaling of operation: control LED and buzzer in the reader through open collector output

relay: 2

-door sensors: 2 (NO or NC)

-Input buttons on duty: 2

-tamper sensor inputs (separate controller and each of the readers)

-power supply: 10 ... 16 VDC

-maximum current consumption: 250mA (without readers)

-temp. Range: -25 C ... + 60 C

-dimensions: 111 x 100 x 25 mm

-weight: 100g

4

Desription

The basic task of the controller is reading identifiers and take action according to the information

contained therein. The controller also constantly monitors all of your input and by changing their state

may take the programmed actions. Each time, the non-volatile memory device is stored information

about the incident.

Data identifiers are reading by the reader and transmitted to the controller. Readers may have

different types of signaling activity. Further description assumes that the reader has an optical and

acoustic signaling is controlled by the controller and the business.

The most common controller is used for controlling access to sites (premises) and / or registration go.

Then the relay controls the electric lock, turnstile or barrier. Door sensors monitor security status.

To gain access to the protected area must be more closely identifier to the appropriate reader. If the

identifier assigned to the appropriate permissions, access to the protected zone will be open -

actuators will be launched for a limited time. This fact will be registered and confirmed by the time the

reader color change from red to green and a short beep.

Long modulated sound when approaching identifier means a refusal of access and lack of modulation

output devices.

The controller has two goals (reader + relay + door sensor), supporting two independent pass-sided or

one-sided.

To register input / output as on duty, before approaching identifier you must press, second hold and

release the red button. Readers will illuminate alternately green and red. Each registration identifier

during blinking is marked as on duty trip.

Activation connected to the controller door sensors, without prior registration ID privileges, alarm

activation (acoustic signal and color change lighting readers). The same occurs after too long

(beneficial) open the passage. Depending on the configuration, the alarm state ends close of a valid

card or deactivation of the sensor (locks the door).

5

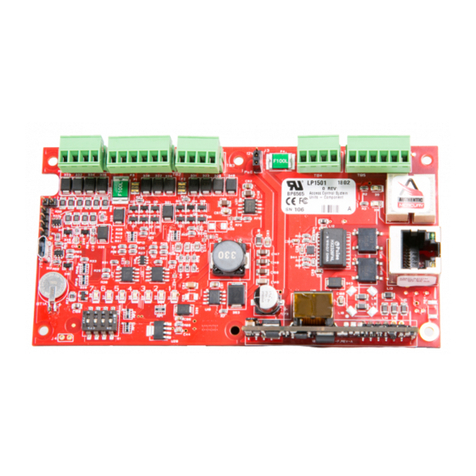

Building

No.

Description

Option

1

The upper strip joints

2

Ethernet Network Interface

3

LED power indicator

4

Power Conditioner

5

Configuration PP signals PM

6

Gateways 2 relay

7

LED indicating operation of the relay gateways 2.

8

Configuration jumpers of gate2 relay

9

Gateways 1 relay

10

LED indicating operation of the relay gateway 1.

11

Configuration jumpers of gate1 relay

12

Side strip joins

13

Signals communication via the system bus

14

Restore Defaults button Network Interface

15

Programming switches

6

16

Auxiliary asynchronous serial interface

●

17

Data from the interface (16) receive LED indicator

●

18

LED indicator sending data to the interface (16)

●

19

Battery Backup clock and its activation jumper

20

Communications processor and LED indicating its operation

21

Real Time Clock processor

22

The main non-volatile memory

23

Additional non-volatile memory (also on the other side of the plate)

●

24

Control processor and LED indicator its operation

25

Readers connectors

26

Input configuration fields reader

27

Lower strip joints

* The selected items are installed depending on the application controller

Description of connectors

7

Connector

Description

Restrictions

ZAS

POWER

Power supply (+)

10-16 VDC 100mA (without readers)

