Skid Pro QASA530 User manual

1

www.skidpro.com

QASA530 Tree Saw

Operators Manual

Skid Pro Attachments

PO Box 982

Alexandria, MN 56308

www.skidpro.com

December 2023

2 www.skidpro.com

Following is a list of videos and documents available to help and enhance maintaining the tree saw.

Contact Product Guru to access correct link.

The list below was current at the time this manual was issued. Additional content may be available.

Activity Name Description

Skidsteer Case Drain Back-Pressure Causes of Skidsteer Case Drain Back-Pressure.

Skidsteer Case Drain Back-Pressure Testing Case Drain Back-Pressure With Open Coupler.

Skidsteer Case Drain Back-Pressure Testing Case Drain Back-Pressure With Pressure Gauge.

Hydraulic Motor Breaking In Replacement Hydraulic Motor.

Remove Seal Remove Seal On Motor Or Load Adapter.

Zero-Leak Relief Valve Demonstrating And Troubleshooting Zero-Leak.

Replace motor shaft seal Replace Shaft Seal On Piston Motor.

3

www.skidpro.com

........................................................................................4

1.1 Introduction................................................................................................................4

.....................................................................................................................4

.............................................................................................5

...............................................................................................................................6

...................................................................6

3.2 Operational Hazards..................................................................................................6

..............................................................................7

.....................................................................................7

......................................................................................7

..................................................................................7

................................................................................................7

..............................................................................................7

..............................................7

.................................................................................8

............................................................................................8

........................................................................................8

.........................................................................8

3.3 Maintenance Hazards................................................................................................9

.......................................................................9

............................................................................................10

....................................................................................................................12

4.1 Hydraulics .................................................................................................................12

.................................................................................................12

.......................................................................................................................13

5.1 Pre-Operation Check List .......................................................................................13

..................................................................................13

...........................................................................................13

........................................................................................................14

5.5 Pressure Relief Adjustment....................................................................................15

..................................................................................................16

6.1 ............................................................................................................16

6.2 Inspections................................................................................................................16

...............................................................................................17

.............................................................................................17

6.5 Motor Shaft Seal ......................................................................................................18

6.6 Zero Leak Case Drain Relief Valve.........................................................................18

..........................................................................................................19

4 www.skidpro.com

Congratulations on your purchase of a Skid Pro Skid

Tree Saw. This equipment has been designed and

manufactured to meet the needs of a discriminating

buyer for ecient clearing of brush, shrubs and trees.

The blade is hydraulic powered by the hydraulic system

on your skid steer.

Replaceable bearings are provided at major pivot

points for extended service life.

Safe, ecient and trouble free operation of your

tree saw requires that you and anyone else who will

be operating or maintaining the tree saw read and

understand this Operator’s Manual.

This manual covers the QASA530 Skid Pro Tree Saw.

Keep this manual with the equipment for frequent

reference and to pass on to new operators or owners.

Call your Skid Pro dealer, distributor or the factory if

you need assistance, information or additional copies

of the manuals.

OPERATOR ORIENTATION - The directions left, right,

front and rear, as mentioned throughout this manual,

are as seen from the skid steer driver’s seat and facing

in the direction of travel.

Skid Pro warrants products purchased from Skid Pro

to the Original Purchaser to be free from defects in

material and workmanship for a period of twelve (12)

months from the warranty start date.

Skid Pro’s requirement for any issue with respect to

attachments shall be limited to repairing or replacing

the defective part, as this is a parts-only warranty and

does not include any labor to replace or install the

part or downtime from resulting issue. Skid Pro has

full technical support & assistance to assure customer

replaces the part properly for optimal performance

on attachment. Skid Pro warranty service does not

include:

1. Transportation to selling dealer’s business location

or, at the option of the original retail purchaser, the

cost of a service call.

2. Used equipment.

3. Components covered by their own non-Skid Pro

warranties

4. Normal maintenance service and expendable wear

out items.

5. Repairs or adjustments caused by improper use;

failure to follow recommended maintenance

procedures; accidents or other casualty.

6. Liability for incidental or consequential damages of

any type, including but not limited to lost prots of

expenses of acquiring replacement equipment.

No agent, employee or representative of Skid Pro has

authority to bind Skid Pro to any warranty except as

specically set fourth herein. Any of these limitations

excluded by local law shall be deemed deleted from

this warranty; all other terms will continue to apply.

Skid Pro, Inc.

Toll Free: 877.378.4642

E-mail: [email protected]

