Skipper ETNSTCI User manual

This manual suits for next models

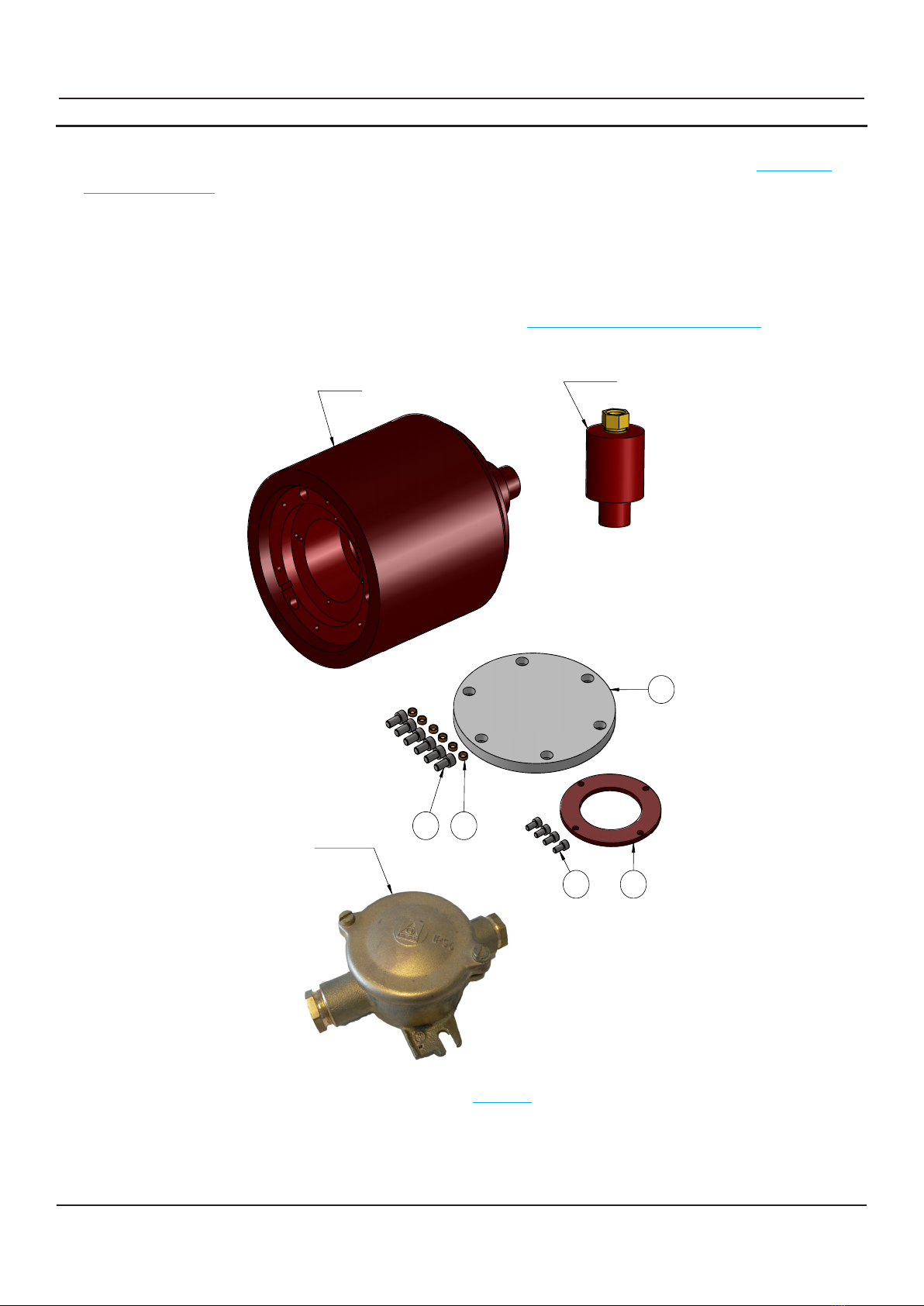

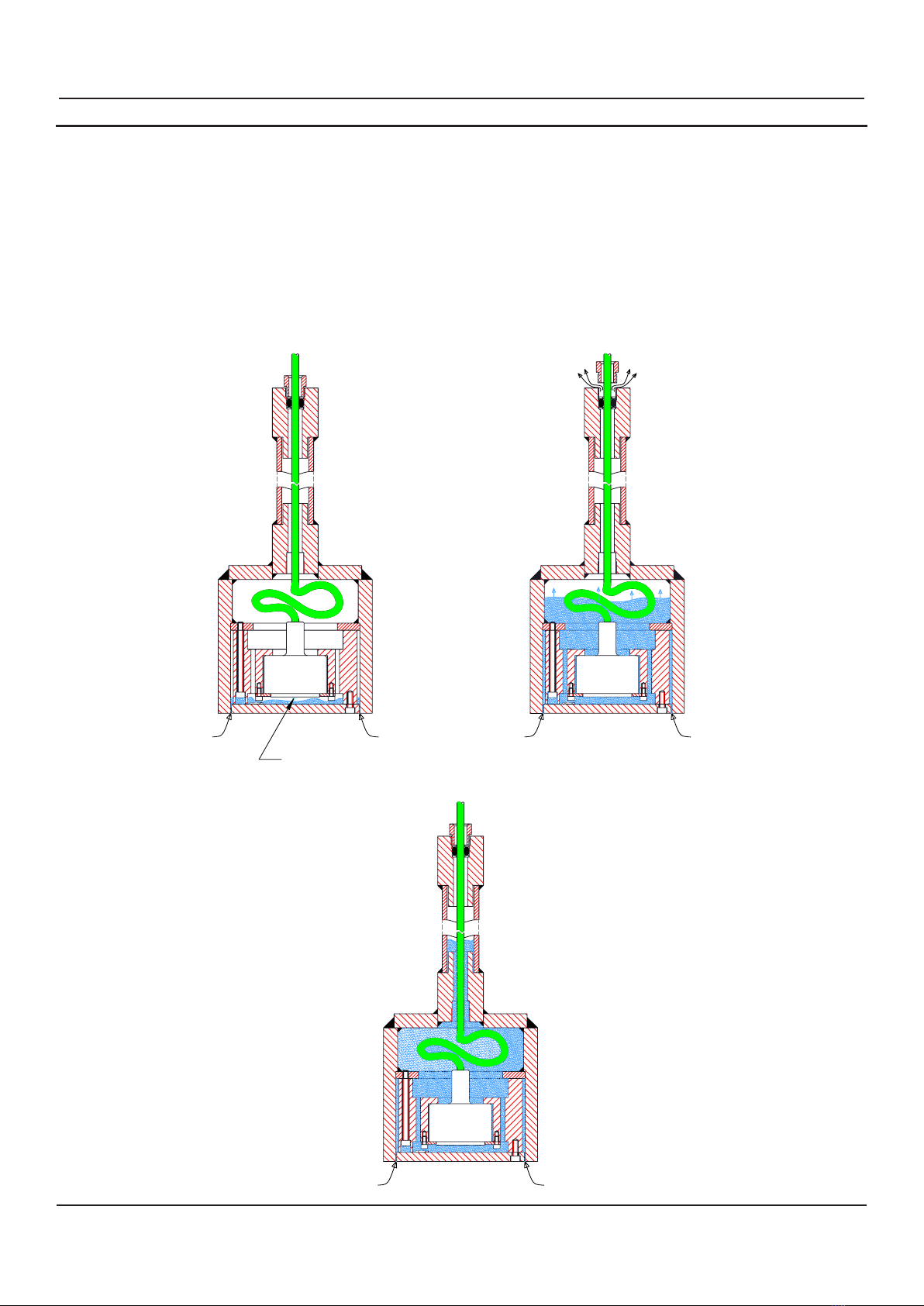

1

Table of contents

Popular Water Heater manuals by other brands

Toyotomi

Toyotomi Oil Miser OM-180 installation manual

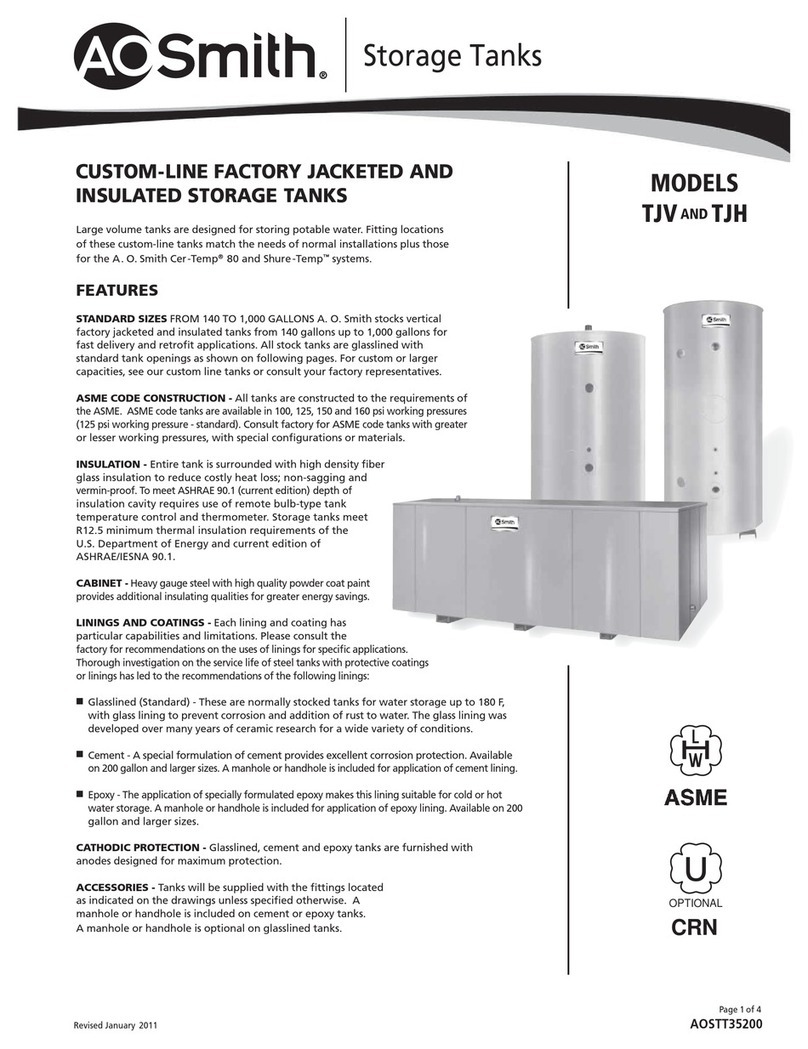

A.O. Smith