GND

GROUND

Supply ground

ETH

Ethernet network

RJ45 Connector

RS485

Bus communication

RS-485

D1

DOOR1

Gateway 1 door sensor

Shorted to GND

D2

DOOR2

Gateway 2 door sensor

Shorted to GND

PP

NC/NO

Relays power

Connected to the contacts

signal relays

PM

COM

Z1

COM1

Gateway 1 relay

Load capacity

1A at 24VDC

0,5A at 125VAC

Maximum voltage: 125VAC or 60VDC

Y1

NC1

X1

NO1

Z2

COM2

Gateway 2 relay

Y2

NC2

X2

NO2

PR1

Programming

PR2

PR3

RS

Additional asynchronous

serial interface

OK

Relays lock

C1

READER1

Gateway 1 reader

C2

READER2

Gateway 2 reader

TMP1

TAMPER1

Reader of gateway1

tamper sensor

Shorted to GND

TMP2

TAMPER2

Reader of gateway2

tamper sensor

TMP

TAMPER

Tamper Sensor Controller

SD

CLOCK SD

Output serial interface

SZ

CLOCK SZ

WS

WE1

INPUT 1

Additional input / output

lines

Shorted to GND

WE2

INPUT2

Shorted to GND

WE3

INPUT3

Shorted to GND

Marital available only on the Web page

WY1

OUTPUT1

Controlled only

through a web page

WY2

OUTPUT2

8

The steps for installation

Connection readers

C1

Gate 1 reader

C2

Gate 2 reader

Reader communicates with the controller using for this purpose conductor, whose completion is

connected to the connector (23).

No.

PIN

Description

Type

1

GND

Ground

Power

Controller

2

ZAS

Power

3

DA0

Data 0

Inputs

4

DA1

Data 1

5

PS

Buttons on duty

NO Input

6

BZ

Buzzer

Outputs

open

collector

7

LZ

Green LED

8

LC

Red LED

If the reader is not equipped with the on duty button or any of siren

these elements can be added by connecting according to the drawing.

Buzzer BZ should be adapted to voltage. Resistors R should be chosen

so that obtain appropriate brightness LEDs (type 1k). Note the polarity

of mounted elements.

9

Relays configuration

PP

Relay contacts power

PM

Z1

Gateway1 relay

The LED

lights up when the

relay’s coil is energized.

Y1

X1

Z1

Gateway2 relay

Y1

X1

Relay outputs system of controller SK30 is designed to provide control of actuators of various kinds. At

each relay is a set of jumpers that configure, additional jumpers are set's power.

Variants of work:

A) Short and open circuit

Only 2 and 3 contacts of jumpers (8) (11) is shorted.

The relay contacts are potential free and isolated from the system controller.

X - normally open (NO)

Y - compact with the common when the relay is not energized (NC)

Z - common (COM)

Shorting pin of power configuration (5) PM and PP contacts can used as a duplicate power supply (ZAS

and GND).

Application: control gates, turnstiles, detentions.

10

B) Connection and disconnection controller’s voltage

Shorted 1 –2 and 3-4 contacts of jumper (8) (11). Founded jumpers (5).

The relay reports to the connected device supply voltage controller.

X - normally open (NO)

Y -shorted with ZAS when the relay is not energized (NC)

Z - GND

PP - shorted with ZAS

PM - shorted to GND

Application: Power electric strikes, electromagnetic lock powered by 12V.

C) Connecting and disconnecting external voltage (PP and PM)

Shorted 1 –2 and 3-4 contacts of jumpers (8) (11). Open jumpers (5).

The relay reports to the connected device the voltage of the contacts PP PM

isolated from the system controller.

X - normally open (NO)

Y - PP closed when the relay is not energized (NC)

Z –PM

Application: switching voltage powered devices such as 24V.

11

System bus service

ETH

Ethernet network

RS485

Bus system

SK30 controller has two interfaces for connecting bus system. The Ethernet interface is implemented

by incorporating Ethernet↔RS485 converter. RS485 line derived on out through the RS485 interface.

Internally to the line is connected the communication processor controller (20). RS485 line can be

connected to other system devices such as SK26 / SK30 controllers, SZ10 / SZ25 clocks.

PIN

Description

A

Bus

B

GND

Ground

Signaling communication via the system bus (13) is completed by 4 LEDs.

LED

Descriptions

RX-A

Received data by network interface

TX-A

Transmitting data by network interface

RX-B

Received data by controller

TX-B

Transmitting data by controller

Connecting cooperating devices.

