Skid Pro QA224 User manual

1

www.skidpro.com

QA224 Stump Grinder

Operation And Maintenance Manual

Skid Pro Attachments

PO Box 982

Alexandria, MN 56308

www.skidpro.com

November 2021

2 www.skidpro.com

Contents

1. IntroduCtIon And WArrAnty ................................................................... 3

1.1 Introduction......................................................................................................3

1.2 Warranty ...........................................................................................................3

2. Component IdentIfICAtIon ......................................................................... 4

3. sAfety ..................................................................................................... 5

3.1 Safety Alert Symbol And Signal Words .........................................................5

3.2 Operational Hazards........................................................................................5

3.2.1 prepAre for emergenCIes ................................................................................................ 6

3.2.2 replACe sAfety sIgns ...................................................................................................... 6

3.2.3 donot AlloW rIders ...................................................................................................... 6

3.2.4 loWer operAtIng speed ................................................................................................... 6

3.2.5 AvoId rollover................................................................................................................ 6

3.2.6 AvoId poWer lInes & underground utIlItIes .................................................................... 6

3.2.7 detACh stump grInder sAfely.......................................................................................... 7

3.2.8 trAnsport sAfely ............................................................................................................ 7

3.2.9 rAIsed AttAChment ........................................................................................................... 7

3.2.10 AvoId hIgh pressure fluIds ........................................................................................... 7

3.3 Maintenance Hazards......................................................................................7

3.4 Hazards From Modifying Equipment .............................................................8

3.5 Safety Warning Labels ....................................................................................8

4. InItIAl setup ........................................................................................... 10

4.1 Hydraulics .......................................................................................................10

5. operAtIon .............................................................................................. 10

5.1 Stabilizer Pin ..................................................................................................10

5.2 Pre-Operation Check List..............................................................................11

5.3 Attaching And Detaching..............................................................................11

5.4 Operation........................................................................................................11

6. routIne mAIntenAnCe ............................................................................ 12

6.1 Inspections......................................................................................................12

6.2 Replace Cutting Teeth .................................................................................12

6.3 Replace Flex Coupler ....................................................................................12

7. troubleshootIng ................................................................................... 14

8. pArts .................................................................................................... 15

8.1 Stump Grinder.................................................................................................15

8.2 S450 Motor ......................................................................................................16

8.3 S550 Motor ......................................................................................................17

8.4 S650 Motor ......................................................................................................18

3

www.skidpro.com

1. IntroduCtIon And WArrAnty

1.1 IntroduCtIon

Congratulations on your purchase of a Skid Pro

Skid Steer Stump Grinder. This equipment has been

designed and manufactured to meet the needs of a

discriminating buyer for efcient grinding of stumps.

Safe, efcient and trouble free operation of your stump

grinder requires that you and anyone else who will be

operating or maintaining the stump grinder, read and

understand this Operator’s Manual.

This manual covers the Skid Pro Skid Steer Stump

Grinder, model QA224.

Keep this manual with the equipment for frequent

reference and to pass on to new operators or owners.

Call your Skid Pro dealer, distributor or the factory if

you need assistance, information or additional copies

of the manuals.

OPERATOR ORIENTATION - The directions left, right,

front and rear, as mentioned throughout this manual,

are as seen from the skid steer driver’s seat and facing

in the direction of travel.

1.2 WArrAnty

Skid Pro warrants products purchased from Skid Pro

to the Original Purchaser to be free from defects in

material and workmanship for a period of twenty four

(24) months from the warranty start date.

Skid Pro’s requirement for any issue with respect to

attachments shall be limited to repairing or replacing

the defective part, as this is a parts-only warranty and

does not include any labor to replace or install the

part or downtime from resulting issue. Skid Pro has

full technical support & assistance to assure customer

replaces the part properly for optimal performance

on attachment. Skid Pro warranty service does not

include:

1. Transportation to selling dealer’s business location

or, at the option of the original retail purchaser, the

cost of a service call.

2. Used equipment.

3. Components covered by their own non-Skid Pro

warranties

4. Normal maintenance service and expendable wear

out items.

5. Repairs or adjustments caused by improper use;

failure to follow recommended maintenance

procedures; accidents or another casualty.