5

www.skidpro.com

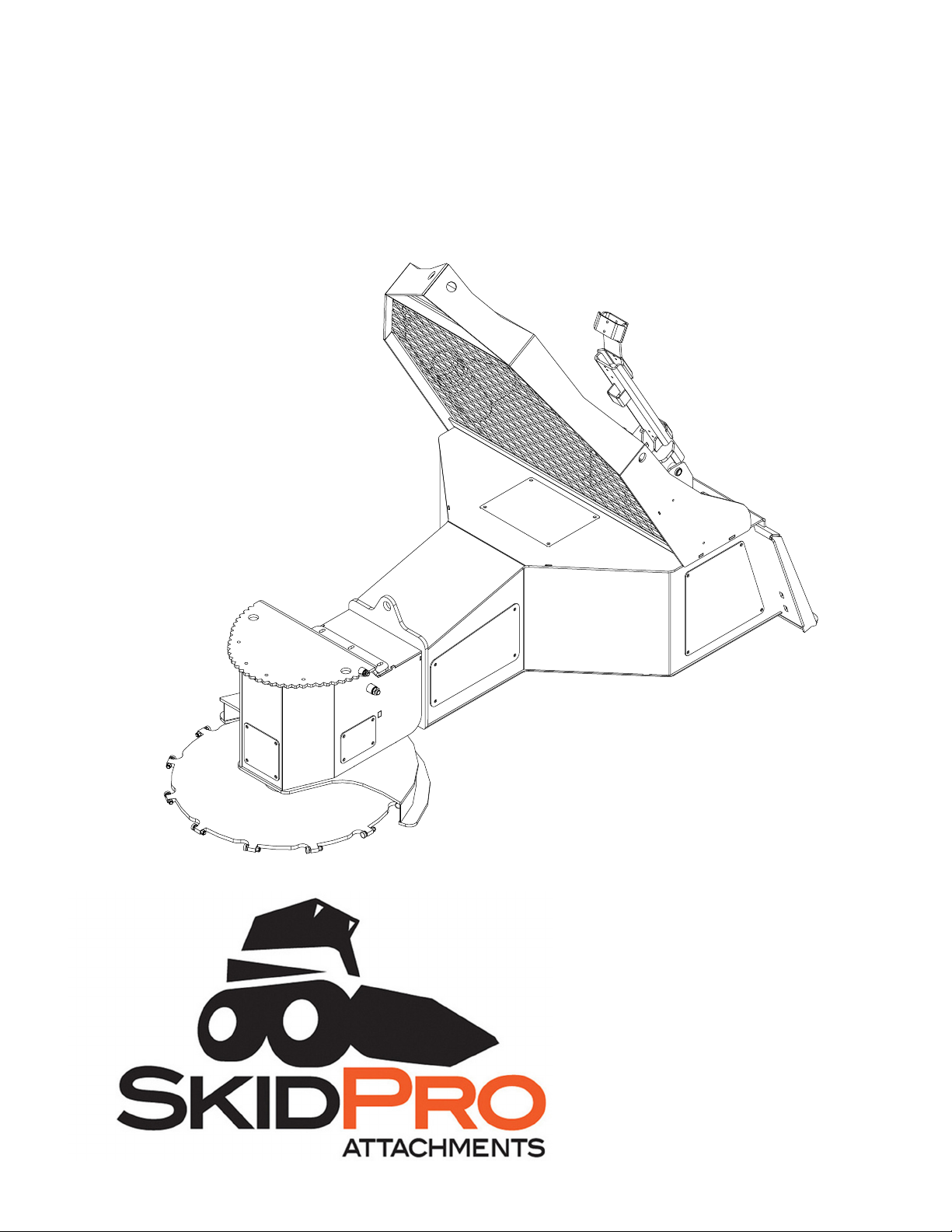

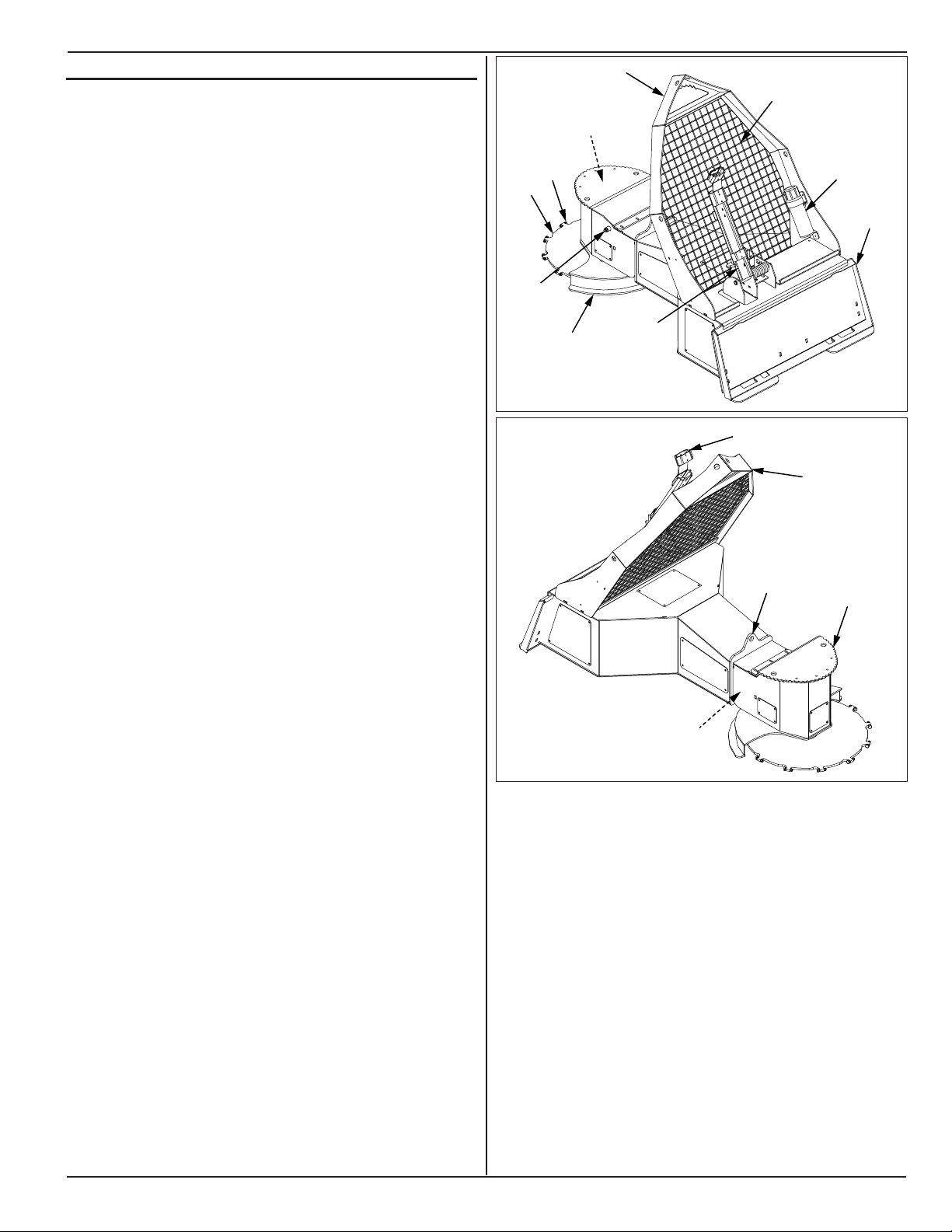

A. Blade

B. Cutting Teeth

C. Hydraulic Motor

D. Angled Push Bar

E. Protective Mesh

F. Operators Manual Tube

G. Quick Attach

H. Hydraulic Hose Holder

I. Blade Guard

J. Lifting Eye

K. Front Push Bar

L. Cutting Head Rotation Motor

M. Zero Leak Relief Valve

A

C

E

B

D

F

G

H

I

M

D

H

J

K

L

6 www.skidpro.com

You must read, understand and follow the instructions

given by the operating unit manufacturers, as well as

the instructions in this manual.

The safety information in this manual is denoted by the

safety alert symbol:

^

This symbol means ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

The level of risk is indicated by the following signal

words:

^^

or serious injury.

^

result in death or serious injury.

^

or moderate injury.

NOTICE - Indicates a situation that could

result in damage to the equipment or other

property.

^

Prevent serious injury or death.

Read and understand this manual before

leaving operators seat.

operation.

^

Prevent serious injury or death from

moving parts.

Moving parts can crush and dismember.

in place.

before adjusting or performing

maintenance.

^

applications.

Any other use may result in personal

^

Prevent serious injury or death.

before operation or transport.

7

www.skidpro.com

^

^

Prevent serious injury or death.

It is recommended that the operating

protect the operator.

Carefully read all safety messages in this manual and

on equipment safety signs. Keep safety signs in good

condition and replace missing or damaged safety

signs.

New equipment components and repair parts must

include the current safety decal.

Learn how to properly operate equipment. NEVER

operate or work around this equipment without proper

instruction, while fatigued or under the inuence of

alcohol, prescription or non-prescription medication or

if feeling ill.

Keep your equipment in proper working condition.