RS

An additional serial interface RS

PIN

Description

RXD

Reception

TXD

Transmission

GND

Ground

12

RTC clock

When the power is switched off an internal real-time clock works is using a battery (19). Don’t remove

jumpers next to bettery.

Use of

Starting up

After power device initialization (approx. 5s). After this gate pass into the stand. In operation, the LED

controller indicating the operation status (20) and (24) flash at a constant frequency. The device is

ready for operation.

Default Configuration

When you first start, and after clearing the configuration, the controller works by default:

● configuration of the readers (66 bit Wiegand received, without parity control)

● registration mode - acceptance of all similar identifiers,

● gateway works independently,

● door sensors are set to NO, inactive

● relay opening time 5s,

● button on duty time 5s,

● time to close the door 10s.

Network interface configuration

Device configuration is performed by a built-in website available on port 80.

The default user name and password: admin

The device is enabled by default automatically obtain an IP address from a DHCP server. If this fails,

the device adopts as its address 192.168.127.254.

Options to configure the device, found on the following web page tabs. Options indescribable are

irrelevant.

13

Description concerned 1.3 version firmware. In earlier versions, some features are not available, and

a description of configuration options may vary slightly.

status

device Model SK30

Mac address The current network parameters

address Type

IP address

subnet Mask

default Gateway

HW version Version hardware platform

SW version Firmware Version

local Time The current time and date

uptime The time from power on

TCP Status he state of network connections

UDP Status

input 3 EC3 state (active = closed)

Output 1, 2 Method of control outputs: the schedule or website.

Control Output 1, 2 Buttons changing the status accordingly OUT1 OUT2

configuration

change your password Change your administration page

Network Settings

address Mode DHCP (default) static magnifiers

IP address Network parameters set for the statistical mode

subnet Mask

default Gateway

Web server port 80 (default)

UDP broadcast Detection tools used by network devices

broadcast ID

UDP Broadcast port

14

NTP time settings

NTP server [IP] Time synchronization server address

Time Zone [h] Time correction with NTP for your current location. The total

value of positive and negative. Default: 1.

Summertime Automatic correction (default) or lack thereof.

Send time to 485 [s] Tempo sync time display.

TCP, UDP

Call hold time [s] The time period of connection without data flow.

Mode A network communications protocol TCP or UDP

TCP Port (SK30) TCP listening port

UDP Port (SK30) UDP port listening for connections

UDP, IP Address (Client) The return address UDP connections

UDP Port (Client) A return port UDP connections

The buffer time [ms] The maximum waiting time for the next data from RS485,

before transmission buffer.

settings 485

speed 9600 (default)

The number of bits 7 + Parity (default)

Stop bits 1 (default)

Output 1, Output 2

8 entries schedule for each day of the week, with the ability to determine the hours and

minutes commencement and the duration of the active state of the corresponding output

Each change must be confirmed Change (with appropriate section) and save restarting the machine's

Complete Restart section.

To restore the default settings Network Interface turn off the machine, wait at least 15 seconds, then

press the button (14) and re-power the device. Release the button (14) after 10 seconds.

15

Warranty

The manufacturer guarantees the efficient operation of the device.

The warranty covers hidden defects, revealed during the operation, which make the product is

inconsistent with the documentation.

Warranty does not cover defects that arise as a result of normal wear and tear or as a result of

improper, inconsistent with the purpose and documentation of the device use.

The manufacturer undertakes to remove defects occurring or replace the product with new ones.

Guarantee is for a period of 24 months from the date of purchase. The basis for warranty service is

properly filled, the form below warranty.

The manufacturer provides a full after sales service authorized by a minimum of 5 years from the date

of completion guarantees.

Table of contents

Popular Controllers manuals by other brands

DAVID

DAVID DigAS DigaStudio Installation notes

HomeSeer Technologies

HomeSeer Technologies HomeTroller Zee quick start guide

Alcatel Vacuum Technology

Alcatel Vacuum Technology adixen ACM 2000 user manual

Linear Technology

Linear Technology LT8609 quick guide

Cognex

Cognex In-Sight VC200 reference guide

Hanna Instruments

Hanna Instruments BL 983324-0 instruction manual