6. Liability for incidental or consequential damages of

any type, including but not limited to lost prots of

expenses of acquiring replacement equipment.

No agent, employee or representative of Skid Pro has

authority to bind Skid Pro to any warranty except as

specically set forth herein. Any of these limitations

excluded by local law shall be deemed deleted from

this warranty; all other terms will continue to apply.

For warranty service contact:

Skid Pro, Inc.

Toll Free: 877.378.4642

E-mail: [email protected]

4 www.skidpro.com

2. Component IdentIfICAtIon

1 - Hydraulic Motor

2 - Quick-Attach

3 - Operators Manual Holding Tube

4 - Cutting Wheel

5 - Cutting Teeth

6 - Debris Guard

1

2

3

4

5

6

5

www.skidpro.com

3. sAfety

3.1 sAfety Alert symbol And sIgnAl

Words

You must read, understand and follow the instructions

given by the operating unit manufacturers, as well as

the instructions in this manual.

The safety information in this manual is denoted by the

safety alert symbol: ^

This symbol means ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

The level of risk is indicated by the following signal

words:

^^ DANGERDANGER

DANGER - Indicates a hazardous situation,

which, if not avoided, WILL result in death

or serious injury.

^ WARNING

WARNING - Indicates a hazardous

situation, which, if not avoided, could

result in death or serious injury.

^ CAUTION

CAUTION - Indicates a hazardous situation,

which, if not avoided, could result in minor

or moderate injury.

NOTICE

NOTICE - Indicates a situation that could

result in damage to the equipment or other

property.

3.2 operAtIonAl hAzArds

^ WARNING

Prevent serious injury or death.

Read and understand this manual before

operating stump grinder.

Always stop engine and remove key before

leaving operators seat.

Never allow anyone near the stump grinder

during operation.

Travel at a safe speed.

^ WARNING

Prevent serious injury or death from

moving parts.

Moving parts can crush and dismember.

Do not operate without guards and shields

in place.

Disconnect and lockout power source

before adjusting or performing

maintenance.

^ WARNING

Use stump grinder only for the designed

applications.

Any other use may result in personal

injury, damage to equipment and may void

the warranty.

^ WARNING

Prevent serious injury or death.

Verify stump grinder is locked to quick

attach hitch before operation or transport.

Carefully read all safety messages in this manual and

on equipment safety signs. Keep safety signs in good

condition and replace missing or damaged safety

signs.

6 www.skidpro.com

New equipment components and repair parts must

include the current safety decal.

Learn how to properly operate equipment. NEVER

operate or work around this equipment without proper

instruction, while fatigued or under the inuence of

alcohol, prescription or non-prescription medication or

if feeling ill.

Keep your equipment in proper working condition.

Knowtheregulationsandlawsthatapplytoyouandyour

industry. This manual is not to replace any regulations

or laws. Additional information may be found at:

www.asae.org or www.osha.gov.

If you do not understand any part of this manual,

contact Skid Pro at 866-232-8224.

3.2.1 prepAre for emergenCIes

Be prepared in case of emergencies.

Keep a re extinguisher and rst aid kit close to the

machine.

Keep emergency phone numbers close to your

phone.

Know your address so emergency services can locate

you if an emergency arises.

3.2.2 replACe sAfety sIgns

Replace missing or damaged safety signs.

Safety sign location are identied in Section 4.5 of this

manual.

Replacement safety signs are available from your

dealer.

3.2.3 donot AlloW rIders

NEVER lift or carry anyone on stump grinder.

NEVER use stump grinder as a work platform.

NEVER allow passengers on stump grinder.

3.2.4 loWer operAtIng speed

Keep stump grinder low and move at slow speeds on

rough or uneven terrain.

3.2.5 AvoId rollover

The equipment may rollover, resulting in death or

serious injury. To help prevent rollover:

• Travel at a slow speed.

• Avoid sharp turns & sudden movement on slopes.

• Carry stump grinder close to the ground.

• Avoid holes, ditches and other obstructions which

may cause equipment to rollover.

• Use caution when operating on slopes and do not

operate on excessively steep slopes.

• Do not exceed load capacity of equipment.

3.2.6 AvoId poWer lInes & underground utIlItIes

^^ DANGERDANGER

Prevent electrocution.

Death or serious injury can result if

equipment comes near or contacts power

lines.