Know the regulations and laws that apply to you and your

industry. This manual is not to replace any regulations

or laws. Additional information may be found at:

www.asae.org or www.osha.gov.

If you do not understand any part of this manual,

contact Skid Pro at 866-232-8224.

Be prepared in case of emergencies. Keep a re

extinguisher and rst aid kit close to the machine.

Keep emergency phone numbers close to your phone.

Know your address so emergency services can locate

you if an emergency arises.

Replace missing or damaged safety signs.

Safety sign location are identied in Section 3.5 of this

manual.

Replacement safety signs are available from your

dealer.

NEVER lift or carry anyone on Tree Saw.

NEVER use Tree Saw as a work platform.

NEVER allow passengers on Tree Saw.

Keep Tree Saw low and move at slow speeds on rough

or uneven terrain.

The equipment may rollover, resulting in death or

serious injury. To help prevent rollover:

• Travel at a slow speed.

• Avoid sharp turns & sudden movement on slopes.

• Carry tree saw close to the ground.

• Avoid holes, ditches and other obstructions which

may cause equipment to rollover.

• Use caution when operating on slopes and do not

operate on excessively steep slopes.

• Do not exceed load capacity of equipment.

^

Prolonged exposure to loud noise can

cause impairment or loss of hearing.

against objectionable or uncomfortable

loud noises.

8 www.skidpro.com

^^

Prevent electrocution.

Death or serious injury can result if

lines.

contact.

Check clearance before raising equipment.

Have local utilities locate and mark under ground wires,

cables, pipelines and other hazards before digging.

DO NOT leave the operator’s seat if any part of the

equipment contacts electric lines or cables.

Detach Tree Saw on a rm and level surface. Tree Saw

may fall over if detached on unlevel or soft surface. Be

sure people, livestock and pets are clear of machinery.

Relieve hydraulic pressure before disconnecting

hydraulic hoses. See your skid steer Operator’s

Manual.

