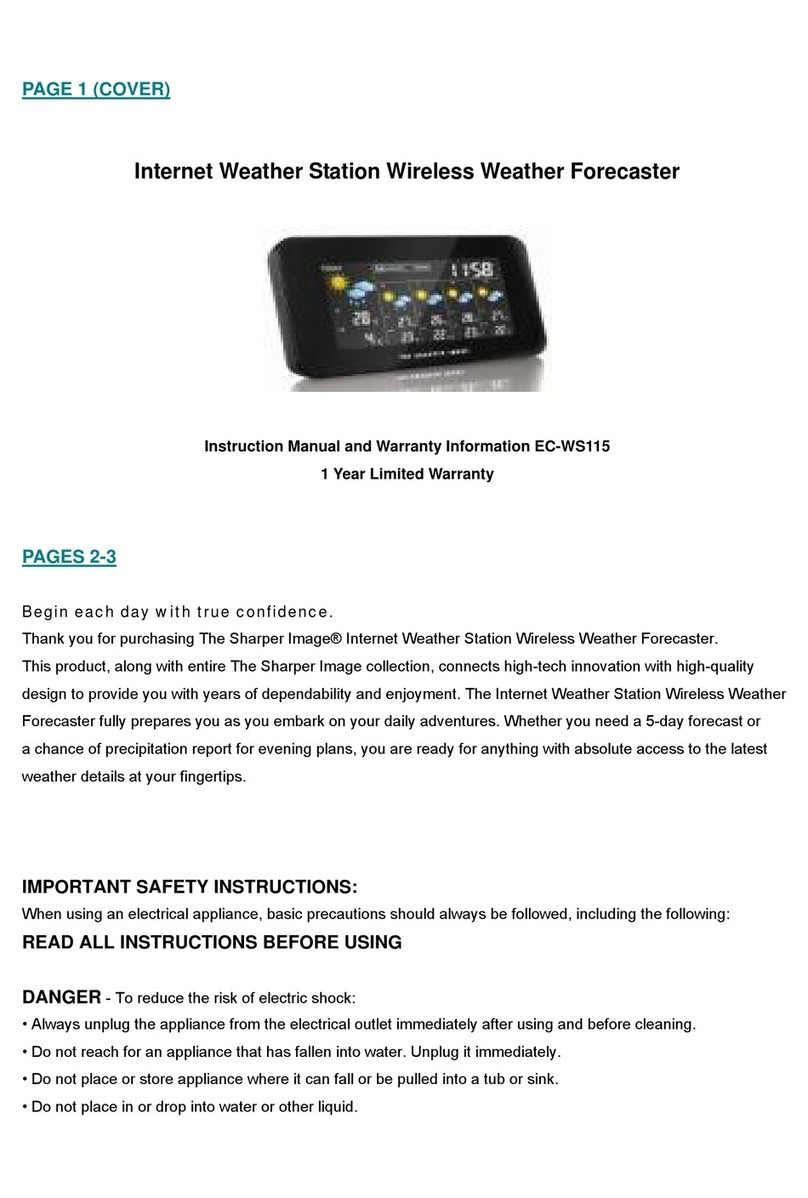

3.3 Erection of Mast on a Concrete Base

3.3.1 Bottom Section Buried in Concrete

Items required: pole, guylines with locking ring, large guy pegs, (mallet, spirit level - not

supplied, although a MiniMet Installation Toolkit is available for purchase – please enquire).

Usually a 3 m pole is supplied, the lower 1m for burying in concrete, resulting in a 2 m mast.

Firstly, at the chosen mast location, dig a hole 1 m deep and approximately 0.5 m diameter.

Place the pole in the centre of the hole - if it has been joined from 1m + 2m sections, keep

the jointed section nearest the top. Fill around the pole with fresh concrete. Leave the

concrete to fully harden.

Pass the guyline locking ring over the top of the pole to about halfway. If the pole has been

made up of two sections, make sure the locking ring is above the joining bolts.

Lay out the guylines at 120 degrees from each other, and at an angle of about 45 degrees

out from the vertical pole. Undo the shackles at the end of the guylines, so that there is

enough adjustment for tightening later. Drive the large 45 cm 'T' pegs into the ground (90 º

angle to the guylines) at the end of each guyline and attach.

Adjust the guyline tautness by locking the ring into place, driving the 'T' pegs fully into the

ground at the correct angle (90º to the guyline), and turning the shackles to tighten, making

sure the mast pole is vertical using the spirit level. Tighten the locking nuts on the shackles.

Finally check all adjustments to ensure the guylines are taut.