Electrocution can occur without direct

contact.

Check clearance before raising equipment.

Havelocal utilities locate and markunder ground wires,

cables, pipelines and other hazards before digging.

DO NOT leave the operator’s seat if any part of the

equipment contacts electric lines or cables.

7

www.skidpro.com

3.2.7 detACh stump grInder sAfely

Detach stump grinder on a rm and level surface.

Stump grinder may fall over if detached on unlevel or

soft surface.

3.2.8 trAnsport sAfely

Carry stump grinder low.

Travel slow and avoid slopes.

3.2.9 rAIsed AttAChment

^ WARNING

Crushing hazard.

Raised, unsupported stump grinder can

fall, resulting in death or serious injury.

Never enter the area under a raised stump

grinder.

A raised stump grinder can lower unexpectedly,

resulting in death or serious injury.

NEVER enter area under a raised stump grinder.

Lower stump grinder to ground, engage parking brake,

shut off engine and remove key before servicing.

3.2.10 AvoId hIgh pressure fluIds

^ WARNING

Pressurized uids can penetrate the skin.

Hydraulic hoses can fail from age, damage

and exposure.

Use body and face protection while

searching for leaks. A tiny, almost invisible

leak can penetrate the skin, thereby

requiring immediate medical attention.

Use wood or cardboard to detect hydraulic

leaks, never use your hands.

Escaping uid under pressure can penetrate the skin

causing serious injury.

Prevent the hazard by relieving pressure before

connecting or disconnecting hydraulic lines. Verify all

connections are tight before applying pressure. Search

for leaks with a piece of cardboard or wood.

Protect hands and body from high pressure uids. If

an accident occurs, see a doctor immediately. Any uid

injected into the skin must be surgically removed within

a few hours or serious infection may result.

Doctors unfamiliar with this type of injury should

reference a knowledgeable medical source.

3.3 mAIntenAnCe hAzArds

Before servicing, park machine on a rm and level

surface, set parking brake, chock wheels, and place

a “Do Not Operate” tag on control panel. Read and

understand this manual. If you do not understand any

part of the manual, contact Skid Pro at 866-232-8224.

Always wear face and/or eye protection, safety shoes,

and other protective equipment appropriate for the job.

Always use Skid Pro replacement parts.

^ WARNING

Crushing hazard.

Before performing inspections, service or

maintenance, lockout operating unit by:

• Park machine on rm, level surface.

• Engage parking brake.

• Turn engine off and remove key.

• Place “Do Not Operate” tag on control

panel.

^ WARNING

Moving parts can crush and cut.

Keep clear of moving components.

Follow lockout procedure before

performing maintenance.

8 www.skidpro.com

^ WARNING

Entanglement hazard.

Keep clear of moving components.

Wear proper protective equipment

appropriate for the job.

^ WARNING

Burn hazard.

Hot and high pressure hydraulic oil.

Allow oil to cool before servicing.

3.4 hAzArds from modIfyIng equIpment

Do not make any alterations to your stump grinder.

Altering may cause your equipment to be unsafe and

may void the manufacturers’ warranty.

3.5 sAfety WArnIng lAbels

^ WARNING

To protect you and others against death or

serious injury, all labels shown must be on

stump grinder and must be legible.

If any of these labels are missing or

cannot be read, contact your dealer for

replacement labels.

1

2

4

3

NS

NS NS

NS - No

n-Slip Pads

Decal 1

5

3

2

9

www.skidpro.com

Decal 2

Decal 3

Decal 4

Decal 5

10 www.skidpro.com

5. operAtIon

^ Quick-Attach must always be fully engaged and

in the locked position.

^ Keep bystanders away from equipment while in

use.

^ Always wear face or eye protection, safety shoes,

and other protective equipment appropriate for

the job.

^ Do not operate, work on or around this machine

while under the inuence of alcohol, drugs or if

feeling ill.

^ Keep clear of moving machinery at all times.

^ Turn off machine before exiting operator station.

^ It is your responsibility to operate this equipment

safely. You must be familiar with the equipment

and all safety practices before use.

^ Do not allow untrained or unqualied people to

operate this equipment.

5.1 stAbIlIzer pIn

Remove stabilizer pin before use to allow cutting wheel

frame to pivot while grinding.