^

blade, be sure to disengage hydraulics

Verify all reectors and Slow Moving Vehicle (SMV)

sign are visible.

Raise tree saw slightly o ground.

Verify hydraulics are disengaged.

Travel at a reasonable and safe speed.

^

Crushing hazard.

resulting in death or serious injury.

A raised Tree Saw can lower unexpectedly, resulting in

death or serious injury.

NEVER enter area under a raised Tree Saw.

Lower Tree Saw to ground, engage parking brake, shut

o engine and remove key before servicing.

^

Hydraulic hoses can fail from age, damage

and exposure.

searching for leaks. A tiny, almost invisible

leak can penetrate the skin, thereby

leaks, never use your hands.

Escaping uid under pressure can penetrate the skin

causing serious injury.

Prevent the hazard by relieving pressure (See skid

steer Operator’s Manual.) before connecting or

disconnecting hydraulic lines. Verify all connections

are tight before applying pressure. Search for leaks

with a piece of cardboard or wood.

Protect hands and body from high pressure uids. If

an accident occurs, see a doctor immediately. Any uid

injected into the skin must be surgically removed within

a few hours or serious infection may result.

Doctors unfamiliar with this type of injury should

reference a knowledgeable medical source.

9

www.skidpro.com

Before servicing, park machine on a rm and level

surface, set parking brake, chock wheels, and place

a “Do Not Operate” tag on control panel. Read and

understand this manual. If you do not understand any

part of the manual, contact Skid Pro at 866-232-8224.

Always wear face and/or eye protection, safety shoes,

and other protective equipment appropriate for the job.

Do not make unauthorized modications. Contact Skid

Pro at 866-232-8224 before you weld, cut/drill holes,

or make any other modications.

Always use Skid Pro replacement parts.

^

Crushing hazard.

•

•

•

• Place “Do Not Operate” tag on control

panel.

^

Moving parts can crush and cut.

Keep clear of moving components.

performing maintenance.

^

Keep clear of moving components.

appropriate for the job.

^

Hot and high pressure hydraulic oil.

^

California to cause cancer.

mask or other safeguards for personal

^

Do not make any alterations to your tree saw. Altering

may cause your equipment to be unsafe and may void

the manufacturers’ warranty.

10 www.skidpro.com

^

If any of these labels are missing or

cannot be read, contact your dealer for

replacement labels.

A

C

D

E

B

A

F

C

B

Decal A - MTB-177

Decal B - MTB-176

Never allow riders; especially children

on carrier or cutter.

cutting

11

www.skidpro.com

Decal C - MTB-065

MTB-065

Decal D - MTB-182

Decal E - D005262

WARNING: This product can expose you to chemicals

including 1,3-Butadiene and lead, which are known to the state of

California to cause cancer and birth defects or other reproductive

harm. For more information go to www.P65Warnings.ca.gov.

D005262

Decal F - MTB-175

12 www.skidpro.com

^^

hydraulic hoses.