A.O. Smith Master-Fit 100 Series Service handbook

Main

Main Mersey Super User, installation & servicing instructions

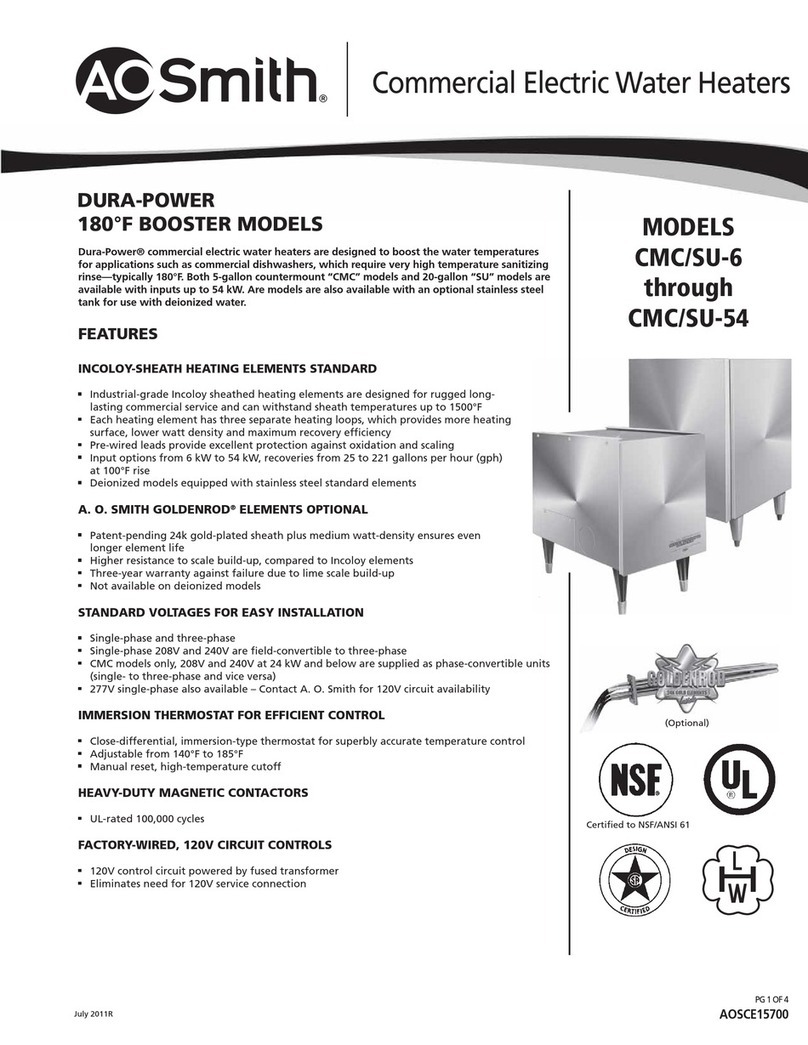

A.O. Smith

A.O. Smith CMC/SU-54 Specification sheet

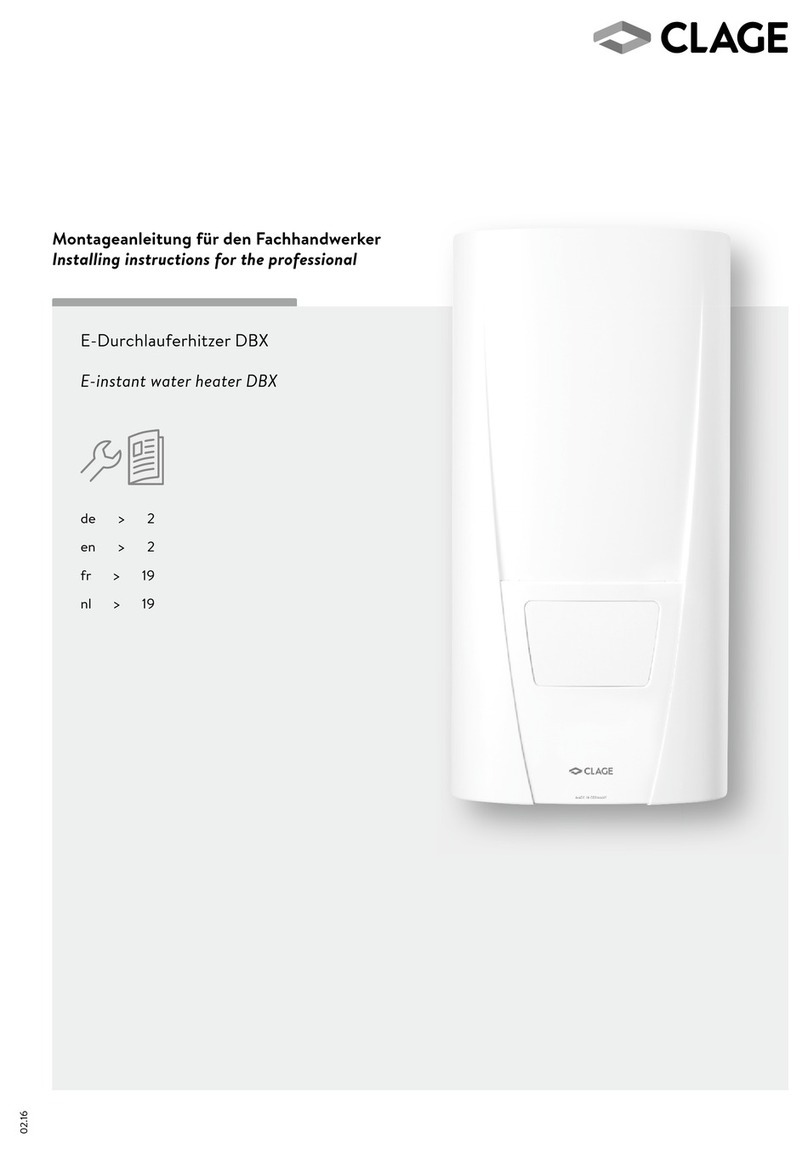

clage

clage DBX 18 BASITRONIC Installing instructions

Bosch

Bosch GWH 450 ESR-L manual

Flexiheat

Flexiheat SFK 50 Instructions for installation, use and maintenance manual

Rinnai

Rinnai INFINITYREU-V3232W Service manual

Navien

Navien NPE-180A installation manual

A.O. Smith

A.O. Smith TJH Specification sheet

iDM

iDM HYGIENIK 2.0 installation instructions

STIEBEL ELTRON

STIEBEL ELTRON VL-G Operation and installation manual

clage

clage BASITRONIC CDX 11-U Installing and operating instructions

GE

GE GeoSpring GEH50DEEDSR Owner's Manual & Installation Instructions

EDA

EDA Recup Eco 310L manual

flowair

flowair AGRO SP Operation manual

Bradford White

Bradford White RE1 Service manual

DeDietrich

DeDietrich Cor-Email Series Installation and user instruction manual