D005443

4. InItIAl setup

4.1 hydrAulICs

^^ WARNING

Pressurized uids can penetrate the skin.

Disconnect and lock out power source

before disconnecting and/or connecting

hydraulic hoses.

Thestumpgrinderisequippedwith short hoses that are

connected to the hydraulic motor. You must connect

your skid steer hoses to these hoses.

Skid steer hoses must be the same size as the stump

grinder hoses. Using smaller diameter hoses will

decrease hydraulic ow.

The stump grinder will have pressure and return

connections. Pressure hose on stump grinder will have

a red tie band (A) on it.

The hose end size is 1/2 in. male JIC for the pressure

and return hoses.

Connect skid steer hoses to the stump grinder hoses.

Be sure stump grinder pressure hose with red tie band

(1) is connect to skid steer pressure hose.

11

www.skidpro.com

5.2 pre-operAtIon CheCk lIst

It is operators responsibility to perform the following

checks prior to operation of equipment.

Review and understand this manual and operating unit

manual.

Verify safety decals are installed and legible. Replace

if damaged or missing.

Verify that all hardware is tight.

Inspect hoses and ttings for wear, damage and leaks.

Replace damaged or leaking hoses before use.

Verify that local utilities have marked all underground

wires, cables and pipelines.

Refertooperatingunitoperator’smanualforprestarting

instructions.

Check swing frame to verify that it is free from

obstruction and can operate smoothly without binding.

Never bar over the rotor, This could cause damage and

result in personal injury or equipment damage.

The stump grinder must be lifted in a vertical direction

only. Due to the weight of the rotor the device must be

adjusted accordingly.

5.3 AttAChIng And detAChIng

1. Read and follow all safety instructions.

2. Attach skid steer to stump grinder. See skid steer

Operator’s Manual.

3. Verify pins are secure in the correct position.

4. Connect hydraulic hoses. Verify hydraulic hoses

are clear of pinch areas.

5. Move to a clear open area to test functions.

5.4 operAtIon

Before starting, stand to side of stump grinder and

look at center point on bottom of cutting wheel, this will

appear different from the skid steer seat and can be

very deceiving.

Operate all functions in an open area with skid steer in

idle to get a good feel for the controls.

^ WARNING

Prevent serious injury or death.

Turn off engine and remove key before

leaving operator’s seat.

1. Attach stump grinder to skid steer. See Attaching

And Detaching in this section.

2. If stump is on a grade, position skid steer in low

area. This will position stump grinder in high area

for a greater advantage of weight for stable cutting.

3. Move over stump so cutting wheel torques

downward, pushing frame up to avoid binding.

4. Engage cutting wheel and slowly lower it in a

controlled manor to desired cutting depth. Always

lower cutting wheel beside stump, never try cutting

down, always cut from the side.

5. Slowly move into the stump.

6. If cutting wheel stalls, stop motion and rise slightly.

After a complete pass, move to home position and

lower cutting wheel to desired position for next

pass.

7. Continue lowering the passes until sump is

completely removed.

12 www.skidpro.com

6. routIne mAIntenAnCe

6.1 InspeCtIons

Check hydraulic hoses and ttings daily for leaks.

Replace hose if worn or damaged.

Inspect the unit for any buildup of contamination (dirt,

stones, etc.).

Check cutting teeth every 2 hours of use. Keep cutting

teethingoodcondition.Unitwillcutfasterandremaining

teeth will last longer if broken teeth are replaced.

6.2 replACe CuttIng teeth

^ WARNING

Crushing hazard.

Raised, unsupported stump grinder can

fall, resulting in death or serious injury.

Never enter the area under a raised stump

grinder.

1. Support stump grinder to prevent falling.

2. Stop skid steer engine and remove key.

^ WARNING

Moving parts can crush and cut.

Keep clear of moving components.

Lockout operating unit before performing

maintenance.

3. Inspectcuttingteethfordamage.Replaceindividual

teeth as needed.