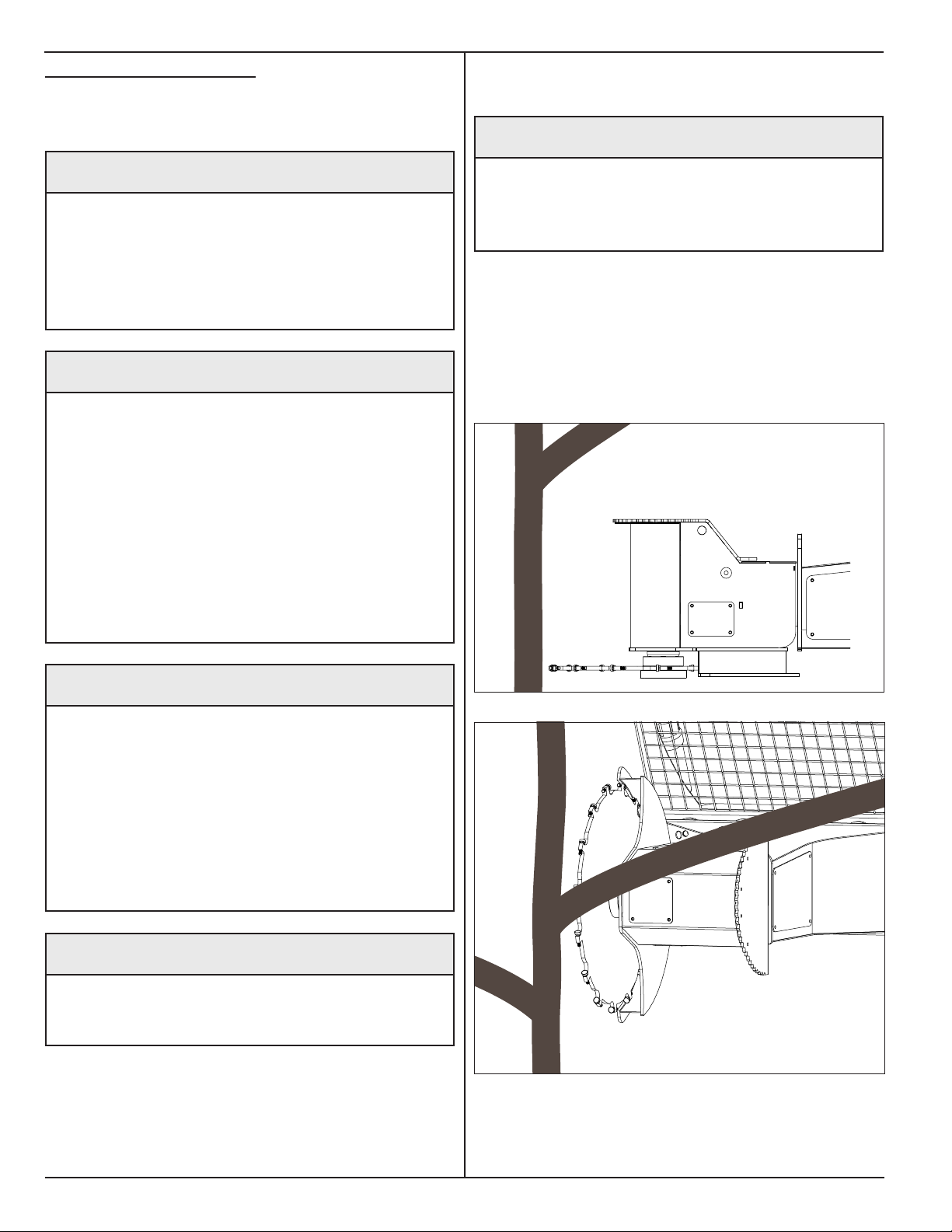

The tree saw is equipped with three hoses, pressure,

return and case drain. Hydraulic couplers are not

provided with the tree saw. You must install couplers

and connect your skidsteer pressure, return and case

drain hoses to the tree saw hoses. Install your couplers

to the hoses listed in the table below.

Fitting Size Hose Description Qty.

3/4 JIC FM Pressure & Return 2

3/8 JIC FM Case Drain 1

Identify the pressure port hose and connect your hoses

to the tree saw hoses.

Maximum allowable case pressure is 100 psi, case

drain is required.

• First, operate all functions in a clear area with

throttle at low idle to get a good feel for the controls

before you actually move into any brush.

• Slow cutting speed if pressure surges up close

to max psi, doing this will greatly reduce blade

stoppage.

• Run throttle only at half speed for rst time users.

• Move the tree saw slowly until you have a better

feel how much the unit can take.

• The machine is equipped with a front push bar and

an angled push bar to push brush or small trees

over. This will allow the tree saw teeth to contact

the lower portion of the brush and the blade to cut

it o.

• For tall brush, you can use the angled push bar to

push the brush over and cut it o close to ground.

Each operator must experiment to nd a technique

that works for them in their application.

^^

disengage hydraulic drive before getting

^

California to cause cancer.

mask or other safeguards for personal

^

13

www.skidpro.com

^ Keep bystanders, livestock, pets, etc away from

equipment while in use.

^ Always wear face or eye protection, safety shoes,

and other protective equipment appropriate for

the job.

^ Do not operate, work on or around this machine

while under the inuence of alcohol, drugs or if

feeling ill.

^Keep clear of moving machinery at all times.

^Stop skid steer engine before leaving operators

area.

^It is your responsibility to operate this equipment

safely. You must be familiar with the equipment

and all safety practices before use.

^ Do not allow untrained or unqualied people to

operate this equipment.

It is operators responsibility to perform the following

checks prior to operation of equipment.

Review and understand this manual and operating unit

manual.

Verify safety decals are installed and legible. Replace

if damaged or missing.

Verify that tree saw is properly attached to skid steer.

Check for entangled material on blade.

Inspect hoses and ttings for wear, damage and leaks

and are properly connected. Replace damaged or

leaking hoses before use.

Verify that all hardware is tight. Verify all guards, doors

and covers are installed and secured.

Verify cutting teeth are in good condition and are tight.

Verify that local utilities have marked all underground

wires, cables and pipelines.

Refer to operating unit operator’s manual for prestarting

instructions.

^

transmission in park.

Only experienced and properly trained

operator’s should operate the skid steer

Attach:

1. Read and follow all safety instructions.

2. Attach tree saw to skid steer. See skid steer

Operator’s Manual.

3. Verify pins are secure in the correct position.

4. Connect hydraulic hoses. Verify hydraulic hoses

are clear of pinch areas and moving parts.

5. Move to a clear open area to test functions.

Detach:

1. Park on a rm, level surface.

2. Engage parking brake. Lower tree saw to the

ground.

3. Shut o engine and remove key.

4. Disconnect hydraulic hoses.

5. Detach tree saw from skid steer. See skid steer

Operator’s Manual.

During the rst few hours of use, avoid hitting stones

as much as possible to allow the carbide teeth to wear

slightly. This can be done by keeping the cutting wheel

above ground level. Brand new carbide tips are razor

sharp and can chip and shatter easily when they hit

hard objects. Once the razor sharpness has worn

away, the tips do not chip as easily. Observing these

precautions will extend the life of the carbide teeth and

reduce operating expenses.

The teeth bolts must be retightened every ten minutes

for the rst hour of use on a new tree saw.

14 www.skidpro.com

Operate all functions in an open area with skid steer in

idle to get a good feel for the controls.

