Edition 07.99

S00.5126.50.20

------------

1 ------------

OCTAVIA Service

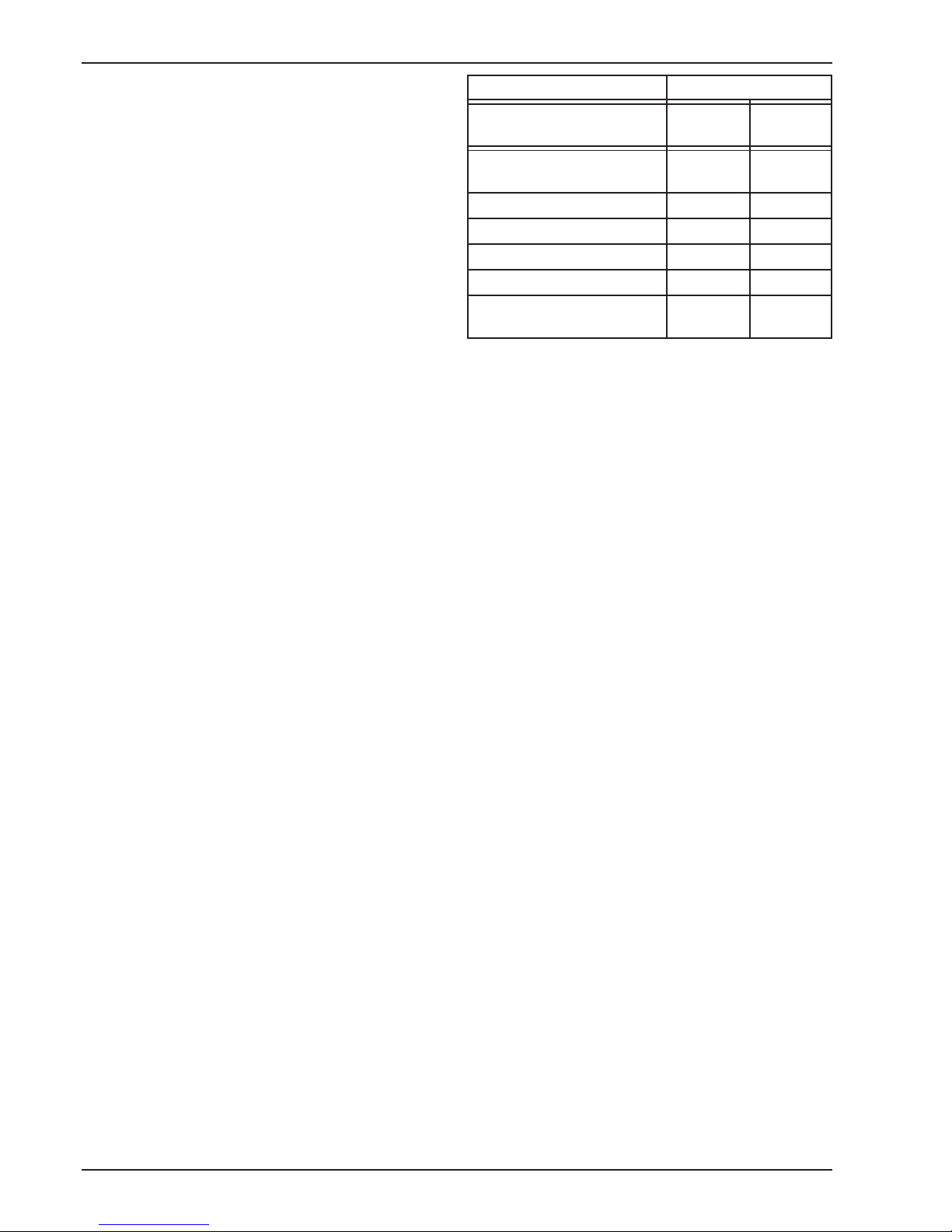

Contens

01 Self-diagnosis Page

Self-diagnosis .............................................................................................................................. 01-1

- Features of self-diagnosis ........................................................................................................ 01-1

- Technical data of self-diagnosis ............................................................................................... 01-1

- Connecting vehicle system tester V.A.G 1552 and selecting engine electronics control unit .. 01-2

- nterrogating and erasing fault memory.................................................................................... 01-4

- Fault table ................................................................................................................................. 01-6

- Final control diagnosis .............................................................................................................. 01-30

- Reading measured value block ................................................................................................ 01-32

- Reading measured value block: display groups 000 to 010 ..................................................... 01-33

- Reading measured value block: display groups 011 to 055 ..................................................... 01-37

2 Fuel Formation/Fuel Injection Page

Servicing Fuel Injection System ................................................................................................ 2 -1

- Safety precautions .................................................................................................................... 24-1

- Rules for cleanliness ................................................................................................................ 24-2

- Technical data .......................................................................................................................... 24-2

- Survey of fitting locations ......................................................................................................... 24-3

- General information on fuel injection system ........................................................................... 24-7

- Removing and installing parts of the fuel injection system ....................................................... 24-8

- Disassembling and assembling fuel rail and injectors ............................................................. 24-10

- Disassembling and assembling intake manifold ...................................................................... 24-10

- Disassembling and assembling air filter ................................................................................... 24-11

- Testing cables and components with test box V.A.G 1598/31 ................................................. 24-12

- Replacing engine control unit ................................................................................................... 24-14

- Testing idling speed .................................................................................................................. 24-15

- Testing operating states of engine............................................................................................ 24-17

- Testing fuel pressure regulator and holding pressure .............................................................. 24-19

- Testing intake system for leaks (unmetered air) ...................................................................... 24-22

- Testing injectors........................................................................................................................ 24-23

- Testing injected quantity, leaktightness and spray pattern of injectors ..................................... 24-25

- Testing fuel pump relay -J17 and actuation .............................................................................. 24-27

- Testing intake manifold pressure sender -G71 ........................................................................ 24-30

- Testing intake manifold temperature sender -G72 ................................................................... 24-31

- Testing coolant temperature sender -G62 ................................................................................ 24-34

- Testing voltage supply for control unit ...................................................................................... 24-38

- Adapting engine electronics control unit to electronic immobiliser ........................................... 24-39

Testing lambda control ............................................................................................................... 2 - 1

- Operation of lambda control ..................................................................................................... 24-41

- Testing lambda probe heater .................................................................................................... 24-47

Testing fuel tank ventilation ....................................................................................................... 2 - 9

- Testing solenoid valve 1 for activated charcoal filter ................................................................ 24-49

Testing electronic power control (electronic throttle) ............................................................. 2 -52

- Operation of electronic throttle system ..................................................................................... 24-52

- Meaning of EPC warning lamp (electronic throttle control fault lamp) in dash panel insert ..... 24-53

- Testing electronic throttle control fault lamp -K132 .................................................................. 24-54

- Testing throttle valve control unit -J338 .................................................................................... 24-56

- Conducting adaptation of throttle valve control unit ................................................................. 24-56

- Testing angle senders for throttle valve drive ........................................................................... 24-59

- Testing accelerator pedal position sender ................................................................................ 24-62