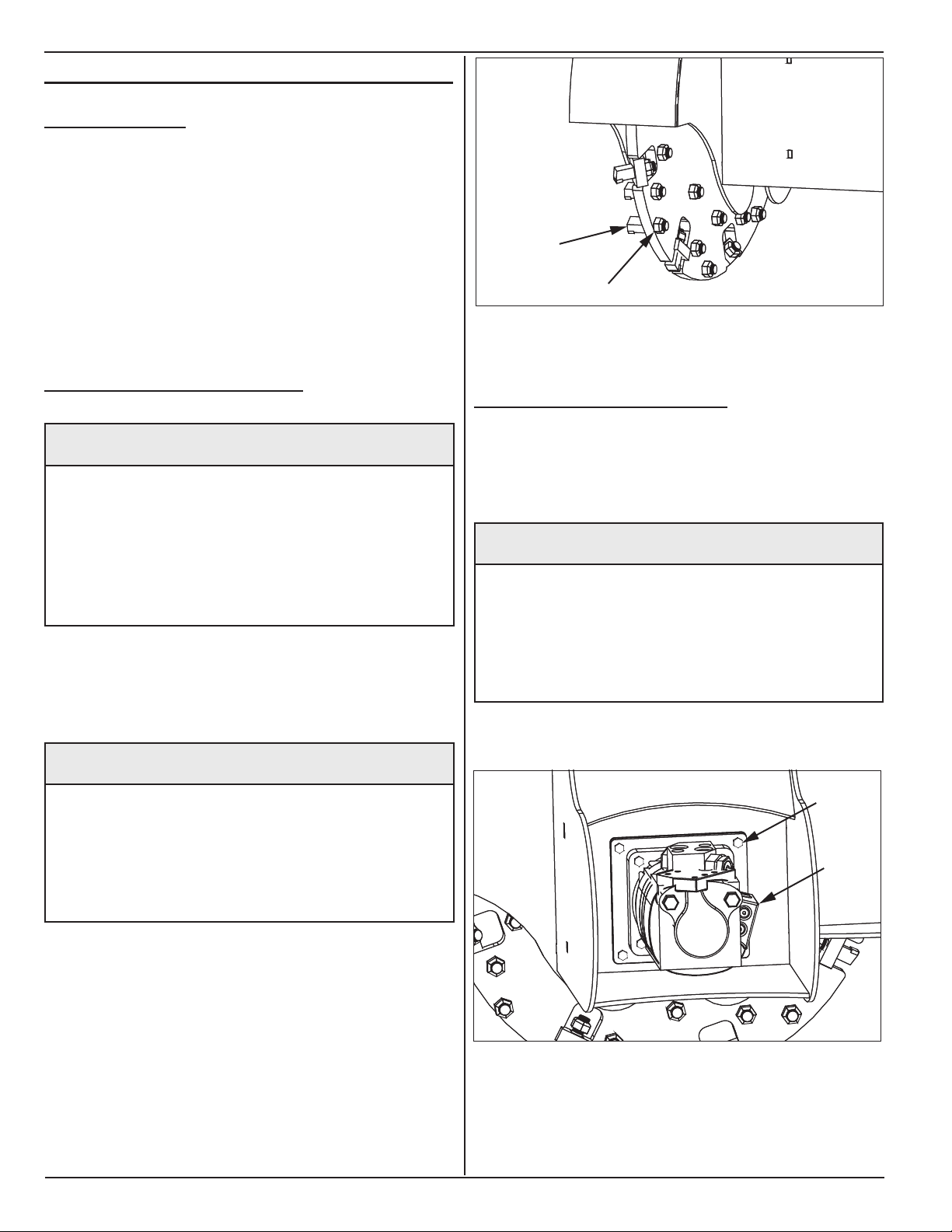

4. Remove lock nut (1) and cutting tooth (2).

5. Install replacement tooth and lock nut. Tighten

locknut (1) to 95 lb/ft (129 Nm) of torque.

6.3 replACe flex Coupler

1. Lower stump grinder to ground.

2. Stop skid steer engine and remove key.

^ WARNING

Moving parts can crush and cut.

Keep clear of moving components.

Lockout operating unit before performing

maintenance.

3. Remove four cap screws (1) and remove hydraulic

motor assembly (2).

1

2

1

2

13

www.skidpro.com

4. Remove and replace ex coupler (3).

Note: Coupler hub on rotor shaft and motor shaft do

not have setscrews. Setscrews are not needed in this

application.