^

Prevent serious injury or death.

1.

2.

3. Disconnect hydraulic drive.

4.

^

Prevent serious injury or death.

are in the vicinity.

cutting area.

Keep all shields in place.

^

California to cause cancer.

mask or other safeguards for personal

^

1. Attach tree saw to skid steer. See Attach and

Detach Tree Saw.

^

Prevent serious injury or death.

forestry guard to protect the operator.

2. Set engine speed to low idle and engage hydraulics.

3. Slowly increase engine speed to high idle. Verify

tree saw is operating smoothly.

4. Rotate cutting head as needed to obtain the closest

cut to trunk or ground.

15

www.skidpro.com

5. Operate hydraulics to move tree saw blade into

brush, shrubs or tree.

6. If blade stalls, stop movement, slightly raise

tree saw and allow blade to regain speed. Slow

movement to prevent further stalling.

^

Moving parts can crush and cut.

Keep clear of moving components.

Lockout operating unit before clearing

jams.

^

come to a complete stop.

7. When cutting is completed, disengage hydraulics

and allow blade to stop.

8. Lower tree saw to ground and stop skid steer

engine.

^

Prevent serious injury or death caused by

unexpected movement.

1.

2.

3.

4.

1. Park on a level surface.

2. Lower tree saw to the ground.

3. Engage parking brake, shut o engine and remove

key.

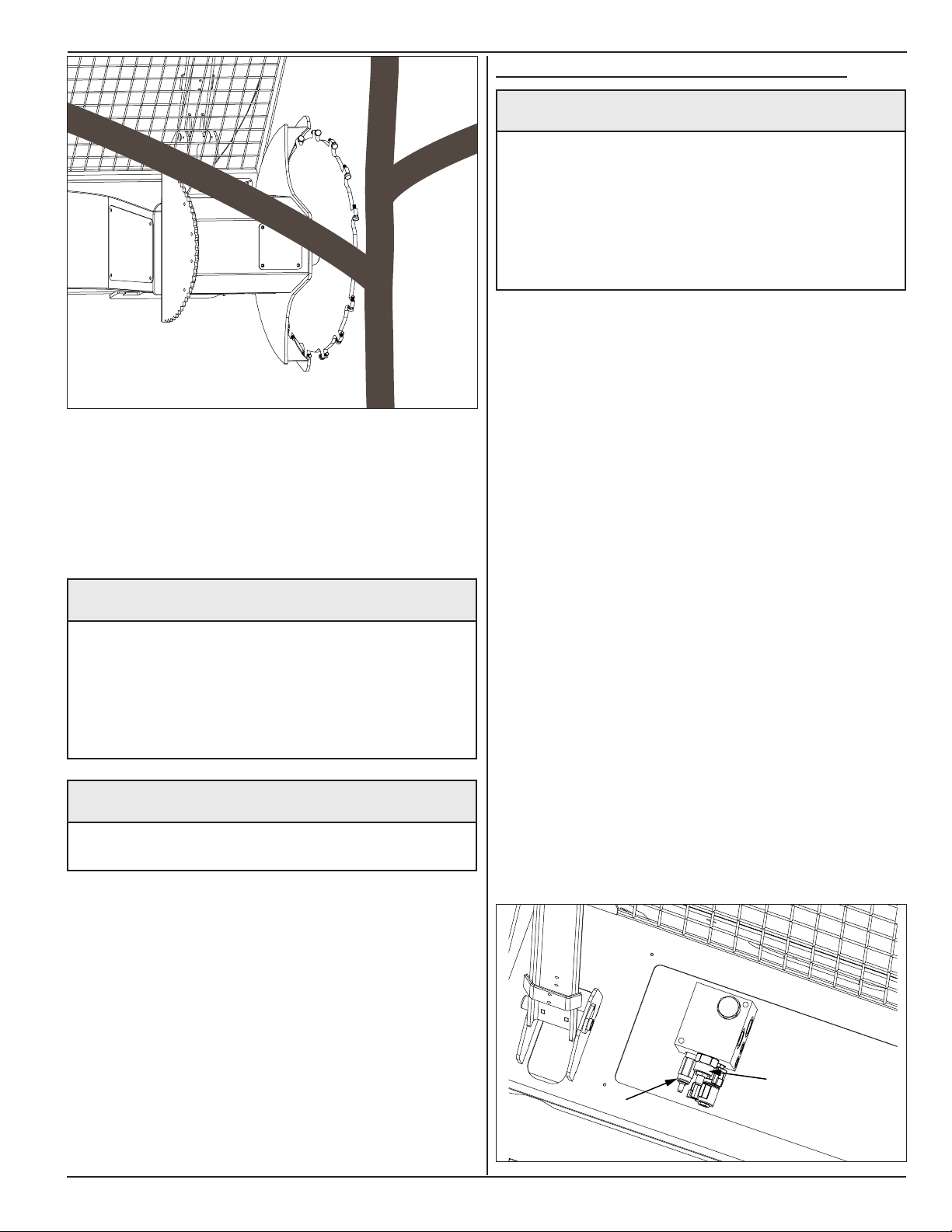

(A) Flow Adjust - Adjusting the ow determines how

much oil is sent to cylinders and blade. The more oil

that is sent to the blade will result in cylinders moving

slower. If more oil is sent to the cylinders, blade speed

will decrease. Typical adjustment is 1/2 turn out from

closed position. To adjust, hold hex screw with hex

wrench and loosen lock nut. Turn hex screw and hold

in position while tightening lock nut. Test operation and

adjust again if desired.