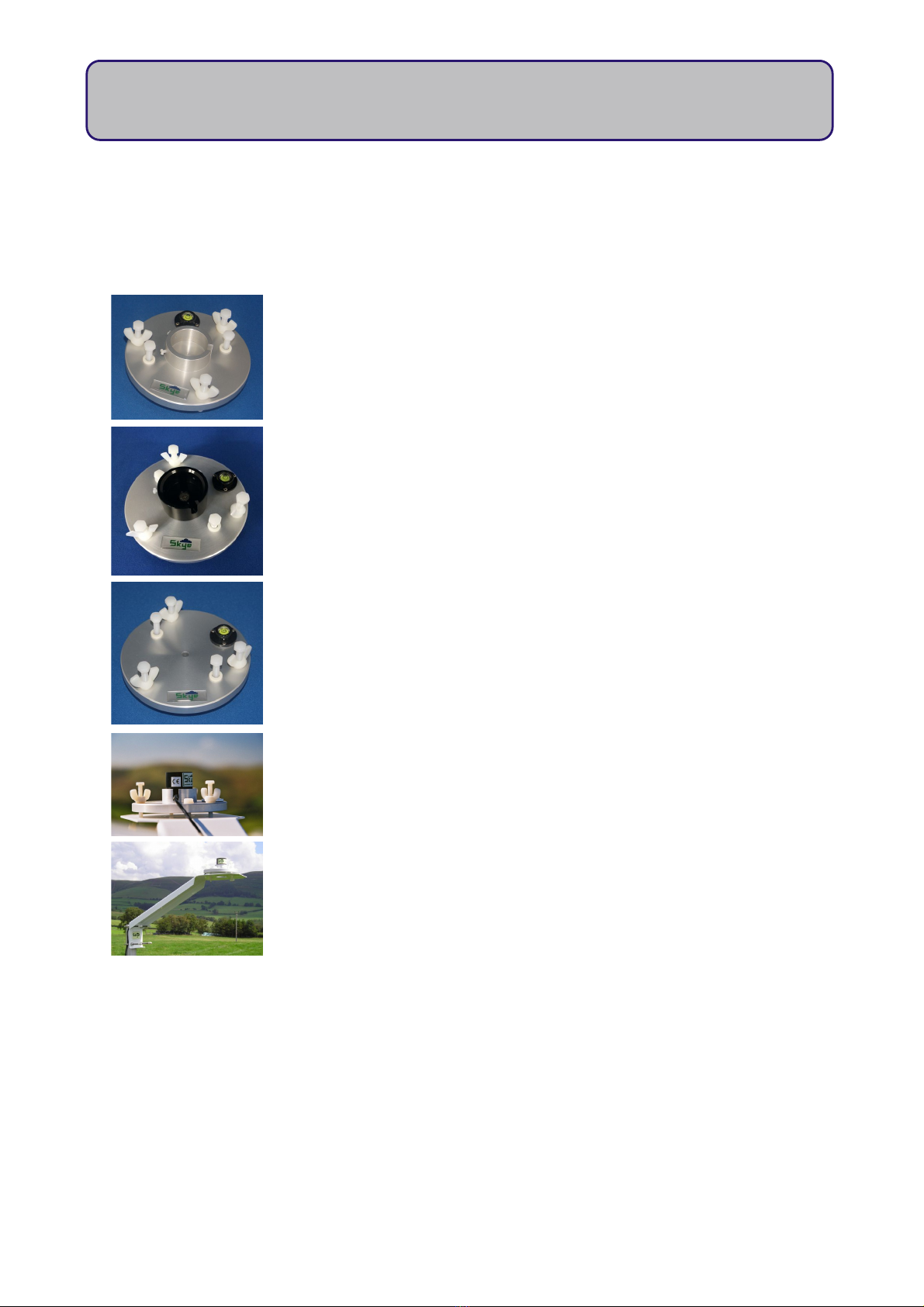

3.3.2 Mast Bolted to a Concrete Base

Items required: pole, base plate, guylines with locking ring, large guy pegs, (concrete bolts,

mallet, spirit level - not supplied, although a MiniMet Installation Toolkit is available for

purchase – please enquire).

Firstly prepare the concrete base according to the dimensions in Appendix 1 and leave to

fully harden. There are two options for fixing the guylines, these may be driven into grass or

soft ground around a central, small 20 cm square concrete base, or they can be bolted into

the concrete if it is the full 1.6 m square area.

Place the aluminium base plate in position (note this isn't fully central if using a large 1.6 m

base - see Appendix 1). Drill holes for the fixing bolts and secure.

Pass the guyline locking ring over the pole to about halfway. If the pole has been made up

of two sections, make sure the locking ring is above the joining bolts. Place the bottom of the

5

MiniMet Installation