5. Install hydraulic motor assembly.

3

14 www.skidpro.com

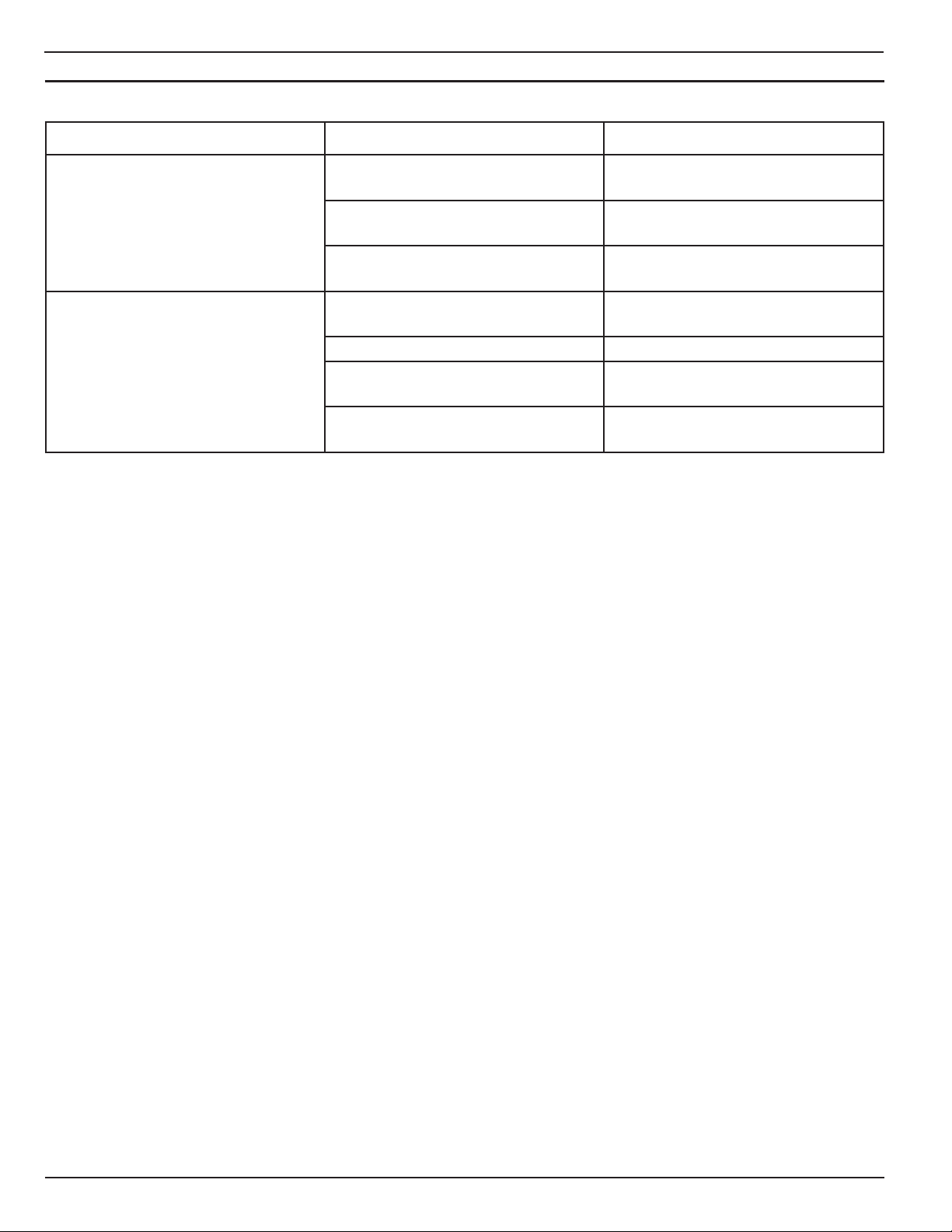

7. troubleshootIng

Problem Probable Cause Solution

Cutting wheel does not spin. Cutting wheel jammed. Remove material from cutting

wheel.

Low oil. Check oil level in skid steer. Add if

necessary.

Not enough oil ow. Check ow control on skid steer.

See your dealer.

Cutting wheel low on power. Low oil. Check oil level in skid steer. Add if

necessary.

Oil lter plugged. Replace skid steer oil lter.

Relief valve not set properly. Set relief valve. Pressure should be

between 2,500 and 3,500 psi.