(B) Pressure relief must be set lower than machine

relief. 1/4 turn out from closed position is approximately

3000 psi (207 bar). To adjust, hold hex screw with

hex wrench and loosen lock nut. Turn hex screw in to

increase pressure, or out to decrease pressure. Turn

hex screw in 1/4 turn increments until desired pressure

is achieved. Hold hex screw in position while tightening

lock nut.

Image is shown with top cover removed for adjustments.

Do not operate with top cover removed.

A

B

16 www.skidpro.com

Maintenance Chart

General Inspection Inspect the unit for any buildup of contamination (dirt, stones,

etc.).

Daily.

Hydraulic Hoses Inspect hydraulic hoses for damage and wear. Daily.

Cutting Teeth The teeth bolts must be retightened every ten minutes for the

rst hour of use on a new tree saw.

First hour of use.

Cutting Teeth Check and replace one at a time as necessary. With daily use

expect to replace 4 to 6 teeth per day. See Replace Cutting

Teeth in this section.

Every 4 hours.

^

Prevent serious injury or death.

1.

2.

3. Disconnect hydraulic drive.

4.

^

California to cause cancer.

mask or other safeguards for personal

^

Inspect the unit for any buildup of contamination (dirt,

stones, etc.).

Check cutting teeth every 4 hours of use. Replace

cutting teeth as needed. Unit will cut faster and

remaining teeth will last longer if broken teeth are

replaced.

Inspect hydraulic hoses for damage and wear. Models

with rotating head may experience premature hose

wear in the areas (A) where hoses go through the

slotted frame. Replace worn or damaged hoses.

Skid Pro has included one replacement set of internal

motor hoses with the tree saw. These hoses were

placed inside the body of the tree saw.

17

www.skidpro.com

Each tooth can be rotated up to two times from its

original position before replacement is necessary.

1. Park tree saw on a level surface.

2. Lower blade to the ground.

3. Shut o engine and lockout engine controls.

4. Inspect teeth for wear on top edge. Once top

edge is worn, rotate tooth so a new edge is on top

(cutting) edge.

5. Loosen locknut (A) on tooth (B) and rotate tooth

1/3 turn. Flat shoulder on tooth will t against

shoulder (C) on tooth holder.

6. Tighten locknut (A) to 65 lb/

ft (88 Nm) of torque.

A B

C

Note: Parts breakdown can be found on Skid Pro’s

website. www.skidpro.com

1. Park tree saw on a level surface.

2. Lower blade to the ground.

3. Shut o engine and lockout engine controls.

4. Inspect cutting teeth (B) for damage and wear.

Replace individual teeth as needed.

5. Remove locknut (A) and tooth (B). Install new tooth.

Flat shoulder on tooth will t against shoulder (C)

on tooth holder.

6. Install locknut. Tighten locknut (A) to 65 lb/ft (88

Nm) of torque.

AB

C

Note: Parts breakdown can be found on Skid Pro's

website. www.skidpro.com

^

Moving parts can crush and cut.

Keep clear of moving components.

Lockout operating unit before performing

maintenance.

18 www.skidpro.com

To prevent hydraulic motor damage, the motor shaft

seal is designed to fail if case pressure exceeds 100

psi (689 kPa).

If motor shaft seal (A) has failed, verify case drain line

is free ow to sump or reservoir. Also check drain line

for blockage. Correct any problems before replacing

shaft seal.

A

Order replacement seal kit from Skid Pro and follow

instructions provided with kit.

Motor Shaft Seal Replacement manual can be found at

www.skidpro.com

Note: Parts breakdown can be found on Skid Pro's

website. www.skidpro.com

6.6 Zero Leak Case Drain Relief Valve

The tree saw is equipped with a case drain line that is

to be routed to the excavator hydraulic reservoir.

It is normal for a hydraulic motor to have a slight amount

of internal leakage.

The case drain line will allow this internal leakage to

be returned to the reservoir, preventing excessive

pressure on the motor seal.

Starting with model year 2022, tree saws will be

equipped with a zero leak relief valve (A) installed in

the case drain line.

If the case drain line is not connected or becomes

obstructed, the zero leak relief valve will vent the

pressurized hydraulic uid to the atmosphere.

The zero leak relief valve will self reset after hydraulic

pressure reduced.

immediately.

A properly installed case drain protected by a zero leak

relief valve will save the work of replacing the motor

shaft seal and also improve the eciency of your

hydraulic system.

A

19

www.skidpro.com

Blade does not spin. Blade jammed. Remove material from blade.

Low oil level. Check oil level. Add if necessary.

Low oil ow. Check ow control on skidsteer. See

your dealer.

Low pressure. Check valve open.

Blade rotates slow or sluggish. Low oil. Check oil level. Add if necessary.

Oil lter plugged. Replace skidsteer oil lter.

Relief valve not set properly. Set relief pressure to motor

specication.

Low oil ow. Set relief pressure to motor

specication.

Excessive vibration. Cutting teeth worn or missing. Replace worn, broken or missing teeth.

Debris lodged in blade. Remove debris.

Rotating cutting head moves slow

or stutters when fully rotated.

On-board pressure relief valve

is set higher than machine relief

valve.

Adjust on-board relief valve to a lower

pressure setting than machine relief

valve. See Section 5.5 Pressure Relief

Adjustment.

Low cutting power. Check to see if blade can be

turn backward with hoses

disconnected.

If blade can be

turned, anti-cavitation

valve (A) may be

stuck open.

Remove and clean

anti-cavitation valve.

Low ow or pressure. Check hydraulic pump ow and pressure

Disconnect pressure line to saw and

install a pressure gauge in line. Test

pressure. Contact your dealer if pressure

is low.

Check blade speed with a photo

tachometer.

Contact your dealer for recommended

blade speed based on the motor and

machine GPM.

Hydraulic uid coming out of zero

leak relief valve.

Case drain connector for

proper connection and line for

obstructions or pinched line.

Connect case drain line if not connected.

Replace line if damage, obstructed or

pinched.

Combo coupler seals. Combo coupler seals may be leaking,

allowing pressurized uid to escape to

the case drain line.

A

20 www.skidpro.com

Skid Pro Attachments

PO Box 982

Alexandria, MN 56308

www.skidpro.com

December 2023

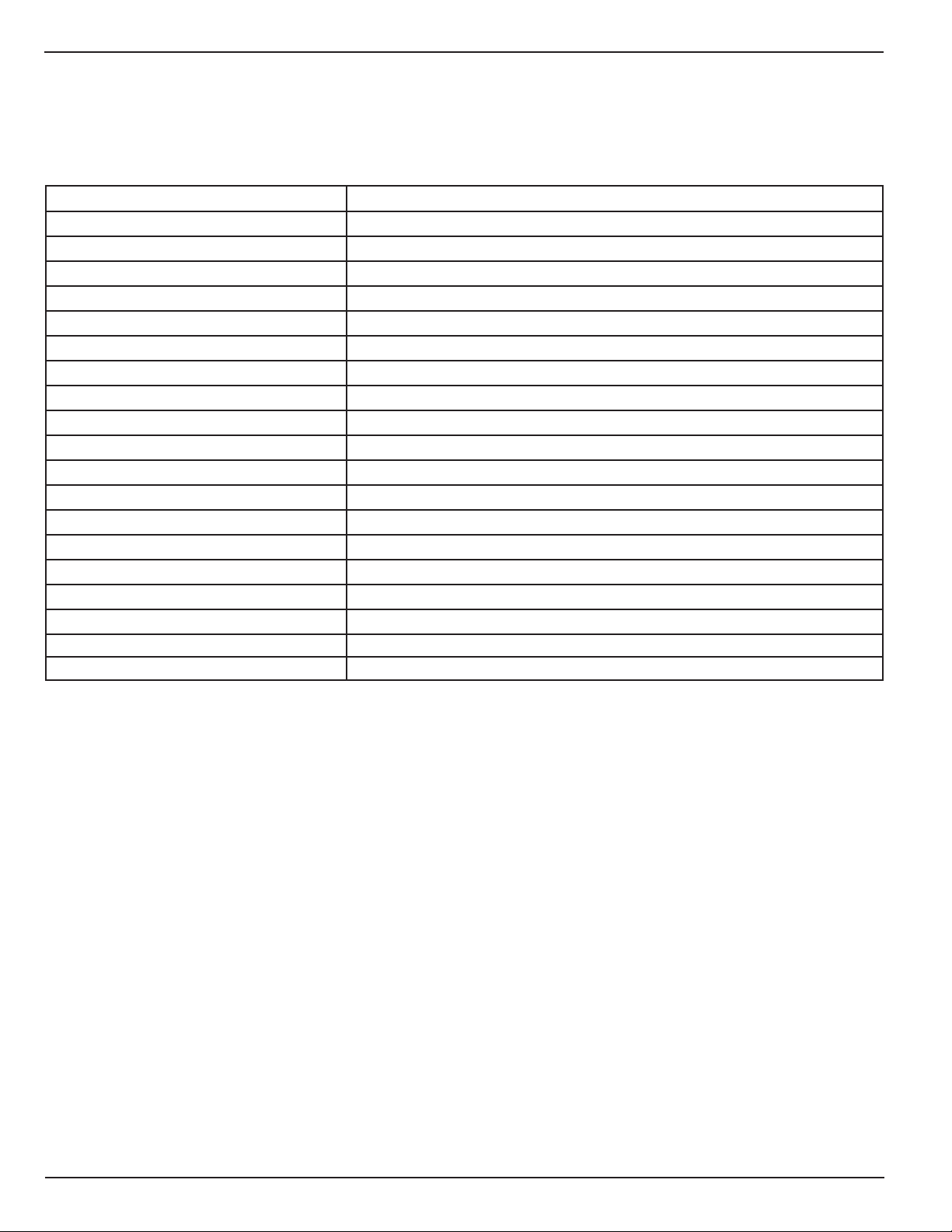

Table of contents