Not enough oil ow. Check ow control on skid steer.

See your dealer.

15

www.skidpro.com

8. pArts

8.1 stump grInder

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

D001127

Skid steer attachment

1

2

SSQT plate

Standard skid steer plate

1

3

D001028

1 x 5" Flange Pin

2

4

D001674

1/2" Hose holder

1

5

Sheet

-

6

D001428

Rotor Frame

1

7

D002336

S1028 Rotor with teeth

1

8

S1028

Rotor Assembly with Keyed Shaft (S18 & S24) less teeth

1

9

750 3P24-1

Rotor Assembly

1

10

D001084

S18 Shaft

1

11

D002924

S1000 tooth holder block (weld- in) 750 3P24-2

8

12

S1000

5/8” threaded stump grinder tooth

34

13

D001773

Tooth Nut

34

14

B2005

4 Blot 210 Flange Green Cast

2

15

F2002

2 x.625 Fine Thread

8

16

S18-10

Safety deflector plate

1

17

D001630

6-pack holder

1

16 www.skidpro.com

8.2 s450 motor

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

D001503

A-Motor Mount

1

2

B2000

L110 Flex

1

3

B2012

Flex Hub L110 1.25"

2

4

B2013

L110 Flex

1

5

D003999

A-Mount Chain Coupler Assembly

1

6

D003749

A-Mount Chain Coupler – Chain

1

7

D003748

Chain Link Coupler 1-1/4 x 5/16 Keyway

2

8

D004149

Complete Hydraulic Motor with Relief Block – A-Mount

1

9

D004147

Hydraulic Motor for A-Mount Options

1

10

D004148

Complete Relief Block for A-Mount Motor

1

11

D001374

Cat Motor Spacer 1.25" Shaft

1

17

www.skidpro.com

8.3 s550 motor

ITEM NO. PART NUMBER DESCRIPTION QTY.

1 D001374 Cat Motor Spacer 1.25" Shaft 1

2 D001404 B Motor Mount 1

3 D001007 Char-Lynn 24 GPM Motor 1

4 D001009 Relief and Anti-Cav Assembly Valve Block 1

5 D001982 #214 O-Ring 2

6 D001981 #116 O-Ring 2

7 D001984 Pressure Relief Valve

1

8 D001983 Anti-Cavitation Check Valve

1

9 D001009 B-Mount Valve 1

10 D001987 #114 O-Ring 2

11 B2000 L110 Flex 1

12 B2012 Flex Hub L110 1.25" 1

13 B2013 L110 Flex 1

14 D002420 Flex L150 Hytrel Insert 1

15 D002419 Flex Hub L150 - 1.25" Keyed 2

16 D004000 B-Mount Chain Coupler Assembly 1

17 D003849 CH6018 Chain for Chain Coupler 1

18 D003995 CB6018 Chain Coupler Hub 1 ¼” Bore x 5/16” 2

18 www.skidpro.com

8.4 s650 motor

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

D001175

Motor

1

2

D001009

Anti-Cavitation Check Valve Assembly

1

3

D001982

#214 O-Ring

2

4

D001981

#116 O-Ring

2

5

D001984

Pressure Relief Valve

1

6

D001983

Anti-Cavitation Check Valve

1

7

D001009

B-Mount Valve

1

8

D001987

#114 O-Ring

2

9

D002062

Seal for 1.5" Shaft - 6000 Series CL Motor

1

10

D001020

L225 Flex Coupler Total Assembly with 6-Spline Insert

1

11

D001018

L225H Flex Hytrel Insert

1

12

D001024

Flex Hub L225 with 1.5" Bore

1

13

D003483

L225 Jaw Coupler - S18

1

14

S18-8

C Mount

1

15

D004001

C-Mount Chain Coupler Assembly

1

16

D003995

CB6018 Chain Coupler Hub 1 ¼” Bore x 5/16”

1

17

D003848

Chain Coupler Hub for C-Mount – Motor Side 1 ½” Bore x 3/8”

1

17

D003849

CH6018 Chain for Chain Coupler

1

19

www.skidpro.com

20 www.skidpro.com

Skid Pro Attachments

PO Box 982

Alexandria, MN 56308

www.skidpro.com

November 2021

Table of contents